Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

145 viewsTechnical Data Sheet Earthing Strip

Technical Data Sheet Earthing Strip

Uploaded by

Sanket PhatangareThis document is a test report from JetcoTech Engineering LLP regarding galvanized steel strips supplied by Emtec Solutions. [1] It details the material descriptions, quantities tested, and inspection results. [2] Testing was conducted according to relevant IS, BSEN, ASTM specifications for galvanized coating thickness, adhesion, surface finish, and other properties. [3] All test results met requirements and the quality of materials was deemed satisfactory.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Practical Approaches To Applied Research and Program Evaluation For Helping Professionals 1St Edition PDF Full Chapter PDFDocument50 pagesPractical Approaches To Applied Research and Program Evaluation For Helping Professionals 1St Edition PDF Full Chapter PDFrasmahjonaki34100% (5)

- Summary - Granovetter (1985) Economic Action and Social StructureDocument2 pagesSummary - Granovetter (1985) Economic Action and Social StructureSimon Fiala100% (12)

- Price List: W.E.F. January 01, 2020Document14 pagesPrice List: W.E.F. January 01, 2020SHASHINo ratings yet

- Test CertificateDocument1 pageTest CertificateAvinash JadhavNo ratings yet

- Cable TCDocument1 pageCable TCSachin wakeNo ratings yet

- Data Sheet GI StripDocument1 pageData Sheet GI StripRuchir ChaturvediNo ratings yet

- Fabrication DetailsDocument28 pagesFabrication DetailsPatel MishalNo ratings yet

- Sample Test Certificate (24.12.2022)Document1 pageSample Test Certificate (24.12.2022)PalaniyandiNo ratings yet

- Gland 9087 18.12 PDFDocument1 pageGland 9087 18.12 PDFSachin wakeNo ratings yet

- S355J2 Plate MTCDocument2 pagesS355J2 Plate MTCHarminder Kumar100% (1)

- Indiana PresentationDocument62 pagesIndiana PresentationRahulNo ratings yet

- Cable Tray CertificateDocument1 pageCable Tray CertificatePritam MitraNo ratings yet

- Barbed Wire MTC - 230912Document1 pageBarbed Wire MTC - 230912dmtcl selcp1No ratings yet

- Tram Grooved Rails New Catalog January 2018Document12 pagesTram Grooved Rails New Catalog January 2018Szabolcs Attila KöllőNo ratings yet

- TSL Bhushan - Colour CoatedDocument21 pagesTSL Bhushan - Colour Coatedabdul jawad100% (1)

- Technical Specification - Waterproof Junction Boxes IP65Document2 pagesTechnical Specification - Waterproof Junction Boxes IP65Gerald FritchNo ratings yet

- 0707711343Document2 pages0707711343venkata krishna reddy MorthlaNo ratings yet

- Rate Analysis Earthen Dam (13-14)Document123 pagesRate Analysis Earthen Dam (13-14)Mehta MalayNo ratings yet

- RMT465477 OK Flux 1071L F7A4 F7P5 EH14 DSDocument1 pageRMT465477 OK Flux 1071L F7A4 F7P5 EH14 DSharikrishnanNo ratings yet

- Panel Rate AnalysisDocument9 pagesPanel Rate AnalysisTreesa Archnana100% (1)

- Goel TMT Physical Report-SignedDocument4 pagesGoel TMT Physical Report-Signedsitaramap10 sathupallyNo ratings yet

- JSW Steel MTCDocument5 pagesJSW Steel MTCNelson 2428No ratings yet

- Weight of G.I.Strip Flat KG MT.: X X X X X X X X XDocument2 pagesWeight of G.I.Strip Flat KG MT.: X X X X X X X X XHiral SolankiNo ratings yet

- Gatepass: 1 2 3 4 5 6 7 8 9 10 Requested By: Approved byDocument2 pagesGatepass: 1 2 3 4 5 6 7 8 9 10 Requested By: Approved byJohn DyNo ratings yet

