Professional Documents

Culture Documents

Material For GRVE Piping Fabrication

Material For GRVE Piping Fabrication

Uploaded by

WinsonLimHuiWahCopyright:

Available Formats

You might also like

- Job Safety Analysis (Jsa)Document11 pagesJob Safety Analysis (Jsa)Noraini Binti Osman50% (2)

- SWANCOR 901-3: Epoxy Vinyl Ester ResinsDocument2 pagesSWANCOR 901-3: Epoxy Vinyl Ester ResinsSofya Andarina100% (1)

- Technical Specifications of CHP NTPC 3x500 MWDocument762 pagesTechnical Specifications of CHP NTPC 3x500 MWSHIVAJI CHOUDHURY100% (1)

- Swancor Chempulse 907: Novolac Epoxy Vinyl Ester ResinDocument4 pagesSwancor Chempulse 907: Novolac Epoxy Vinyl Ester ResinEVLYNNo ratings yet

- TDS - Vinyl 905-2 (En)Document2 pagesTDS - Vinyl 905-2 (En)OXY Composite Tech100% (1)

- HT Swancor 901-Pt-Ve-30Document3 pagesHT Swancor 901-Pt-Ve-30Fernando Cesar PérezNo ratings yet

- 907 1TDSDocument2 pages907 1TDSJainam Shah100% (1)

- Swancor 901Document2 pagesSwancor 901jdiaz87No ratings yet

- TDS SW 901 3Document5 pagesTDS SW 901 3Frans Hendra WinartaNo ratings yet

- Tds - Vinyl 963 (En)Document4 pagesTds - Vinyl 963 (En)OXY Composite TechNo ratings yet

- Ultraform N2320 003 BK120 Q600Document2 pagesUltraform N2320 003 BK120 Q600JoelNo ratings yet

- TDS - Vinyl 901-3 (En)Document2 pagesTDS - Vinyl 901-3 (En)OXY Composite TechNo ratings yet

- Studies On The Effect of Ageing On A Range of UK Polymer Bonded ExplosivesDocument27 pagesStudies On The Effect of Ageing On A Range of UK Polymer Bonded ExplosivesKis KhisbiahNo ratings yet

- More Production: in Less TimeDocument2 pagesMore Production: in Less TimeDaniel GarciaNo ratings yet

- Cx5 14 Single Use Film Validation Guide REFER For ABOUT FILMDocument15 pagesCx5 14 Single Use Film Validation Guide REFER For ABOUT FILMCampaign MediaNo ratings yet

- ReportDocument21 pagesReportFaisal AkhterNo ratings yet

- Vistalon 3666 / 8600 EPDM Rubber Dense Weatherseal - 40 Shore ADocument2 pagesVistalon 3666 / 8600 EPDM Rubber Dense Weatherseal - 40 Shore AShalom JohnNo ratings yet

- Exxon™ Chlorobutyl 5066: RubberDocument2 pagesExxon™ Chlorobutyl 5066: RubberMaram YasserNo ratings yet

- SABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFDocument2 pagesSABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFvishal mehtaNo ratings yet

- Vistamaxx™ 6202: Performance PolymerDocument2 pagesVistamaxx™ 6202: Performance PolymerJose Luis Arana AguilarNo ratings yet

- Rigid 10k DatasheetDocument2 pagesRigid 10k DatasheetAna Maria RodrigoNo ratings yet

- TDS - Premix Marine ThixotropeDocument3 pagesTDS - Premix Marine ThixotropegmNo ratings yet

- Eccoh 5836 TDS01 2018-10Document2 pagesEccoh 5836 TDS01 2018-10bobNo ratings yet

- ExxonMobil LLP846029 Rotational Molding ResinDocument2 pagesExxonMobil LLP846029 Rotational Molding ResinLuis Hernandez GarciaNo ratings yet

- Novolac Vinyl Ester Resin: Asecorr 970Document2 pagesNovolac Vinyl Ester Resin: Asecorr 970Mohammed SafwanNo ratings yet

- Sir - Tds.siropol 8340-PLV-180.v03.202012.no2Document3 pagesSir - Tds.siropol 8340-PLV-180.v03.202012.no2Yousef LotfyNo ratings yet

- 1Dqr&Ohduiru, Qgxvwuldo$Ssolfdwlrqv 3URGXFW1&, Test DataDocument15 pages1Dqr&Ohduiru, Qgxvwuldo$Ssolfdwlrqv 3URGXFW1&, Test DataDouglas RodriguesNo ratings yet

- TDS Resin SHCP268-1Document3 pagesTDS Resin SHCP268-1wongpengchiong7205100% (1)

- Product Data Sheet: Synthetic Gear OilDocument2 pagesProduct Data Sheet: Synthetic Gear OilDiegoNo ratings yet

- Greco Isothane 3080A Polyetherâ Tpuâ ResinDocument2 pagesGreco Isothane 3080A Polyetherâ Tpuâ ResinLoc PhanNo ratings yet

- Exxpro™ 3433: Specialty ElastomerDocument2 pagesExxpro™ 3433: Specialty ElastomerMaram YasserNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetIVANCHUNo ratings yet

