Professional Documents

Culture Documents

2018 SP&RP Checklist Updated 9-2018

2018 SP&RP Checklist Updated 9-2018

Uploaded by

Samer AlsumaryCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Wca-16 Rolls Royce - 250 TV Bow & Stern Tunnel Thrusters PDFDocument115 pagesWca-16 Rolls Royce - 250 TV Bow & Stern Tunnel Thrusters PDFANo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- (Alexei Lapkin, David Constable) Green Chemistry Me (B-Ok - CC) PDFDocument337 pages(Alexei Lapkin, David Constable) Green Chemistry Me (B-Ok - CC) PDFAlex Sustaita100% (1)

- EQUILIBRIUMDocument1 pageEQUILIBRIUMMohammed IliasNo ratings yet

- Price List 2018Document20 pagesPrice List 2018Imml TasbiNo ratings yet

- Costing By-Product and Joint ProductsDocument36 pagesCosting By-Product and Joint ProductseltantiNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Stages of SleepDocument2 pagesStages of SleepCamilia Hilmy FaidahNo ratings yet

- Petroleum Engineering Lab 1 (PGE313) Experiment 2 Determination of PorosityDocument13 pagesPetroleum Engineering Lab 1 (PGE313) Experiment 2 Determination of PorosityAli AbubakarNo ratings yet

- Snag SummmariesDocument171 pagesSnag Summmarieslaltu adgiriNo ratings yet

- RPT CasesDocument13 pagesRPT CasesSNLTNo ratings yet

- Case 621F, 721F Tier 4 Wheel Loader AxelDocument15 pagesCase 621F, 721F Tier 4 Wheel Loader AxelJose CarmonaNo ratings yet

- Relative Color Pickup of Three Different Knits and Predictive Dyeing Recipe FormulationDocument17 pagesRelative Color Pickup of Three Different Knits and Predictive Dyeing Recipe FormulationNguyễn Huy CườngNo ratings yet

- HT Billing System - May'2022Document2 pagesHT Billing System - May'2022V.Sampath RaoNo ratings yet

- Visual Storytelling The Digital Video Documentary - Original PDFDocument44 pagesVisual Storytelling The Digital Video Documentary - Original PDFjparanoti100% (1)

- OHara PDFDocument17 pagesOHara PDFTomás HidalgoNo ratings yet

- SCM and TQM: by Junaid ShaheedDocument8 pagesSCM and TQM: by Junaid ShaheedjunaidsNo ratings yet

- The Normal DistributionDocument30 pagesThe Normal DistributionJohn Rich CaidicNo ratings yet

- EVM TechmaxDocument96 pagesEVM Techmaxnikhileshdhuri97No ratings yet

- Research Progress of The Arti Ficial Intelligence Application in Wastewater Treatment During 2012 - 2022: A Bibliometric AnalysisDocument17 pagesResearch Progress of The Arti Ficial Intelligence Application in Wastewater Treatment During 2012 - 2022: A Bibliometric AnalysisjinxiaohuibabaNo ratings yet

- (12942) Sheet Chemical Bonding 4 Theory eDocument8 pages(12942) Sheet Chemical Bonding 4 Theory eAnurag SinghNo ratings yet

- Free Download All Aeronautical Engg Books: AERO 3-1 BOOKSDocument11 pagesFree Download All Aeronautical Engg Books: AERO 3-1 BOOKSMacen SnoodleNo ratings yet

- Exit Poll CedatosDocument1 pageExit Poll CedatosEcuadorenvivoNo ratings yet

- Regulator InfoDocument6 pagesRegulator InfoAguilar AlexNo ratings yet

- Operation Reasrech On IglooDocument18 pagesOperation Reasrech On IglooMd Yeasin ArafatNo ratings yet

- LECLANCHE Cell Datasheet GL60 GNMC 60ahDocument2 pagesLECLANCHE Cell Datasheet GL60 GNMC 60ahChaitanyaNo ratings yet

- An Overview of Honey: Its Composition, Nutritional and Functional PropertiesDocument5 pagesAn Overview of Honey: Its Composition, Nutritional and Functional PropertiesSandeep SinghNo ratings yet

- Wind EnergyDocument6 pagesWind EnergyRajat DubeyNo ratings yet

- Supplement Guide Memory FocusDocument41 pagesSupplement Guide Memory Focusgogov.digitalNo ratings yet

- Carbon Capture Corrosion Current Practice 2023Document12 pagesCarbon Capture Corrosion Current Practice 2023Wayne MonneryNo ratings yet

- Functional Specification For Deck CraneDocument31 pagesFunctional Specification For Deck Craneaiyubi20% (1)

2018 SP&RP Checklist Updated 9-2018

2018 SP&RP Checklist Updated 9-2018

Uploaded by

Samer AlsumaryOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2018 SP&RP Checklist Updated 9-2018

