Professional Documents

Culture Documents

Report of Inspection, Testing & Maintenance of Fire Pump Assemblies Continued

Report of Inspection, Testing & Maintenance of Fire Pump Assemblies Continued

Uploaded by

Mark Louie GuintoCopyright:

Available Formats

You might also like

- AFSA Inspection Form - Water Based PDFDocument4 pagesAFSA Inspection Form - Water Based PDFMYSTerB100% (3)

- Rectangular Tank Design ROARKS FORMULADocument40 pagesRectangular Tank Design ROARKS FORMULANavasOT100% (3)

- Piping and Instrumentation Diagram DevelopmentFrom EverandPiping and Instrumentation Diagram DevelopmentRating: 3.5 out of 5 stars3.5/5 (3)

- Porsche 912E Service InformationDocument47 pagesPorsche 912E Service InformationOscar Hamer100% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Maintenance RecordDocument6 pagesMaintenance RecordCarlos GonçalvesNo ratings yet

- Sprinkler PDFDocument4 pagesSprinkler PDFAntony JebarajNo ratings yet

- Asme A13.1Document14 pagesAsme A13.1Mark Louie Guinto100% (5)

- Report of Inspection, Testing & Maintenance: of Fire Pump AssembliesDocument6 pagesReport of Inspection, Testing & Maintenance: of Fire Pump AssembliesMatel Franklin AnastaNo ratings yet

- Inspection Form For Fire PumpDocument6 pagesInspection Form For Fire PumpRonny Aja100% (1)

- Report of Inspection, Testing & Maintenance of Fire Pump AssembliesDocument6 pagesReport of Inspection, Testing & Maintenance of Fire Pump Assembliessl1828100% (1)

- Report of Inspection, Testing & Maintenance: of Fire Pump AssembliesDocument1 pageReport of Inspection, Testing & Maintenance: of Fire Pump AssembliesMark Louie GuintoNo ratings yet

- 04 Prime Customized Performance EvaluationDocument50 pages04 Prime Customized Performance Evaluation1974yuzikcool.1030No ratings yet

- Report of Inspection, Testing & Maintenance of Fire Pump Assemblies ContinuedDocument1 pageReport of Inspection, Testing & Maintenance of Fire Pump Assemblies ContinuedMark Louie GuintoNo ratings yet

- Report of Inspection, Testing & Maintenance of Standpipe SystemsDocument8 pagesReport of Inspection, Testing & Maintenance of Standpipe SystemsCubzlookNo ratings yet

- 500MW Turbine O&M Manual Part#3 Of3Document88 pages500MW Turbine O&M Manual Part#3 Of3LakshminarayanNo ratings yet

- EF Series Air Conditioner: User ManualDocument16 pagesEF Series Air Conditioner: User ManualGonzalo VegaNo ratings yet

- Electromagnetic Flowmeter: Installation and Operating InstructionsDocument80 pagesElectromagnetic Flowmeter: Installation and Operating InstructionsavikbhaiNo ratings yet

- Complaince Statement - 02Document3 pagesComplaince Statement - 02Arun CDNo ratings yet

- Maintenance Preventive 104 ModuleDocument8 pagesMaintenance Preventive 104 ModulezinouNo ratings yet

- Service Manual Cobija Termica 6000 Medtronic # 8 (Capitulo Mantenimiento Ingles)Document60 pagesService Manual Cobija Termica 6000 Medtronic # 8 (Capitulo Mantenimiento Ingles)dhcastanoNo ratings yet

- T&CDocument13 pagesT&CAbdurRahmanFNo ratings yet

- TraneDocument22 pagesTraneMadanKarkiNo ratings yet

- Standard Commissioning Procedure For Evaporative Cooling SystemsDocument10 pagesStandard Commissioning Procedure For Evaporative Cooling Systemsbedilu77No ratings yet

- PF7000 A-FRAME and B-FRAME: Medium Voltage Drive Preventive Maintenance Check ListDocument5 pagesPF7000 A-FRAME and B-FRAME: Medium Voltage Drive Preventive Maintenance Check ListRaul quispe quispeNo ratings yet

- Exxon IP 7-3-1 Sootblowers For Fired EquipmentDocument3 pagesExxon IP 7-3-1 Sootblowers For Fired EquipmentGilvan SilvaNo ratings yet

- Instalacion y Mantenimiento de Ventiladores NovencoDocument8 pagesInstalacion y Mantenimiento de Ventiladores NovencoLuis Hernando ZorroNo ratings yet

- Technical Information and Diagnostic GuideDocument19 pagesTechnical Information and Diagnostic Guiden.decelisgNo ratings yet

- Fat Report For Fedegari SterilisersDocument4 pagesFat Report For Fedegari Sterilisersrahul_inj84100% (1)