- WWW - Techsil.co - Uk: Technical BulletinDocument3 pagesWWW - Techsil.co - Uk: Technical BulletinJackson PhinniNo ratings yet

- Catalogo NORSOKDocument2 pagesCatalogo NORSOKkirlaniano@gmail.com100% (1)

- Rotolene: Meet The Unbeatable The Resin That Has It AllDocument2 pagesRotolene: Meet The Unbeatable The Resin That Has It Allrosy_hernandez_8No ratings yet

- TDS - MT 950 - enDocument2 pagesTDS - MT 950 - enTo RaNo ratings yet

- MA8110 TDS Rev11Document2 pagesMA8110 TDS Rev11Rushikesh DeshpandeNo ratings yet

- Abs Ex58f - AsiaDocument4 pagesAbs Ex58f - AsiaGiang CaoNo ratings yet

- PPC - MTCDocument1 pagePPC - MTCNaresh KumarNo ratings yet

- MegaPlast BrochureDocument23 pagesMegaPlast BrochureThao TonNo ratings yet

- PFR 06HCDocument16 pagesPFR 06HCprasanna kumarNo ratings yet

- Tasnee LD 4025as Polyethylene: DescriptionDocument2 pagesTasnee LD 4025as Polyethylene: Descriptiontrần hải namNo ratings yet

- ASA Technical GuideDocument9 pagesASA Technical GuideksharidasNo ratings yet

- Design Tip 2Document6 pagesDesign Tip 2andreafarronatoNo ratings yet

- Trial Mix Report - C40Document5 pagesTrial Mix Report - C40Hari BardosonoNo ratings yet

- Aegis5-14 Film Validation Guide: Five-Layer, 14 Mil Cast Fi LMDocument15 pagesAegis5-14 Film Validation Guide: Five-Layer, 14 Mil Cast Fi LMCampaign MediaNo ratings yet

- SABIC® PC Resin PC0703R - AsiaDocument4 pagesSABIC® PC Resin PC0703R - AsiaLong Trịnh ĐìnhNo ratings yet

- Exceed™ XP 6056ML: Performance PolymerDocument2 pagesExceed™ XP 6056ML: Performance PolymerkjmontilNo ratings yet

- Propriedades Das Matrizes PolimericasDocument7 pagesPropriedades Das Matrizes PolimericasllepsterlNo ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- TDS Enus 0Document2 pagesTDS Enus 0Diego TellezNo ratings yet

- Asi2677 Single Use Film Validation GuideDocument17 pagesAsi2677 Single Use Film Validation GuideCampaign MediaNo ratings yet

- Sh-300pv-En - TDS-SC SolutionDocument2 pagesSh-300pv-En - TDS-SC Solutionteeskuncoro_12906321No ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- Mdpe 3305MQDocument2 pagesMdpe 3305MQHữu LộcNo ratings yet

- Megolon S540 PDFDocument2 pagesMegolon S540 PDFMuhammad Shabbir AwanNo ratings yet

- PP Compound 4Document2 pagesPP Compound 4Aparesh GantaitNo ratings yet

- Elemelt™ TC 955 0R02 B Copolyester Black TDSDocument2 pagesElemelt™ TC 955 0R02 B Copolyester Black TDSftonelli86No ratings yet

- PP20GF 601Document3 pagesPP20GF 601李万福No ratings yet

- Forge nozzle dimension tableDocument1 pageForge nozzle dimension tableWinsonLimHuiWahNo ratings yet

- Blast Loads For Axen TEG PackageDocument6 pagesBlast Loads For Axen TEG PackageWinsonLimHuiWahNo ratings yet

- Student Performance EvaluationDocument1 pageStudent Performance EvaluationWinsonLimHuiWahNo ratings yet

- Vessel Report3Document1 pageVessel Report3WinsonLimHuiWahNo ratings yet

- EU Directive 2014 - PEDDocument99 pagesEU Directive 2014 - PEDWinsonLimHuiWahNo ratings yet

- Class RulesDocument1 pageClass RulesWinsonLimHuiWahNo ratings yet

- Vessel Report 2Document9 pagesVessel Report 2WinsonLimHuiWahNo ratings yet

- Winson Lim Hui Wah - Mechanical Engineer (Static Equipment)Document4 pagesWinson Lim Hui Wah - Mechanical Engineer (Static Equipment)WinsonLimHuiWahNo ratings yet

- 20240213103806538Document20 pages20240213103806538WinsonLimHuiWahNo ratings yet

- Vessel Report1Document9 pagesVessel Report1WinsonLimHuiWahNo ratings yet

- Vocabulary (Part 5) and Create Sentence Standard 6 - Q3 2023 (REV2)Document33 pagesVocabulary (Part 5) and Create Sentence Standard 6 - Q3 2023 (REV2)WinsonLimHuiWahNo ratings yet

- Project Manager ProfilesDocument1 pageProject Manager ProfilesWinsonLimHuiWahNo ratings yet

- Application AI For Pressure Vessel FabricationDocument2 pagesApplication AI For Pressure Vessel FabricationWinsonLimHuiWahNo ratings yet

