Professional Documents

Culture Documents

Datasheet MY3XGLOG 107 Eng

Datasheet MY3XGLOG 107 Eng

Uploaded by

Pedro TorringtonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datasheet MY3XGLOG 107 Eng

Datasheet MY3XGLOG 107 Eng

Uploaded by

Pedro TorringtonCopyright:

Available Formats

TECHNICAL DOCUMENTATION 9/06/2005 GAUGE MyChron 3 XG

Notes: MyChron 3 XG LOG technical documentation, dimensions LOG

and pinout – Version 1.07

Internal lateral accelerometer

CH1 Beacon Speed

ECU

RPM

Power

CH2 CH3 CH4 CH5

Figure 1: MyChron 3 XG LOG

Introduction

MyChron 3 XG LOG represents the perfect synthesis between MyChron 3

Gold XG and MyChron 3 LOG advanced for car applications: this new

logger merges the functionalities and the features of those 2 previous

loggers and constitutes a milestone moment in AIM data logger history.

MyChron 3 XG LOG monitors and displays RPM, 5 fully configurable

analog inputs (pressure, temperature, potentiometers, Lambda probe and

Pitot tube, speed sensors), 2 speed inputs, internal lateral G-sensor (to

map tracks), gear number and lap (split) times.

MyChron 3 XG LOG is interfaceable with the most common ECU, like

Bosch, Carmo, Efi, MecTronic, MoTec and others, through an RS232

cable or a CAN cable (connected to the gauge ECU-RPM-POWER input)

to sample the data out coming from the ECU.

To have a complete list of compatibles ECUs, communication protocol and

connection with AIM logger, please refer to “documents” page of our

website www.aim-sportline.com, where You find a dedicated datasheet

called ECU-AIM logger.

The logger records the following parameters:

• 5 analog inputs: pressure and temperature sensors (VDO, thermo-

resistors, thermocouples), potentiometers (linear and circular),

Lambda probe and Pitot tube;

• lap and split times;

• 2 speed inputs;

• Internal lateral G-sensor to map tracks;

• Gear number;

• Logger’s temperature;

• All the channels acquired from the engine’s ECU.

Technical documentation: MyChron 3 XG LOG – Version 1.07 1

Data are stored in a huge 8 Mbytes internal flash memory and may be downloaded to a PC

through an USB cable.

For further information on the gauge’s display, please refer to the following drawing.

Gear display

10 fully configurable shift lights

Speed unit of measure Low battery warning

Night vision

RPM graphical bar

Configurable RPM scaling RPM digital value

Speed

Best lap time

Battery voltage

2nd displayed channel

4 alarm led:

from "AL 1" to "AL 4"

Temperature unit of measure

1st displayed channel

Lap / Split times

Displayed input channels USB port

Figure 2: MyChron 3 XG LOG display

Installation notes

• We recommend to choose a place where the instrument will not be

in contact with oil or fuel, be sure that the gauge is not installed too

close to heat sources and protect the instrument from vibrations;

• We remind you that MyChron 3 XG LOG is not equipped with

internal batteries, so it needs to be powered by an external 9 – 15V

power source (i.e. the car’s battery). Do not exceed these limits.

Speed

direction

In order to correctly measure the

Lateral lateral g-force using the internal

accelerometer

accelerometer, it is suggested to

install the gauge with the

Junction box’s front panel

perpendicular to the vehicle’s

speed, as shown in Figure 3.

Figure 3: How to correctly install Your MyChron 3 XG LOG (Junction box’s top side view)

• Once the gauge and the Junction box have been correctly installed,

you may plug all the sensors inside the junction box front panel;

• Moreover, you may connect the gauge to the engine’s ECU using

the serial/CAN cable.

