Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 29-Dec-16 Mech

Saudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 29-Dec-16 Mech

Uploaded by

Abdul HafeezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 29-Dec-16 Mech

Saudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 29-Dec-16 Mech

Uploaded by

Abdul HafeezCopyright:

Available Formats

SAUDI ARAMCO ID/PID - 29-Dec-2016 - REV. 2016.08.00 (Standards Cutoff - August 31, 2016) Rev. 2016.08.

00 31-Aug-16

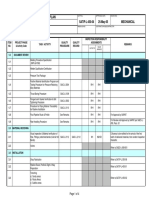

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 29-Dec-16 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A. General Requirements

All relative documents are available i.e Drawing, manufacturer SAES-G-005

A1

recommended tolerances,etc.API 686, Ch 7, Para 5.5

Tapered dowels with threaded outer ends shall be used for doweling

equipment. Threads are to be used for removing dowels. Note: Dowels SAES-G-005

A2

are furnished by the Vendor, and are installed in the field at the time of Para 5.5

final alignment.API 686, Ch 7,

The user or the designated machinery representative and the equipment

installer shall mutually agree on the appropriate type of alignment to be SAES-G-005

A3

used for rotating equipment trains.API 686, Ch 7, Para 5.5

Para. 4.1

Unless otherwise specified by the user, the equipment installer shall use

SAES-G-005

A4 laser alignment methods to align equipment trains. API 686, Ch 7, Para.

Para 5.5

4.2.1

Reverse or Rim / Face Alignment is performed while turning both shafts at

SAES-G-005

A5 the same time in the direction of rotation.API 686, Ch 7, Para. 4.2.1.2 See

Para 5.5

Note 2

Electrical power and instrumentation connections to machinery are

SAES-G-005

A6 confirmed not interfering with machinery alignment. API 686, Ch 6,

Para 5.5

Para. 4.1.4

Soft foot check is done with piping disconnected on each equipment foot.

SAES-G-005

A7 Note: Maximum permissible movement is 0.05 millimeter (2 mils) at each

Para 5.5

foot, API 686, Ch 7,Para. 5.4.4.1

Fixed and movable equipments are defined and are free to turn. API 686, SAES-G-005

A8

Ch 6, Para. 4.11.1, Ch 7, Par 5.4.4.1 Para 5.5

Data of alignment are recorded in SATR-G-2004 or approved equivalent SAES-G-005

A9

alignment form. API 610 Ch 7 Para 5.3.1 Para 5.5

For all pumps, 3 mm (1/8 in) thick stainless steel shim packs are

SAES-G-005

A10 furnished. Shim packs are not thicker than 12 mm (0,5 in) nor contain

Para 5.5

more than 5 shims. API-686. Para 5.4.2.2

Alignment is within the Manufacturer's tolerances Before Piping and

conduit are attached. Pipe strain checks are per the manufacturer's SAES-G-005

A11

procedures. Alignment is within the Manufacturer's tolerances after pipe & Para 5.5

conduit attached.API 686, Ch 7, Para. 5.4.5

The total stack thickness and number of shims shall be recorded on the

alignment datasheet. Measurement shall be recorded to the nearest 0.02

SAES-G-005

A12 mm (1 mil). For relatively large shims, the measurement will be in two or

Para 5.5

more locations to confirm the flatness requirement API 686, Ch 7, Para.

5.4.2.3

Holddown bolts are bolt bound, after final alignment the

SAES-G-005

A12 hold-down bolt hole are reasonably centered based on visual examination.