- MVCC-Tech SpecDocument3 pagesMVCC-Tech Specvishnu ojhaNo ratings yet

- BCH Enclosure Price List JULY2017Document18 pagesBCH Enclosure Price List JULY2017rcv436No ratings yet

- Offshore A312A358 R2Document1 pageOffshore A312A358 R2Prathamesh OmtechNo ratings yet

- Cable TCDocument1 pageCable TCSachin wakeNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.maharia_22No ratings yet

- PSP TCDocument7 pagesPSP TCPSP kanpurdehatNo ratings yet

- Zhengbang Super Alloy Ltd.: BS EN 10204.3.1/产品质量证明Document1 pageZhengbang Super Alloy Ltd.: BS EN 10204.3.1/产品质量证明Sales HBS SolutionsNo ratings yet

- Page 1 of 1: Test Certificate No. 0000141878Document1 pagePage 1 of 1: Test Certificate No. 0000141878Vishwanathan NagarajanNo ratings yet

- MOE Simplex - 24.06.2016 PDFDocument4 pagesMOE Simplex - 24.06.2016 PDFSabyasachi BangalNo ratings yet

- PRICE - LIST Recd From Amrender On - 20-4-2017Document11 pagesPRICE - LIST Recd From Amrender On - 20-4-2017naresh singlaNo ratings yet

- Price List No. 164 Price List No. 164Document12 pagesPrice List No. 164 Price List No. 164mshNo ratings yet

- TC Epilux 610 Prime CTNG.Document1 pageTC Epilux 610 Prime CTNG.Tarun KaushalNo ratings yet

- Letter - 31072023 - Process Inspection Charges by RITESDocument5 pagesLetter - 31072023 - Process Inspection Charges by RITES1005 ABIRAME H.SNo ratings yet

- IS 2062 E250A 25mm PlateDocument3 pagesIS 2062 E250A 25mm PlateKandula RajuNo ratings yet

- Commented - 8' PIPE TCDocument1 pageCommented - 8' PIPE TCAqib Khan VCSPNo ratings yet

- QAP For MS Pipes RevisedDocument3 pagesQAP For MS Pipes RevisedAnuj PandeyNo ratings yet

- GLN 703 Specs - TdsDocument1 pageGLN 703 Specs - TdsAnonymous MDkp0hnb3lNo ratings yet

- JSW Steel LimitedDocument1 pageJSW Steel LimitedVenkatesh KumarNo ratings yet

- Jai Balaji All Products Price List Wef 18-08-2021Document55 pagesJai Balaji All Products Price List Wef 18-08-2021M/S.TEJEET ELECTRICAL & ENGG. CORP.No ratings yet

- Gyproc 2Document3 pagesGyproc 2Govind NataniNo ratings yet

- Ispat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsDocument4 pagesIspat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsAbhi Sheoran100% (2)

- Espol 38.00 Revised 07032016Document2 pagesEspol 38.00 Revised 07032016Vinay YadavNo ratings yet

- Avk Saudi National Price ListDocument52 pagesAvk Saudi National Price Listshafeeqm3086No ratings yet

- Infracem - WK-19Document1 pageInfracem - WK-19Sirajul IslamNo ratings yet

- Mild Steel TMT BarDocument5 pagesMild Steel TMT BarEktaNo ratings yet

- JSW TCDocument2 pagesJSW TCSabyasachi BangalNo ratings yet

- Inspection of Earth WireDocument4 pagesInspection of Earth WireNirmal WiresNo ratings yet

- Mill Bushan SteelDocument14 pagesMill Bushan SteelAnu MuNo ratings yet

- 6X1830 HR CoilDocument1 page6X1830 HR CoilBhavik PanchalNo ratings yet

- MCC Panel OfferDocument9 pagesMCC Panel OfferSrinivas RaoNo ratings yet

- Material Test Certificate: Diamond Pipe Supports Pvt. LTDDocument1 pageMaterial Test Certificate: Diamond Pipe Supports Pvt. LTDAneesh ConstantineNo ratings yet