- GeneralAire DS25LC Owners ManualDocument32 pagesGeneralAire DS25LC Owners ManualJigga mannNo ratings yet

- PM Report at Purefoods Hormel Powerplant 1Document2 pagesPM Report at Purefoods Hormel Powerplant 1Karlo X CorpuzNo ratings yet

- Booster Pump Agiba PDFDocument518 pagesBooster Pump Agiba PDFhamadaNo ratings yet

- ZTE Macro BTS IntroDocument15 pagesZTE Macro BTS IntroJohn EarleyNo ratings yet

- Netmarks 2016 Guide To Digital MarketingDocument10 pagesNetmarks 2016 Guide To Digital MarketingEjaz BashirNo ratings yet

- Sysmex CA-1500 - PMI - ProDocument2 pagesSysmex CA-1500 - PMI - ProBakhrom KasimovNo ratings yet

- Electrical Actuator For Air Damper Upgrade: 1 Delivery ScopeDocument5 pagesElectrical Actuator For Air Damper Upgrade: 1 Delivery ScopeАндрей КозловNo ratings yet

- DX Service and MaintDocument20 pagesDX Service and MaintCarlos MenaNo ratings yet

- Manual SCK 21 52 GBDocument28 pagesManual SCK 21 52 GBsebastian88% (8)

- Instrumentation For Fired Heaters IP 15-1-1: ScopeDocument14 pagesInstrumentation For Fired Heaters IP 15-1-1: ScopeLuis Alonso Aguirre LopezNo ratings yet

- Pump Installation and Commisioning Check ListDocument1 pagePump Installation and Commisioning Check Lista.albin.jrNo ratings yet

- Thermal Fluid HeatersDocument166 pagesThermal Fluid Heatersbornluky100% (1)

- Grundfos CHI PumpDocument8 pagesGrundfos CHI PumpHamdi Al-sarooryNo ratings yet

- HPN0211PA04BDocument13 pagesHPN0211PA04BkentNo ratings yet

- Preventative Maintenance Agreement: Extending Equipment LifeDocument8 pagesPreventative Maintenance Agreement: Extending Equipment LifeJo Ziza SugihartoNo ratings yet

- 160 88-CL1Document4 pages160 88-CL1vanthe140591No ratings yet

- IrrigationDocument7 pagesIrrigationAhmed HussienNo ratings yet

- PRD Doc Epr 7106-00001 Sen Ain V3Document5 pagesPRD Doc Epr 7106-00001 Sen Ain V3gabrieldarochaaNo ratings yet

- Equipment Details: Periodic Preventive MaintenanceDocument2 pagesEquipment Details: Periodic Preventive MaintenanceanfalapNo ratings yet

- IOC/M&I/ELECT/E/18/2012 Electrical Motor Operated Valve Actuator & Master Station Rev.-0 Page 21 of 27Document6 pagesIOC/M&I/ELECT/E/18/2012 Electrical Motor Operated Valve Actuator & Master Station Rev.-0 Page 21 of 27Anonymous fLgaidVBhzNo ratings yet

- 09 Attachment 3 - ECM Functional Test Instructions, P. 15: VAV TerminalsDocument4 pages09 Attachment 3 - ECM Functional Test Instructions, P. 15: VAV Terminalsiman2222No ratings yet

- Engineering and Maintenance DeptDocument2 pagesEngineering and Maintenance Deptjherson gravidesNo ratings yet

- 557113822Document7 pages557113822Billy BrownNo ratings yet

- G 2711 NDocument23 pagesG 2711 NValerică HizanuNo ratings yet

- Maintenance Procedures: Mfr. Description Date Issued: Revision DateDocument8 pagesMaintenance Procedures: Mfr. Description Date Issued: Revision DateCarolina Diaz MurillasNo ratings yet

- Standard Commissioning Procedure For Exhaust Air Heat Recovery SystemsDocument14 pagesStandard Commissioning Procedure For Exhaust Air Heat Recovery SystemsAbdul Mohid SheikhNo ratings yet

- AGGREKO MANUAL Temperature Control EquipmentsDocument19 pagesAGGREKO MANUAL Temperature Control EquipmentsgabyNo ratings yet

- 23 82 19 - Fan Coil UnitsDocument4 pages23 82 19 - Fan Coil UnitsLoraine AnnNo ratings yet

- Lube Oil Duplex Filter: Adnhfx (HP) Series 1 0 / 2 0 1 2 E D I T I O NDocument7 pagesLube Oil Duplex Filter: Adnhfx (HP) Series 1 0 / 2 0 1 2 E D I T I O NMohammed ElarbedNo ratings yet

- Compress Air Commissioning ProcedureDocument6 pagesCompress Air Commissioning Procedurevishwas salunkheNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Process System Value and Exergoeconomic Performance of Captive Power PlantsFrom EverandProcess System Value and Exergoeconomic Performance of Captive Power PlantsNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 26 WeldDocument1 page26 WeldMark Louie GuintoNo ratings yet