Technical documentation: MyChron 3 XG LOG – Version 1.07 2

How to use the ECU-RPM-POWER input

Your MyChron 3 XG LOG is equipped with a 7 pins female connector

labelled as ECU-RPM-POWER. This multi-purpose connector is used for:

● ECU connection – CAN protocol

● ECU connection – RS232 serial protocol

● Power input: external 9 – 15V power source, RED (+) and BLACK

(-) wires;

● RPM input: the logger has 2 supplementary RPM inputs for coil

(150-400 V) or square wave (8-50 V) RPM signals. Usually the

RPM signal is sampled from the ECU and so you do not need to

use one of these 2 wires.

To connect your MyChron 3 XG LOG to the ECU, please use the serial

RS232 / CAN cable and connect it to the gauge as shown in Figure 4.

Please note that your ECU may be equipped with a CAN or with an

RS232 serial communication protocol, so you do not have to connect

both “CAN + / CAN -” and “RS232 TX / RS232 RX” wires to the ECU,

but only the ones concerning the correct communication protocol.

CH1 Beacon Speed

RS232 TX & RS232 RX

ECU

RPM

Power

GND

CAN + & CAN -

} ENGINE'S

ECU

CH2 CH3 CH4 CH5

Figure 4: How to connect Your MyChron 3 XG LOG To the ECU

How to connect MyChron 3 XG LOG to the PC

In order to connect your MyChron 3 XG LOG to the PC, please use the

USB data download cable and plug it both in the gauge’s USB port and in

the PC’s USB port, as explained in Figure 5. Moreover, please use a 9-15

Volts external power source to switch on the gauge.

CH1 Beacon Speed

ECU

RPM

Power

CH2 CH3 CH4 CH5

Figure 6: How to connect Your MyChron 3 XG LOG to the Pc

Technical documentation: MyChron 3 XG LOG – Version 1.07 3

Software

Once the logger installed and the sensors plugged in, to configure the logger,please use Race

Studio 2, the software developed by Aim to configure its instruments and analyze stored data.

Please run Race Studio 2, select “M3 LOG / To correctly configure your MyChron 3 XG

VISOR/XGLOG”, press “System manager” LOG, please set all parameters reported in

button and follow these steps: the configuration window shown in the

previous figure:

• Display language.

• Obscuring time and Number of splits.

• Speed channel, wheel circumference

and pulses per wheel revolution.

• Channels and alarms concerning the 2

display pages.

• Gear channel: calculated or none

1) Set the input channels 3) Transmit the configuration

Press “Channels” button to set the sensors

installed on your car; this window appears.

Once the input channels set and configured

to transmit the configuration to the logger

please press “OK” button and than

“Transmit” button on the following wndow.

Please note: to transmit the configuration,

the gauge must be switched on and

connected to the PC, as shown in Figure 5.

4) Calibrate/auto-calibrate sensors

After configuration transmission you have

to calibrate/auto-calibrate the sensors.

To set an input channel, double-click on the cell “Potentiometer distance” and “Internal

corresponding to the desired one: the pop up lateral accelerometer” sensors need auto-

window circled above appears. calibration, while “Mid zero potentiometer”,

2) How to configure the gauge “zero based potentiometer” and “on-board

Once set the desired input channels, press gear sensor” need calibration. Please press

“Configuration” button to set all the other “Calibrate” button and this window appears

parameters. The window below appears.

G-force sensor and “potentiometer distance” 5) Re-transmit the configuration

sensor need to be auto-calibrated pressing Once the calibration/autocalibration has

Technical documentation: MyChron 3 XG LOG – Version 1.07 4

button “Click here to auto-calibrate all finished, it is absolutely necessary to re-

sensors in the list”. transmit the configuration to your MyChron 3

To calibrate “on-board” gear sensor, “Mid XG LOG pressing the “Transmit” button.

zero potentiometer” or “zero based

potentiometer”, click on the corresponding

“Calibrate” button and follow the instructions

prompted on your PC’s monitor.

Please note: calibration/auto calibration

procedure is fundamental to acquire

correct data.