- Door Cum Partition SectionsDocument27 pagesDoor Cum Partition SectionsPRASENJIT DHARNo ratings yet

- Li# 1 - 3c X 70 + 35mm2 Swa Fr-3 BahraDocument2 pagesLi# 1 - 3c X 70 + 35mm2 Swa Fr-3 BahraMuhammad ShahidNo ratings yet

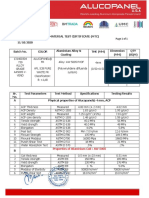

- Material Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Document4 pagesMaterial Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Waleed Obieden100% (1)

- Test Certificate: CM/L-NO:5200036277Document10 pagesTest Certificate: CM/L-NO:5200036277TARUNKUMARNo ratings yet

- DSR Electrical 2012Document78 pagesDSR Electrical 2012জেত বন100% (2)

- Polycab Pricelist 2020 PDFDocument4 pagesPolycab Pricelist 2020 PDFTapas HiraNo ratings yet

- Salt Spray ReportDocument1 pageSalt Spray ReportaslamNo ratings yet

- Consumer LED Lighting Price List: W.E.F. 1 Sep 2019Document24 pagesConsumer LED Lighting Price List: W.E.F. 1 Sep 2019Sanket PhatangareNo ratings yet

- Polycab Flexible CablesDocument13 pagesPolycab Flexible CablesSanket PhatangareNo ratings yet

- Segment Model Name Size (Sweep) MRP: Polycab India LimitedDocument3 pagesSegment Model Name Size (Sweep) MRP: Polycab India LimitedSanket PhatangareNo ratings yet

- Polycab House WiresDocument2 pagesPolycab House WiresSanket PhatangareNo ratings yet

- Bulkhead Catlouge WiproDocument1 pageBulkhead Catlouge WiproSanket PhatangareNo ratings yet

- Technical Datasheet Wipro BulkheadDocument1 pageTechnical Datasheet Wipro BulkheadSanket PhatangareNo ratings yet

- English A Status ReportDocument3 pagesEnglish A Status ReportNataliasol07No ratings yet

- Synergetic Photocatalytic-Activity Enhancement of Lanthanum Doped TiO2 On Halloysite Nanocomposites For Degradation of Organic DyeDocument8 pagesSynergetic Photocatalytic-Activity Enhancement of Lanthanum Doped TiO2 On Halloysite Nanocomposites For Degradation of Organic DyeBachi NanoNo ratings yet

- EC Type-Approval Certificate No. DK0199.274 Revision 2Document1 pageEC Type-Approval Certificate No. DK0199.274 Revision 2MjeriteljXNo ratings yet

- Urban Coherence: A Morphological DefinitionDocument19 pagesUrban Coherence: A Morphological DefinitionOlgu CaliskanNo ratings yet

- Chi-Square and Related DistributionDocument7 pagesChi-Square and Related DistributionMohammedseid AhmedinNo ratings yet

- Hoop DreamsDocument4 pagesHoop DreamsJordan DiFazioNo ratings yet

- Teradata Interview QuestionsDocument11 pagesTeradata Interview QuestionsnarendrareddybanthiNo ratings yet

- Age and Gender DetectionDocument4 pagesAge and Gender DetectionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mowbray SlidesCarnivalDocument30 pagesMowbray SlidesCarnivalschaNo ratings yet

- Comaroff, John L. Rules and Rulers. Political Processes in A Tswana ChiefdownDocument21 pagesComaroff, John L. Rules and Rulers. Political Processes in A Tswana ChiefdownDiego AlbertoNo ratings yet

- s7 200 Smart Pid ManualDocument37 pagess7 200 Smart Pid ManualSửa chữa Biến Tần - Servo - UPSNo ratings yet

- Transit 2006.5 (04/2006-) : New Product IntroductionDocument81 pagesTransit 2006.5 (04/2006-) : New Product Introductionmail4281No ratings yet

