Professional Documents

Culture Documents

Schindler 9700 Operation & Maintenance Manual 2012

Schindler 9700 Operation & Maintenance Manual 2012

Uploaded by

KonstarothCopyright:

Available Formats

You might also like

- Troubleshooting Schindler Miconic TX and TX-GCDocument31 pagesTroubleshooting Schindler Miconic TX and TX-GCDon Luong100% (1)

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- Orion - Gulliver Vertical Platform Lift: User ManualDocument24 pagesOrion - Gulliver Vertical Platform Lift: User ManualSuraj Yadav100% (1)

- Board Lisa 20 ErrorDocument28 pagesBoard Lisa 20 ErrorYok MulyonoNo ratings yet

- Schindler Spare Part Price List Y2020 TTDocument29 pagesSchindler Spare Part Price List Y2020 TTmirza farouq100% (2)

- Ctrl70a V101 2019 3 15Document53 pagesCtrl70a V101 2019 3 15Ali DiabNo ratings yet

- TM Pte 01 - Port 1.2: The PORT Technology - Technical DocumentsDocument64 pagesTM Pte 01 - Port 1.2: The PORT Technology - Technical DocumentsResul Şenay100% (1)

- E-Series HR Escalator With S-Controller Service GuideDocument71 pagesE-Series HR Escalator With S-Controller Service GuideJeffrey Newman100% (1)

- Technical Manual and Electronical Regulation Vvvf-4: Cabin DoorsDocument7 pagesTechnical Manual and Electronical Regulation Vvvf-4: Cabin DoorsMohammed Qaid AlathwaryNo ratings yet

- Afpelevator Doorcontroller Ec10 DDocument40 pagesAfpelevator Doorcontroller Ec10 DTroubleshootingNo ratings yet

- Fermator Car Door CD30 Maintenance Manual Premium - 09.18Document76 pagesFermator Car Door CD30 Maintenance Manual Premium - 09.18alfrelia0% (1)

- Adjusting Diana Brake ImemDocument16 pagesAdjusting Diana Brake Imemgrenui100% (1)

- J264103 - en - 1 - Commissioning & Diagnosis of DO DSF 9 Door DriveDocument30 pagesJ264103 - en - 1 - Commissioning & Diagnosis of DO DSF 9 Door DrivePio Rodolfo50% (2)

- 100 - 1. Lift Controller ManualDocument41 pages100 - 1. Lift Controller ManualDjordje GavrilovicNo ratings yet

- Decoder For Monarch - STEP ManualDocument7 pagesDecoder For Monarch - STEP ManualMohammed HussenNo ratings yet

- ASG-11.65.031 Maintenance KDL32Document12 pagesASG-11.65.031 Maintenance KDL32Mike Rushe100% (1)

- RL19560 Schematics XXDocument26 pagesRL19560 Schematics XXAsif AbbasovNo ratings yet

- Service Manual: Diagnosis Code ListDocument55 pagesService Manual: Diagnosis Code Listyveshouthoofdthotmail.comNo ratings yet

- Schindler Escalator 9700AE - Brake MaintenanceDocument4 pagesSchindler Escalator 9700AE - Brake MaintenanceHùng VĩNo ratings yet

- k604522 MX Basic Fixtures Mantto PDFDocument49 pagesk604522 MX Basic Fixtures Mantto PDFBenjamin Gonzalez100% (1)

- KONE LCE375 Control System: Quick Reference K 42512000 - 03 Edition 10-2009Document156 pagesKONE LCE375 Control System: Quick Reference K 42512000 - 03 Edition 10-2009Don LuongNo ratings yet

- Schindler SMART 002 LED Error CodesDocument9 pagesSchindler SMART 002 LED Error CodesDon Luong100% (1)

- Evacuation Instruction Schindler: EuroliftDocument2 pagesEvacuation Instruction Schindler: EuroliftMartynas Karkauskas100% (1)

- 2 (A) - TKE Door Operator - HD-03 HD-04 W IMSDocument68 pages2 (A) - TKE Door Operator - HD-03 HD-04 W IMSNickNo ratings yet

- Schéma Électrique WitturDocument19 pagesSchéma Électrique WitturMoh DaraNo ratings yet

- Thyssen-DiagnosticDocument55 pagesThyssen-Diagnosticraymon janszenNo ratings yet

- Shindler MarcoDocument51 pagesShindler MarcoBLT ChuchinNo ratings yet

- Mitsubishi Elevator GPS-III Fault Code - A Water Logging - Netease BlogDocument7 pagesMitsubishi Elevator GPS-III Fault Code - A Water Logging - Netease BlogTroubleshootingNo ratings yet

- Kone Nanospace PDFDocument45 pagesKone Nanospace PDFgustavo sanchezNo ratings yet

- Yaskawa L1000A Lift Application Short EN ManualDocument41 pagesYaskawa L1000A Lift Application Short EN ManualGogik AntoNo ratings yet

- Field Test Genius 20 - GearlessDocument3 pagesField Test Genius 20 - GearlessStefan Hodan100% (1)

- Modu-Tool Basic Operating Instructions PDFDocument2 pagesModu-Tool Basic Operating Instructions PDFAliRouyouNo ratings yet

- OTIS 506, 506SL, 510 UNITS: Precision Escalator Products, IncDocument10 pagesOTIS 506, 506SL, 510 UNITS: Precision Escalator Products, IncmohammedalathwaryNo ratings yet

- HATMSI47 1811 E - OPC LM1 PR - ManualDocument14 pagesHATMSI47 1811 E - OPC LM1 PR - ManualMahran Mastouri100% (1)