Technical documentation: MyChron 3 XG LOG – Version 1.07 5

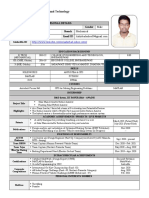

Dimensions in millimetres [inches]

126 [4,96]

120 [4.72]

48 [1,89] 110 [4.33]

87 [3,43] 100 [3,94]

CH1 Beacon Speed

39 [1,54]

ECU

4 [0,16]

RPM

Power

CH2 CH3 CH4 CH5

Channels 1÷5 pinout

Pin Function Pin Function 7 1

4 1

6 2

1 Analog input 3 +V battery 3 2 5 3

4

2 GND 4 V reference

4 & 7 pins female Binder 712 connectors pinout:

Speed channel pinout external view

Pin Function Pin Function Technical characteristics

1 Speed 1 3 +V battery General Value

2 GND 4 Speed 2 characteristics

Input channels 5

Beacon channel pinout Input ch. from ECU Max. 64

Max sampling freq. Up to 200 Hz

Pin Function Pin Function per channel

Total sampling 1000 Hz

1 Magn. / Opt.

3 +V battery frequency

codified lap

Internal g-sensor Biaxial, ±10g

2 GND 4 Optic not codified lap

External power From 9 to 15 VDC

Voltage output (V 4.5 V (for

ECU-RPM-POWER channel pinout ref.) potentiometers)

Internal memory 8 Mb flash EPROM

Pin Function Pin Function ECU interface Serial / CAN protocol

PC interface 300 kbyte/sec USB

1 CAN + 5 RS232 RX port

2 CAN - 6 RPM 150-400 V (coil

input) and Sq. Wave Other characteristics Value

(>8V)

3 + V batt. 7 GND M3 XG LOG dimensions 126x92x24 mm

4 RS232 TX Display dimensions 87x48 mm

Environmental IP 65

Technical documentation: MyChron 3 XG LOG – Version 1.07 6

You might also like

- REST API Guide For DevelopersDocument27 pagesREST API Guide For DevelopersGachuru AloisNo ratings yet

- ANSYS Polyflow Examples Manual 18.2Document6 pagesANSYS Polyflow Examples Manual 18.2Panda HeroNo ratings yet

- Honda NMEA 2000: Operating InstructionsDocument14 pagesHonda NMEA 2000: Operating InstructionsNuty IonutNo ratings yet

- Citroen-AL4 Fault FindingDocument50 pagesCitroen-AL4 Fault FindingArthit Utthawang100% (4)

- Caldera V9 enDocument21 pagesCaldera V9 enteteteteNo ratings yet

- Technical Documentation 4/06/2004: Gauge Mychron 3 Plus/Gold BikeDocument4 pagesTechnical Documentation 4/06/2004: Gauge Mychron 3 Plus/Gold BikeCalinNo ratings yet

- Motor ControlDocument5 pagesMotor ControlnooriusefNo ratings yet

- Manual and Remote Start Unit With J1939 Interface: FeaturesDocument4 pagesManual and Remote Start Unit With J1939 Interface: FeaturesJulioNo ratings yet

- The 85 MM Speedometer Requires A Dash Panel Hole Diameter of 86mm. It Can Accommodate A Maximum Dash Panel Thickness of 7mmDocument3 pagesThe 85 MM Speedometer Requires A Dash Panel Hole Diameter of 86mm. It Can Accommodate A Maximum Dash Panel Thickness of 7mmCarlos OrregoNo ratings yet

- Description: PrintDocument8 pagesDescription: PrintAUTOSCOPE DIAGNOSIS PERUNo ratings yet

- C3-C10164 - 98 (Rev 2.0)Document22 pagesC3-C10164 - 98 (Rev 2.0)JUAN PABLO ACOSTANo ratings yet

- En - stm32f7 WDG Timers GptimDocument61 pagesEn - stm32f7 WDG Timers GptimLODELBARRIO RDNo ratings yet

- Informacion PLM IIIDocument6 pagesInformacion PLM IIIAle SilliéNo ratings yet

- STAG-TAP-03: Connection and Programming InstructionsDocument28 pagesSTAG-TAP-03: Connection and Programming InstructionsGarth OwenNo ratings yet