2018 SP&RP Checklist Updated 9-2018

Uploaded by

Samer AlsumaryCopyright:

Available Formats

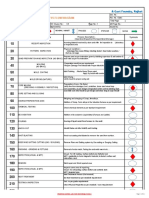

SPILL PREVENTION & RESPONSE PLAN CHECK LIST

FOR BUSINESSES IN DAYTON’S SOURCE WATER PROTECTION AREA

DISCLAIMER: THIS DOCUMENT IS TO SERVE AS A GUIDANCE DOCUMENT ONLY. It is not to be

considered a Spill Prevention & Response Plan (SP&RP). It is a checklist intended to ensure that all items below are

addressed in a SP&RP developed by a business in the Source Water Protection Area. The SP&RP, supporting

documents, and logs for the activities/practices/procedures in the checklist below shall be made available to the

Departments of Water and Fire during Source Water Protection Program inspections. Requirements are as follows:

SPILL PREVENTION

Regulated Substance Management: All Regulated Substances, including chemical wastes, are to be managed in a

way that prevents release, and is consistent with protocol established by Federal, State and Local regulatory agencies.

For each “Yes” response, describe how each requirement is currently addressed.

For each “No” response, describe how each requirement is proposed to be addressed.

For each “Not Applicable” response, the owner and/or operator shall provide justification why this

requirement is not applicable to the site (example – this requirement is not applicable to our site because we

do not handle flammable materials).

Storage:

1. All Regulated Substance containers are in good condition, Yes ____ No ____ Not Applicable ____

compatible with the materials stored within, and residual spills on ___________________________________

the exterior of the containers are cleaned immediately. ___________________________________

2. All Regulated Substance containers are accessible and spacing Yes ____ No ____ Not Applicable ____

between containers provides sufficient access to perform periodic ___________________________________

inspections and respond to releases. ___________________________________

3. All Regulated Substances are stored inside buildings or if outside; Yes ____ No ____ Not Applicable ____

under a cover, on an impermeable surface, with secondary ___________________________________

containment. ___________________________________

4. Regulated Substances not used on a daily basis are stored in Yes ____ No ____ Not Applicable ____

cabinets, or in designated areas. ___________________________________

___________________________________

5. All waste drums allow at least 4 inches of headspace to allow for Yes ____ No ____ Not Applicable ____

expansion. ___________________________________

___________________________________

6. Regulated Substances are stored in proper cabinets and only with Yes ____ No ____ Not Applicable ____

compatible materials. (i.e. flammability cabinets) ___________________________________

___________________________________

7. Incompatible substances are stored a safe distance apart or in a Yes ____ No ____ Not Applicable ____

manner which precludes mixing to prevent potential explosion or ___________________________________

fire. ___________________________________

9-21-18 Disclaimer: This document is a guidance document only. Page 1

It is not to be considered a Spill Prevention & Response Plan.

SPILL PREVENTION & RESPONSE PLAN CHECK LIST

Housekeeping:

8. All spills or leaks which are small and easily contained are Yes ____ No ____ Not Applicable ____

immediately cleaned up and properly disposed. ___________________________________

___________________________________

9. Signage is used to identify hazardous substance and Yes ____ No ____ Not Applicable ____

nonhazardous substance storage or waste collection areas. ___________________________________

___________________________________

10. A log (Attachment 1) documenting that storage areas for Yes ____ No ____ Not Applicable ____

Equipment and Regulated Substance are inspected monthly to ___________________________________

ensure leaks or spills are not occurring is maintained. * ___________________________________

11. Work areas and Regulated Substance storage areas are kept clean Yes ____ No ____ Not Applicable ____

and in good general condition. ___________________________________

___________________________________

12. Flammable materials in drums or totes are grounded during Yes ____ No ____ Not Applicable ____

material transfer to prevent static spark. ___________________________________

___________________________________

Handling:

13. All Regulated Substances, including chemical wastes, are Yes ____ No ____ Not Applicable ____

properly marked and labeled in accordance with all federal, state ___________________________________

and local regulations. ___________________________________

14. Regulated Substances transferred to secondary containers are Yes ____ No ____ Not Applicable ____

marked with the chemical’s name. ___________________________________

___________________________________

15. All Regulated Substances that are transferred from larger to Yes ____ No ____ Not Applicable ____

smaller containers are transferred by use of a funnel or spigot. ___________________________________

___________________________________

16. All Regulated Substance containers are closed when not in use. Yes ____ No ____ Not Applicable ____

___________________________________

___________________________________

17. Drip pans or other collection devices are used to contain drips or Yes ____ No ____ Not Applicable ____

leaks from dispensing containers or equipment. ___________________________________

___________________________________

18. A Disposal Practices log (Attachment 2) documenting Yes ____ No ____ Not Applicable ____

substances, dates removed, quantities removed, and vendor used ___________________________________

is maintained. * ___________________________________

9-21-18 Disclaimer: This document is a guidance document only. Page 2

It is not to be considered a Spill Prevention & Response Plan.