Para 5.5

(API 610.Para 5.4.3.4)

Saudi Aramco: Company General Use

Reverse rim (dial) indicator methods or laser alignment equipment, the

SAES-G-005

A13 maximum out of tolerance is 0.5 mm per meter (0.5 mils per in.) at both

Para 5.5

flex plane locations.. (API 686.Para 5.4.6.2)

Rim and face alignment with both close coupled machines or

elastomeric couplings, the angularity shall not be greater than 0.03 SAES-G-005

A14

degrees and the offset at the center of the coupling shall not exceed 0.02 Para 5.6

mm (1 mil). (API 686.Para 5.4.6.5)

During alignment and pipe strain checks, the bearing bracket support foot

(if existing) on single stage overhung pumps shall be loosened. The

maximum amount of movement at the coupling during the tightening

process shall be 0.05 mm (2 mils). Once this alignment is completed, for SAES-G-005

A15

final acceptance, the bearing bracket support shall be shimmed and Para 5.7

tightened. The maximum amount of movement at the coupling during the

tightening of the bearing bracket support foot shall be 0.05 mm (2 mils)..

(API 686.Para 5.4.7)

Unless other wise specified, the final tightning of the hold down bolts is the

SAES-G-005

A15 Torque tightning and the values are recorded. API 686, Ch 7, Para.

Para 5.5

5.4.3.5

Final Alignment was performed AFTER Hydrotest of piping and

completion & acceptance of piping supports. NO COLD SPRING!

See Note 1 & Attachments 1 & 2.

Complete Checklists. Note: After final piping bolt- SAES-G-005

A16

up, final shaft alignment are verified and all machinery is hand rotated to Para 5.5

ensure that neither binding nor case distortion has occurred during piping

installation. Piping spring hanger & spring support stops are installed

during final shaft alignment checks.API 686, Ch 7, Para. 5.4.8, 9

REMARKS:

NOTES: 1-Complete the associated checklists of API 686 Chapter 7 & Chapter 6 & attach to this checklist. 2- Rim and face alignment is

recommended when the coupling hub or shaft end flange diameteirs greater than the spacing between indicators or one of the train elements cannot be

turn. API 686-Ch7 Sec 4- 4.2.2. Laser alignment shall be used when specified by the user or the designated machinery representative. 4.3.1 Note: 2

CAUTION—Some equipment may be damaged by rotating it in the opposite direction of normal rotation. Turning of the equipment without lubrication on

the sliding surfaces can cause damage. 5.4.3.1 Undercutting of hold-down bolts for alignment is not permitted.

ATTACHMENTS: ATTACHMENT 1 - API RP 686 FINAL ALIGNMENT CHAPTER 7

ATTACHMENT 2 - API RP 686 FINAL ALIGNMENT, Check list & (PIPING CONCERNS) CHAPTER 6, 7

REFERENCE DOCUMENTS:

1. 31-SAMSS-004, Centrifugal Pumps, (30 April 2012)

2. SAES-G-005 Centrifugal Pumps, (28 July 2009)

3. API 686, Recommended Practice for Machinery Installation and Installation Design, (SECOND EDITION, DECEMBER 2009)

4. API 610, Centrifugal Pumps for Petroleum,Petrochemical and Natural Gas Industries, 10th Edition, October 2004

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 29-Dec-2016 - REV. 2016.08.00 (Standards Cutoff - August 31, 2016) Rev. 2016.08.00 31-Aug-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 29-Dec-16 MECH-

ATTACHMENT 1 - API RP 686 FINAL ALIGNMENT CHAPTER 7

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 29-Dec-2016 - REV. 2016.08.00 (Standards Cutoff - August 31, 2016) Rev. 2016.08.00 31-Aug-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 29-Dec-16 MECH-

ATTACHMENT 1 - API RP 686 FINAL ALIGNMENT (PIPING CONCERNS) CHAPTER 6

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

You might also like

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Saudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 30-Apr-17 MechDocument23 pagesSaudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 30-Apr-17 Mechkarthi51289No ratings yet

- Manual Oil Cooler BloksmaDocument6 pagesManual Oil Cooler Bloksmaapi-377451960% (5)

- Insp Checklist - Piping AlignmentDocument1 pageInsp Checklist - Piping AlignmentesutjiadiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldManoj KumarNo ratings yet

- SATR - J - 6702 Rev 0 PDFDocument8 pagesSATR - J - 6702 Rev 0 PDFAdel KlkNo ratings yet