- Bottom Plate Bending StressDocument2 pagesBottom Plate Bending StressWinsonLimHuiWahNo ratings yet

- Additional Information (Knowledge Manager)Document1 pageAdditional Information (Knowledge Manager)WinsonLimHuiWahNo ratings yet

- Next Wave of RevolutionDocument4 pagesNext Wave of RevolutionWinsonLimHuiWahNo ratings yet

- UASA 英文 new formatDocument5 pagesUASA 英文 new formatWinsonLimHuiWahNo ratings yet

- English STD 6-ModelsDocument2 pagesEnglish STD 6-ModelsWinsonLimHuiWahNo ratings yet

- A Passionate Entrepreneur in Engineering SolutionDocument1 pageA Passionate Entrepreneur in Engineering SolutionWinsonLimHuiWahNo ratings yet

- 01-IWW1-Side ViewDocument1 page01-IWW1-Side ViewWinsonLimHuiWahNo ratings yet

- Asme Sec Viii Div 1 WorkshopDocument1 pageAsme Sec Viii Div 1 WorkshopWinsonLimHuiWahNo ratings yet

- English Standard 6 - Part 4 For March 23Document4 pagesEnglish Standard 6 - Part 4 For March 23WinsonLimHuiWahNo ratings yet

- English Standard 6 - Part 5,6 and 7 For March 23Document4 pagesEnglish Standard 6 - Part 5,6 and 7 For March 23WinsonLimHuiWahNo ratings yet

- JUSHI Safety Datasheet New PDFDocument10 pagesJUSHI Safety Datasheet New PDFWinsonLimHuiWahNo ratings yet

- Gmail - Selected Topics For Level 3 PVElite TrainingDocument1 pageGmail - Selected Topics For Level 3 PVElite TrainingWinsonLimHuiWahNo ratings yet

- Proposal For TVET MalaysiaDocument21 pagesProposal For TVET MalaysiaWinsonLimHuiWah100% (1)

- Criteria For Level 12 and 3Document3 pagesCriteria For Level 12 and 3WinsonLimHuiWahNo ratings yet

- Microsoft Word - ETERSET 2960-2 - MSDSDocument5 pagesMicrosoft Word - ETERSET 2960-2 - MSDSWinsonLimHuiWahNo ratings yet

- Section 9-Inspection-Philosophy PDFDocument20 pagesSection 9-Inspection-Philosophy PDFWinsonLimHuiWahNo ratings yet

- BVI-HSE Daily Report 2023-11-02Document3 pagesBVI-HSE Daily Report 2023-11-02dorwagofNo ratings yet

- 808D Commissioning Guide 0113 enDocument66 pages808D Commissioning Guide 0113 enSam eagle goodNo ratings yet

- LBM NptelDocument25 pagesLBM Nptelsubramanya1982No ratings yet

- Peb Design PPT ModelDocument37 pagesPeb Design PPT ModelYELLAMANDA SANKATINo ratings yet

- CV For Civil EngineerDocument6 pagesCV For Civil EngineerRAREEENo ratings yet

- Plastic Injection Mold Assembly and Disassembly ChecklistDocument4 pagesPlastic Injection Mold Assembly and Disassembly ChecklistAnurag SrivastavaNo ratings yet

- Pdms Taining ListDocument2 pagesPdms Taining ListNatchimuthu Durai Balan67% (3)

- Hpe Support Center: Hpe Proliant Microserver Gen8 - OverviewDocument3 pagesHpe Support Center: Hpe Proliant Microserver Gen8 - Overviewdionis_ponsaNo ratings yet

- Agreed Site Measurement RecordDocument40 pagesAgreed Site Measurement Recordලහිරු විතානාච්චිNo ratings yet

- Prosopis Juliflora in ConcreteDocument7 pagesProsopis Juliflora in ConcreteCampus ConnectNo ratings yet

- 1 - DK1100A English ManualDocument32 pages1 - DK1100A English Manualsales mitrasuryaNo ratings yet

- Hotel Management Database ProjectDocument45 pagesHotel Management Database ProjectFarrukh Tahir100% (1)

- 2089-WAOC AD 2-1 SD AD 2-6Document6 pages2089-WAOC AD 2-1 SD AD 2-6Verdy TariganNo ratings yet

- Jeep 4.7 Motor 2Document1 pageJeep 4.7 Motor 2Agustin Borge GarciaNo ratings yet

- Detailed Solutions To ExercisesDocument123 pagesDetailed Solutions To Exerciseslutfi awn100% (5)

- Manufacturing Conference & Expo 2017 BOPP Film Lolita Plant ReportDocument54 pagesManufacturing Conference & Expo 2017 BOPP Film Lolita Plant ReportayaanNo ratings yet

- Operating, Maintenance & Parts Manual: Rated LoadsDocument48 pagesOperating, Maintenance & Parts Manual: Rated LoadsAmanNo ratings yet

- Process Industry Practices Structural: PIP STE05121 Anchor Bolt Design GuideDocument55 pagesProcess Industry Practices Structural: PIP STE05121 Anchor Bolt Design GuideWNo ratings yet