- 7 - Asme A13.1Document1 page7 - Asme A13.1Mark Louie GuintoNo ratings yet

- Seam Welds: Figure 10-32Document1 pageSeam Welds: Figure 10-32Mark Louie GuintoNo ratings yet

- 15 WeldDocument1 page15 WeldMark Louie GuintoNo ratings yet

- 13 WeldDocument1 page13 WeldMark Louie GuintoNo ratings yet

- Unequal Leg Fillet Welds: Largest Right Triangle That Can Be Formed Within The WeldDocument1 pageUnequal Leg Fillet Welds: Largest Right Triangle That Can Be Formed Within The WeldMark Louie GuintoNo ratings yet

- Fire Sprinkler System Design and Installation RequirementsDocument16 pagesFire Sprinkler System Design and Installation RequirementsMark Louie GuintoNo ratings yet

- Intermittent Welds: Figure 10-7Document1 pageIntermittent Welds: Figure 10-7Mark Louie GuintoNo ratings yet

- COP2013Document124 pagesCOP2013Mark Louie GuintoNo ratings yet

- Boiler Room Air SupplyDocument3 pagesBoiler Room Air SupplyMark Louie GuintoNo ratings yet

- 2021 Book UncertaintyInMechanicalEngineeDocument313 pages2021 Book UncertaintyInMechanicalEngineeMark Louie Guinto100% (2)

- 2021 Book MasteringUncertaintyInMechanicDocument483 pages2021 Book MasteringUncertaintyInMechanicMark Louie Guinto100% (2)

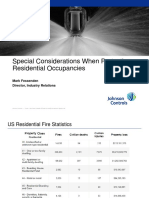

- Special Considerations When Protecting Residential OccupanciesDocument53 pagesSpecial Considerations When Protecting Residential OccupanciesMark Louie GuintoNo ratings yet

- Egress and Fire ProtectionDocument30 pagesEgress and Fire ProtectionMark Louie GuintoNo ratings yet

- Property Risk Consulting Guidelines: Sprinkler System HydraulicsDocument17 pagesProperty Risk Consulting Guidelines: Sprinkler System HydraulicsMark Louie GuintoNo ratings yet

- Cesar PmeDocument20 pagesCesar PmeFrancis Michael JacintoNo ratings yet

- BFP Fire Safety SeminarDocument60 pagesBFP Fire Safety SeminarMark Louie GuintoNo ratings yet

- V-Wheels (25203-02)Document33 pagesV-Wheels (25203-02)nicopoehlmannNo ratings yet

- Ericsson's GSM System Model: SS Switching System AUC HLR MXE MINDocument9 pagesEricsson's GSM System Model: SS Switching System AUC HLR MXE MINtelcoNo ratings yet

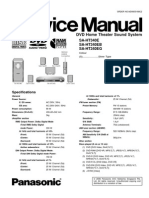

- Panasonic Sa Ht340Document95 pagesPanasonic Sa Ht340madme2567% (3)

- Xii - CHEM AKASH - Project - 2023 - 24Document3 pagesXii - CHEM AKASH - Project - 2023 - 24Priyaranjan PattanayakNo ratings yet

- The Effects of Corporate Brand Attributes On Attitudinal and Behavioural Consumer LoyaltyDocument12 pagesThe Effects of Corporate Brand Attributes On Attitudinal and Behavioural Consumer LoyaltyjoannakamNo ratings yet

- 100 Practical Exercises in Music Composition 0190057246 9780190057244 Compress 3Document45 pages100 Practical Exercises in Music Composition 0190057246 9780190057244 Compress 3Lê Thanh XuânNo ratings yet

- Type CO Circuit Opening Overcurrent Relay - Autores Varios - Editorial ABB - 1984Document24 pagesType CO Circuit Opening Overcurrent Relay - Autores Varios - Editorial ABB - 1984Manuel OrtegaNo ratings yet

- JEE Study MaterialDocument1 pageJEE Study MaterialKabilan SekarNo ratings yet

- Ecse-2610 Computer Components & Operations (Coco) : Scope & Course MechanicsDocument15 pagesEcse-2610 Computer Components & Operations (Coco) : Scope & Course Mechanicsdale carmackNo ratings yet

- AlpsDocument4 pagesAlpsciohaniNo ratings yet

- Mar1020 Datasheet PDFDocument3 pagesMar1020 Datasheet PDFjaysonlkhNo ratings yet

- RT Flex Presentation Eng PDFDocument11 pagesRT Flex Presentation Eng PDFHanish SainiNo ratings yet