- Orona Arca3 SchémasDocument38 pagesOrona Arca3 Schémasmahfoud ascenseursNo ratings yet

- S45933449 1 PDFDocument3 pagesS45933449 1 PDFLieven BenoitNo ratings yet

- 104 Door Control Board PM-SSCDocument16 pages104 Door Control Board PM-SSCKevin SilvaNo ratings yet

- Variador Kone V3f20 InglésDocument30 pagesVariador Kone V3f20 InglésRDRNo ratings yet

- Mantenimiento Maquina de TraccionDocument23 pagesMantenimiento Maquina de TraccionGustavo ZambranoNo ratings yet

- KONE - Machine Room Type - 1600 KG, Speed 2.5 PDFDocument1 pageKONE - Machine Room Type - 1600 KG, Speed 2.5 PDFNghia100% (1)

- Controller With EMIDocument11 pagesController With EMIMohammed Qaid AlathwaryNo ratings yet

- BMT Basic Maintenance Tasks For KONE Monospace With KCE TechnologyDocument24 pagesBMT Basic Maintenance Tasks For KONE Monospace With KCE TechnologyMohammad Younus BaigNo ratings yet

- Escalator Travolator Servicetool DAA31402AAD - STMDocument49 pagesEscalator Travolator Servicetool DAA31402AAD - STMCoil9850% (2)

- Microzed V Microzed V3.5 3.5: User'S ManualDocument58 pagesMicrozed V Microzed V3.5 3.5: User'S ManualKhaled ZakariaNo ratings yet

- System Galaxy Quick Guide: Configuration and OperationDocument47 pagesSystem Galaxy Quick Guide: Configuration and OperationTushar ImranNo ratings yet

- Ba TW45C 08 12 enDocument64 pagesBa TW45C 08 12 enangela1590100% (1)

- GLE IMEM TREND Fault 67-71Document7 pagesGLE IMEM TREND Fault 67-71Ash100% (1)

- AM-04.08.021 Brake MxMachDocument6 pagesAM-04.08.021 Brake MxMachFERNSNo ratings yet

- EM-1 ManualDocument32 pagesEM-1 ManualDale Peacock100% (1)

- ASG-10 20 008 - Main - en A 1Document10 pagesASG-10 20 008 - Main - en A 1Polinho Donacimento100% (2)

- iV5L Manual ENG J55w6muhDocument388 pagesiV5L Manual ENG J55w6muhMohammad ShayebNo ratings yet

- HAMCB Debugging ManualDocument39 pagesHAMCB Debugging ManualMACRO TECH LLC100% (1)

- 25 TM Installation ManualDocument18 pages25 TM Installation ManualReynold Suarez83% (6)

- CT Unidrive SP Elevator Solution Software User Guide - Issue 3 PDFDocument222 pagesCT Unidrive SP Elevator Solution Software User Guide - Issue 3 PDFjayb1984No ratings yet

- NICE1000 Elevator Integrated Controller: Setup Manual - Brief Version 1.4Document51 pagesNICE1000 Elevator Integrated Controller: Setup Manual - Brief Version 1.4Habibulla BavajiNo ratings yet

- SICON-2001 Operation ManualDocument61 pagesSICON-2001 Operation ManualMohammed Qaid Alathwary100% (1)

- AS-11.65.031 KDL32 RepairDocument48 pagesAS-11.65.031 KDL32 RepairMike Rushe100% (1)

- Elevator Mechanic's Helper: Passbooks Study GuideFrom EverandElevator Mechanic's Helper: Passbooks Study GuideNo ratings yet

- Daily DSR Gomd-V 19-02-2024Document28 pagesDaily DSR Gomd-V 19-02-2024amit kumarNo ratings yet

- TD830Document47 pagesTD830edomaldoNo ratings yet

- Electrical Principles (EET0113) : Direct Current (DC)Document10 pagesElectrical Principles (EET0113) : Direct Current (DC)Amirah MohdNo ratings yet

- Ultra Thin Fan Coil - Arctic Heat PumpsDocument9 pagesUltra Thin Fan Coil - Arctic Heat Pumpsjohnking5555No ratings yet

- E5 Electromagnetic Induction s2 A2324Document14 pagesE5 Electromagnetic Induction s2 A2324AJ CarambasNo ratings yet

- Rotating Machinery (ETD 15) - Electrotechnical Division-Public Safety Standards of IndiaDocument6 pagesRotating Machinery (ETD 15) - Electrotechnical Division-Public Safety Standards of IndiasasikumarNo ratings yet

- A Compact Microstrip-Fed Patch Antenna With Enhanced Bandwidth and Harmonic SuppressionDocument8 pagesA Compact Microstrip-Fed Patch Antenna With Enhanced Bandwidth and Harmonic SuppressionBouhafs AbdelkaderNo ratings yet

- User Guide: English (3 - 6)Document24 pagesUser Guide: English (3 - 6)Rafa Redondo PianistaNo ratings yet

- Advance MemoryDocument56 pagesAdvance MemoryPratyush MishraNo ratings yet

- Metallized Polyproplene Film Capacitor Mpe: FeaturesDocument5 pagesMetallized Polyproplene Film Capacitor Mpe: FeaturesJulian MataNo ratings yet

- BALLUFDocument12 pagesBALLUFSting DâuNo ratings yet

- Amplificador de Potencia de Baja Frecuencia Cd8227gpDocument8 pagesAmplificador de Potencia de Baja Frecuencia Cd8227gplaboratorio fercorNo ratings yet