- Pump Clinic 43Document3 pagesPump Clinic 43fnahas_bhNo ratings yet

- Bob 1.0.1 Vulnhub WalkthroughDocument17 pagesBob 1.0.1 Vulnhub WalkthroughhexoNo ratings yet

- Draw WorksDocument3 pagesDraw WorksUsman AhmedNo ratings yet

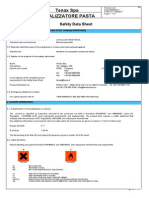

- Catalizzatore Pasta 11768Document6 pagesCatalizzatore Pasta 11768sachinvijanNo ratings yet

- Bootstrap 4 Cheat Sheet 10v400 Alpha6Document12 pagesBootstrap 4 Cheat Sheet 10v400 Alpha6hero100% (1)

- 316 LSDocument5 pages316 LSRouse ToxquiNo ratings yet

- STAMFORD Parts Manual Issue 13Document168 pagesSTAMFORD Parts Manual Issue 13Anonymous 4IAJBGeX100% (2)

- Brake ChamberDocument59 pagesBrake ChamberKanesh MaheshNo ratings yet

- DH DVR510451085116CDocument1 pageDH DVR510451085116CLuis SalazarNo ratings yet

- InvatexacDocument4 pagesInvatexacJorge100% (1)

Material For GRVE Piping Fabrication

Material For GRVE Piping Fabrication

Uploaded by

WinsonLimHuiWahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material For GRVE Piping Fabrication

Material For GRVE Piping Fabrication

Uploaded by

WinsonLimHuiWahCopyright:

Available Formats

ġ

High Corrosion Resistant Epoxy Vinyl Ester Resin

Description: ġ

ETERSET 2960P-5 is a premium grade prepromoter epoxy-based vinyl ester

resin. It has good resistance to a wide range of acids, alkalis and salt solutions. It provides

good mechanical properties and high heat distortion temperature. ġ

ġ

Performance: ġ

Less air bubble release when mixing with MEKPO.ġġ

Less heat release when the resin cure.ġġ

Exhibits good chemical resistance.ġġ

Offers good wet-out. ġ

Comply with FDA regulation 21 CFR 177.2420.ġġ

DNV register approval for marine.ġġ

ġ

Suggested use:ġġ

Filament winding and hand lay-up for FRP tanks and pipes for corrosion

control application.

Hightech Polymer Sdn Bhd Tel +604 324 3800(Ext : 224)

(A Subsidiary of Wah Lee Industrial Corporation) Fax +604 324 3811

Lot 2969, MK 16, Kaw. Perusahaan Acku, Mobile +6016 463 7178 (KOK)

Sungai Lokan, S.P.U. 13400 Butterworth, fbkok@hp.wahlee.com

Penang, Malaysia http://www.hightech.com.my

ġ

ġ

ġ

SPECIFICATIONSġ

ġ

Appearance Yellowish Liquidġġ

Viscosity-Brookfield at 25! 350-450ġġ

(#3 spindle at 60rpm, cps)ġġ

Acid value <10ġġ

Styrene monomer content, % 42-45ġġ

Gel time, min 30-40ġġ

(MEKPO(55%) 1.0%,at 30!)ġġ

TYPICAL PERFORMANCE DATAġ

For Guidance Only

Typical Curing Characteristics :

Room temperature cure at 30!ĭġMEKPO (55%) 1.0%

Total time to peak exotherm, mins 50-60

Peak Exotherm,ġ!! ! ! ! ! ! ! 140-150

ġ

Typical Physical Properties of Cured Casting : Measurement Test Methodġ

Barcol hardness 35 ASTM D2583

Volume shrinkage, % 8.0 ASTM D2566ġ

2

Tensile strength Kg/mm 8.9ġġ ġ ASTM D638ġ

2

Tensile modulus Kg/mm 341ġġ ġ ASTM D638ġ

Elongation, % 5.1ġġ ġ ASTM D638ġ

2

Flexural strength Kg/mm 14.7ġġ ġ ASTM D790ġ

2

Flexural modulus Kg/mm 350ġġ ġ ASTM D790ġ

Heat distortion temp. ! 108ġġ ġ ASTM D648

Hightech Polymer Sdn Bhd Tel +604 324 3800(Ext : 224)

(A Subsidiary of Wah Lee Industrial Corporation) Fax +604 324 3811

Lot 2969, MK 16, Kaw. Perusahaan Acku, Mobile +6016 463 7178 (KOK)

Sungai Lokan, S.P.U. 13400 Butterworth, fbkok@hp.wahlee.com

Penang, Malaysia http://www.hightech.com.my

ġ

ġ

ġ

Typical Physical Properties of Cured Casting : Measurement Test Methodġ

Barcol hardness 35 ASTM D2583ġ

4

Tensile strength (X10 psi) 1.26 ġġ ASTM D638ġ

5

Tensile modulus (X10 psi) 4.8ġ ġ ASTM D638ġ

Elongation, % 5.1ġġ ġ ASTM D638ġ

4

Flexural strength (X10 psi) 2.09ġ ġ ASTM D790ġ

5

Flexural modulus (X10 psi) 5.0ġġ ġ ASTM D790ġ

Heat distortion temp. ! 108ġġ ġ ASTM D648

Typical Gel Time of Eterset 2960-5:

Time to gel

Formulas 10-20 min 20-40 min 40-60 min

Temp.

