Professional Documents

Culture Documents

Leadtec Fluoride ION Sensor Manual

Leadtec Fluoride ION Sensor Manual

Uploaded by

Chun Jie GohOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Leadtec Fluoride ION Sensor Manual

Leadtec Fluoride ION Sensor Manual

Uploaded by

Chun Jie GohCopyright:

Available Formats

CALIBRATION

Use fresh buffer for calibration. Prepare two

calibration buffers of 50mL. The ideal buffer

values should cover the common operating

range for measurement. The second buffer

solution value must match the first buffer solution

with 10 times multiplication difference. Add 1 mL

of ISAB solution into each buffer solution.

1. Rinse the electrode with water and dab it dry

with lint free cloth.

2. Immerse the probe in the First Point buffer

(lowest ppm value).

3. Initiate first point calibration from the controller

4. Rinse the electrode and dab it dry with lint free

cloth

5. Immerse the probe in the Second Point buffer

and begin Second Point calibration from

controller to complete .

Example 1

The fluoride range of the process:

User Guide

0.56 ppm

First Point

Second Point

: 0.1 ppm

: 1.0 ppm

Fluoride Sensor

Leadtec Instruments (Asia) Sdn Bhd (1220327-P)

B-8-810, Kelana Square Block B, 17, 100, Jalan Pusat Perniagaan 1,

Jalan SS7/26, Kelana Square, 47301 Pusat Perniagaan Raja Uda, 12300

Petaling Jaya, Selangor, Butterworth,Pulau Pinang,

Malaysia. Malaysia.

Phone : (+60)3 - 7611 0701 Phone : (+60)4 - 3200 701

Fax : (+60)4 - 7611 0702 Fax : (+60)4 - 3233 327 www.leadtec-asia.com

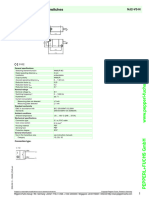

PREPARATIONS FOR USE DIMENSIONS SPECIFICATIONS

1. Unpack the sensor from the box and inspect Measuring Principle Ion Selective

for any physical damage. If any defects or (Potentiometric)

damage are present, report promptly to your

E-6802

supplier to resolve this issue. Measuring Range 0.02 – 2000 ppm

2. Pre-soak the sensor with 100 ppm fluoride Other ranges are upon

solution for about 30 minutes. request

3. Calibration is required before use.

4. The conductive layer covering the sensor Resolution 0.01 ppm

cable must be removed in order to isolate the

circuit connection from the Reference.

Otherwise, the sensor will display incorrect Slope 56 ± 6 mV @ 25oC

readings.

Endpoint Time Typically, 10 to 30

seconds

REF

E-6902

Interferences Hydroxide Ions

PX

Aluminum (III) Ions

Conductive layer not removed Iron (III) Ions

Temperature Range 5 – 50oC

REF

pH Range 2 – 8 pH

PX

INSTALLATION

Conductive layer removed Potential Drift 2 mV per day

The fluoride sensor can be installed in-line or

immersion . Body Material ABS

1. Remove the sensor cap and rinse thoroughly.

STORAGE 2. After rinsing, the electrode is ready to be Types of Installation:

fasten on piping and holders. 1. Immersion

2. In-line

When the probe is not in operation, clean the

sensor thoroughly to remove impurities. Dab

off remaining liquid and keep the sensor dry.

Secure the protective cap back on.

WIRING DIAGRAM

MAINTENANCE

Fluoride probe will exhibit indications when cleaning

is required. The probe will require longer Cleaning

stabilization time, measures erratic reading and,

having difficulties to perform calibration. Clean the Rinse the sensor thoroughly with water and

sensor when these key indications occur. It should dab the sensor dry. Should the stain remains

be done periodically throughout the operation for intact to the sensor, rinse the sensor

optimum performance. with cleaning solution and immerse it

into a 100ppm fluoride solution for 1 hour.