- STAG - TAP - 03 - Manual - ENG - v1.3 2 PDFDocument28 pagesSTAG - TAP - 03 - Manual - ENG - v1.3 2 PDFGarth Owen100% (1)

- STAG-TAP-03: Connection and Programming InstructionsDocument28 pagesSTAG-TAP-03: Connection and Programming InstructionsGarth OwenNo ratings yet

- Infineon-Component - PSoC - 4 - Timer - Counter - and - PWM - V1.10-Software Module Datasheets-V02 - 01-ENDocument42 pagesInfineon-Component - PSoC - 4 - Timer - Counter - and - PWM - V1.10-Software Module Datasheets-V02 - 01-ENFatenn BellakhdharNo ratings yet

- TM Ga800sw 064Document28 pagesTM Ga800sw 064physicudoNo ratings yet

- En - stm32l4 WDG Timers GptimDocument64 pagesEn - stm32l4 WDG Timers GptimGia LữNo ratings yet

- InstumentationDocument55 pagesInstumentation200987No ratings yet

- Configuring The FlexTimer For Position and Speed Measurement With An EncoderDocument10 pagesConfiguring The FlexTimer For Position and Speed Measurement With An EncoderSumeet TrivediNo ratings yet

- Microprocessor Controlled Ac and DC DrivesDocument27 pagesMicroprocessor Controlled Ac and DC DrivesnarayanNo ratings yet

- Attiny 13 Datasheet PDFDocument169 pagesAttiny 13 Datasheet PDFTed SunNo ratings yet

- Communicating With Auto-Adjust Turbo-Meter Gas Flowmeters: Last Updated: 19 June 2009Document9 pagesCommunicating With Auto-Adjust Turbo-Meter Gas Flowmeters: Last Updated: 19 June 2009syed jeelani ahmedNo ratings yet

- LCD Display ManualDocument8 pagesLCD Display ManualrloopelectricalsolutionsNo ratings yet

- By: Truong Phan Hung NgoDocument15 pagesBy: Truong Phan Hung NgowillalizadeNo ratings yet

- #4 ARacer C Super X Track Tuning and Data AnalysisDocument31 pages#4 ARacer C Super X Track Tuning and Data Analysismida0114No ratings yet

- Decoding Tachometer Signals Using CompactRIO and LabVIEW FPGADocument3 pagesDecoding Tachometer Signals Using CompactRIO and LabVIEW FPGAOualid LamraouiNo ratings yet

- EZZ023535Document35 pagesEZZ023535fr946ntyjgNo ratings yet

- E8 SeriesDocument2 pagesE8 SeriesRichie CottonNo ratings yet

- LCD Controller Users' Manual: Electric Bicycle Meter KT - LCD3 Product User ManualDocument33 pagesLCD Controller Users' Manual: Electric Bicycle Meter KT - LCD3 Product User ManualTeodor SacaleanuNo ratings yet

- LinkG4_CANBase_102_engDocument8 pagesLinkG4_CANBase_102_engfarmtuningecuNo ratings yet

- Programmable Logic Controller: This Datasheet Has Been Downloaded From at ThisDocument12 pagesProgrammable Logic Controller: This Datasheet Has Been Downloaded From at ThisEmanuel NavasNo ratings yet

- GE-1400 HT-6100: Diesel Engine TachometersDocument4 pagesGE-1400 HT-6100: Diesel Engine TachometersF. Z.No ratings yet

- Dkg-109 Automatic Mains Failure Unit: DescriptionDocument2 pagesDkg-109 Automatic Mains Failure Unit: Descriptionandy habibiNo ratings yet

- Dkg-109 Automatic Mains Failure Unit: DescriptionDocument2 pagesDkg-109 Automatic Mains Failure Unit: DescriptionhomayounNo ratings yet