- Balanza para Extraccion de Sangre Ae 500a v2 Manual de Servicio Tecnico - CompressDocument43 pagesBalanza para Extraccion de Sangre Ae 500a v2 Manual de Servicio Tecnico - Compressbioingenieria houssayNo ratings yet

- Validating Surge TestDocument9 pagesValidating Surge Testquality10No ratings yet

- Electric Circuit Fundamentals: Essential QuestionDocument15 pagesElectric Circuit Fundamentals: Essential QuestionMOBILEE CANCERERNo ratings yet

- Wibotic Aerial DS-4PGDocument3 pagesWibotic Aerial DS-4PGJuanito PerezNo ratings yet

- Selector Guide PDFDocument45 pagesSelector Guide PDFTudosie AlexeyNo ratings yet

- Diomedes: Inno Vation T Ha T Lif Tsy OuDocument2 pagesDiomedes: Inno Vation T Ha T Lif Tsy Outhanggimme.phanNo ratings yet

- Fabrication of Windmill Power Generator PDFDocument2 pagesFabrication of Windmill Power Generator PDFKellyNo ratings yet

- (Neopis) Epic U300 Manual 20210702 RevDocument80 pages(Neopis) Epic U300 Manual 20210702 RevTrương Quốc HuyNo ratings yet

- Future Challenges For Electric VehiclesDocument3 pagesFuture Challenges For Electric VehiclesIQPC GmbHNo ratings yet

- Ca 250Document20 pagesCa 250KALIL100% (1)

- A PH Meter Has A Membrane That Allows Acidic IonsDocument4 pagesA PH Meter Has A Membrane That Allows Acidic IonsWaltas KariukiNo ratings yet

- 20 KV Transmission LineDocument21 pages20 KV Transmission LineOctavianto ZakiNo ratings yet

- Webinar - Gerakan Inisiatif Listrik Tenaga Surya - 20210619Document25 pagesWebinar - Gerakan Inisiatif Listrik Tenaga Surya - 20210619Abbi Pamungkas100% (1)

- Objective Type QuestionsDocument6 pagesObjective Type QuestionscoolkannaNo ratings yet

- EEE 4 1 CS Syllabus - UG - R20Document52 pagesEEE 4 1 CS Syllabus - UG - R20Sai Hari Nath ReddyNo ratings yet

- NSP4201MR6 ESD and Surge Protection DeviceDocument7 pagesNSP4201MR6 ESD and Surge Protection DeviceBelkis Amion AlbonigaNo ratings yet

- Datasheet 545W BIFACIALDocument2 pagesDatasheet 545W BIFACIALJoryel CapelNo ratings yet

- Low Power Ic SyllabusDocument2 pagesLow Power Ic SyllabusjayaprasadkalluriNo ratings yet

Schindler 9700 Operation & Maintenance Manual 2012

Schindler 9700 Operation & Maintenance Manual 2012

Uploaded by

KonstarothOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Schindler 9700 Operation & Maintenance Manual 2012

Schindler 9700 Operation & Maintenance Manual 2012

Uploaded by

KonstarothCopyright:

Available Formats

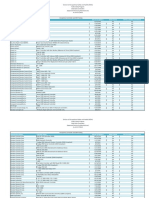

4 Escalator Control System PLC Operating State Messages and Error Codes J 572 810

6 Error Table

Error properties:

+A = safety brake

+C = electronically interlocked

Display Error

Abbreviation Error Message Corrective Actions Ref. Doc.

Code Properties

00-JR_T/B-Start key

00 E_JR_T/B Q 409 661

SW (Not Centered)

Check combs for damage

Check step for damage (before and

beneath the combplate)

Check whether:

Combplate contact, combplate returns to its initial

10 E_KKP_TL position Q 409 460

top left

side adjusting screws are set too

tightly

skirt panel touches combplate

antilift screws are set too low

combplate guide is heavily fouled

Check handrail entry for trapped

foreign objects

Handrail entry contact,

11 E_KHLE_TL Check rubber collar for damage Q 409 653

top left

Check collar for correct setting

Check contact setting

Check for foreign objects trapped

between step and skirting

12 E_KSL_TL Skirt contact, top left Q 409 648

Check for visible defects of step or

skirting

Check stop button for damage

14 E_DH_T Emergency stop, top Q 409 661

Start the unit

Check combs for damage

Check step for damage (before and

beneath the combplate)

Check whether:

combplate returns to its initial

Combplate contact,

15 E_KKP_BL position Q 409 460

bottom left

side adjusting screws are set too

tightly

skirt panel touches combplate

antilift screws are set too low

combplate guide is heavily fouled

Check handrail entry for trapped

foreign objects

Handrail entry contact,

16 E_KHLE_BL Check rubber collar for damage Q 409 653

bottom left

Check collar for correct setting

Check contact setting

Visual check of step band

Chain tension contact, Check contact setting

17 E_KKS_BR +C Q 409 602

bottom right Check spring tension

Reset error

Check INBMG

Activate inspection operation

18 E_INBMG 15% motor overspeed +C Perform technical test Volume VJ

Check sensor setting

Reset error

Foggy Bottom Station Operation & Maintenance Manual 4-31

Washington Metropolitan Area Transit Authority

4 Escalator Control System PLC Operating State Messages and Error Codes J 572 810

Display Error

Abbreviation Error Message Corrective Actions Ref. Doc.