CoOct 6% 0.5% 0.5% 0.5 %

15! DMA 0.05% 0.03% --

MEKPO 1.5% 1.0% 1.0%

CoOct 6% 0.3% 0.3% 0.1 %

20! DMA 0.05% -- --

MEKPO 1% 1% 1%

CoOct 6% 0.4 % 0.15% 0.05 %

25! DMA -- -- --

MEKPO 1% 1% 1%

CoOct 6% 0.3% 0.1% 0.1%

30! HQ (10%) -- 0.03% 0.07%

MEKPO 1.0% 1.0% 1.0%

CoOct 6% 0.2 % 0.1% 0.1%

35! HQ (10%) -- 0.05% 0.13%

MEKPO 1.0% 1.0% 1.0%

CoOct : Cobalt Octoate

DMA : Dimethyl Aniline

HQ(10%) : 1 g of Hydroquinone in 9 g of ethanol

The gel time is only for your reference, please do test gel time in small quantity (50-100g) before

use, because the properties of Cobalt/MEKPO from different makers may lead to different results.

Hightech Polymer Sdn Bhd Tel +604 324 3800(Ext : 224)

(A Subsidiary of Wah Lee Industrial Corporation) Fax +604 324 3811

Lot 2969, MK 16, Kaw. Perusahaan Acku, Mobile +6016 463 7178 (KOK)

Sungai Lokan, S.P.U. 13400 Butterworth, fbkok@hp.wahlee.com

Penang, Malaysia http://www.hightech.com.my

ġ

ġ

ġ

ETERSET 2960-5 Anti-Corrosion FRP Structural Design Suggestion

Fiberglass(%) Chemical Surface Types of

Fiberglass

0% Contact Surface Resin

10% Surfacing veil

Corrosion 30% Chopped

Layer mat(300g/m2)

30% Chopped

mat(300g/m2)

50% Woven roving

Structural 30% Chopped mat

Layer 50% Woven roving

30% Outside Layer Chopped mat

If need to increase the thickness, please laminate woven roving/ chopped mat by sequence

and last layer must be chopped mat.

Recommended Storage : ġ

Typical storage life at temperature below 25! is 6 months. Storage life decreases with

increasing temperature. Avoid exposure to heat sources such as direct sunlight or steam pipes.

During storage periodically aerate air into resin will extend shelf life.

!

Uif!jogpsnbujpo!dpoubjofe!ifsfjo!jt!dpssfdu!up!uif!cftu!pg!pvs!lopxmfehf/!Uif!sfdpnnfoebujpot!ps!tvhhftujpot!dpoubjofe!jo!!

uijt!cvmmfujo!bsf!nbef!xjuipvu!hvbsbouff!ps!sfqsftfoubujpo!bt!up!sftvmut/!Xf!tvhhftu!uibu!zpv!fwbmvbuf!uiftf!sfdpnnfoebujpot!!

boe!tvhhftujpot!jo!zpvs!pxo!mbcpsbupsz!qsjps!up!vtf/!Pvs!sftqpotjcjmjuz!gps!dmbjnt!bsjtjoh!gspn!csfbdi!pg!xbssbouz/!!!

ofhmjhfodf/!ps!puifsxjtf!jt!mjnjufe!up!uif!qvsdibtf!qsjdf!pg!uif!nbufsjbm/!

ġ

Hightech Polymer Sdn Bhd Tel +604 324 3800(Ext : 224)

(A Subsidiary of Wah Lee Industrial Corporation) Fax +604 324 3811

Lot 2969, MK 16, Kaw. Perusahaan Acku, Mobile +6016 463 7178 (KOK)

Sungai Lokan, S.P.U. 13400 Butterworth, fbkok@hp.wahlee.com

Penang, Malaysia http://www.hightech.com.my

ġ

ġ

You might also like

- Job Safety Analysis (Jsa)Document11 pagesJob Safety Analysis (Jsa)Noraini Binti Osman50% (2)

- SWANCOR 901-3: Epoxy Vinyl Ester ResinsDocument2 pagesSWANCOR 901-3: Epoxy Vinyl Ester ResinsSofya Andarina100% (1)

- Technical Specifications of CHP NTPC 3x500 MWDocument762 pagesTechnical Specifications of CHP NTPC 3x500 MWSHIVAJI CHOUDHURY100% (1)

- Swancor Chempulse 907: Novolac Epoxy Vinyl Ester ResinDocument4 pagesSwancor Chempulse 907: Novolac Epoxy Vinyl Ester ResinEVLYNNo ratings yet

- TDS - Vinyl 905-2 (En)Document2 pagesTDS - Vinyl 905-2 (En)OXY Composite Tech100% (1)

- HT Swancor 901-Pt-Ve-30Document3 pagesHT Swancor 901-Pt-Ve-30Fernando Cesar PérezNo ratings yet