- FMDS0799 - HTF Loss PreventionDocument22 pagesFMDS0799 - HTF Loss PreventionEvert AlexNo ratings yet

- Method Statement For Hot TappingDocument13 pagesMethod Statement For Hot TappingAmb Patrick OghateNo ratings yet

- Saudi Aramco Inspection Checklist: Mounting Plate Installation and Leveling For Pumps SAIC-G-2021 30-Apr-17 MechDocument15 pagesSaudi Aramco Inspection Checklist: Mounting Plate Installation and Leveling For Pumps SAIC-G-2021 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6911 24-Jul-18 Inst Foundation Fiedlbus System - Design / Procurement PackageDocument4 pagesSaudi Aramco Inspection Checklist: SAIC-J-6911 24-Jul-18 Inst Foundation Fiedlbus System - Design / Procurement Packagenisha_khanNo ratings yet

- SAIC-L-2094 Rev 7Document18 pagesSAIC-L-2094 Rev 7Jaseel KanhirathingalNo ratings yet

- SATR-L-2001 Flange Joint Tightening Test ReportDocument6 pagesSATR-L-2001 Flange Joint Tightening Test ReportAnonymous S9qBDVkyNo ratings yet

- SATR-L-2001 Rev 2 - Flange Joint Tightening Inspection ReportDocument12 pagesSATR-L-2001 Rev 2 - Flange Joint Tightening Inspection Reportdeepa narayan100% (1)

- Saic M 1073Document6 pagesSaic M 1073Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Relief Valve Installation SAIC-J-2009 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Relief Valve Installation SAIC-J-2009 24-Jul-18 Mechnisha_khanNo ratings yet

- SAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FDocument8 pagesSAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FKirubhakarPooranamNo ratings yet

- SATR-L-2001 Rev. 5Document10 pagesSATR-L-2001 Rev. 5Neelam AhmadNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldDocument32 pagesSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldIrshad Iqbal100% (2)

- SAIC-W-2006 Rev 8Document4 pagesSAIC-W-2006 Rev 8saravananmenmathiNo ratings yet

- SAIC-W-2031 In-Process Welding Inspection of Hot TapDocument2 pagesSAIC-W-2031 In-Process Welding Inspection of Hot TapAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 Weldm4metzNo ratings yet

- SAIC-G-2022 Rev 2Document25 pagesSAIC-G-2022 Rev 2faisal hussainNo ratings yet

- SAIC-D-2020 Tank Trim Installation MAS-rlcDocument3 pagesSAIC-D-2020 Tank Trim Installation MAS-rlcAnonymous S9qBDVkyNo ratings yet

- Saic W 2005Document1 pageSaic W 2005Abdelaziz MohamedNo ratings yet

- Saudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 25-May-05 MechDocument2 pagesSaudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 25-May-05 MechAnonymous S9qBDVkyNo ratings yet

- Saic G 2002Document32 pagesSaic G 2002jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocument3 pagesSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Equipment Tolerances Rev 2Document18 pagesEquipment Tolerances Rev 2Stephen Raj100% (1)

- SAIC-A-2021 Rev 6 Pnematic Test - 3Document4 pagesSAIC-A-2021 Rev 6 Pnematic Test - 3pookkoya thangalNo ratings yet

- Saic F 2008Document4 pagesSaic F 2008usmanNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection ChecklistDocument22 pagesSaudi Aramco Inspection ChecklistAhdal NoushadNo ratings yet

- SAIC-W-2039 Welder & Operator Certification Review Issuance of JCC (Job Clearance Card) & Review Performance - PipelinesDocument9 pagesSAIC-W-2039 Welder & Operator Certification Review Issuance of JCC (Job Clearance Card) & Review Performance - PipelinesilliasuddinNo ratings yet

- Saudi Aramco Inspection Checklist: Inspect Assembly of Air-Cooled Heat Exchanger ComponentsDocument12 pagesSaudi Aramco Inspection Checklist: Inspect Assembly of Air-Cooled Heat Exchanger ComponentsmominNo ratings yet