- 2008111341644421Document2 pages2008111341644421Mohamad AleemuddinNo ratings yet

- Halfen Cast-In Channels: ConcreteDocument92 pagesHalfen Cast-In Channels: ConcreteFernando Castillo HerreraNo ratings yet

- GSCFF APF TechniquesDocument18 pagesGSCFF APF TechniquesMaharaniNo ratings yet

- Global Crisis ManagementDocument8 pagesGlobal Crisis ManagementSantanu Thomas DeyNo ratings yet

- Marinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Air Start Distributor OperationDocument2 pagesMarinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Air Start Distributor OperationArun SNo ratings yet

- CapstoneDocument16 pagesCapstoneKaithlyn LandichoNo ratings yet

- Aquatic ActivitiesDocument21 pagesAquatic ActivitiesJames Baryl GarceloNo ratings yet

- Classrooms Decide The Future of The Nation by Awais Raza 2K19 ENG 40Document6 pagesClassrooms Decide The Future of The Nation by Awais Raza 2K19 ENG 40Maryam HamdanNo ratings yet

- ARM130A1 - Aermacchi MB.339 Series Archived NOVDocument5 pagesARM130A1 - Aermacchi MB.339 Series Archived NOVLava R5s2019No ratings yet

- Final Module in Principles and Theories in Language AcquisitionDocument14 pagesFinal Module in Principles and Theories in Language AcquisitionChristel VirtucioNo ratings yet

- WMA12 01 Que 20211013Document32 pagesWMA12 01 Que 20211013Md Shahidul Islam IslamNo ratings yet

- Hasegawa v. Giron, G.R. No. 184536, August 14, 2013Document6 pagesHasegawa v. Giron, G.R. No. 184536, August 14, 2013Braian HitaNo ratings yet

- Track Line Safety Inside Tata Steel Works SS/GEN-24: by Sachin ParanjapeDocument14 pagesTrack Line Safety Inside Tata Steel Works SS/GEN-24: by Sachin ParanjapePrakash Kumar100% (1)

- Lecture 6 - RTL SynthesisDocument72 pagesLecture 6 - RTL SynthesisantoniocljNo ratings yet

- Day 2Document11 pagesDay 2KM HiềnNo ratings yet

- Maths Connect 3R Resourcebank-PackDocument176 pagesMaths Connect 3R Resourcebank-Packmusman1977No ratings yet

Technical Data Sheet Earthing Strip

Technical Data Sheet Earthing Strip

Uploaded by

Sanket Phatangare0 ratings0% found this document useful (0 votes)

145 views1 pageThis document is a test report from JetcoTech Engineering LLP regarding galvanized steel strips supplied by Emtec Solutions. [1] It details the material descriptions, quantities tested, and inspection results. [2] Testing was conducted according to relevant IS, BSEN, ASTM specifications for galvanized coating thickness, adhesion, surface finish, and other properties. [3] All test results met requirements and the quality of materials was deemed satisfactory.

Original Description:

TECHNICAL DATA SHEET EARTHING STRIP

Original Title

TECHNICAL DATA SHEET EARTHING STRIP

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is a test report from JetcoTech Engineering LLP regarding galvanized steel strips supplied by Emtec Solutions. [1] It details the material descriptions, quantities tested, and inspection results. [2] Testing was conducted according to relevant IS, BSEN, ASTM specifications for galvanized coating thickness, adhesion, surface finish, and other properties. [3] All test results met requirements and the quality of materials was deemed satisfactory.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

145 views1 pageTechnical Data Sheet Earthing Strip

Technical Data Sheet Earthing Strip

Uploaded by

Sanket PhatangareThis document is a test report from JetcoTech Engineering LLP regarding galvanized steel strips supplied by Emtec Solutions. [1] It details the material descriptions, quantities tested, and inspection results. [2] Testing was conducted according to relevant IS, BSEN, ASTM specifications for galvanized coating thickness, adhesion, surface finish, and other properties. [3] All test results met requirements and the quality of materials was deemed satisfactory.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