- 907 1TDSDocument2 pages907 1TDSJainam Shah100% (1)

- Swancor 901Document2 pagesSwancor 901jdiaz87No ratings yet

- TDS SW 901 3Document5 pagesTDS SW 901 3Frans Hendra WinartaNo ratings yet

- Tds - Vinyl 963 (En)Document4 pagesTds - Vinyl 963 (En)OXY Composite TechNo ratings yet

- Ultraform N2320 003 BK120 Q600Document2 pagesUltraform N2320 003 BK120 Q600JoelNo ratings yet

- TDS - Vinyl 901-3 (En)Document2 pagesTDS - Vinyl 901-3 (En)OXY Composite TechNo ratings yet

- Studies On The Effect of Ageing On A Range of UK Polymer Bonded ExplosivesDocument27 pagesStudies On The Effect of Ageing On A Range of UK Polymer Bonded ExplosivesKis KhisbiahNo ratings yet

- More Production: in Less TimeDocument2 pagesMore Production: in Less TimeDaniel GarciaNo ratings yet

- Cx5 14 Single Use Film Validation Guide REFER For ABOUT FILMDocument15 pagesCx5 14 Single Use Film Validation Guide REFER For ABOUT FILMCampaign MediaNo ratings yet

- ReportDocument21 pagesReportFaisal AkhterNo ratings yet

- Vistalon 3666 / 8600 EPDM Rubber Dense Weatherseal - 40 Shore ADocument2 pagesVistalon 3666 / 8600 EPDM Rubber Dense Weatherseal - 40 Shore AShalom JohnNo ratings yet

- Exxon™ Chlorobutyl 5066: RubberDocument2 pagesExxon™ Chlorobutyl 5066: RubberMaram YasserNo ratings yet

- SABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFDocument2 pagesSABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFvishal mehtaNo ratings yet

- Vistamaxx™ 6202: Performance PolymerDocument2 pagesVistamaxx™ 6202: Performance PolymerJose Luis Arana AguilarNo ratings yet

- Rigid 10k DatasheetDocument2 pagesRigid 10k DatasheetAna Maria RodrigoNo ratings yet

- TDS - Premix Marine ThixotropeDocument3 pagesTDS - Premix Marine ThixotropegmNo ratings yet

- Eccoh 5836 TDS01 2018-10Document2 pagesEccoh 5836 TDS01 2018-10bobNo ratings yet

- ExxonMobil LLP846029 Rotational Molding ResinDocument2 pagesExxonMobil LLP846029 Rotational Molding ResinLuis Hernandez GarciaNo ratings yet

- Novolac Vinyl Ester Resin: Asecorr 970Document2 pagesNovolac Vinyl Ester Resin: Asecorr 970Mohammed SafwanNo ratings yet

- Sir - Tds.siropol 8340-PLV-180.v03.202012.no2Document3 pagesSir - Tds.siropol 8340-PLV-180.v03.202012.no2Yousef LotfyNo ratings yet

- 1Dqr&Ohduiru, Qgxvwuldo$Ssolfdwlrqv 3URGXFW1&, Test DataDocument15 pages1Dqr&Ohduiru, Qgxvwuldo$Ssolfdwlrqv 3URGXFW1&, Test DataDouglas RodriguesNo ratings yet

- TDS Resin SHCP268-1Document3 pagesTDS Resin SHCP268-1wongpengchiong7205100% (1)

- Product Data Sheet: Synthetic Gear OilDocument2 pagesProduct Data Sheet: Synthetic Gear OilDiegoNo ratings yet

- Greco Isothane 3080A Polyetherâ Tpuâ ResinDocument2 pagesGreco Isothane 3080A Polyetherâ Tpuâ ResinLoc PhanNo ratings yet

- Exxpro™ 3433: Specialty ElastomerDocument2 pagesExxpro™ 3433: Specialty ElastomerMaram YasserNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetIVANCHUNo ratings yet

- WWW - Techsil.co - Uk: Technical BulletinDocument3 pagesWWW - Techsil.co - Uk: Technical BulletinJackson PhinniNo ratings yet

- Catalogo NORSOKDocument2 pagesCatalogo NORSOKkirlaniano@gmail.com100% (1)

- Rotolene: Meet The Unbeatable The Resin That Has It AllDocument2 pagesRotolene: Meet The Unbeatable The Resin That Has It Allrosy_hernandez_8No ratings yet

- TDS - MT 950 - enDocument2 pagesTDS - MT 950 - enTo RaNo ratings yet

- MA8110 TDS Rev11Document2 pagesMA8110 TDS Rev11Rushikesh DeshpandeNo ratings yet

- Abs Ex58f - AsiaDocument4 pagesAbs Ex58f - AsiaGiang CaoNo ratings yet

- PPC - MTCDocument1 pagePPC - MTCNaresh KumarNo ratings yet

- MegaPlast BrochureDocument23 pagesMegaPlast BrochureThao TonNo ratings yet

- PFR 06HCDocument16 pagesPFR 06HCprasanna kumarNo ratings yet

- Tasnee LD 4025as Polyethylene: DescriptionDocument2 pagesTasnee LD 4025as Polyethylene: Descriptiontrần hải namNo ratings yet