Code Properties

Check chain tension

Check chain for excessive elongation

Drive chain contact, Check chain for breakage

19 E_KAK_R +A +C Q 409 453

right Reset error

Release the safety brake, if available

(during down travel)

Check for smoke or dust

1A E_KBFM_T Smoke detector, top

Check smoke detector functionality

Check all three phases (measure

between ground and phase)

Check INBMG

1C E_INBMG_MU Motor underspeed +C Activate inspection operation Volume VJ

Perform technical test

Check sensor setting

Reset error

Check for trapped objects:

between riser and rear edge of

Step upthrust contact,

1D E_KUS_TR adjacent step Q 409 709

top right

between riser and skirting (during

down travel)

Check for foreign objects trapped

between

Skirt contact, bottom

1F E_KSL_BL step and skirting Q 409 648

left

Check for visible defects of step or

skirting

Check motor temperature

24 E_WTHM_TR Motor thermistor, right With PES versions A to C, connect the

PTC resistor between 1 and A2

(instead of 2)

Check whether the motor, SB, SKV

and SRE contactors are in position of

Contactor dropout

25 E_SFE rest

check

Check whether the SFE contactor picks

up

Check steps for damage and deflection

ATTENTION:

Inspection run only possible with

KKA-B jumpered in the safety circuit

Step level contact, Reset error

28 E_KKA_B +C Manually reset step level contact (if Q 409 601

bottom

error cannot be reset electronically

mechanically interlocked design)

DO NOT FORGET to remove jumper

from KKA-B in the safety circuit

afterwards

2A E_JH_T Stop button, top Release the JH-T switch Q 409 480

Handrail rupture Check handrail for damage or breakage

2B E_KHLB_BL Q 409 650

contact Check handrail tension

2C E_JH_B Stop button, bottom Release the JH-B switch Q 409 480

Controlled drive Read out error on GFU (see error table

2D E_KSGFU

failure GFU reference manual)

Check INVK-T and INVK-B

Activate inspection operation

30 E_INVK_TB1 15% PLC-S overspeed +C Q 409 710

Perform technical tests

Reset error

Foggy Bottom Station Operation & Maintenance Manual 4-32

Washington Metropolitan Area Transit Authority

4 Escalator Control System PLC Operating State Messages and Error Codes J 572 810

Display Error

Abbreviation Error Message Corrective Actions Ref. Doc.

Code Properties

Check drive chain for breakage

Check INVK-T and INVK-B

Activate inspection operation

Perform technical tests

31 E_INVK_TB2 PLC-S underspeed +C Check whether main contactors pick Q 409 710

up

Check whether the motor has all three

phases present

Reset error

Check handrail speed

Handrail monitor, left Try to stop the handrail by hand

32 E_INHL_ML Q 409 650

PLC-M Activate inspection operation

Perform technical test

Check handrail speed

Handrail monitor, Try to stop the handrail by hand

33 E_INHL_MR Q 409 650

right PLC-M Activate inspection operation

Perform technical test

Check power supply of brake solenoid

34 E_MGB Service brake contact Volume VJ

Check brake solenoid for malfunction

Check pawl setting

35 E_MGBA Active safety brake Check pawl for free movement Q 409 710

Check lifting solenoid of pawl

Check steps for damage and deflection

ATTENTION:

Inspection run only possible with

KKA-B jumpered in the safety circuit

Reset error

36 E_KKA_T Step level contact, top +C Manually reset step level contact (if Q 409 601

error cannot be reset electronically

mechanically interlocked design)

DO NOT FORGET to remove jumper

from KKA-B in the safety circuit

afterwards

Check INBMG

Initiator for braking

38 E_INBMG_FLT Activate inspection operation Volume VJ

distance measurement

Perform technical test

Check step or pallet band for

completeness

Check power supply of initiator

Missing step or pallet,

39 E_INVK_T1 +C Check initiator setting Q 409 465

top, PLC-S

Activate inspection operation

Perform technical tests

Reset error

Check power supply of initiator

Check initiator setting

Initiator defective, top,

3A E_INVK_T2 Activate inspection operation Q 409 465

PLC-S

Perform technical tests

Replace initiator (if defective)

Foggy Bottom Station Operation & Maintenance Manual 4-33

Washington Metropolitan Area Transit Authority

4 Escalator Control System PLC Operating State Messages and Error Codes J 572 810

Display Error

Abbreviation Error Message Corrective Actions Ref. Doc.

Code Properties

Check step or pallet band for

completeness

Check power supply of initiator

Missing step or pallet,

3B E_INVK_B1 +C Check initiator setting Q 409 465

bottom, PLC-S

Activate inspection operation

Perform technical tests

Reset error

Check power supply of initiator

Check initiator setting

Initiator defective,

3C E_INVK_B2 Activate inspection operation Q 409 465

bottom, PLC-S

Perform technical tests

Replace initiator (if defective)

Check INVK-T and INVK-B

15% PLC-M Activate inspection operation

3E E_INVK_TB3 +C Q 409 710

overspeed Perform technical tests

Reset error

Check drive chain for breakage

Check INVK-T and INVK-B

Activate inspection operation

Perform technical tests

3F E_INVK_TB4 PLC-M underspeed +C Check whether main contactors pick Q 409 710

up

Check whether the motor has all three

phases present

Reset error

Wait for 5 minutes

43 E_KOMH_TR Oil level, drive motor Q 409 447

Manually check oil level

Close inspection cover

Activate "Engineer on Site"