- Experiment 4Document28 pagesExperiment 4nellyNo ratings yet

- Assigment Sheet Tast 2 Aina MardianaDocument10 pagesAssigment Sheet Tast 2 Aina MardianaAina MardianaNo ratings yet

- TWMC Price BookDocument221 pagesTWMC Price BookleelsNo ratings yet

- Flat Glass Inspection Criteria Per ASTM C 1036 - 06 (Abridged)Document4 pagesFlat Glass Inspection Criteria Per ASTM C 1036 - 06 (Abridged)batteekhNo ratings yet

- Rinnai Malaysia RO E6208TA EM User ManualDocument16 pagesRinnai Malaysia RO E6208TA EM User ManualthaiNo ratings yet

- Password Based Circuit Breaker Control To Ensure Electric Line Mans Safety and Load Sharing IJERTCONV5IS13135Document4 pagesPassword Based Circuit Breaker Control To Ensure Electric Line Mans Safety and Load Sharing IJERTCONV5IS13135Pratiksha SankapalNo ratings yet

- BJT Differential AmplifierDocument4 pagesBJT Differential Amplifierdominggo100% (4)

- 1.5 Inverse Functions & LogarithmsDocument11 pages1.5 Inverse Functions & Logarithms郭大維No ratings yet

- Mitigating Congestion in Wireless Sensor NetworksDocument14 pagesMitigating Congestion in Wireless Sensor NetworksIglesia RestauracionNo ratings yet

- Protective Transformers: by N.H, Shton, Revised by E.J.MellorDocument31 pagesProtective Transformers: by N.H, Shton, Revised by E.J.MellorJavier MaldonadoNo ratings yet

- Intro:: SCI 403 J. Marinay Physics IDocument11 pagesIntro:: SCI 403 J. Marinay Physics IKRISTELLE GEM CABANIGNo ratings yet

- Emcee Script For Math Camp 2023Document3 pagesEmcee Script For Math Camp 2023Analyn Canoy Suazo100% (1)

- Boyles Law EditedDocument10 pagesBoyles Law EditedRico FernandezNo ratings yet

- Inteligen4 200 2.1.2 New Features ListDocument10 pagesInteligen4 200 2.1.2 New Features ListGilder GonzalezNo ratings yet

- How To Perform ShortDocument3 pagesHow To Perform Shortbanga_gsNo ratings yet

- Iso 2896 - 2001 eDocument16 pagesIso 2896 - 2001 ehappyhandslearningcenter2023No ratings yet

Report of Inspection, Testing & Maintenance of Fire Pump Assemblies Continued

Report of Inspection, Testing & Maintenance of Fire Pump Assemblies Continued

Uploaded by

Mark Louie GuintoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Report of Inspection, Testing & Maintenance of Fire Pump Assemblies Continued

Report of Inspection, Testing & Maintenance of Fire Pump Assemblies Continued

Uploaded by

Mark Louie GuintoCopyright:

Available Formats

REV.

3/03

Report of Inspection, Testing & Maintenance of Fire Pump Assemblies…continued

Inspecting Firm: Inspection Contract#

Name of Inspected Property:

Inspector Name: Date:

Inspection Frequency: Monthly Quarterly Annually Other

*Items necessary only in the absence of manufacturer’s recommendations

Semi-Annual Inspection, Testing and Maintenance for Fire Pump Assemblies

Y N/A N Y N/A N

D.1.0 System in service before conducting tasks D.4.1 *Manual starting means of electrically driven

pumps operated

D.1.1 Pertinent parties notified before conducting tasks

D.4.2 *Antifreeze protection level tested and

D.2.0 Control valve supervisory switches initiate adjusted as necessary

distinct signal during first two hand wheel

revolutions or before valve stem moved D.4.3 *Electrical system safeties and alarms operated

one-fifth from normal position D.4.4 *Electrical system boxes, panels, and cabinets

D.2.1 Signal restored only when valve returned to cleaned

normal position D.5.0 Fire pump assembly maintenance performed

D.3.0 Adequate drainage provided before flow testing in accordance with mfg. recommendations

D.3.1 Main drain test conducted D.6.0 Pertinent parties notified of task conclusion

D.3.2 Supply water gauge reading before flow (static) psi D.7.0 ALARM PANEL CLEAR

D.8.0 SYSTEM RETURNED TO SERVICE

D.3.3 Gauge reading during stable flow (residual) psi

D.9.0 COMMENTS:

D.3.4 Time for supply pressure to return to normal sec

D.4.0 *Flexible exhaust section inspected and in

good condition

Annual Inspection for Fire Pump Assemblies Annual Maintenance for Fire Pump Assemblies

E.1.0 System in service on inspection F.1.0 System in service before conducting maintenance