SPILL PREVENTION & RESPONSE PLAN CHECK LIST

Spill Response Supplies:

19. Spill clean-up supplies are compatible with the Regulated Yes ____ No ____ Not Applicable ____

Substances stored on site. ___________________________________

___________________________________

20. Spill supplies are stored in areas where spills are likely to occur Yes ____ No ____ Not Applicable ____

(loading docks, chemical storage areas, locations where ___________________________________

Regulated Substances are being transferred). ___________________________________

21. Spill kits are sufficient to contain the amount of Regulated Yes ____ No ____ Not Applicable ____

Substances that may be spilled or released. ___________________________________

___________________________________

22. A log (Attachment 3) documenting spill supplies are inspected Yes ____ No ____ Not Applicable ____

monthly to ensure they are complete is maintained. * ___________________________________

___________________________________

Secondary Containment:

23. All Regulated Substances in containers 55-gallons or greater, or Yes ____ No ____ Not Applicable ____

any sized containers if there is a potential for a release to the ___________________________________

environment, are stored in appropriate secondary containment. ___________________________________

24. A log (Attachment 4) documenting that secondary containment is Yes ____ No ____ Not Applicable ____

checked monthly is maintained.* ___________________________________

___________________________________

25. A log (Attachment 5) documenting the removal of any storm Yes ____ No ____ Not Applicable ____

water contained in any outside secondary containment system is ___________________________________

maintained.* ___________________________________

Engineering Controls:

26. An operations and maintenance log (Attachment 6) documenting Yes ____ No ____ Not Applicable ____

that all engineering controls have been inspected and are in good ___________________________________

operating condition shall be updated on a monthly basis. * ___________________________________

27. An inventory of all machines including oil and/or coolant Yes ____ No ____ Not Applicable ____

reservoir capacities shall be updated when any changes in ___________________________________

inventory are made. ___________________________________

28. Preventative maintenance activities to reduce the potential for Yes ____ No ____ Not Applicable ____

release from equipment have been implemented. ___________________________________

___________________________________

9-21-18 Disclaimer: This document is a guidance document only. Page 3

It is not to be considered a Spill Prevention & Response Plan.

SPILL PREVENTION & RESPONSE PLAN CHECK LIST

Employee Training: Includes training on spill prevention (above) and spill response (below).

29. A log (Attachment 7) documenting employee training on the Yes ____ No ____ Not Applicable ____

proper handling of Regulated Substances is maintained. * ___________________________________

___________________________________

30. All employees receive periodic training on the location and use of Yes ____ No ____ Not Applicable ____

the spill response supplies and procedures. ___________________________________

___________________________________

31. A log (Attachment 7) documenting employee training on Spill Yes ____ No ____ Not Applicable ____

Response Procedures is maintained.* ___________________________________

___________________________________

32. All employees receive periodic review of the Spill Prevention & Yes ____ No ____ Not Applicable ____

Response Plan. ___________________________________

___________________________________

33. Spill Response Procedures, incorporating all appropriate training, Yes ____ No ____ Not Applicable ____

notification, response, and cleanup/disposal measures, have been ___________________________________

generated and are available for review by all employees. ___________________________________

34. All employees receive hazard communication training, including Yes ____ No ____ Not Applicable ____

the location of safety data sheets. ___________________________________

___________________________________

Facility Site Plans: See Attachment 8 (a,b,c) for Information, Site Diagram, and Flow Example.

35. Site diagrams (Attachment 8b) have been generated and are Yes ____ No ____ Not Applicable ____

available for review by all employees. Contains site specific ___________________________________

information, as applicable, as referenced in Attachment 8c.* ___________________________________

36. Flow diagrams (Attachment 8c) have been generated and are Yes ____ No ____ Not Applicable ____

available for review by all employees. Contains site specific ___________________________________

information, as applicable, as referenced in Attachment 8c.* ___________________________________

Other Practices for Groundwater and Storm Water (MS4) Protection: See Attachment 9.

If answered Yes to the below, use Attachment 9 for brief write-up of these practices.

37. Has the business implemented other site-specific practices that Yes ____ No ____ Not Applicable ____

reduce the risk to the MS4 storm system? Note: Storm water ___________________________________

runoff goes directly to out rivers untreated. ___________________________________

38. Has the business implemented other site-specific practices that Yes ____ No ____ Not Applicable ____

reduce the risk to the groundwater? Note: The regions drinking ___________________________________

water source is the Great Miami Buried Valley Aquifer. ___________________________________

9-21-18 Disclaimer: This document is a guidance document only. Page 4

It is not to be considered a Spill Prevention & Response Plan.