- ASA Technical GuideDocument9 pagesASA Technical GuideksharidasNo ratings yet

- Design Tip 2Document6 pagesDesign Tip 2andreafarronatoNo ratings yet

- Trial Mix Report - C40Document5 pagesTrial Mix Report - C40Hari BardosonoNo ratings yet

- Aegis5-14 Film Validation Guide: Five-Layer, 14 Mil Cast Fi LMDocument15 pagesAegis5-14 Film Validation Guide: Five-Layer, 14 Mil Cast Fi LMCampaign MediaNo ratings yet

- SABIC® PC Resin PC0703R - AsiaDocument4 pagesSABIC® PC Resin PC0703R - AsiaLong Trịnh ĐìnhNo ratings yet

- Exceed™ XP 6056ML: Performance PolymerDocument2 pagesExceed™ XP 6056ML: Performance PolymerkjmontilNo ratings yet

- Propriedades Das Matrizes PolimericasDocument7 pagesPropriedades Das Matrizes PolimericasllepsterlNo ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- TDS Enus 0Document2 pagesTDS Enus 0Diego TellezNo ratings yet

- Asi2677 Single Use Film Validation GuideDocument17 pagesAsi2677 Single Use Film Validation GuideCampaign MediaNo ratings yet

- Sh-300pv-En - TDS-SC SolutionDocument2 pagesSh-300pv-En - TDS-SC Solutionteeskuncoro_12906321No ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- Mdpe 3305MQDocument2 pagesMdpe 3305MQHữu LộcNo ratings yet

- Megolon S540 PDFDocument2 pagesMegolon S540 PDFMuhammad Shabbir AwanNo ratings yet

- PP Compound 4Document2 pagesPP Compound 4Aparesh GantaitNo ratings yet

- Elemelt™ TC 955 0R02 B Copolyester Black TDSDocument2 pagesElemelt™ TC 955 0R02 B Copolyester Black TDSftonelli86No ratings yet

- PP20GF 601Document3 pagesPP20GF 601李万福No ratings yet

- Forge nozzle dimension tableDocument1 pageForge nozzle dimension tableWinsonLimHuiWahNo ratings yet

- Blast Loads For Axen TEG PackageDocument6 pagesBlast Loads For Axen TEG PackageWinsonLimHuiWahNo ratings yet

- Student Performance EvaluationDocument1 pageStudent Performance EvaluationWinsonLimHuiWahNo ratings yet

- Vessel Report3Document1 pageVessel Report3WinsonLimHuiWahNo ratings yet

- EU Directive 2014 - PEDDocument99 pagesEU Directive 2014 - PEDWinsonLimHuiWahNo ratings yet

- Class RulesDocument1 pageClass RulesWinsonLimHuiWahNo ratings yet

- Vessel Report 2Document9 pagesVessel Report 2WinsonLimHuiWahNo ratings yet

- Winson Lim Hui Wah - Mechanical Engineer (Static Equipment)Document4 pagesWinson Lim Hui Wah - Mechanical Engineer (Static Equipment)WinsonLimHuiWahNo ratings yet

- 20240213103806538Document20 pages20240213103806538WinsonLimHuiWahNo ratings yet

- Vessel Report1Document9 pagesVessel Report1WinsonLimHuiWahNo ratings yet

- Vocabulary (Part 5) and Create Sentence Standard 6 - Q3 2023 (REV2)Document33 pagesVocabulary (Part 5) and Create Sentence Standard 6 - Q3 2023 (REV2)WinsonLimHuiWahNo ratings yet

- Project Manager ProfilesDocument1 pageProject Manager ProfilesWinsonLimHuiWahNo ratings yet

- Application AI For Pressure Vessel FabricationDocument2 pagesApplication AI For Pressure Vessel FabricationWinsonLimHuiWahNo ratings yet

- Bottom Plate Bending StressDocument2 pagesBottom Plate Bending StressWinsonLimHuiWahNo ratings yet

- Additional Information (Knowledge Manager)Document1 pageAdditional Information (Knowledge Manager)WinsonLimHuiWahNo ratings yet

- Next Wave of RevolutionDocument4 pagesNext Wave of RevolutionWinsonLimHuiWahNo ratings yet

- UASA 英文 new formatDocument5 pagesUASA 英文 new formatWinsonLimHuiWahNo ratings yet

- English STD 6-ModelsDocument2 pagesEnglish STD 6-ModelsWinsonLimHuiWahNo ratings yet

- A Passionate Entrepreneur in Engineering SolutionDocument1 pageA Passionate Entrepreneur in Engineering SolutionWinsonLimHuiWahNo ratings yet

- 01-IWW1-Side ViewDocument1 page01-IWW1-Side ViewWinsonLimHuiWahNo ratings yet

- Asme Sec Viii Div 1 WorkshopDocument1 pageAsme Sec Viii Div 1 WorkshopWinsonLimHuiWahNo ratings yet