Cover of inspection

45 E_PRE_T Open inspection cover Q 409 480

outlet open, top

Check whether the SRE contactor

drops out

Check handrail entry for trapped

foreign objects

Handrail entry contact,

48 E_KHLE_TR Check rubber collar for damage Q 409 653

top right

Check collar for correct setting

Check contact setting

Check handrail entry for trapped

foreign objects

Handrail entry contact,

49 E_KHLE_BR Check rubber collar for damage Q 409 653

bottom right

Check collar for correct setting

Check contact setting

Check combs for damage

Check step for damage (before and

beneath the combplate)

Check whether:

combplate returns to its initial

Combplate contact,

4A E_KKP_TR position Q 409 460

top right

side adjusting screws are set too

tightly

skirt panel touches combplate

antilift screws are set too low

combplate guide is heavily fouled

Foggy Bottom Station Operation & Maintenance Manual 4-34

Washington Metropolitan Area Transit Authority

4 Escalator Control System PLC Operating State Messages and Error Codes J 572 810

Display Error

Abbreviation Error Message Corrective Actions Ref. Doc.

Code Properties

Check combs for damage

Check step for damage (before and

beneath the combplate)

Check whether:

combplate returns to its initial

Combplate contact,

4B E_KKP_BR position Q 409 460

bottom right

side adjusting screws are set too

tightly

skirt panel touches combplate

antilift screws are set too low

combplate guide is heavily fouled

Check pcb connector for proper fit

Safety circuit

4C E_RSK Check how far the safety circuit is

interruption

energized

Check handrail speed

Handrail monitor, left, Try to stop the handrail by hand

50 E_INHL_L Q 409 650

PLC-S Activate inspection operation

Perform technical test

Check handrail speed

Handrail monitor, Try to stop the handrail by hand

51 E_INHL_R Q 409 650

right, PLC-S Activate inspection operation

Perform technical test

Check relay

53 E_SEIS Seismic monitor

Check external evaluation

Check for soiling

55 E_WFU Braking resistor Short circuits to ground

Check resistance value

57 E_JEOS_T Engineer on Site

Close inspection cover

Activate "Engineer on Site"

Cover of inspection

75 E_PRE_B Open inspection cover Q 409 480

outlet open, bottom

Check whether the SRE contactor

drops out

Check for trapped objects:

between riser and rear edge of

Step upthrust contact,

7B E_KUS_TL adjacent step Q 409 709

top left

between riser and skirting (during

down travel)

Motor Right overload

80 E_JMH Q 409 478

device

Check whether the step chain locking

Step chain locking device is engaged

86 E_KBV_L Q 409 926

device contact, top left Check contact setting

Reset error

Visual check of step band

Chain tension contact, Check contact setting

87 E_KKS_BL +C Q 409 602

bottom left Check spring tension

Reset error

Check for trapped objects:

between riser and rear edge of

Step upthrust contact,

88 E_KUS_BL adjacent step Q 409 709

bottom left

between riser and skirting (during

down travel)

PLC-M drive chain

8E E_KAK_M Q 409 453

contacts P1227

Foggy Bottom Station Operation & Maintenance Manual 4-35

Washington Metropolitan Area Transit Authority

4 Escalator Control System PLC Operating State Messages and Error Codes J 572 810

Display Error

Abbreviation Error Message Corrective Actions Ref. Doc.

Code Properties

PLC-S drive chain

8F E_KAK_S Q 409 453

contacts P1233

Thermal switch brake

90 E_THBB_R Volume VJ

band, right

Check rollers for minimum thickness

Chain roller detection

C0 E_INCRW-L Check sensor setting Q 409 465A

left

Reset error

Check rollers for minimum thickness

Step roller detection

C1 E_INSRW-L Check sensor setting Q 409 465A

left

Reset error

Check rollers for minimum thickness

Chain roller detection

C2 E_INCRW-R Check sensor setting Q 409 465A

right

Reset error

Check rollers for minimum thickness

Step roller detection

C3 E_INSRW-R Check sensor setting Q 409 465A

right

Reset error

Check INBMG

Activate inspection operation

Perform technical test

CC E_INBMG_MO 25% motor overspeed +A +C Check sensor setting Volume VJ

Reset error

Release the safety brake, if available

(during down travel)

Check INVK-T and INVK-B

Activate inspection operation

CE E_INVK_TB5 25% PLC-S overspeed +A +C Q 409 710

Perform technical tests

Reset error

Check INVK-T and INVK-B

25% PLC-M Activate inspection operation

CF E_INVK_TB6 +A +C Q 409 710

overspeed Perform technical tests

Reset error

Motor disconnect

D0 E_JMH1_R Q 409 478

switch, right

Smoke detector, Check for smoke or dust

D1 E_KBFM_B

bottom Check smoke detector functionality

Check for trapped objects:

between riser and rear edge of

Step upthrust contact,

D8 E_KUS_BR adjacent step Q 409 709

bottom right

between riser and skirting (during

down travel)

Check brake pad for minimum

Brake pad monitor,

D9 E_INBB thickness Volume VJ

service brake

Replace brake pad (if too thin)

Check emergency stop at remote

Stop button, customer-

DA E_RHBS location

provided

Check the RHBS relay

DB E_KWS_B Water level monitor Check for ingress of water Q 409 484

Check automatic lubrication system

Central lubrication Level switch

DF E_KDZS Q 409 924

pressure Manometric switch

State of lines

Foggy Bottom Station Operation & Maintenance Manual 4-36

Washington Metropolitan Area Transit Authority

4 Escalator Control System PLC Operating State Messages and Error Codes J 572 810

Display Error

Abbreviation Error Message Corrective Actions Ref. Doc.

