Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

5 viewsSection 1: Food Chemistry and Nutrition: XE - G Food Technology

Section 1: Food Chemistry and Nutrition: XE - G Food Technology

Uploaded by

Kshirsagar TejasX

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Module Appetizers 1Document9 pagesModule Appetizers 1Oliver Narag100% (1)

- 12wb Bimbap MealDocument1 page12wb Bimbap Mealapi-186364677No ratings yet

- Sample Business PlanDocument6 pagesSample Business Plantrixie maeNo ratings yet

- Food Engineering and Technology mtqp06Document3 pagesFood Engineering and Technology mtqp06Dev JagarwalNo ratings yet

- Syllabus For The Post of Assistant Professor Food Technology and Food Processing in Higher Education Department 02 - 08 - 2023Document4 pagesSyllabus For The Post of Assistant Professor Food Technology and Food Processing in Higher Education Department 02 - 08 - 2023ﹺ ﹺ ﹺ ﹺNo ratings yet

- Syllabus For Food Technology (XL: Section M) : Food Chemistry and NutritionDocument2 pagesSyllabus For Food Technology (XL: Section M) : Food Chemistry and NutritionVishal Kumar VermaNo ratings yet

- Syllabus For Food Technology (Xe: Section G) : Food Chemistry and NutritionDocument2 pagesSyllabus For Food Technology (Xe: Section G) : Food Chemistry and NutritionAnonymous 8pCXXsNo ratings yet

- Food Science TechnologyDocument1 pageFood Science TechnologysagarikarayabarapuNo ratings yet

- FT Syllabus Patent Examiner MainsDocument5 pagesFT Syllabus Patent Examiner MainsUtkarsh DeshmukhNo ratings yet

- NDRI-PG SyllabusDairy Processing GroupDocument45 pagesNDRI-PG SyllabusDairy Processing Groupheartwin1No ratings yet

- Food Technology (FT)Document2 pagesFood Technology (FT)SRIKANTH PATELNo ratings yet

- Ag 2210Document20 pagesAg 2210Dickson MahanamaNo ratings yet

- Further Details Regarding Main Topics of PROGRAMME No. 05/2020 (Item No: 32)Document4 pagesFurther Details Regarding Main Topics of PROGRAMME No. 05/2020 (Item No: 32)English Master IELTS AcademyNo ratings yet

- Fda Syallabus MainDocument4 pagesFda Syallabus MainRAMESH PHADTARENo ratings yet

- Food Science&TechnologyDocument14 pagesFood Science&TechnologyTerri PerryNo ratings yet

- Food ScienceDocument125 pagesFood ScienceMothika SNo ratings yet

- Wa0013.Document4 pagesWa0013.Nikhil JainNo ratings yet

- Livestock Product TechnologyDocument3 pagesLivestock Product TechnologyRajat SinghNo ratings yet

- Introduction To Food TechnologyDocument42 pagesIntroduction To Food TechnologyNGUYEN CONG DUONGNo ratings yet

- Bio TechnologyDocument2 pagesBio Technologyurvesh_patel44No ratings yet

- Food Processing BackgroundDocument9 pagesFood Processing Backgroundthe dark knightNo ratings yet

- Food PreservationDocument46 pagesFood Preservationazfar_mmas4206100% (2)

- HSB NutritionDocument15 pagesHSB NutritionOsmany MadrigalNo ratings yet

- Laboratory AssistantDocument2 pagesLaboratory AssistantArun Krishnan 122No ratings yet

- Food Science and Technology Scqp12Document4 pagesFood Science and Technology Scqp12vexam57704No ratings yet

- Food Safety OfficerDocument4 pagesFood Safety OfficerAkhilesh RamakrishnanNo ratings yet

- 6 - Toxicants Formed During ProcessingDocument45 pages6 - Toxicants Formed During Processingismailmannur100% (1)

- Food Technology Food Processing UgDocument5 pagesFood Technology Food Processing UgGG GamingNo ratings yet

- DairyDocument4 pagesDairyrajrahaneNo ratings yet

- Food Scie Certm1notesDocument30 pagesFood Scie Certm1notesCynthia ngenyNo ratings yet

- Handout - Livestock Product Processing - FinalDocument64 pagesHandout - Livestock Product Processing - FinalEskindir AmanuelNo ratings yet