- English Standard 6 - Part 4 For March 23Document4 pagesEnglish Standard 6 - Part 4 For March 23WinsonLimHuiWahNo ratings yet

- English Standard 6 - Part 5,6 and 7 For March 23Document4 pagesEnglish Standard 6 - Part 5,6 and 7 For March 23WinsonLimHuiWahNo ratings yet

- JUSHI Safety Datasheet New PDFDocument10 pagesJUSHI Safety Datasheet New PDFWinsonLimHuiWahNo ratings yet

- Gmail - Selected Topics For Level 3 PVElite TrainingDocument1 pageGmail - Selected Topics For Level 3 PVElite TrainingWinsonLimHuiWahNo ratings yet

- Proposal For TVET MalaysiaDocument21 pagesProposal For TVET MalaysiaWinsonLimHuiWah100% (1)

- Criteria For Level 12 and 3Document3 pagesCriteria For Level 12 and 3WinsonLimHuiWahNo ratings yet

- Microsoft Word - ETERSET 2960-2 - MSDSDocument5 pagesMicrosoft Word - ETERSET 2960-2 - MSDSWinsonLimHuiWahNo ratings yet

- Section 9-Inspection-Philosophy PDFDocument20 pagesSection 9-Inspection-Philosophy PDFWinsonLimHuiWahNo ratings yet

- BVI-HSE Daily Report 2023-11-02Document3 pagesBVI-HSE Daily Report 2023-11-02dorwagofNo ratings yet

- 808D Commissioning Guide 0113 enDocument66 pages808D Commissioning Guide 0113 enSam eagle goodNo ratings yet

- LBM NptelDocument25 pagesLBM Nptelsubramanya1982No ratings yet

- Peb Design PPT ModelDocument37 pagesPeb Design PPT ModelYELLAMANDA SANKATINo ratings yet

- CV For Civil EngineerDocument6 pagesCV For Civil EngineerRAREEENo ratings yet

- Plastic Injection Mold Assembly and Disassembly ChecklistDocument4 pagesPlastic Injection Mold Assembly and Disassembly ChecklistAnurag SrivastavaNo ratings yet

- Pdms Taining ListDocument2 pagesPdms Taining ListNatchimuthu Durai Balan67% (3)

- Hpe Support Center: Hpe Proliant Microserver Gen8 - OverviewDocument3 pagesHpe Support Center: Hpe Proliant Microserver Gen8 - Overviewdionis_ponsaNo ratings yet

- Agreed Site Measurement RecordDocument40 pagesAgreed Site Measurement Recordලහිරු විතානාච්චිNo ratings yet

- Prosopis Juliflora in ConcreteDocument7 pagesProsopis Juliflora in ConcreteCampus ConnectNo ratings yet

- 1 - DK1100A English ManualDocument32 pages1 - DK1100A English Manualsales mitrasuryaNo ratings yet

- Hotel Management Database ProjectDocument45 pagesHotel Management Database ProjectFarrukh Tahir100% (1)

- 2089-WAOC AD 2-1 SD AD 2-6Document6 pages2089-WAOC AD 2-1 SD AD 2-6Verdy TariganNo ratings yet

- Jeep 4.7 Motor 2Document1 pageJeep 4.7 Motor 2Agustin Borge GarciaNo ratings yet

- Detailed Solutions To ExercisesDocument123 pagesDetailed Solutions To Exerciseslutfi awn100% (5)

- Manufacturing Conference & Expo 2017 BOPP Film Lolita Plant ReportDocument54 pagesManufacturing Conference & Expo 2017 BOPP Film Lolita Plant ReportayaanNo ratings yet

- Operating, Maintenance & Parts Manual: Rated LoadsDocument48 pagesOperating, Maintenance & Parts Manual: Rated LoadsAmanNo ratings yet

- Process Industry Practices Structural: PIP STE05121 Anchor Bolt Design GuideDocument55 pagesProcess Industry Practices Structural: PIP STE05121 Anchor Bolt Design GuideWNo ratings yet

- Pump Clinic 43Document3 pagesPump Clinic 43fnahas_bhNo ratings yet

- Bob 1.0.1 Vulnhub WalkthroughDocument17 pagesBob 1.0.1 Vulnhub WalkthroughhexoNo ratings yet

- Draw WorksDocument3 pagesDraw WorksUsman AhmedNo ratings yet

- Catalizzatore Pasta 11768Document6 pagesCatalizzatore Pasta 11768sachinvijanNo ratings yet

- Bootstrap 4 Cheat Sheet 10v400 Alpha6Document12 pagesBootstrap 4 Cheat Sheet 10v400 Alpha6hero100% (1)

- 316 LSDocument5 pages316 LSRouse ToxquiNo ratings yet

- STAMFORD Parts Manual Issue 13Document168 pagesSTAMFORD Parts Manual Issue 13Anonymous 4IAJBGeX100% (2)

- Brake ChamberDocument59 pagesBrake ChamberKanesh MaheshNo ratings yet

- DH DVR510451085116CDocument1 pageDH DVR510451085116CLuis SalazarNo ratings yet

- InvatexacDocument4 pagesInvatexacJorge100% (1)