- Saudi Aramco Inspection Checklist: Valve Installation Inspection & Valve Stroking SAIC-L-2043 30-Apr-17 PipeDocument10 pagesSaudi Aramco Inspection Checklist: Valve Installation Inspection & Valve Stroking SAIC-L-2043 30-Apr-17 Pipesuresh100% (1)

- Saic W 2035Document2 pagesSaic W 2035ABDUL RAHMAN ALI MIRNo ratings yet

- Saic D 2025Document10 pagesSaic D 2025jerinNo ratings yet

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsDocument2 pagesSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyNo ratings yet

- SAIC-W-2087 Post-Welding Visual Inspection PDFDocument2 pagesSAIC-W-2087 Post-Welding Visual Inspection PDFkarioke mohaNo ratings yet

- SAIC-W-2008 Rev 7 - Review of Procedure For Weld IdentificationDocument2 pagesSAIC-W-2008 Rev 7 - Review of Procedure For Weld Identificationmahmoud hegazyNo ratings yet

- SAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesDocument6 pagesSAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesAhdal NoushadNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldjahaanNo ratings yet

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Document6 pagesSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshNo ratings yet

- SAIC-L-2095 Rev 7Document6 pagesSAIC-L-2095 Rev 7Jaseel KanhirathingalNo ratings yet

- SAIC-A-2006 Rev 7Document5 pagesSAIC-A-2006 Rev 7Shyam Sundar GayenNo ratings yet

- SAIC-A-2006 Rev 6Document16 pagesSAIC-A-2006 Rev 6biplabpal2009No ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistjunaidNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechAbdul HafeezNo ratings yet

- General Instruction Gi 7 029Document8 pagesGeneral Instruction Gi 7 029mohamedNo ratings yet

- General Instruction Gi 7 029Document8 pagesGeneral Instruction Gi 7 029MahmoodNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Dec-09 WeldDocument9 pagesSaudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saudi Aramco Inspection Checklist 6232Document19 pagesSaudi Aramco Inspection Checklist 6232Munir Choudary100% (1)

- Satr A 2007Document2 pagesSatr A 2007usmanNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldDocument27 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 Mechkarthi51289No ratings yet

- Saic W 2006Document1 pageSaic W 2006Abdelaziz MohamedNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- SAIC-W-2005 Rev 8Document5 pagesSAIC-W-2005 Rev 8saravananmenmathiNo ratings yet

- Saic-P-3003 Rev 0 PDFDocument4 pagesSaic-P-3003 Rev 0 PDFHesham HelalNo ratings yet

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- Aramco CBT Questions-Answere For QAQC Welding-PART-03Document11 pagesAramco CBT Questions-Answere For QAQC Welding-PART-03Abdul Hafeez100% (1)

- Aramco CBT Questions-Answere For QAQC Welding-PART-04Document14 pagesAramco CBT Questions-Answere For QAQC Welding-PART-04Abdul Hafeez50% (2)

- Water and Electric Systems Technology: CompanyDocument1 pageWater and Electric Systems Technology: CompanyAbdul HafeezNo ratings yet

- Submittal Status & Pending Document With Aramco: Project: Replacement of GT and Pipiing of Abqaiq PlantDocument5 pagesSubmittal Status & Pending Document With Aramco: Project: Replacement of GT and Pipiing of Abqaiq PlantAbdul HafeezNo ratings yet

- Aramco CBT Questions-Answere For QAQC WeldingDocument10 pagesAramco CBT Questions-Answere For QAQC WeldingAbdul HafeezNo ratings yet

- Punch List: Upgradation of 120-Gt-14Document1 pagePunch List: Upgradation of 120-Gt-14Abdul HafeezNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechAbdul HafeezNo ratings yet

- Removable Contact Wear-FaceDocument1 pageRemovable Contact Wear-FaceFethi BELOUISNo ratings yet