- PG - M.sc. - Home Science - Nutrition and Dietetics - 365 13 - Advanced Food Science - English - 2206Document236 pagesPG - M.sc. - Home Science - Nutrition and Dietetics - 365 13 - Advanced Food Science - English - 2206sanju osNo ratings yet

- Food Leacture 1Document38 pagesFood Leacture 1nahomabebezewdye2No ratings yet

- Food and Milk SanitationDocument37 pagesFood and Milk SanitationRuth Mary PadaNo ratings yet

- The Food System and Its SectorsDocument3 pagesThe Food System and Its SectorsBaloch ExpertNo ratings yet

- Single-Cell-ProteinDocument11 pagesSingle-Cell-ProteinKhalid AbduNo ratings yet

- Basic Principles Methods Terms and Terminologies of Food Processing FinalDocument43 pagesBasic Principles Methods Terms and Terminologies of Food Processing FinalLove PuraNo ratings yet

- Food Safety Officer Syllabus PSCDocument2 pagesFood Safety Officer Syllabus PSCA RahmanNo ratings yet

- FSTDocument17 pagesFSTKhizra YounasNo ratings yet

- MSC Ind. Biotech. Syllabus (2008-09)Document4 pagesMSC Ind. Biotech. Syllabus (2008-09)Dr-Alok Prasad DasNo ratings yet

- Lecture 1 Introduction BBDocument34 pagesLecture 1 Introduction BBHuyen Tram NguyenNo ratings yet

- Food ScienceDocument526 pagesFood SciencePuja BarmanNo ratings yet

- Food PreservationDocument5 pagesFood PreservationMark Christian P. MesinaNo ratings yet

- RD Exam Syllabus Without ReferencesDocument25 pagesRD Exam Syllabus Without ReferencesAakriti SharmaNo ratings yet

- Obt351-Food, Nutrition and Health-744666708-Obt351 Food, Nutrition and HealthDocument51 pagesObt351-Food, Nutrition and Health-744666708-Obt351 Food, Nutrition and HealthBME 018 GOKUL GNo ratings yet

- BCH 419Document40 pagesBCH 419idriscognitoleadsNo ratings yet

- Introduction To Food Technology, General Aspect of Food IndustryDocument11 pagesIntroduction To Food Technology, General Aspect of Food Industrysarvesh.bhartiNo ratings yet

- Marshmallow Technology of Increased Nutritional VaDocument9 pagesMarshmallow Technology of Increased Nutritional VaNhi Võ ThịNo ratings yet

- Developments in Functional FoodsDocument19 pagesDevelopments in Functional FoodsRam GantaNo ratings yet

- Centre For Global Food Technology: CSIR-Central Food Technological Research InstituteDocument6 pagesCentre For Global Food Technology: CSIR-Central Food Technological Research InstituteSenthil MuruganNo ratings yet

- Application of Chemistry in Food ProcessingDocument24 pagesApplication of Chemistry in Food ProcessingAkinola AyomideNo ratings yet

- Principles of Food Processing and Halal Requirement (WEEK 11)Document48 pagesPrinciples of Food Processing and Halal Requirement (WEEK 11)aishah1997No ratings yet

- Biochemical Changes Associated With The Processing of FoodsDocument4 pagesBiochemical Changes Associated With The Processing of FoodsAdapa Prabhakara GandhiNo ratings yet

- Concept of Food and Food Preparation and Preservation and Its SignificanceDocument4 pagesConcept of Food and Food Preparation and Preservation and Its SignificanceMeriel GuintoNo ratings yet

- FoodDocument7 pagesFoodZAhirNo ratings yet

- Semester-Ii NME-2: 3 Hrs / 2 CRDocument3 pagesSemester-Ii NME-2: 3 Hrs / 2 CRChristopher JeyakumarNo ratings yet

- Syllabus For Entrance Examination For Admission To M.Sc. Degree in Food Science and NutritionDocument2 pagesSyllabus For Entrance Examination For Admission To M.Sc. Degree in Food Science and NutritionYashraj SinghNo ratings yet

- MSC Entrance Exam 2018Document3 pagesMSC Entrance Exam 2018Barnali DuttaNo ratings yet