Code Properties

Check for foreign objects trapped

between step and skirting

E0 E_KSL_TR Skirt contact, top right Q 409 648

Check for visible defects of step or

skirting

Check for foreign objects trapped

Skirt contact, bottom between step and skirting

E1 E_KSL_BR Q 409 648

right Check for visible defects of step or

skirting

Emergency stop, Check stop button for damage

E4 E_DH_B Q 409 661

bottom Start the unit

Handrail rupture

E5 E_KHLB_BR Q 409 650

contact, bottom right

Check step or pallet band for

completeness

Check power supply of initiator

Missing step or pallet,

E7 E_INVK_B3 +C Check initiator setting Q 409 465

bottom, PLC-M

Activate inspection operation

Perform technical tests

Reset error

Check braking distance

Braking distance Check INBMG

EA E_INBMG_D +A +C Volume VJ

exceeded Activate inspection operation

Perform technical test

Check power supply of initiator

Check initiator setting

Initiator defective, top,

EC E_INVK_T3 Activate inspection operation Q 409 465

PLC-M

Perform technical tests

Replace initiator (if defective)

EF E_MSP Motor overload device

Check step or pallet band for

completeness

Check power supply of initiator

Missing step or pallet,

F0 E_INVK_T4 +C Check initiator setting Q 409 465

top, PLC-M

Activate inspection operation

Perform technical tests

Reset error

Check power supply of initiator

Check initiator setting

Initiator defective,

F1 E_INVK_B4 Activate inspection operation Q 409 465

bottom, PLC-M

Perform technical tests

Replace initiator (if defective)

RGBA contactor Check function of RGBA and RGBA1

F7 E_RGBA +C

dropout check relays

SCct bypass test

F8 E_RSK_BP

failure

Communication Check cable and connections

FA E_COMMCM

failure PLCM

Communication Check cable and connections

FB E_COMMCS

failure PLCS Check 24 VDC on PLCS

Check cable and connections

Communication

FC E_COMMTJ Check 24 VDC on bus coupler at TJ

failure COUPLER TJ

Replace fuse

Foggy Bottom Station Operation & Maintenance Manual 4-37

Washington Metropolitan Area Transit Authority

4 Escalator Control System PLC Operating State Messages and Error Codes J 572 810

Display Error

Abbreviation Error Message Corrective Actions Ref. Doc.

Code Properties

Check cable and connections

Communication

FD E_COMMBJ Check 24 VDC on bus coupler at BJ

failure COUPLER BJ

Replace fuse

Communication Check cable and connections

FE E_COMMVFD

failure VFD Establish incoming power

Redundancy check Check above conditions

FF E_REDNCY

PLCM & PLCS

PARA verification

J7 E_J7

error PLC-M/PLC-S

Foggy Bottom Station Operation & Maintenance Manual 4-38

Washington Metropolitan Area Transit Authority

You might also like

- Troubleshooting Schindler Miconic TX and TX-GCDocument31 pagesTroubleshooting Schindler Miconic TX and TX-GCDon Luong100% (1)

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- Orion - Gulliver Vertical Platform Lift: User ManualDocument24 pagesOrion - Gulliver Vertical Platform Lift: User ManualSuraj Yadav100% (1)

- Board Lisa 20 ErrorDocument28 pagesBoard Lisa 20 ErrorYok MulyonoNo ratings yet

- Schindler Spare Part Price List Y2020 TTDocument29 pagesSchindler Spare Part Price List Y2020 TTmirza farouq100% (2)

- Ctrl70a V101 2019 3 15Document53 pagesCtrl70a V101 2019 3 15Ali DiabNo ratings yet

- TM Pte 01 - Port 1.2: The PORT Technology - Technical DocumentsDocument64 pagesTM Pte 01 - Port 1.2: The PORT Technology - Technical DocumentsResul Şenay100% (1)

- E-Series HR Escalator With S-Controller Service GuideDocument71 pagesE-Series HR Escalator With S-Controller Service GuideJeffrey Newman100% (1)

- Technical Manual and Electronical Regulation Vvvf-4: Cabin DoorsDocument7 pagesTechnical Manual and Electronical Regulation Vvvf-4: Cabin DoorsMohammed Qaid AlathwaryNo ratings yet

- Afpelevator Doorcontroller Ec10 DDocument40 pagesAfpelevator Doorcontroller Ec10 DTroubleshootingNo ratings yet

- Fermator Car Door CD30 Maintenance Manual Premium - 09.18Document76 pagesFermator Car Door CD30 Maintenance Manual Premium - 09.18alfrelia0% (1)

- Adjusting Diana Brake ImemDocument16 pagesAdjusting Diana Brake Imemgrenui100% (1)

- J264103 - en - 1 - Commissioning & Diagnosis of DO DSF 9 Door DriveDocument30 pagesJ264103 - en - 1 - Commissioning & Diagnosis of DO DSF 9 Door DrivePio Rodolfo50% (2)

- 100 - 1. Lift Controller ManualDocument41 pages100 - 1. Lift Controller ManualDjordje GavrilovicNo ratings yet

- Decoder For Monarch - STEP ManualDocument7 pagesDecoder For Monarch - STEP ManualMohammed HussenNo ratings yet

- ASG-11.65.031 Maintenance KDL32Document12 pagesASG-11.65.031 Maintenance KDL32Mike Rushe100% (1)

- RL19560 Schematics XXDocument26 pagesRL19560 Schematics XXAsif AbbasovNo ratings yet