SPILL PREVENTION & RESPONSE PLAN CHECK LIST

SPILL RESPONSE

Spill Response Procedures are facility specific for dealing with spills and shall be implemented immediately

whenever there is a release of a Regulated Substance which escapes containment and are consistent with protocol

established by Federal, State and Local regulatory agencies.

For each “Yes” response, describe how each requirement is currently addressed.

For each “No” response, describe how each requirement is proposed to be addressed.

For each “Not Applicable” response, the owner and/or operator shall provide justification why this

requirement is not applicable to the site (example – this requirement is not applicable to our site because

we do not handle flammable materials).

See Employee Training above (#’s 30, 31, 32, 33) and Attachment 7 for Spill Response considerations.

See Attachment 10 for Spill Procedures:

Initial Response, Notification, Cleanup, Disposal, & Final Report measures to be taken.

Notification/Reporting a Release: See Attachment 10.

39. All appropriate notifications are posted and available for Yes ____ No ____ Not Applicable ____

review by all employees. ___________________________________

___________________________________

40. All appropriate notifications are updated whenever a change Yes ____ No ____ Not Applicable ____

has occurred and employees are notified of changes. ___________________________________

___________________________________

41. Employees know what information is needed and are Yes ____ No ____ Not Applicable ____

prepared to provide the information when reporting a release. ___________________________________

___________________________________

Spill Response Actions: See Attachment 10.

42. If the spill is small and its chemical properties are known, Yes ____ No ____ Not Applicable ____

proper supplies are available to stop and contain it. (See #21 ___________________________________

from above) ___________________________________

43. If the spill is small and its chemical properties are known, Yes ____ No ____ Not Applicable ____

adsorbent, booms, drain covers, etc. are available to protect ___________________________________

drains. ___________________________________

44. If spill cannot be contained/controlled, employees have been Yes ____ No ____ Not Applicable ____

trained in proper procedures for evacuation and reporting the ___________________________________

spill. ___________________________________

45. A log (Attachment 3) is maintained noting who has Yes ____ No ____ Not Applicable ____

replaced/restocked the materials/supplies used. * ___________________________________

___________________________________

9-21-18 Disclaimer: This document is a guidance document only. Page 5

It is not to be considered a Spill Prevention & Response Plan.

SPILL PREVENTION & RESPONSE PLAN CHECK LIST

Spill Disposal: See Attachment 10.

46. Procedures are in place to characterize the waste and Yes ____ No ____ Not Applicable ____

determine the wastes status prior in order to dispose properly ___________________________________

___________________________________

47. A Disposal Practices log (Attachment 2) documenting what Yes ____ No ____ Not Applicable ____

substances spilled, dates removed, quantities removed, and ___________________________________

vendors is maintained. * ___________________________________

Final Report: See Attachment 10.

48. Someone is designated to prepare a report of the incident to Yes ____ No ____ Not Applicable ____

be submitted to the Department of Water within 30-days of ___________________________________

the incident. ___________________________________

RECORD KEEPING

All procedures in the Spill Prevention and Spill Response sections that have been implemented and all logs and forms

shall be reviewed and immediately amended whenever:

1. The procedures fail in a spill event

2. The facility changes in its design, construction, equipment, operation, maintenance, use, or other

3. The list of emergency contacts change

49. Someone has been designated to maintain and update logs, Yes ____ No ____ Not Applicable ____

forms, plans when any of the above occur: ___________________________________

___________________________________

ATTACHMENTS

The following attachments, in the form of Logs, Forms, Templates, and Information, are being provided as examples

only. Not all Attachments will apply to all sites/facilities. Each site/facility will need to adapt the format and

information needed to their facility’s procedures, processes, meeting state, local, and federal requirements.

- Attachment 1: Storage Area Log

- Attachment 2: Disposal Log

- Attachment 3: Spill Response Equipment Log

- Attachment 4: Secondary Containment & BMP Maintenance Log

- Attachment 5: Storm Water Containment-Removal Log

- Attachment 6: Equipment, Machine, BMP Maintenance Log

- Attachment 7: Employee Training Log

- Attachment 8a: Site Diagram & Flow Information

- Attachment 8b: Site Diagram Template

- Attachment 8c: Flow Diagram Template

- Attachment 9: Other Practices for Water Resource Protection

- Attachment 10: Spill Response Procedure Information

9-21-18 Disclaimer: This document is a guidance document only. Page 6

It is not to be considered a Spill Prevention & Response Plan.

ATTACHMENT 1

SPILL PREVENTION & RESPONSE PLAN REQUIRED CONTENT EXAMPLE

Facility (Plant) Name: __________________________________________________

Facility Address: ______________________________________________________________________________________________

STORAGE AREAS

Instructions: Add information to the first two columns describing the Regulated Substances being stored and the type of secondarily containment.