E.2.0 Hangers and seismic bracing appear F.2.0 Pertinent parties notified before conducting

undamaged and tightly attached maintenance

E.3.0 Piping appears free of mechanical damage F.3.0 Operating stems of OS&Y (including backflow)

valves lubricated

E.3.1 Piping appears free of leakage

F.3.1 Valve completely closed and reopened

E.3.2 Piping appears free of corrosion

F.4.0 Adequate drainage provided before flow testing

E.3.3 Piping appears properly aligned

F.4.1 Main drain test conducted

E.3.4 Piping appears free of external loading

E.4.0 Building is secure such as not to expose F.4.2 Supply water gauge reading before flow (static) psi

piping to freezing conditions (prior to F.4.3 Gauge reading during stable flow (residual) psi

freezing weather)

F.4.4 Time for supply pressure to return to normal sec

E.4.1 Adequate heat is provided maintaining

temperatures at 40°F or higher F.5.0 Fire pump assembly maintenance performed in

(prior to freezing weather) accordance with mfg. recommendations

E.5.0 *Pump shaft end play within specified tolerances F.5.1 *Pump bearing lubricated

E.5.1 *Pressure gauge and sensor accuracy verified F.5.2 *Gauges recalibrated or changed (when 5% or

to be within 5% more out of calibration)

E.5.2 *Pump coupling alignment within specified F.5.3 *Wet pit suction screens checked (cleaned as

tolerances necessary) after every operation

E.5.3 *Electrical connections tightened as necessary F.5.4 *Mechanical transmission coupling lubricated

E.5.4 *Mechanical moving parts lubrication verified F.5.5 *Mechanical transmission right-angle

(excluding starters and relays) gear drive lubricated

E.5.5 *Pressure switch setting calibration verified F.5.6 *Electric drive motor bearings lubricated

E.5.6 *Fuel tank vents and overflow piping free F.5.7 *Fuel tank voided of water and foreign material

from obstructions F.5.8 *Diesel engine lubrication system oil and filter

E.5.7 *Fuel piping in good condition changed (or 50 hrs whichever comes first)

E.5.8 *Combustion air ductwork and louvers in F.5.9 *Diesel engine cooling system antifreeze changed

good condition F.5.10 *Diesel engine cooling system heat

E.5.9 *Exhaust system hangers and supports in exchanger rodded out

place and in good condition F.5.11 *Electrical system circuit breakers or fuses

E.5.10 *Electrical control and power wiring changed (every 2 years)

connections checked for tightness F.6.0 Pertinent parties notified after conclusion of

E.6.0 Fire pump assembly maintenance performed maintenance

in accordance with mfg. recommendations F.7.0 ALARM PANEL CLEAR

E.7.0 ALARM PANEL CLEAR F.8.0 SYSTEM RETURNED TO SERVICE

E.8.0 COMMENTS: F.9.0 COMMENTS:

(All “NO” answers to be explained.) (AFSA Form 110A)

INSPECTOR’S INITIAL ________ OWNER/DESIGNATED REP. INITIAL ________ DATE _______________ Page 2 of 6

You might also like

- AFSA Inspection Form - Water Based PDFDocument4 pagesAFSA Inspection Form - Water Based PDFMYSTerB100% (3)

- Rectangular Tank Design ROARKS FORMULADocument40 pagesRectangular Tank Design ROARKS FORMULANavasOT100% (3)

- Piping and Instrumentation Diagram DevelopmentFrom EverandPiping and Instrumentation Diagram DevelopmentRating: 3.5 out of 5 stars3.5/5 (3)

- Porsche 912E Service InformationDocument47 pagesPorsche 912E Service InformationOscar Hamer100% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Maintenance RecordDocument6 pagesMaintenance RecordCarlos GonçalvesNo ratings yet

- Sprinkler PDFDocument4 pagesSprinkler PDFAntony JebarajNo ratings yet

- Asme A13.1Document14 pagesAsme A13.1Mark Louie Guinto100% (5)

- Report of Inspection, Testing & Maintenance: of Fire Pump AssembliesDocument6 pagesReport of Inspection, Testing & Maintenance: of Fire Pump AssembliesMatel Franklin AnastaNo ratings yet

- Inspection Form For Fire PumpDocument6 pagesInspection Form For Fire PumpRonny Aja100% (1)

- Report of Inspection, Testing & Maintenance of Fire Pump AssembliesDocument6 pagesReport of Inspection, Testing & Maintenance of Fire Pump Assembliessl1828100% (1)

- Report of Inspection, Testing & Maintenance: of Fire Pump AssembliesDocument1 pageReport of Inspection, Testing & Maintenance: of Fire Pump AssembliesMark Louie GuintoNo ratings yet

- 04 Prime Customized Performance EvaluationDocument50 pages04 Prime Customized Performance Evaluation1974yuzikcool.1030No ratings yet