- Productos LacteosDocument18 pagesProductos LacteosDavid RosilloNo ratings yet

- Food ProcessingDocument47 pagesFood ProcessingPadmanaaban Prabhu100% (1)

- Food PDFDocument29 pagesFood PDFvaniagiraldiNo ratings yet

- Food ProcessingDocument8 pagesFood ProcessingRowel GanzonNo ratings yet

- Strawberry-Basil Tart PDFDocument7 pagesStrawberry-Basil Tart PDFNaghmeh Banafshi100% (1)

- HPP Ideologi KopiDocument8 pagesHPP Ideologi KopiFachri AkbarNo ratings yet

- Data Surveyor Dan Yang SurveyDocument27 pagesData Surveyor Dan Yang SurveyWedi PacaranNo ratings yet

- Guía Nutricional - KFCDocument7 pagesGuía Nutricional - KFCErnesto Espinosa RamirezNo ratings yet

- Chapter 1Document29 pagesChapter 1PaalNo ratings yet

- Different Types of MealsDocument15 pagesDifferent Types of Mealsharshal kushwahNo ratings yet

- TLE 10 1st Quarter TestDocument4 pagesTLE 10 1st Quarter TestJonel Rule100% (11)

- Winter Spring 2017 Catalog UsDocument80 pagesWinter Spring 2017 Catalog UsChristineMurphyNo ratings yet

- List Bumbu Yang Tidak Dipakai NewDocument1 pageList Bumbu Yang Tidak Dipakai NewBavarian Culinary HausNo ratings yet

- Pjesmarica 2017Document171 pagesPjesmarica 2017iva ivkovicNo ratings yet

- The Mistress of Spices: Worksheet Answer KeyDocument3 pagesThe Mistress of Spices: Worksheet Answer KeycarlallopesNo ratings yet

- BPP Module 1Document17 pagesBPP Module 1Neil Jean Marcos Bautista100% (1)

- Easy Gnocchi Recipe Homemade Potato Recipes Jamie Oliver PDFDocument1 pageEasy Gnocchi Recipe Homemade Potato Recipes Jamie Oliver PDFAnna GalliziaNo ratings yet

- English For Hotel and Restaurant - Group 2Document2 pagesEnglish For Hotel and Restaurant - Group 2elita100% (1)

- Internship Report Muhammad ArshadDocument95 pagesInternship Report Muhammad ArshadMusama3838 RaoNo ratings yet

- Manda FreqDocument539 pagesManda FreqTom StNo ratings yet

- Chocolate Chip Brookies - Crazy For CrustDocument2 pagesChocolate Chip Brookies - Crazy For CrustmustabeenasadNo ratings yet

- 601 4533 X l2 Cert Food Cookery Sample Portfolio Unit 1 Issue 2 October 2016Document41 pages601 4533 X l2 Cert Food Cookery Sample Portfolio Unit 1 Issue 2 October 2016Kristel AcordonNo ratings yet

- Order Sheet: Order Date Distributor Name Haris Traders Order # Item Code Description Unit Weight Units/Carton Kgs/CartonDocument6 pagesOrder Sheet: Order Date Distributor Name Haris Traders Order # Item Code Description Unit Weight Units/Carton Kgs/CartonGoopNo ratings yet

- Ingles 26 y 27Document2 pagesIngles 26 y 27Jhessica PaulinaNo ratings yet

- Food FanaticsDocument68 pagesFood Fanaticsartodd1100% (2)

- Sample Survey QuestionnaireDocument2 pagesSample Survey Questionnairezamiel.mercadejas09No ratings yet

- Croque Monsieur Recipe Makes 6 Sandwiches. Toasting BreadDocument2 pagesCroque Monsieur Recipe Makes 6 Sandwiches. Toasting BreadmxpxaxoNo ratings yet

- French Food Guide - GlossaryDocument21 pagesFrench Food Guide - GlossarysikandgauravNo ratings yet

- Journal of Nutrition & Food Sciences: Fermented Shrimp Products As Source of Umami in Southeast AsiaDocument5 pagesJournal of Nutrition & Food Sciences: Fermented Shrimp Products As Source of Umami in Southeast AsiaAdinda LarasatiNo ratings yet

- Conservatory Breakfast MenuDocument2 pagesConservatory Breakfast MenusafinditNo ratings yet