- 13 Ecu-BoschDocument22 pages13 Ecu-BoschThiên ThanhNo ratings yet

- Lesson: Embedded Systems I/O TimersDocument9 pagesLesson: Embedded Systems I/O TimersPuspala ManojkumarNo ratings yet

- 2005 GatewayManualDocument22 pages2005 GatewayManualjose BritoNo ratings yet

- GTR-168CP User ManualDocument6 pagesGTR-168CP User ManualLusy NoviaanjarsariNo ratings yet

- User Manual: HGM1780 Automatic Genset ControllerDocument23 pagesUser Manual: HGM1780 Automatic Genset Controllereduardoguerra155_604No ratings yet

- Manual de Operare CF UltraMaXX - ENDocument2 pagesManual de Operare CF UltraMaXX - ENPedro FoxNo ratings yet

- SPRT 723 BDocument5 pagesSPRT 723 BAmarYalavarthiNo ratings yet

- SBP550FDocument12 pagesSBP550FHernan Quispe EsystemNo ratings yet

- P052fa3 - P068386Document10 pagesP052fa3 - P068386Yannick de WalqueNo ratings yet

- Unit 5 - Microcontroller & Embedded System - WWW - Rgpvnotes.inDocument7 pagesUnit 5 - Microcontroller & Embedded System - WWW - Rgpvnotes.inDEFENCE MOTIVATIONNo ratings yet

- 40 Yanmar Tier4F - Service ProceduresDocument28 pages40 Yanmar Tier4F - Service ProceduresflajemeNo ratings yet

- Angle of Attack Sensor Based On Arduino UNO MicrocontrollerDocument4 pagesAngle of Attack Sensor Based On Arduino UNO MicrocontrollerNaji YakzanNo ratings yet

- Dkg-509 Automatic Mains Failure Unit: DescriptionDocument2 pagesDkg-509 Automatic Mains Failure Unit: DescriptionAziz ArrahalNo ratings yet

- CHPT 15Document11 pagesCHPT 15Juan Pablo CaicedoNo ratings yet

- Presentation DUT-E Eng v2.2Document27 pagesPresentation DUT-E Eng v2.2Sergey TretyakovNo ratings yet

- 3-Axis Stepper Motor Control Using An 8-Bit PIC MicrocontrollerDocument28 pages3-Axis Stepper Motor Control Using An 8-Bit PIC Microcontrollerعبد الكريم ملوحNo ratings yet

- AN594 - Using The CCP Module(s)Document25 pagesAN594 - Using The CCP Module(s)Guillermo Hernandez100% (3)

- Abstractions Quad PDF 160818031405Document43 pagesAbstractions Quad PDF 160818031405石大明No ratings yet

- Operating Instructions Econ-A: PR PR PR PR C C C C M M M MDocument21 pagesOperating Instructions Econ-A: PR PR PR PR C C C C M M M MSudipto MajumderNo ratings yet

- Rajkumar Seminar ReportDocument22 pagesRajkumar Seminar ReportRaj KumarNo ratings yet

- pb-chl8318 ASP1212Document4 pagespb-chl8318 ASP1212techgamebr85No ratings yet

- Configuring The Flextimer For Position and Speed Measurement With An EncoderDocument10 pagesConfiguring The Flextimer For Position and Speed Measurement With An EncoderElias CarvalhoNo ratings yet

- Data SheetDocument829 pagesData SheetJose RodriguezNo ratings yet

- DTC P0500 Vehicle Speed Sensor Malfunction: Circuit DescriptionDocument3 pagesDTC P0500 Vehicle Speed Sensor Malfunction: Circuit DescriptionJimmyNo ratings yet

- Dkg-547 Automatic Mains Failure Unit With J1939 Interface: DescriptionDocument2 pagesDkg-547 Automatic Mains Failure Unit With J1939 Interface: DescriptionabotalebNo ratings yet

- Ata 77 - Engine Indicating CorDocument23 pagesAta 77 - Engine Indicating CorIdrisNo ratings yet

- Preliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960From EverandPreliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960No ratings yet