- Report of Inspection, Testing & Maintenance of Fire Pump Assemblies ContinuedDocument1 pageReport of Inspection, Testing & Maintenance of Fire Pump Assemblies ContinuedMark Louie GuintoNo ratings yet

- Report of Inspection, Testing & Maintenance of Standpipe SystemsDocument8 pagesReport of Inspection, Testing & Maintenance of Standpipe SystemsCubzlookNo ratings yet

- 500MW Turbine O&M Manual Part#3 Of3Document88 pages500MW Turbine O&M Manual Part#3 Of3LakshminarayanNo ratings yet

- EF Series Air Conditioner: User ManualDocument16 pagesEF Series Air Conditioner: User ManualGonzalo VegaNo ratings yet

- Electromagnetic Flowmeter: Installation and Operating InstructionsDocument80 pagesElectromagnetic Flowmeter: Installation and Operating InstructionsavikbhaiNo ratings yet

- Complaince Statement - 02Document3 pagesComplaince Statement - 02Arun CDNo ratings yet

- Maintenance Preventive 104 ModuleDocument8 pagesMaintenance Preventive 104 ModulezinouNo ratings yet

- Service Manual Cobija Termica 6000 Medtronic # 8 (Capitulo Mantenimiento Ingles)Document60 pagesService Manual Cobija Termica 6000 Medtronic # 8 (Capitulo Mantenimiento Ingles)dhcastanoNo ratings yet

- T&CDocument13 pagesT&CAbdurRahmanFNo ratings yet

- TraneDocument22 pagesTraneMadanKarkiNo ratings yet

- Standard Commissioning Procedure For Evaporative Cooling SystemsDocument10 pagesStandard Commissioning Procedure For Evaporative Cooling Systemsbedilu77No ratings yet

- PF7000 A-FRAME and B-FRAME: Medium Voltage Drive Preventive Maintenance Check ListDocument5 pagesPF7000 A-FRAME and B-FRAME: Medium Voltage Drive Preventive Maintenance Check ListRaul quispe quispeNo ratings yet

- Exxon IP 7-3-1 Sootblowers For Fired EquipmentDocument3 pagesExxon IP 7-3-1 Sootblowers For Fired EquipmentGilvan SilvaNo ratings yet

- Instalacion y Mantenimiento de Ventiladores NovencoDocument8 pagesInstalacion y Mantenimiento de Ventiladores NovencoLuis Hernando ZorroNo ratings yet

- Technical Information and Diagnostic GuideDocument19 pagesTechnical Information and Diagnostic Guiden.decelisgNo ratings yet

- Fat Report For Fedegari SterilisersDocument4 pagesFat Report For Fedegari Sterilisersrahul_inj84100% (1)

- GeneralAire DS25LC Owners ManualDocument32 pagesGeneralAire DS25LC Owners ManualJigga mannNo ratings yet

- PM Report at Purefoods Hormel Powerplant 1Document2 pagesPM Report at Purefoods Hormel Powerplant 1Karlo X CorpuzNo ratings yet

- Booster Pump Agiba PDFDocument518 pagesBooster Pump Agiba PDFhamadaNo ratings yet

- ZTE Macro BTS IntroDocument15 pagesZTE Macro BTS IntroJohn EarleyNo ratings yet

- Netmarks 2016 Guide To Digital MarketingDocument10 pagesNetmarks 2016 Guide To Digital MarketingEjaz BashirNo ratings yet

- Sysmex CA-1500 - PMI - ProDocument2 pagesSysmex CA-1500 - PMI - ProBakhrom KasimovNo ratings yet

- Electrical Actuator For Air Damper Upgrade: 1 Delivery ScopeDocument5 pagesElectrical Actuator For Air Damper Upgrade: 1 Delivery ScopeАндрей КозловNo ratings yet

- DX Service and MaintDocument20 pagesDX Service and MaintCarlos MenaNo ratings yet

- Manual SCK 21 52 GBDocument28 pagesManual SCK 21 52 GBsebastian88% (8)

- Instrumentation For Fired Heaters IP 15-1-1: ScopeDocument14 pagesInstrumentation For Fired Heaters IP 15-1-1: ScopeLuis Alonso Aguirre LopezNo ratings yet

- Pump Installation and Commisioning Check ListDocument1 pagePump Installation and Commisioning Check Lista.albin.jrNo ratings yet

- Thermal Fluid HeatersDocument166 pagesThermal Fluid Heatersbornluky100% (1)

- Grundfos CHI PumpDocument8 pagesGrundfos CHI PumpHamdi Al-sarooryNo ratings yet

- HPN0211PA04BDocument13 pagesHPN0211PA04BkentNo ratings yet

- Preventative Maintenance Agreement: Extending Equipment LifeDocument8 pagesPreventative Maintenance Agreement: Extending Equipment LifeJo Ziza SugihartoNo ratings yet