- Mochachos Menu August 2018Document2 pagesMochachos Menu August 2018Raeesa SNo ratings yet

Section 1: Food Chemistry and Nutrition: XE - G Food Technology

Section 1: Food Chemistry and Nutrition: XE - G Food Technology

Uploaded by

Kshirsagar Tejas0 ratings0% found this document useful (0 votes)

5 views1 pageX

Original Title

XE_G

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentX

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

5 views1 pageSection 1: Food Chemistry and Nutrition: XE - G Food Technology

Section 1: Food Chemistry and Nutrition: XE - G Food Technology

Uploaded by

Kshirsagar TejasX

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

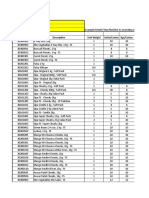

XE - G Food Technology

Section 1: Food Chemistry and Nutrition

Carbohydrates: structure and functional properties of mono-, oligo-, & poly- saccharides including starch,

cellulose, pectic substances and dietary fibre, gelatinization and retrogradation of starch. Proteins: classification

and structure of proteins in food, biochemical changes in post mortem and tenderization of muscles. Lipids:

classification and structure of lipids, rancidity, polymerization and polymorphism. Pigments: carotenoids,

chlorophylls, anthocyanins, tannins and myoglobin. Food flavours: terpenes, esters, aldehydes, ketones and

quinines. Enzymes: specificity, simple and inhibition kinetics, coenzymes, enzymatic and non- enzymatic

browning. Nutrition: balanced diet, essential amino acids and essential fatty acids, protein efficiency ratio, water

soluble and fat soluble vitamins, role of minerals in nutrition, co-factors, anti-nutrients, nutraceuticals, nutrient

deficiency diseases. Chemical and biochemical changes: changes occur in foods during differentprocessing.

Section 2: Food Microbiology

Characteristics of microorganisms: morphology of bacteria, yeast, mold and actinomycetes, spores and

vegetative cells, gram-staining. Microbial growt h: growth and death kinetics, serial dilution technique. Food

spoilage: spoilage microorganisms in different food products including milk, fish, meat, egg, cereals and their

products. Toxins from microbes: pathogens and non-pathogens including Staphylococcus, Salmonella, Shigella,

Escherichia, Bacillus, Clostridium, and Aspergillus genera. Fermented foods and beverages: curd, yoghurt,

cheese, pickles, soya-sauce, sauerkraut, idli, dosa, vinegar, alcoholic beverages and sausage.

Section 3: Food Products Technology

Processing principles: thermal processing, chilling, freezing, dehydration, addition of preservatives and food

additives, irradiation, fermentation, hurdle technology, intermediate moisture foods. Food pack aging and

storage: packaging materials, aseptic packaging, controlled and modified atmosphere storage. Cereal processing

and products: milling of rice, wheat, and maize, parboiling of paddy, bread, biscuits, extruded products and ready

to eat breakfast cereals. Oil processing: expelling, solvent extraction, refining and hydrogenation. Fruits and

vegetables p processing: extraction, clarification, concentration and packaging of fruit juice, jam, jelly,

marmalade, squash, candies, tomato sauce, ketchup, and puree, potato chips, pickles. Plantation crops processing

and products: tea, coffee, cocoa, spice, extraction of essential oils and oleoresins from spices. Milk and milk

products processing: pasteurization and sterilization, cream, butter, ghee, ice- cream, cheese and milk powder.

Processing of animal products: drying, canning, and freezing of fish and meat; production of egg powder. Waste

utilization: pectin from fruit wastes, uses of by-products from rice milling. Food standards and quality

maintenance: FPO, PFA, A-Mark, ISI, HACCP, food plant sanitation and cleaning in place (CIP).

Section 4: Food Engineering

Mass and energy balance; Momentum transfer: Flow rate and pressure drop relationships for Newtonian fluids

flowing through pipe, Reynolds number. Heat transfer: heat transfer by conduction, convection, radiation, heat

exchangers. Mass transfer: molecular diffusion and Flick's law, conduction and convective mass transfer,

permeability through single and multilayer films. Mechanical operations: size reduction of solids, high pressure

homogenization, filtration, centrifugation, settling, sieving, mixing & agitation of liquid. Thermal operations:

thermal sterilization, evaporation of liquid foods, hot air drying of solids, spray and freeze-drying, freezing and

crystallization. Mass transfer operations: psychometric, humidification and dehumidificationoperations.