- Service Manual: Diagnosis Code ListDocument55 pagesService Manual: Diagnosis Code Listyveshouthoofdthotmail.comNo ratings yet

- Schindler Escalator 9700AE - Brake MaintenanceDocument4 pagesSchindler Escalator 9700AE - Brake MaintenanceHùng VĩNo ratings yet

- k604522 MX Basic Fixtures Mantto PDFDocument49 pagesk604522 MX Basic Fixtures Mantto PDFBenjamin Gonzalez100% (1)

- KONE LCE375 Control System: Quick Reference K 42512000 - 03 Edition 10-2009Document156 pagesKONE LCE375 Control System: Quick Reference K 42512000 - 03 Edition 10-2009Don LuongNo ratings yet

- Schindler SMART 002 LED Error CodesDocument9 pagesSchindler SMART 002 LED Error CodesDon Luong100% (1)

- Evacuation Instruction Schindler: EuroliftDocument2 pagesEvacuation Instruction Schindler: EuroliftMartynas Karkauskas100% (1)

- 2 (A) - TKE Door Operator - HD-03 HD-04 W IMSDocument68 pages2 (A) - TKE Door Operator - HD-03 HD-04 W IMSNickNo ratings yet

- Schéma Électrique WitturDocument19 pagesSchéma Électrique WitturMoh DaraNo ratings yet

- Thyssen-DiagnosticDocument55 pagesThyssen-Diagnosticraymon janszenNo ratings yet

- Shindler MarcoDocument51 pagesShindler MarcoBLT ChuchinNo ratings yet

- Mitsubishi Elevator GPS-III Fault Code - A Water Logging - Netease BlogDocument7 pagesMitsubishi Elevator GPS-III Fault Code - A Water Logging - Netease BlogTroubleshootingNo ratings yet

- Kone Nanospace PDFDocument45 pagesKone Nanospace PDFgustavo sanchezNo ratings yet

- Yaskawa L1000A Lift Application Short EN ManualDocument41 pagesYaskawa L1000A Lift Application Short EN ManualGogik AntoNo ratings yet

- Field Test Genius 20 - GearlessDocument3 pagesField Test Genius 20 - GearlessStefan Hodan100% (1)

- Modu-Tool Basic Operating Instructions PDFDocument2 pagesModu-Tool Basic Operating Instructions PDFAliRouyouNo ratings yet

- OTIS 506, 506SL, 510 UNITS: Precision Escalator Products, IncDocument10 pagesOTIS 506, 506SL, 510 UNITS: Precision Escalator Products, IncmohammedalathwaryNo ratings yet

- HATMSI47 1811 E - OPC LM1 PR - ManualDocument14 pagesHATMSI47 1811 E - OPC LM1 PR - ManualMahran Mastouri100% (1)

- Orona Arca3 SchémasDocument38 pagesOrona Arca3 Schémasmahfoud ascenseursNo ratings yet

- S45933449 1 PDFDocument3 pagesS45933449 1 PDFLieven BenoitNo ratings yet

- 104 Door Control Board PM-SSCDocument16 pages104 Door Control Board PM-SSCKevin SilvaNo ratings yet

- Variador Kone V3f20 InglésDocument30 pagesVariador Kone V3f20 InglésRDRNo ratings yet

- Mantenimiento Maquina de TraccionDocument23 pagesMantenimiento Maquina de TraccionGustavo ZambranoNo ratings yet

- KONE - Machine Room Type - 1600 KG, Speed 2.5 PDFDocument1 pageKONE - Machine Room Type - 1600 KG, Speed 2.5 PDFNghia100% (1)

- Controller With EMIDocument11 pagesController With EMIMohammed Qaid AlathwaryNo ratings yet

- BMT Basic Maintenance Tasks For KONE Monospace With KCE TechnologyDocument24 pagesBMT Basic Maintenance Tasks For KONE Monospace With KCE TechnologyMohammad Younus BaigNo ratings yet

- Escalator Travolator Servicetool DAA31402AAD - STMDocument49 pagesEscalator Travolator Servicetool DAA31402AAD - STMCoil9850% (2)

- Microzed V Microzed V3.5 3.5: User'S ManualDocument58 pagesMicrozed V Microzed V3.5 3.5: User'S ManualKhaled ZakariaNo ratings yet

- System Galaxy Quick Guide: Configuration and OperationDocument47 pagesSystem Galaxy Quick Guide: Configuration and OperationTushar ImranNo ratings yet

- Ba TW45C 08 12 enDocument64 pagesBa TW45C 08 12 enangela1590100% (1)

- GLE IMEM TREND Fault 67-71Document7 pagesGLE IMEM TREND Fault 67-71Ash100% (1)

- AM-04.08.021 Brake MxMachDocument6 pagesAM-04.08.021 Brake MxMachFERNSNo ratings yet

- EM-1 ManualDocument32 pagesEM-1 ManualDale Peacock100% (1)

- ASG-10 20 008 - Main - en A 1Document10 pagesASG-10 20 008 - Main - en A 1Polinho Donacimento100% (2)

- iV5L Manual ENG J55w6muhDocument388 pagesiV5L Manual ENG J55w6muhMohammad ShayebNo ratings yet

- HAMCB Debugging ManualDocument39 pagesHAMCB Debugging ManualMACRO TECH LLC100% (1)

- 25 TM Installation ManualDocument18 pages25 TM Installation ManualReynold Suarez83% (6)