- 160 88-CL1Document4 pages160 88-CL1vanthe140591No ratings yet

- IrrigationDocument7 pagesIrrigationAhmed HussienNo ratings yet

- PRD Doc Epr 7106-00001 Sen Ain V3Document5 pagesPRD Doc Epr 7106-00001 Sen Ain V3gabrieldarochaaNo ratings yet

- Equipment Details: Periodic Preventive MaintenanceDocument2 pagesEquipment Details: Periodic Preventive MaintenanceanfalapNo ratings yet

- IOC/M&I/ELECT/E/18/2012 Electrical Motor Operated Valve Actuator & Master Station Rev.-0 Page 21 of 27Document6 pagesIOC/M&I/ELECT/E/18/2012 Electrical Motor Operated Valve Actuator & Master Station Rev.-0 Page 21 of 27Anonymous fLgaidVBhzNo ratings yet

- 09 Attachment 3 - ECM Functional Test Instructions, P. 15: VAV TerminalsDocument4 pages09 Attachment 3 - ECM Functional Test Instructions, P. 15: VAV Terminalsiman2222No ratings yet

- Engineering and Maintenance DeptDocument2 pagesEngineering and Maintenance Deptjherson gravidesNo ratings yet

- 557113822Document7 pages557113822Billy BrownNo ratings yet

- G 2711 NDocument23 pagesG 2711 NValerică HizanuNo ratings yet

- Maintenance Procedures: Mfr. Description Date Issued: Revision DateDocument8 pagesMaintenance Procedures: Mfr. Description Date Issued: Revision DateCarolina Diaz MurillasNo ratings yet

- Standard Commissioning Procedure For Exhaust Air Heat Recovery SystemsDocument14 pagesStandard Commissioning Procedure For Exhaust Air Heat Recovery SystemsAbdul Mohid SheikhNo ratings yet

- AGGREKO MANUAL Temperature Control EquipmentsDocument19 pagesAGGREKO MANUAL Temperature Control EquipmentsgabyNo ratings yet

- 23 82 19 - Fan Coil UnitsDocument4 pages23 82 19 - Fan Coil UnitsLoraine AnnNo ratings yet

- Lube Oil Duplex Filter: Adnhfx (HP) Series 1 0 / 2 0 1 2 E D I T I O NDocument7 pagesLube Oil Duplex Filter: Adnhfx (HP) Series 1 0 / 2 0 1 2 E D I T I O NMohammed ElarbedNo ratings yet

- Compress Air Commissioning ProcedureDocument6 pagesCompress Air Commissioning Procedurevishwas salunkheNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Process System Value and Exergoeconomic Performance of Captive Power PlantsFrom EverandProcess System Value and Exergoeconomic Performance of Captive Power PlantsNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 26 WeldDocument1 page26 WeldMark Louie GuintoNo ratings yet

- 7 - Asme A13.1Document1 page7 - Asme A13.1Mark Louie GuintoNo ratings yet

- Seam Welds: Figure 10-32Document1 pageSeam Welds: Figure 10-32Mark Louie GuintoNo ratings yet

- 15 WeldDocument1 page15 WeldMark Louie GuintoNo ratings yet

- 13 WeldDocument1 page13 WeldMark Louie GuintoNo ratings yet

- Unequal Leg Fillet Welds: Largest Right Triangle That Can Be Formed Within The WeldDocument1 pageUnequal Leg Fillet Welds: Largest Right Triangle That Can Be Formed Within The WeldMark Louie GuintoNo ratings yet

- Fire Sprinkler System Design and Installation RequirementsDocument16 pagesFire Sprinkler System Design and Installation RequirementsMark Louie GuintoNo ratings yet

- Intermittent Welds: Figure 10-7Document1 pageIntermittent Welds: Figure 10-7Mark Louie GuintoNo ratings yet

- COP2013Document124 pagesCOP2013Mark Louie GuintoNo ratings yet

- Boiler Room Air SupplyDocument3 pagesBoiler Room Air SupplyMark Louie GuintoNo ratings yet

- 2021 Book UncertaintyInMechanicalEngineeDocument313 pages2021 Book UncertaintyInMechanicalEngineeMark Louie Guinto100% (2)

- 2021 Book MasteringUncertaintyInMechanicDocument483 pages2021 Book MasteringUncertaintyInMechanicMark Louie Guinto100% (2)

- Special Considerations When Protecting Residential OccupanciesDocument53 pagesSpecial Considerations When Protecting Residential OccupanciesMark Louie GuintoNo ratings yet

- Egress and Fire ProtectionDocument30 pagesEgress and Fire ProtectionMark Louie GuintoNo ratings yet

- Property Risk Consulting Guidelines: Sprinkler System HydraulicsDocument17 pagesProperty Risk Consulting Guidelines: Sprinkler System HydraulicsMark Louie GuintoNo ratings yet