You might also like

- Module Appetizers 1Document9 pagesModule Appetizers 1Oliver Narag100% (1)

- 12wb Bimbap MealDocument1 page12wb Bimbap Mealapi-186364677No ratings yet

- Sample Business PlanDocument6 pagesSample Business Plantrixie maeNo ratings yet

- Food Engineering and Technology mtqp06Document3 pagesFood Engineering and Technology mtqp06Dev JagarwalNo ratings yet

- Syllabus For The Post of Assistant Professor Food Technology and Food Processing in Higher Education Department 02 - 08 - 2023Document4 pagesSyllabus For The Post of Assistant Professor Food Technology and Food Processing in Higher Education Department 02 - 08 - 2023ﹺ ﹺ ﹺ ﹺNo ratings yet

- Syllabus For Food Technology (XL: Section M) : Food Chemistry and NutritionDocument2 pagesSyllabus For Food Technology (XL: Section M) : Food Chemistry and NutritionVishal Kumar VermaNo ratings yet

- Syllabus For Food Technology (Xe: Section G) : Food Chemistry and NutritionDocument2 pagesSyllabus For Food Technology (Xe: Section G) : Food Chemistry and NutritionAnonymous 8pCXXsNo ratings yet

- Food Science TechnologyDocument1 pageFood Science TechnologysagarikarayabarapuNo ratings yet

- FT Syllabus Patent Examiner MainsDocument5 pagesFT Syllabus Patent Examiner MainsUtkarsh DeshmukhNo ratings yet

- NDRI-PG SyllabusDairy Processing GroupDocument45 pagesNDRI-PG SyllabusDairy Processing Groupheartwin1No ratings yet

- Food Technology (FT)Document2 pagesFood Technology (FT)SRIKANTH PATELNo ratings yet

- Ag 2210Document20 pagesAg 2210Dickson MahanamaNo ratings yet

- Further Details Regarding Main Topics of PROGRAMME No. 05/2020 (Item No: 32)Document4 pagesFurther Details Regarding Main Topics of PROGRAMME No. 05/2020 (Item No: 32)English Master IELTS AcademyNo ratings yet

- Fda Syallabus MainDocument4 pagesFda Syallabus MainRAMESH PHADTARENo ratings yet

- Food Science&TechnologyDocument14 pagesFood Science&TechnologyTerri PerryNo ratings yet

- Food ScienceDocument125 pagesFood ScienceMothika SNo ratings yet

- Wa0013.Document4 pagesWa0013.Nikhil JainNo ratings yet

- Livestock Product TechnologyDocument3 pagesLivestock Product TechnologyRajat SinghNo ratings yet

- Introduction To Food TechnologyDocument42 pagesIntroduction To Food TechnologyNGUYEN CONG DUONGNo ratings yet

- Bio TechnologyDocument2 pagesBio Technologyurvesh_patel44No ratings yet

- Food Processing BackgroundDocument9 pagesFood Processing Backgroundthe dark knightNo ratings yet

- Food PreservationDocument46 pagesFood Preservationazfar_mmas4206100% (2)

- HSB NutritionDocument15 pagesHSB NutritionOsmany MadrigalNo ratings yet

- Laboratory AssistantDocument2 pagesLaboratory AssistantArun Krishnan 122No ratings yet

- Food Science and Technology Scqp12Document4 pagesFood Science and Technology Scqp12vexam57704No ratings yet

- Food Safety OfficerDocument4 pagesFood Safety OfficerAkhilesh RamakrishnanNo ratings yet

- 6 - Toxicants Formed During ProcessingDocument45 pages6 - Toxicants Formed During Processingismailmannur100% (1)

- Food Technology Food Processing UgDocument5 pagesFood Technology Food Processing UgGG GamingNo ratings yet

- DairyDocument4 pagesDairyrajrahaneNo ratings yet

- Food Scie Certm1notesDocument30 pagesFood Scie Certm1notesCynthia ngenyNo ratings yet

- Handout - Livestock Product Processing - FinalDocument64 pagesHandout - Livestock Product Processing - FinalEskindir AmanuelNo ratings yet