Complete this inspection log monthly. Note any issues to be addressed to prevent a release of a Regulated Substance. Initial and date the form.

Regulated Substances in Description of Any Secondary Containment

Comments Date Initial

Storage Used in the Storage Area

9-21-18 Disclaimer: This document is a guidance document only. Page 7

It is not to be considered a Spill Prevention & Response Plan.

ATTACHMENT 2

SPILL PREVENTION & RESPONSE PLAN REQUIRED CONTENT EXAMPLE

Facility (Plant) Name: __________________________________________________

Facility Address: ______________________________________________________________________________________________

DISPOSAL LOG

Instructions: Complete this inspection log EACH TIME a Regulated Substance is removed from the facility for off-site disposal.

Regulated Quantity Date

Removal Vendor Name Comments Initials

Substance Removed Removed

9-21-18 Disclaimer: This document is a guidance document only. Page 8

It is not to be considered a Spill Prevention & Response Plan.

ATTACHMENT 3

SPILL PREVENTION & RESPONSE PLAN REQUIRED CONTENT EXAMPLE

Facility (Plant) Name: __________________________________________________

Facility Address: ______________________________________________________________________________________________

SPILL EQUIPMENT SUPPLY & RESTOCK LOG

Instructions: The following table lists the spill control and emergency response equipment located on-site. The equipment listed are examples

only. The list should reflect what each facility needs for its operation. Modified as needed based on the actual equipment located at the facility.

Complete the equipment inspection monthly to ensure the equipment is available and operational. Faulty equipment or spent supplies will be

replaced or repaired as soon as practical following completion of a spill response event or the inspection.

Date

Describe Any Restock

Spill Response Equipment Description Quantity Location Date Initials Restock Initials

Needed

Completed

Absorbent sheets or square pads

Absorbent booms or socks

Absorbent, granular (oil-dry, fiber-perl)

Drain covers

Spill response equipment kit

85-gallon Poly overpack container

Empty 55-gallon drum

Plastic bag

Non-sparking shovel

Scrub brushes/ brooms/ or mops

Safety goggles/face shield

Tyvek Covering/boot covers

Rubber gloves

9-21-18 Disclaimer: This document is a guidance document only. Page 9

It is not to be considered a Spill Prevention & Response Plan.

ATTACHMENT 4

SPILL PREVENTION & RESPONSE PLAN REQUIRED CONTENT EXAMPLE

Facility (Plant) Name: __________________________________________________

Facility Address: ______________________________________________________________________________________________

BEST MANAGEMENT PRACTICES (BMPS) & SECONDARY CONTAINMENT INSPECTION LOG

Instructions: Use the third column describing the Best Management Practice (BMP) and/or the type of secondarily containment being used. The

BMPs and Secondary Containment listed are examples only. The list should reflect what each facility needs for its operation. Modified as needed

based on the actual equipment located at the facility.

Complete this inspection log monthly. Note any issues to be addressed to prevent a release of a Regulated Substance. Initial and date the form.

Description of Best Management Practice or Type of

Chemical Amount Comments Date Initials

Secondary Containment Used

Use of spigots when transferring chemicals

Outside storage is covered

Tanks are doubled walled

Drums are stored in a containment system

Flammable cabinets are in use

Pallets are used to capture any leaks

Drip pans used to contain drips or leaks from equipment.

9-21-18 Disclaimer: This document is a guidance document only. Page 10

It is not to be considered a Spill Prevention & Response Plan.

ATTACHMENT 5

SPILL PREVENTION & RESPONSE PLAN REQUIRED CONTENT EXAMPLE

Facility (Plant) Name: __________________________________________________

Facility Address: ______________________________________________________________________________________________

STORM WATER SECONDARY CONTAINMENT INSPECTION & WATER REMOVAL LOG

Instructions: Complete this inspection log after each rain event and after each time water is removed from a secondary containment area. Note any

issues that might need to be addressed to prevent a release of a Regulated Substance. Initial and date the form.

Use a separate form for each outside storm water containment system.

Location of Storm Water containment system: ________________________________________________________________________________

Type and amount of chemicals or materials held in the containment unit: _________________________________________________________

__________________________________________________________________________________

Description/Appearance of Water Amount of Water Contractor Performing Removal &

Comments Date Initials

Being Removed Being Removed Disposal

9-21-18 Disclaimer: This document is a guidance document only. Page 11

It is not to be considered a Spill Prevention & Response Plan.

ATTACHMENT 6

SPILL PREVENTION & RESPONSE PLAN REQUIRED CONTENT EXAMPLE

Facility (Plant) Name: __________________________________________________

Facility Address: ______________________________________________________________________________________________

MACHINE & EQUIPMENT ENGINEERING CONTROLS MAINTENANCE

Instructions: Add information to the first two columns describing equipment and what Regulated Substance is being used in equipment

Complete this inspection log monthly and each time repairs/maintenance is performed. Note any issues that might need to be addressed to

prevent a release of a Regulated Substance. Initial and date the form.