- Cesar PmeDocument20 pagesCesar PmeFrancis Michael JacintoNo ratings yet

- BFP Fire Safety SeminarDocument60 pagesBFP Fire Safety SeminarMark Louie GuintoNo ratings yet

- V-Wheels (25203-02)Document33 pagesV-Wheels (25203-02)nicopoehlmannNo ratings yet

- Ericsson's GSM System Model: SS Switching System AUC HLR MXE MINDocument9 pagesEricsson's GSM System Model: SS Switching System AUC HLR MXE MINtelcoNo ratings yet

- Panasonic Sa Ht340Document95 pagesPanasonic Sa Ht340madme2567% (3)

- Xii - CHEM AKASH - Project - 2023 - 24Document3 pagesXii - CHEM AKASH - Project - 2023 - 24Priyaranjan PattanayakNo ratings yet

- The Effects of Corporate Brand Attributes On Attitudinal and Behavioural Consumer LoyaltyDocument12 pagesThe Effects of Corporate Brand Attributes On Attitudinal and Behavioural Consumer LoyaltyjoannakamNo ratings yet

- 100 Practical Exercises in Music Composition 0190057246 9780190057244 Compress 3Document45 pages100 Practical Exercises in Music Composition 0190057246 9780190057244 Compress 3Lê Thanh XuânNo ratings yet

- Type CO Circuit Opening Overcurrent Relay - Autores Varios - Editorial ABB - 1984Document24 pagesType CO Circuit Opening Overcurrent Relay - Autores Varios - Editorial ABB - 1984Manuel OrtegaNo ratings yet

- JEE Study MaterialDocument1 pageJEE Study MaterialKabilan SekarNo ratings yet

- Ecse-2610 Computer Components & Operations (Coco) : Scope & Course MechanicsDocument15 pagesEcse-2610 Computer Components & Operations (Coco) : Scope & Course Mechanicsdale carmackNo ratings yet

- AlpsDocument4 pagesAlpsciohaniNo ratings yet

- Mar1020 Datasheet PDFDocument3 pagesMar1020 Datasheet PDFjaysonlkhNo ratings yet

- RT Flex Presentation Eng PDFDocument11 pagesRT Flex Presentation Eng PDFHanish SainiNo ratings yet

- Experiment 4Document28 pagesExperiment 4nellyNo ratings yet

- Assigment Sheet Tast 2 Aina MardianaDocument10 pagesAssigment Sheet Tast 2 Aina MardianaAina MardianaNo ratings yet

- TWMC Price BookDocument221 pagesTWMC Price BookleelsNo ratings yet

- Flat Glass Inspection Criteria Per ASTM C 1036 - 06 (Abridged)Document4 pagesFlat Glass Inspection Criteria Per ASTM C 1036 - 06 (Abridged)batteekhNo ratings yet

- Rinnai Malaysia RO E6208TA EM User ManualDocument16 pagesRinnai Malaysia RO E6208TA EM User ManualthaiNo ratings yet

- Password Based Circuit Breaker Control To Ensure Electric Line Mans Safety and Load Sharing IJERTCONV5IS13135Document4 pagesPassword Based Circuit Breaker Control To Ensure Electric Line Mans Safety and Load Sharing IJERTCONV5IS13135Pratiksha SankapalNo ratings yet

- BJT Differential AmplifierDocument4 pagesBJT Differential Amplifierdominggo100% (4)

- 1.5 Inverse Functions & LogarithmsDocument11 pages1.5 Inverse Functions & Logarithms郭大維No ratings yet

- Mitigating Congestion in Wireless Sensor NetworksDocument14 pagesMitigating Congestion in Wireless Sensor NetworksIglesia RestauracionNo ratings yet

- Protective Transformers: by N.H, Shton, Revised by E.J.MellorDocument31 pagesProtective Transformers: by N.H, Shton, Revised by E.J.MellorJavier MaldonadoNo ratings yet

- Intro:: SCI 403 J. Marinay Physics IDocument11 pagesIntro:: SCI 403 J. Marinay Physics IKRISTELLE GEM CABANIGNo ratings yet

- Emcee Script For Math Camp 2023Document3 pagesEmcee Script For Math Camp 2023Analyn Canoy Suazo100% (1)

- Boyles Law EditedDocument10 pagesBoyles Law EditedRico FernandezNo ratings yet

- Inteligen4 200 2.1.2 New Features ListDocument10 pagesInteligen4 200 2.1.2 New Features ListGilder GonzalezNo ratings yet

- How To Perform ShortDocument3 pagesHow To Perform Shortbanga_gsNo ratings yet

- Iso 2896 - 2001 eDocument16 pagesIso 2896 - 2001 ehappyhandslearningcenter2023No ratings yet