- PG - M.sc. - Home Science - Nutrition and Dietetics - 365 13 - Advanced Food Science - English - 2206Document236 pagesPG - M.sc. - Home Science - Nutrition and Dietetics - 365 13 - Advanced Food Science - English - 2206sanju osNo ratings yet

- Food Leacture 1Document38 pagesFood Leacture 1nahomabebezewdye2No ratings yet

- Food and Milk SanitationDocument37 pagesFood and Milk SanitationRuth Mary PadaNo ratings yet

- The Food System and Its SectorsDocument3 pagesThe Food System and Its SectorsBaloch ExpertNo ratings yet

- Single-Cell-ProteinDocument11 pagesSingle-Cell-ProteinKhalid AbduNo ratings yet

- Basic Principles Methods Terms and Terminologies of Food Processing FinalDocument43 pagesBasic Principles Methods Terms and Terminologies of Food Processing FinalLove PuraNo ratings yet

- Food Safety Officer Syllabus PSCDocument2 pagesFood Safety Officer Syllabus PSCA RahmanNo ratings yet

- FSTDocument17 pagesFSTKhizra YounasNo ratings yet

- MSC Ind. Biotech. Syllabus (2008-09)Document4 pagesMSC Ind. Biotech. Syllabus (2008-09)Dr-Alok Prasad DasNo ratings yet

- Lecture 1 Introduction BBDocument34 pagesLecture 1 Introduction BBHuyen Tram NguyenNo ratings yet

- Food ScienceDocument526 pagesFood SciencePuja BarmanNo ratings yet

- Food PreservationDocument5 pagesFood PreservationMark Christian P. MesinaNo ratings yet

- RD Exam Syllabus Without ReferencesDocument25 pagesRD Exam Syllabus Without ReferencesAakriti SharmaNo ratings yet

- Obt351-Food, Nutrition and Health-744666708-Obt351 Food, Nutrition and HealthDocument51 pagesObt351-Food, Nutrition and Health-744666708-Obt351 Food, Nutrition and HealthBME 018 GOKUL GNo ratings yet

- BCH 419Document40 pagesBCH 419idriscognitoleadsNo ratings yet

- Introduction To Food Technology, General Aspect of Food IndustryDocument11 pagesIntroduction To Food Technology, General Aspect of Food Industrysarvesh.bhartiNo ratings yet

- Marshmallow Technology of Increased Nutritional VaDocument9 pagesMarshmallow Technology of Increased Nutritional VaNhi Võ ThịNo ratings yet

- Developments in Functional FoodsDocument19 pagesDevelopments in Functional FoodsRam GantaNo ratings yet

- Centre For Global Food Technology: CSIR-Central Food Technological Research InstituteDocument6 pagesCentre For Global Food Technology: CSIR-Central Food Technological Research InstituteSenthil MuruganNo ratings yet

- Application of Chemistry in Food ProcessingDocument24 pagesApplication of Chemistry in Food ProcessingAkinola AyomideNo ratings yet

- Principles of Food Processing and Halal Requirement (WEEK 11)Document48 pagesPrinciples of Food Processing and Halal Requirement (WEEK 11)aishah1997No ratings yet

- Biochemical Changes Associated With The Processing of FoodsDocument4 pagesBiochemical Changes Associated With The Processing of FoodsAdapa Prabhakara GandhiNo ratings yet

- Concept of Food and Food Preparation and Preservation and Its SignificanceDocument4 pagesConcept of Food and Food Preparation and Preservation and Its SignificanceMeriel GuintoNo ratings yet

- FoodDocument7 pagesFoodZAhirNo ratings yet

- Semester-Ii NME-2: 3 Hrs / 2 CRDocument3 pagesSemester-Ii NME-2: 3 Hrs / 2 CRChristopher JeyakumarNo ratings yet

- Syllabus For Entrance Examination For Admission To M.Sc. Degree in Food Science and NutritionDocument2 pagesSyllabus For Entrance Examination For Admission To M.Sc. Degree in Food Science and NutritionYashraj SinghNo ratings yet

- MSC Entrance Exam 2018Document3 pagesMSC Entrance Exam 2018Barnali DuttaNo ratings yet

- Productos LacteosDocument18 pagesProductos LacteosDavid RosilloNo ratings yet

- Food ProcessingDocument47 pagesFood ProcessingPadmanaaban Prabhu100% (1)