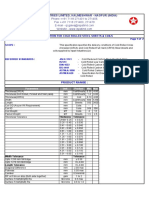

JETCOTECH ENGINEERING LLP

Survey no 44/3p1, Opp. Old Pipli Bus Stand, Jetpar Road, morbi-363642,

Gujarat, India. Mob. +91-9925039423

Client Name: - EMTEC SOLUTIONS T.C. NO. 001

TESTING DATE

G.I. DATE

Sr. No. Material Description Item Code Quantity

1 G.I. Strip 25x6 mm 5750

2 G.I. Strip 50x6 mm 3854

3 G.I. Strip 25x3 mm 650

INSPECTION

Sample from the above quantity for Galvanizing thickness and Surface Appearance Found Satisfactory

Testing of the above Materials were carried out as per IS/BSEN / ASTM SPECIFICATION Detail of which

are as Under:

Sr. No. Specification Test Details Requirement Test Result Observed

1 IS 2629 Thickness Test by 85 Microns 92 Satisfactory

Elcometer 86

90

2 IS 2629 Adhesion Test by Coated Zinc No Flakes of Zinc Satisfactory

ASTM 123 Hammer blow Should Not Flake coating was found,

Weight of hammer off hence adhesion found

210 Gram Adequate

3 IS 2633 Preece Test by Permanent Red No Red Deposit of Satisfactory

CuSO4 SH2O Spots on copper was observed

solution, for galvanizing on Galvanizing dips of

measuring the Surface should one Minute each in

uniformity of coating not be formed CuSO4 SH2O

4 IS 6745 Pipe Test by 610 Gram Per Sq. 630 Gram Per Sq. Mtr. Satisfactory

IS 4759 Antimony trichloride Mtr.

BSEN ISO1461 hydrochloric acid

ASTM A90

5 IS 4736 Visual surface Reasonably No improper Surface Satisfactory

condition smooth & free found

from

imperfections

On the above Inspection & Testing, Material Found conformed to relevant specification and hence

Quality of Material were found Satisfactory.

For, JETCOTECH ENGINEERING LLP.

Q.A. HEAD SIGNATURE

You might also like

- Practical Approaches To Applied Research and Program Evaluation For Helping Professionals 1St Edition PDF Full Chapter PDFDocument50 pagesPractical Approaches To Applied Research and Program Evaluation For Helping Professionals 1St Edition PDF Full Chapter PDFrasmahjonaki34100% (5)

- Summary - Granovetter (1985) Economic Action and Social StructureDocument2 pagesSummary - Granovetter (1985) Economic Action and Social StructureSimon Fiala100% (12)

- Price List: W.E.F. January 01, 2020Document14 pagesPrice List: W.E.F. January 01, 2020SHASHINo ratings yet

- Test CertificateDocument1 pageTest CertificateAvinash JadhavNo ratings yet

- Cable TCDocument1 pageCable TCSachin wakeNo ratings yet

- Data Sheet GI StripDocument1 pageData Sheet GI StripRuchir ChaturvediNo ratings yet

- Fabrication DetailsDocument28 pagesFabrication DetailsPatel MishalNo ratings yet

- Sample Test Certificate (24.12.2022)Document1 pageSample Test Certificate (24.12.2022)PalaniyandiNo ratings yet

- Gland 9087 18.12 PDFDocument1 pageGland 9087 18.12 PDFSachin wakeNo ratings yet

- S355J2 Plate MTCDocument2 pagesS355J2 Plate MTCHarminder Kumar100% (1)

- Indiana PresentationDocument62 pagesIndiana PresentationRahulNo ratings yet

- Cable Tray CertificateDocument1 pageCable Tray CertificatePritam MitraNo ratings yet

- Barbed Wire MTC - 230912Document1 pageBarbed Wire MTC - 230912dmtcl selcp1No ratings yet