- CT Unidrive SP Elevator Solution Software User Guide - Issue 3 PDFDocument222 pagesCT Unidrive SP Elevator Solution Software User Guide - Issue 3 PDFjayb1984No ratings yet

- NICE1000 Elevator Integrated Controller: Setup Manual - Brief Version 1.4Document51 pagesNICE1000 Elevator Integrated Controller: Setup Manual - Brief Version 1.4Habibulla BavajiNo ratings yet

- SICON-2001 Operation ManualDocument61 pagesSICON-2001 Operation ManualMohammed Qaid Alathwary100% (1)

- AS-11.65.031 KDL32 RepairDocument48 pagesAS-11.65.031 KDL32 RepairMike Rushe100% (1)

- Elevator Mechanic's Helper: Passbooks Study GuideFrom EverandElevator Mechanic's Helper: Passbooks Study GuideNo ratings yet

- Daily DSR Gomd-V 19-02-2024Document28 pagesDaily DSR Gomd-V 19-02-2024amit kumarNo ratings yet

- TD830Document47 pagesTD830edomaldoNo ratings yet

- Electrical Principles (EET0113) : Direct Current (DC)Document10 pagesElectrical Principles (EET0113) : Direct Current (DC)Amirah MohdNo ratings yet

- Ultra Thin Fan Coil - Arctic Heat PumpsDocument9 pagesUltra Thin Fan Coil - Arctic Heat Pumpsjohnking5555No ratings yet

- E5 Electromagnetic Induction s2 A2324Document14 pagesE5 Electromagnetic Induction s2 A2324AJ CarambasNo ratings yet

- Rotating Machinery (ETD 15) - Electrotechnical Division-Public Safety Standards of IndiaDocument6 pagesRotating Machinery (ETD 15) - Electrotechnical Division-Public Safety Standards of IndiasasikumarNo ratings yet

- A Compact Microstrip-Fed Patch Antenna With Enhanced Bandwidth and Harmonic SuppressionDocument8 pagesA Compact Microstrip-Fed Patch Antenna With Enhanced Bandwidth and Harmonic SuppressionBouhafs AbdelkaderNo ratings yet

- User Guide: English (3 - 6)Document24 pagesUser Guide: English (3 - 6)Rafa Redondo PianistaNo ratings yet

- Advance MemoryDocument56 pagesAdvance MemoryPratyush MishraNo ratings yet

- Metallized Polyproplene Film Capacitor Mpe: FeaturesDocument5 pagesMetallized Polyproplene Film Capacitor Mpe: FeaturesJulian MataNo ratings yet

- BALLUFDocument12 pagesBALLUFSting DâuNo ratings yet

- Amplificador de Potencia de Baja Frecuencia Cd8227gpDocument8 pagesAmplificador de Potencia de Baja Frecuencia Cd8227gplaboratorio fercorNo ratings yet

- Balanza para Extraccion de Sangre Ae 500a v2 Manual de Servicio Tecnico - CompressDocument43 pagesBalanza para Extraccion de Sangre Ae 500a v2 Manual de Servicio Tecnico - Compressbioingenieria houssayNo ratings yet

- Validating Surge TestDocument9 pagesValidating Surge Testquality10No ratings yet

- Electric Circuit Fundamentals: Essential QuestionDocument15 pagesElectric Circuit Fundamentals: Essential QuestionMOBILEE CANCERERNo ratings yet

- Wibotic Aerial DS-4PGDocument3 pagesWibotic Aerial DS-4PGJuanito PerezNo ratings yet

- Selector Guide PDFDocument45 pagesSelector Guide PDFTudosie AlexeyNo ratings yet

- Diomedes: Inno Vation T Ha T Lif Tsy OuDocument2 pagesDiomedes: Inno Vation T Ha T Lif Tsy Outhanggimme.phanNo ratings yet

- Fabrication of Windmill Power Generator PDFDocument2 pagesFabrication of Windmill Power Generator PDFKellyNo ratings yet

- (Neopis) Epic U300 Manual 20210702 RevDocument80 pages(Neopis) Epic U300 Manual 20210702 RevTrương Quốc HuyNo ratings yet

- Future Challenges For Electric VehiclesDocument3 pagesFuture Challenges For Electric VehiclesIQPC GmbHNo ratings yet

- Ca 250Document20 pagesCa 250KALIL100% (1)

- A PH Meter Has A Membrane That Allows Acidic IonsDocument4 pagesA PH Meter Has A Membrane That Allows Acidic IonsWaltas KariukiNo ratings yet

- 20 KV Transmission LineDocument21 pages20 KV Transmission LineOctavianto ZakiNo ratings yet

- Webinar - Gerakan Inisiatif Listrik Tenaga Surya - 20210619Document25 pagesWebinar - Gerakan Inisiatif Listrik Tenaga Surya - 20210619Abbi Pamungkas100% (1)

- Objective Type QuestionsDocument6 pagesObjective Type QuestionscoolkannaNo ratings yet

- EEE 4 1 CS Syllabus - UG - R20Document52 pagesEEE 4 1 CS Syllabus - UG - R20Sai Hari Nath ReddyNo ratings yet

- NSP4201MR6 ESD and Surge Protection DeviceDocument7 pagesNSP4201MR6 ESD and Surge Protection DeviceBelkis Amion AlbonigaNo ratings yet

- Datasheet 545W BIFACIALDocument2 pagesDatasheet 545W BIFACIALJoryel CapelNo ratings yet

- Low Power Ic SyllabusDocument2 pagesLow Power Ic SyllabusjayaprasadkalluriNo ratings yet