Description of Regulated Substance

Description of Condition of

BMP or Secondary and Amount Contained Comments Date Initials

Equipment Equipment/Machine

Containment in Machine Reservoir

9-21-18 Disclaimer: This document is a guidance document only. Page 12

It is not to be considered a Spill Prevention & Response Plan.

ATTACHMENT 7

SPILL PREVENTION & RESPONSE PLAN REQUIRED CONTENT EXAMPLES

Facility (Plant) Name: _________________________________________________________

Facility Address: _____________________________________________________________

EMPLOYEE TRAINING FORM

Instructions: Complete this example training log EACH TIME training is performed. The included

topics are examples and should be modified as needed based on the actual topics discussed at the facility.

The following Spill Plan Training Form should be completed each time a training session related to the SPRP is

performed. Training is required at a minimum ANNUALLY to assure understanding of the plan. Participants should

print their name, employee number, and then sign their name in the appropriate spaces provided below. The trainer

should complete the upper portion of the form, including topics covered in addition to the general review of the plan.

Trainer’s Name:

Date and Time of Training:

Training Topics: Spill Prevention & Response Plan OSHA HazCom & SDSs

Emergency Notification Procedures Proper Handling of and Disposal of Regulated Substances

List Training Materials:

Attendees must print their name and sign below to receive credit for attending the training:

Name (print) Employee # Signature

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

9-21-18 Disclaimer: This document is a guidance document only. Page 13

It is not to be considered a Spill Prevention & Response Plan.

ATTACHMENT 8a

SPILL PREVENTION AND RESPONSE PLAN REQUIRED CONTENT EXAMPLES

Facility (Plant) Name: _________________________________________________________

Facility Address: _____________________________________________________________

INFORMATION FOR ATTACHMENTS 8a SITE DIAGRAM & 8b FLOW TEMPLATES

The Site Diagrams shall be reviewed annually and amended whenever changes are made.

The site diagrams shall include both inside and outside details including, but not limited to the following:

Outside storage of Regulated Substances including structure providing cover

Bulk storage areas (ASTs and USTs). Note: new USTs are prohibited

Processes which store, consume and/or discharge Regulated Substances including equipment reservoirs

containing oils, coolants and/or solvents

Hazardous, non-hazardous and waste oil storage areas

Self-contained storage including parts washers, and machines that use Regulated Substances

Safety Data Sheets stations (Globally Harmonized Systems)

Emergency contact numbers

Engineering controls (secondary containment, spill containment pallets, oil/water separators, spill control

carts, etc.)

Flammability cabinets

Spill kit storage areas

Delivery and disposal routes of Regulated Substance products/waste.

Locations of all storm catch basins, and/or dry well drains, and/or French drains

The direction of onsite drainage flow and the end-of-pipe discharge location (example: discharges to the

Great Miami River at Outfall Designation GML70 or discharges to the groundwater via direct infiltration

through the dry well or French drain)

Inside floor drains: Confirm they drain to sanitary.

9-21-18 Disclaimer: This document is a guidance document only. Page 14

It is not to be considered a Spill Prevention & Response Plan.

ATTACHMENT 8b

SPILL PREVENTION & RESPONSE PLAN REQUIRED CONTENT EXAMPLE

Facility (Plant) Name: __________________________________________________

Facility Address: ______________________________________________________________________________________________

SITE DIAGRAM TEMPLATE

Above-Ground

Catch Basin Direction of Flow Storage Tank Floor Drain Spill Kit

Maintenance

Bldg.

Waste Misc. Flammability

Shed – Oil

Oil Drums Cabinet

Drum Storage

Haz Chem.

Drum Storage

Plant 2

Plant 1

Oil

Flammability

Drums

Cabinet

Shed – Non-Haz.

Parts Waste Drum Storage

washer Oil Outside Drum

Storage Area with Canopy

9-21-18 Disclaimer: This document is a guidance document only. Page 15

It is not to be considered a Spill Prevention & Response Plan.

ATTACHMENT 8c

SPILL PREVENTION & RESPONSE PLAN REQUIRED CONTENT EXAMPLE

Facility (Plant) Name: __________________________________________________

Facility Address: ______________________________________________________________________________________________

REGULATED SUBSTANCE DELIVERY & DISPOSAL ROUTES FLOW DIAGRAM TEMPLATE

Incoming Deliveries Waste Oil

Outgoing - Disposal Truck Dock

Tanks

Truck

Entrance

Parking

Maint. Oil Drum

Storage

Bldg.