- Tram Grooved Rails New Catalog January 2018Document12 pagesTram Grooved Rails New Catalog January 2018Szabolcs Attila KöllőNo ratings yet

- TSL Bhushan - Colour CoatedDocument21 pagesTSL Bhushan - Colour Coatedabdul jawad100% (1)

- Technical Specification - Waterproof Junction Boxes IP65Document2 pagesTechnical Specification - Waterproof Junction Boxes IP65Gerald FritchNo ratings yet

- 0707711343Document2 pages0707711343venkata krishna reddy MorthlaNo ratings yet

- Rate Analysis Earthen Dam (13-14)Document123 pagesRate Analysis Earthen Dam (13-14)Mehta MalayNo ratings yet

- RMT465477 OK Flux 1071L F7A4 F7P5 EH14 DSDocument1 pageRMT465477 OK Flux 1071L F7A4 F7P5 EH14 DSharikrishnanNo ratings yet

- Panel Rate AnalysisDocument9 pagesPanel Rate AnalysisTreesa Archnana100% (1)

- Goel TMT Physical Report-SignedDocument4 pagesGoel TMT Physical Report-Signedsitaramap10 sathupallyNo ratings yet

- JSW Steel MTCDocument5 pagesJSW Steel MTCNelson 2428No ratings yet

- Weight of G.I.Strip Flat KG MT.: X X X X X X X X XDocument2 pagesWeight of G.I.Strip Flat KG MT.: X X X X X X X X XHiral SolankiNo ratings yet

- Gatepass: 1 2 3 4 5 6 7 8 9 10 Requested By: Approved byDocument2 pagesGatepass: 1 2 3 4 5 6 7 8 9 10 Requested By: Approved byJohn DyNo ratings yet

- MVCC-Tech SpecDocument3 pagesMVCC-Tech Specvishnu ojhaNo ratings yet

- BCH Enclosure Price List JULY2017Document18 pagesBCH Enclosure Price List JULY2017rcv436No ratings yet

- Offshore A312A358 R2Document1 pageOffshore A312A358 R2Prathamesh OmtechNo ratings yet

- Cable TCDocument1 pageCable TCSachin wakeNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.maharia_22No ratings yet

- PSP TCDocument7 pagesPSP TCPSP kanpurdehatNo ratings yet

- Zhengbang Super Alloy Ltd.: BS EN 10204.3.1/产品质量证明Document1 pageZhengbang Super Alloy Ltd.: BS EN 10204.3.1/产品质量证明Sales HBS SolutionsNo ratings yet

- Page 1 of 1: Test Certificate No. 0000141878Document1 pagePage 1 of 1: Test Certificate No. 0000141878Vishwanathan NagarajanNo ratings yet

- MOE Simplex - 24.06.2016 PDFDocument4 pagesMOE Simplex - 24.06.2016 PDFSabyasachi BangalNo ratings yet

- PRICE - LIST Recd From Amrender On - 20-4-2017Document11 pagesPRICE - LIST Recd From Amrender On - 20-4-2017naresh singlaNo ratings yet

- Price List No. 164 Price List No. 164Document12 pagesPrice List No. 164 Price List No. 164mshNo ratings yet

- TC Epilux 610 Prime CTNG.Document1 pageTC Epilux 610 Prime CTNG.Tarun KaushalNo ratings yet

- Letter - 31072023 - Process Inspection Charges by RITESDocument5 pagesLetter - 31072023 - Process Inspection Charges by RITES1005 ABIRAME H.SNo ratings yet

- IS 2062 E250A 25mm PlateDocument3 pagesIS 2062 E250A 25mm PlateKandula RajuNo ratings yet

- Commented - 8' PIPE TCDocument1 pageCommented - 8' PIPE TCAqib Khan VCSPNo ratings yet

- QAP For MS Pipes RevisedDocument3 pagesQAP For MS Pipes RevisedAnuj PandeyNo ratings yet

- GLN 703 Specs - TdsDocument1 pageGLN 703 Specs - TdsAnonymous MDkp0hnb3lNo ratings yet