You might also like

- Sodium InstrumentationDocument9 pagesSodium InstrumentationsumanthrgowdaNo ratings yet

- Env. Aspect Impact Identification - Form (Project)Document1 pageEnv. Aspect Impact Identification - Form (Project)Chun Jie Goh100% (1)

- AOI Drift Indicator SystemDocument4 pagesAOI Drift Indicator SystemahnafNo ratings yet

- CDR-EL-1109 - CDR Sample ElectricalDocument1 pageCDR-EL-1109 - CDR Sample ElectricalCDR Download100% (1)

- Xiying Ammonium SensorDocument14 pagesXiying Ammonium Sensorsalsasafira926No ratings yet

- RK500-25 COD Sensor Specification v3.0Document2 pagesRK500-25 COD Sensor Specification v3.0imammashari2022No ratings yet

- W560-A Ammonia Sensor User ManualDocument12 pagesW560-A Ammonia Sensor User ManualkepyarNo ratings yet

- Retro-Reflex Sensor: Technical DataDocument2 pagesRetro-Reflex Sensor: Technical DataAmila BalasooriyaNo ratings yet

- Lases01700 1Document2 pagesLases01700 1qaisar.qb123No ratings yet

- Tf02 Datasheet enDocument12 pagesTf02 Datasheet enBryan PucaNo ratings yet

- Quick Start Guide 499atrdo Trace Dissolved Oxygen Sensor Rosemount en 990776Document20 pagesQuick Start Guide 499atrdo Trace Dissolved Oxygen Sensor Rosemount en 990776ckavi561No ratings yet

- RKL-01 Submersible Liquid Transmitter SensorDocument3 pagesRKL-01 Submersible Liquid Transmitter Sensoroto bambosNo ratings yet

- Honeywell Sensing Zephyr Digital Airflow 10 SLPM 300 SLPM Installation Instructions 50080060 C enDocument7 pagesHoneywell Sensing Zephyr Digital Airflow 10 SLPM 300 SLPM Installation Instructions 50080060 C enAlejandro Palomino AmaroNo ratings yet

- Doc024 52 93026Document28 pagesDoc024 52 93026Long Nguyễn VănNo ratings yet

- POLYMETRON 8398 Inductive Probe Manual-221 183 098Document28 pagesPOLYMETRON 8398 Inductive Probe Manual-221 183 098Long Nguyễn VănNo ratings yet

- RK500-02 PH Sensor: FeaturesDocument3 pagesRK500-02 PH Sensor: FeaturesRahmat AlbarzanjieNo ratings yet

- CL223Document2 pagesCL223Syed FuzailNo ratings yet

- 39408, CP25QXVT80 Wengler Level SensorDocument19 pages39408, CP25QXVT80 Wengler Level SensorVigneshkumar JagannathanNo ratings yet

- Electrochemical Galvanic Fuel Cell Trace Oxygen SensorDocument1 pageElectrochemical Galvanic Fuel Cell Trace Oxygen SensorGhasemNo ratings yet

- pH/ORP: User GuideDocument2 pagespH/ORP: User GuideEry AzmiNo ratings yet

- Bcelectronics Tu7685Document3 pagesBcelectronics Tu7685denios09No ratings yet

- Opsis O2000.enDocument4 pagesOpsis O2000.enManzoor-ul- HassanNo ratings yet

- Signet 4150 TurbidimeterDocument20 pagesSignet 4150 TurbidimeterMorassa ChonaNo ratings yet

- RK500-04 Fluorescence Principle DO Sensor Specification v3.0Document2 pagesRK500-04 Fluorescence Principle DO Sensor Specification v3.0Hossein AkbariNo ratings yet

- RK500-04 Dissolved Oxygen Sensor: FeaturesDocument2 pagesRK500-04 Dissolved Oxygen Sensor: FeaturesHao VănNo ratings yet

- EAX2 Sensor Nivel UltrasónicoDocument8 pagesEAX2 Sensor Nivel UltrasónicoMarco Antonio Fuenzalida PinoNo ratings yet

- EAX2 Ultrasonic Level Transmitter - NewDocument8 pagesEAX2 Ultrasonic Level Transmitter - NewJohnny Liu JohnnyNo ratings yet

- HC-404 Total Hydrocarbon Analyzer ManualDocument21 pagesHC-404 Total Hydrocarbon Analyzer ManualnataliaportilloNo ratings yet

- peg 파생물질 70-6809-Non-Ionic-Surfactants-Polysorbate-20-Polysorbate-80-and-Triton-X100Document2 pagespeg 파생물질 70-6809-Non-Ionic-Surfactants-Polysorbate-20-Polysorbate-80-and-Triton-X100woonyoung leeNo ratings yet

- Lab EquipmentDocument29 pagesLab EquipmentkrunalNo ratings yet

- Proximity Switch (FO Venting) 106406 - EngDocument4 pagesProximity Switch (FO Venting) 106406 - EngfarisazharuNo ratings yet