Offices

Milling (CNC)

Machines Stamping

Press

Plant 1 Plant 2

Grinding

Machine

s Oil Drum & Waste

Oil Storage

Drum Stamping

Storage- Press

Storage Shed –

Coolants/Oil

Misc. Containers Outside Drum

Storage Area w/ canopy

9-21-18 Disclaimer: This document is a guidance document only. Page 16

It is not to be considered a Spill Prevention & Response Plan.

ATTACHMENT 9

SPILL PREVENTION AND RESPONSE PLAN REQUIRED CONTENT EXAMPLES

Facility (Plant) Name: _________________________________________________________

Facility Address: _____________________________________________________________

OTHER PRACTICES

Briefly describe any other site-specific practices your business has implemented which reduce risk to the

groundwater (SWPP - our drinking water source) or to the storm system (MS4 - goes to our rivers untreated).

SEE #37 ABOVE

Has the business implemented other site-specific practices that reduce the risk to the MS4 storm system?

Note: Storm water runoff goes directly to out rivers untreated.

Attach additional sheets if necessary.

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

SEE #38 ABOVE

Has the business implemented other site-specific practices that reduce the risk to the groundwater?

Note: The regions drinking water source is groundwater from the Great Miami Buried Valley Aquifer.

Attach additional sheets if necessary.

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

________________________________________________________________________

9-21-18 Disclaimer: This document is a guidance document only. Page 17

It is not to be considered a Spill Prevention & Response Plan.

ATTACHMENT 10

SPILL PREVENTION & RESPONSE PLAN INFORMATION

SPILL PROCEDURES:

INITIAL RESPONSE, NOTIFICATION, CLEANUP, DISPOSAL, & FINAL REPORT

In the event of a regulated substance spill or release, immediately take the following measures to keep the spill

from entering sewer or storm drains, spreading off-site, or affecting human health.

Initial Response:

Stop, contain, and clean up the chemical spill if:

1. The spilled chemical and its hazardous properties have been identified

2. The spill is small and easily contained

If a spill or release cannot be controlled (i.e. escapes containment) or injuries have occurred due to the release

the following procedures should be implemented:

1. Summon help or alert others of the release

2. Evacuate immediate area, and provide care to the injured- Call 911

3. If potential fire or explosion hazards exist, initiate evacuation procedures- Call 911.

4. Respond defensively to any uncontrolled spills

Use appropriate personal protective equipment when responding to any spill

Attempt to shut off the source of the release (if safe to do so)

Eliminate sources of ignition (if safe to do so)

5. Protect drains by use of adsorbent, booms or drain covers (if safe to do so)

Notification of a Release:

If a spill, of any quantity, has escaped containment and has been released to soil, surface water, storm water

drains, or dry well drains, the following notifications are to be performed immediately:

1. Fire Department (911)

2. Dayton Division of Environmental Management (between 8:00 am - 5:00 pm) at (937) 333-3725

3. Dayton Division of Water Supply & Treatment (if after hours) at (937) 333-6030

4. Ohio EPA Emergency Hotline at 1-800 282-9378

5. National Response Center (within 24-hours if a release of oil or fuel to surface water, or a release of a

chemical with an established Reportable Quantity-RQ)

6. Notify onsite emergency contact(s)

7. Notify trained staff and response contractor to assist with the spill response and cleanup activities

8. Coordinate response activities with local emergency personnel (fire department).

9. Provide Safety Data Sheets (SDS) (also referred to as MSDS/GHS) information responders

10. Notify appropriate agency if a release has entered the environment

When reporting a release, prepare to provide the following information:

1. Your name and telephone number from where you are calling

2. Exact address of the release or threatened release

3. Date, time, cause and type of incident (fire, air release, spill, etc.)

4. Material and quantity of the release, to the extent known

5. Current condition of the facility

6. Possible hazards to the public health and/or environment outside of the facility

9-21-18 Disclaimer: This document is a guidance document only. Page 18

It is not to be considered a Spill Prevention & Response Plan.

ATTACHMENT 10 (continued)

SPILL PREVENTION & RESPONSE PLAN INFORMATION

SPILL PROCEDURES:

INITIAL RESPONSE, NOTIFICATION, CLEANUP, DISPOSAL, & FINAL REPORT

Spill Cleanup & Disposal:

In the event of a hazardous substance release spill cleanup materials are to be properly characterized to

determine if it designates as a Dangerous Waste. The onsite emergency contact, with the assistance of waste

disposal vendor and other resources will determine the wastes status prior to disposal.

Use Attachment 2 - Disposal Log and Attachment 3 - Spill Supply & Restock Log.

Final Report:

A detailed report of the incident including substance released, amount released, impacts to the environment,

measures taken for mitigation, and offsite disposal manifest shall be submitted to the Department of Water

within 30-days of the incident.