- Food PDFDocument29 pagesFood PDFvaniagiraldiNo ratings yet

- Food ProcessingDocument8 pagesFood ProcessingRowel GanzonNo ratings yet

- Strawberry-Basil Tart PDFDocument7 pagesStrawberry-Basil Tart PDFNaghmeh Banafshi100% (1)

- HPP Ideologi KopiDocument8 pagesHPP Ideologi KopiFachri AkbarNo ratings yet

- Data Surveyor Dan Yang SurveyDocument27 pagesData Surveyor Dan Yang SurveyWedi PacaranNo ratings yet

- Guía Nutricional - KFCDocument7 pagesGuía Nutricional - KFCErnesto Espinosa RamirezNo ratings yet

- Chapter 1Document29 pagesChapter 1PaalNo ratings yet

- Different Types of MealsDocument15 pagesDifferent Types of Mealsharshal kushwahNo ratings yet

- TLE 10 1st Quarter TestDocument4 pagesTLE 10 1st Quarter TestJonel Rule100% (11)

- Winter Spring 2017 Catalog UsDocument80 pagesWinter Spring 2017 Catalog UsChristineMurphyNo ratings yet

- List Bumbu Yang Tidak Dipakai NewDocument1 pageList Bumbu Yang Tidak Dipakai NewBavarian Culinary HausNo ratings yet

- Pjesmarica 2017Document171 pagesPjesmarica 2017iva ivkovicNo ratings yet

- The Mistress of Spices: Worksheet Answer KeyDocument3 pagesThe Mistress of Spices: Worksheet Answer KeycarlallopesNo ratings yet

- BPP Module 1Document17 pagesBPP Module 1Neil Jean Marcos Bautista100% (1)

- Easy Gnocchi Recipe Homemade Potato Recipes Jamie Oliver PDFDocument1 pageEasy Gnocchi Recipe Homemade Potato Recipes Jamie Oliver PDFAnna GalliziaNo ratings yet

- English For Hotel and Restaurant - Group 2Document2 pagesEnglish For Hotel and Restaurant - Group 2elita100% (1)

- Internship Report Muhammad ArshadDocument95 pagesInternship Report Muhammad ArshadMusama3838 RaoNo ratings yet

- Manda FreqDocument539 pagesManda FreqTom StNo ratings yet

- Chocolate Chip Brookies - Crazy For CrustDocument2 pagesChocolate Chip Brookies - Crazy For CrustmustabeenasadNo ratings yet

- 601 4533 X l2 Cert Food Cookery Sample Portfolio Unit 1 Issue 2 October 2016Document41 pages601 4533 X l2 Cert Food Cookery Sample Portfolio Unit 1 Issue 2 October 2016Kristel AcordonNo ratings yet

- Order Sheet: Order Date Distributor Name Haris Traders Order # Item Code Description Unit Weight Units/Carton Kgs/CartonDocument6 pagesOrder Sheet: Order Date Distributor Name Haris Traders Order # Item Code Description Unit Weight Units/Carton Kgs/CartonGoopNo ratings yet

- Ingles 26 y 27Document2 pagesIngles 26 y 27Jhessica PaulinaNo ratings yet

- Food FanaticsDocument68 pagesFood Fanaticsartodd1100% (2)

- Sample Survey QuestionnaireDocument2 pagesSample Survey Questionnairezamiel.mercadejas09No ratings yet

- Croque Monsieur Recipe Makes 6 Sandwiches. Toasting BreadDocument2 pagesCroque Monsieur Recipe Makes 6 Sandwiches. Toasting BreadmxpxaxoNo ratings yet

- French Food Guide - GlossaryDocument21 pagesFrench Food Guide - GlossarysikandgauravNo ratings yet

- Journal of Nutrition & Food Sciences: Fermented Shrimp Products As Source of Umami in Southeast AsiaDocument5 pagesJournal of Nutrition & Food Sciences: Fermented Shrimp Products As Source of Umami in Southeast AsiaAdinda LarasatiNo ratings yet

- Conservatory Breakfast MenuDocument2 pagesConservatory Breakfast MenusafinditNo ratings yet

- Mochachos Menu August 2018Document2 pagesMochachos Menu August 2018Raeesa SNo ratings yet