- Metering Valves: S, M, L, and 31 SeriesDocument9 pagesMetering Valves: S, M, L, and 31 SeriesaliNo ratings yet

- STI HSS Column Load Tables LRFD PDFDocument123 pagesSTI HSS Column Load Tables LRFD PDFAhmed Ali MohammedNo ratings yet

- Pump (English) TemplateDocument1 pagePump (English) TemplateMichael HaiseNo ratings yet

- CCG To VR ViewNitPdf - 2933316Document25 pagesCCG To VR ViewNitPdf - 2933316ChetanNo ratings yet

- Electrical CatalogsDocument817 pagesElectrical Catalogsenghatem100% (3)

- Ciac Evaporadora 36,000 BtuDocument1 pageCiac Evaporadora 36,000 BtuCésar ArmasNo ratings yet

- Inline Inductor Mi-25 To Mi-65 Series: Installation, Operation, and Maintenance ManualDocument40 pagesInline Inductor Mi-25 To Mi-65 Series: Installation, Operation, and Maintenance Manualjohn dimailigNo ratings yet

- HSE Standars For Pipeline Construction Onshore WILIDocument8 pagesHSE Standars For Pipeline Construction Onshore WILIGhazi KallelNo ratings yet

- Sprinkler DesignDocument10 pagesSprinkler Designsk lukoNo ratings yet

- Power Piping Inpection ReportDocument1 pagePower Piping Inpection Reportpalmasia millingincNo ratings yet

- Technical Leaflet Cim 3723BDocument12 pagesTechnical Leaflet Cim 3723BblindjaxxNo ratings yet

- A545-736-11-42-DS-0034 - A - Flow TeeDocument2 pagesA545-736-11-42-DS-0034 - A - Flow TeeMurli ramchandranNo ratings yet

- High Temperature Steels in Pulverised Coal Technology - ccc234Document70 pagesHigh Temperature Steels in Pulverised Coal Technology - ccc234vnchromeNo ratings yet

- ASTM - E1137 - مشخصات دماسنجهای مقاومتی صنعتیDocument7 pagesASTM - E1137 - مشخصات دماسنجهای مقاومتی صنعتیhosein bagheriNo ratings yet

- Industrial Use of Molten Nitrate/Nitrite Salts: R. W. Carling, R. W. MarDocument34 pagesIndustrial Use of Molten Nitrate/Nitrite Salts: R. W. Carling, R. W. MarDarwin CastellanosNo ratings yet

- Manufacturers in Oil and Gas Industry EgyptDocument107 pagesManufacturers in Oil and Gas Industry Egyptsachin0% (1)

- Astm A 234Document8 pagesAstm A 234acolombelNo ratings yet

- Flush Valve Systems by Schell SpecifierDocument7 pagesFlush Valve Systems by Schell SpecifierThasleem ThasliNo ratings yet

- Flexible, Flame-Retardant, Dual-Color, Polyolefin TubingDocument3 pagesFlexible, Flame-Retardant, Dual-Color, Polyolefin TubingMiraziz AliyevNo ratings yet

- 1 SATIP-L-450-04 Cross Country Buried Pipeline-Rev 1Document4 pages1 SATIP-L-450-04 Cross Country Buried Pipeline-Rev 1Bighneswar PatraNo ratings yet

- Electrical Equipment Materials List 2020-10-16Document60 pagesElectrical Equipment Materials List 2020-10-16Reduwan SufiyanNo ratings yet

- Erico 11 - Pipe Rollers & SupportDocument0 pagesErico 11 - Pipe Rollers & Supporthappale2002No ratings yet

- Fired Heater Solutions A4 Rev.05 15 WebDocument6 pagesFired Heater Solutions A4 Rev.05 15 WebtugrulNo ratings yet

- T2700 Tower Specifications PDFDocument8 pagesT2700 Tower Specifications PDFmdalt9180No ratings yet

- EemuaokDocument5 pagesEemuaokseluarbolaNo ratings yet