DISCLAIMER: THIS DOCUMENT IS TO SERVE AS A GUIDANCE DOCUMENT ONLY. It is not to

be considered a Spill Prevention & Response Plan (SP&RP). It is a checklist intended to ensure that items are

addressed in a SP&RP developed by a business in the Source Water Protection Area. Questions regarding this

document should be directed to the City of Dayton, Department of Water, Division of Environmental

Management at (937) 333-3725.

9-21-18 Disclaimer: This document is a guidance document only. Page 19

It is not to be considered a Spill Prevention & Response Plan.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Wca-16 Rolls Royce - 250 TV Bow & Stern Tunnel Thrusters PDFDocument115 pagesWca-16 Rolls Royce - 250 TV Bow & Stern Tunnel Thrusters PDFANo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- (Alexei Lapkin, David Constable) Green Chemistry Me (B-Ok - CC) PDFDocument337 pages(Alexei Lapkin, David Constable) Green Chemistry Me (B-Ok - CC) PDFAlex Sustaita100% (1)

- EQUILIBRIUMDocument1 pageEQUILIBRIUMMohammed IliasNo ratings yet

- Price List 2018Document20 pagesPrice List 2018Imml TasbiNo ratings yet

- Costing By-Product and Joint ProductsDocument36 pagesCosting By-Product and Joint ProductseltantiNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Stages of SleepDocument2 pagesStages of SleepCamilia Hilmy FaidahNo ratings yet

- Petroleum Engineering Lab 1 (PGE313) Experiment 2 Determination of PorosityDocument13 pagesPetroleum Engineering Lab 1 (PGE313) Experiment 2 Determination of PorosityAli AbubakarNo ratings yet

- Snag SummmariesDocument171 pagesSnag Summmarieslaltu adgiriNo ratings yet

- RPT CasesDocument13 pagesRPT CasesSNLTNo ratings yet

- Case 621F, 721F Tier 4 Wheel Loader AxelDocument15 pagesCase 621F, 721F Tier 4 Wheel Loader AxelJose CarmonaNo ratings yet

- Relative Color Pickup of Three Different Knits and Predictive Dyeing Recipe FormulationDocument17 pagesRelative Color Pickup of Three Different Knits and Predictive Dyeing Recipe FormulationNguyễn Huy CườngNo ratings yet

- HT Billing System - May'2022Document2 pagesHT Billing System - May'2022V.Sampath RaoNo ratings yet

- Visual Storytelling The Digital Video Documentary - Original PDFDocument44 pagesVisual Storytelling The Digital Video Documentary - Original PDFjparanoti100% (1)

- OHara PDFDocument17 pagesOHara PDFTomás HidalgoNo ratings yet

- SCM and TQM: by Junaid ShaheedDocument8 pagesSCM and TQM: by Junaid ShaheedjunaidsNo ratings yet

- The Normal DistributionDocument30 pagesThe Normal DistributionJohn Rich CaidicNo ratings yet

- EVM TechmaxDocument96 pagesEVM Techmaxnikhileshdhuri97No ratings yet

- Research Progress of The Arti Ficial Intelligence Application in Wastewater Treatment During 2012 - 2022: A Bibliometric AnalysisDocument17 pagesResearch Progress of The Arti Ficial Intelligence Application in Wastewater Treatment During 2012 - 2022: A Bibliometric AnalysisjinxiaohuibabaNo ratings yet

- (12942) Sheet Chemical Bonding 4 Theory eDocument8 pages(12942) Sheet Chemical Bonding 4 Theory eAnurag SinghNo ratings yet

- Free Download All Aeronautical Engg Books: AERO 3-1 BOOKSDocument11 pagesFree Download All Aeronautical Engg Books: AERO 3-1 BOOKSMacen SnoodleNo ratings yet

- Exit Poll CedatosDocument1 pageExit Poll CedatosEcuadorenvivoNo ratings yet

- Regulator InfoDocument6 pagesRegulator InfoAguilar AlexNo ratings yet

- Operation Reasrech On IglooDocument18 pagesOperation Reasrech On IglooMd Yeasin ArafatNo ratings yet

- LECLANCHE Cell Datasheet GL60 GNMC 60ahDocument2 pagesLECLANCHE Cell Datasheet GL60 GNMC 60ahChaitanyaNo ratings yet

- An Overview of Honey: Its Composition, Nutritional and Functional PropertiesDocument5 pagesAn Overview of Honey: Its Composition, Nutritional and Functional PropertiesSandeep SinghNo ratings yet

- Wind EnergyDocument6 pagesWind EnergyRajat DubeyNo ratings yet

- Supplement Guide Memory FocusDocument41 pagesSupplement Guide Memory Focusgogov.digitalNo ratings yet

- Carbon Capture Corrosion Current Practice 2023Document12 pagesCarbon Capture Corrosion Current Practice 2023Wayne MonneryNo ratings yet

- Functional Specification For Deck CraneDocument31 pagesFunctional Specification For Deck Craneaiyubi20% (1)