- Mp503 English PDFDocument7 pagesMp503 English PDFФлавио ПересNo ratings yet

- Opb960 990Document6 pagesOpb960 990zakaria alhosinyNo ratings yet

- Ultrasonic Oxygen Sensor Module Gasboard7500EDocument6 pagesUltrasonic Oxygen Sensor Module Gasboard7500ECarlos Julián Muñoz QuirogaNo ratings yet

- Rishabh CT SpecificationsDocument2 pagesRishabh CT SpecificationsMiguel Andres Osorio JaramilloNo ratings yet

- Data Sheet LD86PCV3 ENDocument2 pagesData Sheet LD86PCV3 ENهبال حمزةNo ratings yet

- OptiX SDH Test PrinciplesDocument55 pagesOptiX SDH Test PrinciplesRafael SenaNo ratings yet

- Lite On - Lite S A0003819919 1 1737446Document9 pagesLite On - Lite S A0003819919 1 1737446GADOM gadpmNo ratings yet

- LIT2819Document4 pagesLIT2819huyvuNo ratings yet

- d378 Aanderaa Oxygen Sensor 4330w 4330 4330f Low enDocument2 pagesd378 Aanderaa Oxygen Sensor 4330w 4330 4330f Low enDominique LefevreNo ratings yet

- PH ORP 1110 1120 - Operation ManualDocument9 pagesPH ORP 1110 1120 - Operation ManualMarcela DuckardtNo ratings yet

- LC200A EN ManualDocument10 pagesLC200A EN ManualGiovani DiasNo ratings yet

- OPSISDocument3 pagesOPSISflywheel2006No ratings yet

- Datasheet PH Digital Sensor PHEHT - 2Document2 pagesDatasheet PH Digital Sensor PHEHT - 2mangabrielNo ratings yet

- RK520-05 NPK Sensor Specification v3.0Document2 pagesRK520-05 NPK Sensor Specification v3.0silverrianNo ratings yet

- Product User's Manual - HC-SR04 Ultrasonic SensorDocument6 pagesProduct User's Manual - HC-SR04 Ultrasonic SensorMichael Fields100% (2)

- Hydranautics Hydracore70 MembraneDocument1 pageHydranautics Hydracore70 MembraneOuassouNo ratings yet

- Analog Communications LabDocument54 pagesAnalog Communications LabjaswanthjNo ratings yet

- User Manual - OPTOD - PlasticDocument17 pagesUser Manual - OPTOD - PlasticmangabrielNo ratings yet

- Datasheet LMS511-20190 1059529 enDocument10 pagesDatasheet LMS511-20190 1059529 enSlobodan MilosavljevicNo ratings yet

- Dod Dot2000Document12 pagesDod Dot2000Jorge AriasNo ratings yet

- Transformer Protection Final Rev.01 PDFDocument2 pagesTransformer Protection Final Rev.01 PDFNader Asgar Pangarungan MamarobaNo ratings yet

- TDR RI-407 User Manual ENG v3Document69 pagesTDR RI-407 User Manual ENG v3Phong DuongNo ratings yet

- Level Sensor ManualDocument7 pagesLevel Sensor ManualSatyasrinivas PulavarthiNo ratings yet

- Conductivity Sensor 4019Document2 pagesConductivity Sensor 4019Dietrich ThomysNo ratings yet

- WQ-FDO Global WaterDocument1 pageWQ-FDO Global WaterleonardoNo ratings yet

- Datasheet EHANDocument3 pagesDatasheet EHANrenzoNo ratings yet

- Surface Mount 2920L SeriesDocument6 pagesSurface Mount 2920L SeriesAfonso MoutinhoNo ratings yet

- RK300-06 Noise Sensor User Manualv1.0Document2 pagesRK300-06 Noise Sensor User Manualv1.0Aristocrazy Subono Subono SubonoNo ratings yet

- Datasheet OPTOD - PlasticDocument3 pagesDatasheet OPTOD - PlasticmangabrielNo ratings yet

- SCM-W Datasheet v41Document10 pagesSCM-W Datasheet v41nguyenam2008No ratings yet

- IT 8310 RS Operation Manual 2020 CDocument64 pagesIT 8310 RS Operation Manual 2020 CChun Jie GohNo ratings yet

- D4F869 Aeration Tank Operation Calculations Si UnitsDocument2 pagesD4F869 Aeration Tank Operation Calculations Si UnitsChun Jie GohNo ratings yet