- JSW Steel LimitedDocument1 pageJSW Steel LimitedVenkatesh KumarNo ratings yet

- Jai Balaji All Products Price List Wef 18-08-2021Document55 pagesJai Balaji All Products Price List Wef 18-08-2021M/S.TEJEET ELECTRICAL & ENGG. CORP.No ratings yet

- Gyproc 2Document3 pagesGyproc 2Govind NataniNo ratings yet

- Ispat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsDocument4 pagesIspat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsAbhi Sheoran100% (2)

- Espol 38.00 Revised 07032016Document2 pagesEspol 38.00 Revised 07032016Vinay YadavNo ratings yet

- Avk Saudi National Price ListDocument52 pagesAvk Saudi National Price Listshafeeqm3086No ratings yet

- Infracem - WK-19Document1 pageInfracem - WK-19Sirajul IslamNo ratings yet

- Mild Steel TMT BarDocument5 pagesMild Steel TMT BarEktaNo ratings yet

- JSW TCDocument2 pagesJSW TCSabyasachi BangalNo ratings yet

- Inspection of Earth WireDocument4 pagesInspection of Earth WireNirmal WiresNo ratings yet

- Mill Bushan SteelDocument14 pagesMill Bushan SteelAnu MuNo ratings yet

- 6X1830 HR CoilDocument1 page6X1830 HR CoilBhavik PanchalNo ratings yet

- MCC Panel OfferDocument9 pagesMCC Panel OfferSrinivas RaoNo ratings yet

- Material Test Certificate: Diamond Pipe Supports Pvt. LTDDocument1 pageMaterial Test Certificate: Diamond Pipe Supports Pvt. LTDAneesh ConstantineNo ratings yet

- Door Cum Partition SectionsDocument27 pagesDoor Cum Partition SectionsPRASENJIT DHARNo ratings yet

- Li# 1 - 3c X 70 + 35mm2 Swa Fr-3 BahraDocument2 pagesLi# 1 - 3c X 70 + 35mm2 Swa Fr-3 BahraMuhammad ShahidNo ratings yet

- Material Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Document4 pagesMaterial Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Waleed Obieden100% (1)

- Test Certificate: CM/L-NO:5200036277Document10 pagesTest Certificate: CM/L-NO:5200036277TARUNKUMARNo ratings yet

- DSR Electrical 2012Document78 pagesDSR Electrical 2012জেত বন100% (2)

- Polycab Pricelist 2020 PDFDocument4 pagesPolycab Pricelist 2020 PDFTapas HiraNo ratings yet

- Salt Spray ReportDocument1 pageSalt Spray ReportaslamNo ratings yet

- Consumer LED Lighting Price List: W.E.F. 1 Sep 2019Document24 pagesConsumer LED Lighting Price List: W.E.F. 1 Sep 2019Sanket PhatangareNo ratings yet

- Polycab Flexible CablesDocument13 pagesPolycab Flexible CablesSanket PhatangareNo ratings yet

- Segment Model Name Size (Sweep) MRP: Polycab India LimitedDocument3 pagesSegment Model Name Size (Sweep) MRP: Polycab India LimitedSanket PhatangareNo ratings yet

- Polycab House WiresDocument2 pagesPolycab House WiresSanket PhatangareNo ratings yet

- Bulkhead Catlouge WiproDocument1 pageBulkhead Catlouge WiproSanket PhatangareNo ratings yet

- Technical Datasheet Wipro BulkheadDocument1 pageTechnical Datasheet Wipro BulkheadSanket PhatangareNo ratings yet

- English A Status ReportDocument3 pagesEnglish A Status ReportNataliasol07No ratings yet

- Synergetic Photocatalytic-Activity Enhancement of Lanthanum Doped TiO2 On Halloysite Nanocomposites For Degradation of Organic DyeDocument8 pagesSynergetic Photocatalytic-Activity Enhancement of Lanthanum Doped TiO2 On Halloysite Nanocomposites For Degradation of Organic DyeBachi NanoNo ratings yet