- Oracle Fusion HCM Technical Training Course Content PDFDocument5 pagesOracle Fusion HCM Technical Training Course Content PDFBala KulandaiNo ratings yet

- The Information Systems Revolution Transforming Business and ManagementDocument40 pagesThe Information Systems Revolution Transforming Business and ManagementUtkarsh SethiNo ratings yet

- DAC6800+BCA4 and DAC6800+BCA4Z Digital-to-Analog Audio ConvertersDocument60 pagesDAC6800+BCA4 and DAC6800+BCA4Z Digital-to-Analog Audio ConvertersTechne PhobosNo ratings yet

- Bucket Hat Pattern by AppleGreen CottageDocument6 pagesBucket Hat Pattern by AppleGreen CottageNizar SilliniNo ratings yet

- Lightweight Portable Security (LPS) : Secure Web ClientDocument1 pageLightweight Portable Security (LPS) : Secure Web ClientbolaaajiiiNo ratings yet

- B.Tech CSE 2018 FT 1Document1 pageB.Tech CSE 2018 FT 1Dr. M.SujithaNo ratings yet

- Sum of A Number Using SwingDocument8 pagesSum of A Number Using Swingrakhitha1083No ratings yet

- Why Rust?: Trustworthy, Concurrent Systems ProgrammingDocument60 pagesWhy Rust?: Trustworthy, Concurrent Systems ProgrammingBathandwa Themba100% (1)

- Autorun InfoDocument3 pagesAutorun InfoChaithanya BharadwajNo ratings yet

- Bim - Level of DetailDocument17 pagesBim - Level of Detailsehyong0419No ratings yet

- Lab 7Document6 pagesLab 7Khadija KhanNo ratings yet

- Multibeam Calibration ModuleDocument41 pagesMultibeam Calibration ModuleYano MaximataNo ratings yet

- Pbapro TSM 23nov2016Document2 pagesPbapro TSM 23nov2016jcfermosellNo ratings yet

- Assignment 2aDocument5 pagesAssignment 2aRam Prasad Reddy SadiNo ratings yet

- 4 Instruction PipelineDocument13 pages4 Instruction PipelineAKASH PALNo ratings yet

- 8086 ProgrammingDocument203 pages8086 Programmingaramadevi50% (2)

- Intro To ANSYS Ncode DL - R14.5 - WS08Document31 pagesIntro To ANSYS Ncode DL - R14.5 - WS08Andres CasteloNo ratings yet

- College of Engineering and Technology BhubaneswarDocument1 pageCollege of Engineering and Technology BhubaneswarAshirbad SahuNo ratings yet

- Gartner Analyst Perspectives On Vendor BriefingsDocument19 pagesGartner Analyst Perspectives On Vendor BriefingsSanat MohantyNo ratings yet

- Net Neutrality Company Sign On LetterDocument3 pagesNet Neutrality Company Sign On LetterSam Gustin100% (2)

- Unit 1Document17 pagesUnit 1pallavi shimpiNo ratings yet

- اسئلة واجوبة معالجة متوازية نهائيةDocument10 pagesاسئلة واجوبة معالجة متوازية نهائيةAmmar H AL MadaniNo ratings yet

- Process Resilience: by Ravalika PolaDocument17 pagesProcess Resilience: by Ravalika PolaMohammad Saquib AlamNo ratings yet

- Philips SPC 900NC PC Camera: Instructions For UseDocument22 pagesPhilips SPC 900NC PC Camera: Instructions For UseLucian FaraonNo ratings yet

- 2021 LTIA AND LTIA-IS Prov OrientationDocument50 pages2021 LTIA AND LTIA-IS Prov OrientationMaria Fiona Duran Merquita100% (2)

- A Preliminary Design-Phase Security Methodology For Cyber-Physical SystemsDocument22 pagesA Preliminary Design-Phase Security Methodology For Cyber-Physical SystemsRofans ManaoNo ratings yet

- PrincipalsDocument10 pagesPrincipalskasuNo ratings yet