- 316L Stainless Steel Sanitary Tri-Clamp End Connections: Koflo CorporationDocument1 page316L Stainless Steel Sanitary Tri-Clamp End Connections: Koflo CorporationChun Jie GohNo ratings yet

- QuestionDocument2 pagesQuestionChun Jie GohNo ratings yet

- A Detailed Study On Loss Processes in Solar CellsDocument11 pagesA Detailed Study On Loss Processes in Solar CellsFernando DiasNo ratings yet

- Tower Crane AccidentDocument37 pagesTower Crane Accidentparawansa muisNo ratings yet

- Management Strategies For Primary Dysmenorrhea: 9.1 Topic OverviewDocument19 pagesManagement Strategies For Primary Dysmenorrhea: 9.1 Topic OverviewAgusdiwana SuarniNo ratings yet

- 21CLD Learning Activity Cover SheetDocument9 pages21CLD Learning Activity Cover SheetMariana VoloshynNo ratings yet

- Ask A Question Create A Poll: Why Is The Number "13" Considered An "Unlucky" Number?Document28 pagesAsk A Question Create A Poll: Why Is The Number "13" Considered An "Unlucky" Number?Andres TugguinNo ratings yet

- BOSCH Lbb4432 KeypadDocument2 pagesBOSCH Lbb4432 KeypadJulie HalimNo ratings yet

- SKB Salary Scale Budget 2013 Vols 1-2Document23 pagesSKB Salary Scale Budget 2013 Vols 1-2Kerine HeronNo ratings yet

- Essay Topic - Distance LearningDocument3 pagesEssay Topic - Distance LearningFalling stonesNo ratings yet

- Air Compressor Basic ConceptsDocument32 pagesAir Compressor Basic Conceptsjkahamed100% (11)

- CHAPTER # 1the Nature of Matter and Periodicity of Atomic PropertiesDocument48 pagesCHAPTER # 1the Nature of Matter and Periodicity of Atomic PropertiesAnonymous UfzcLV8ZNo ratings yet

- Beauty Care (Nail Care) Services: Quarter 1, Week 5Document17 pagesBeauty Care (Nail Care) Services: Quarter 1, Week 5Are Pee Etc100% (1)

- BCG Large-Project ManagementDocument17 pagesBCG Large-Project ManagementReyLeonNo ratings yet

- 1 Service InformationDocument11 pages1 Service InformationSaad ElhemediNo ratings yet

- Buthaina AlmamariDocument3 pagesButhaina Almamaributhin7heartNo ratings yet

- The Pretenders WorkpackDocument30 pagesThe Pretenders WorkpackMaría José PucilloNo ratings yet

- Ma2016 Article OverviewOnVerticalAndDirectionDocument31 pagesMa2016 Article OverviewOnVerticalAndDirectionDarryan DhanpatNo ratings yet

- 02 Algorithm AnalysisDocument49 pages02 Algorithm AnalysisĐăng BùiNo ratings yet

- Kayla Malik Resume February 2017Document2 pagesKayla Malik Resume February 2017api-340785737No ratings yet

- API 650 FabricationDocument143 pagesAPI 650 Fabricationahmad_koros100% (1)

- Chapter 1Document42 pagesChapter 1Karen BalatucanNo ratings yet

- GP Maths Grade 10 June 2023 P2 and MemoDocument11 pagesGP Maths Grade 10 June 2023 P2 and Memoshaybusiness022No ratings yet

- Number Theory and Public Key Cryptography: SyllabusDocument26 pagesNumber Theory and Public Key Cryptography: SyllabusGeethanjali KotaruNo ratings yet

- Retail Management Final ExamDocument17 pagesRetail Management Final ExamAkhilesh JadhavNo ratings yet

- Dump Valves: DVU SeriesDocument2 pagesDump Valves: DVU SeriesalopezvillavicencioNo ratings yet

- Exercise PlanDocument4 pagesExercise Planj.kendall.reidNo ratings yet

- CC103 Engineering Surveying 1 Chapter 2Document15 pagesCC103 Engineering Surveying 1 Chapter 2Xendra AqeylaaNo ratings yet

- Simple Sentence and Subject Verb AgreementDocument4 pagesSimple Sentence and Subject Verb AgreementAre prety neldaNo ratings yet

- GR 19 (MND)Document6 pagesGR 19 (MND)arorayash603No ratings yet