- EC Type-Approval Certificate No. DK0199.274 Revision 2Document1 pageEC Type-Approval Certificate No. DK0199.274 Revision 2MjeriteljXNo ratings yet

- Urban Coherence: A Morphological DefinitionDocument19 pagesUrban Coherence: A Morphological DefinitionOlgu CaliskanNo ratings yet

- Chi-Square and Related DistributionDocument7 pagesChi-Square and Related DistributionMohammedseid AhmedinNo ratings yet

- Hoop DreamsDocument4 pagesHoop DreamsJordan DiFazioNo ratings yet

- Teradata Interview QuestionsDocument11 pagesTeradata Interview QuestionsnarendrareddybanthiNo ratings yet

- Age and Gender DetectionDocument4 pagesAge and Gender DetectionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mowbray SlidesCarnivalDocument30 pagesMowbray SlidesCarnivalschaNo ratings yet

- Comaroff, John L. Rules and Rulers. Political Processes in A Tswana ChiefdownDocument21 pagesComaroff, John L. Rules and Rulers. Political Processes in A Tswana ChiefdownDiego AlbertoNo ratings yet

- s7 200 Smart Pid ManualDocument37 pagess7 200 Smart Pid ManualSửa chữa Biến Tần - Servo - UPSNo ratings yet

- Transit 2006.5 (04/2006-) : New Product IntroductionDocument81 pagesTransit 2006.5 (04/2006-) : New Product Introductionmail4281No ratings yet

- 2008111341644421Document2 pages2008111341644421Mohamad AleemuddinNo ratings yet

- Halfen Cast-In Channels: ConcreteDocument92 pagesHalfen Cast-In Channels: ConcreteFernando Castillo HerreraNo ratings yet

- GSCFF APF TechniquesDocument18 pagesGSCFF APF TechniquesMaharaniNo ratings yet

- Global Crisis ManagementDocument8 pagesGlobal Crisis ManagementSantanu Thomas DeyNo ratings yet

- Marinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Air Start Distributor OperationDocument2 pagesMarinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Air Start Distributor OperationArun SNo ratings yet

- CapstoneDocument16 pagesCapstoneKaithlyn LandichoNo ratings yet

- Aquatic ActivitiesDocument21 pagesAquatic ActivitiesJames Baryl GarceloNo ratings yet

- Classrooms Decide The Future of The Nation by Awais Raza 2K19 ENG 40Document6 pagesClassrooms Decide The Future of The Nation by Awais Raza 2K19 ENG 40Maryam HamdanNo ratings yet

- ARM130A1 - Aermacchi MB.339 Series Archived NOVDocument5 pagesARM130A1 - Aermacchi MB.339 Series Archived NOVLava R5s2019No ratings yet

- Final Module in Principles and Theories in Language AcquisitionDocument14 pagesFinal Module in Principles and Theories in Language AcquisitionChristel VirtucioNo ratings yet

- WMA12 01 Que 20211013Document32 pagesWMA12 01 Que 20211013Md Shahidul Islam IslamNo ratings yet

- Hasegawa v. Giron, G.R. No. 184536, August 14, 2013Document6 pagesHasegawa v. Giron, G.R. No. 184536, August 14, 2013Braian HitaNo ratings yet

- Track Line Safety Inside Tata Steel Works SS/GEN-24: by Sachin ParanjapeDocument14 pagesTrack Line Safety Inside Tata Steel Works SS/GEN-24: by Sachin ParanjapePrakash Kumar100% (1)

- Lecture 6 - RTL SynthesisDocument72 pagesLecture 6 - RTL SynthesisantoniocljNo ratings yet

- Day 2Document11 pagesDay 2KM HiềnNo ratings yet

- Maths Connect 3R Resourcebank-PackDocument176 pagesMaths Connect 3R Resourcebank-Packmusman1977No ratings yet