Professional Documents

Culture Documents

Distribution Boards

Distribution Boards

Uploaded by

sallammohamedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Distribution Boards

Distribution Boards

Uploaded by

sallammohamedCopyright:

Available Formats

AHC Co.

SECTION 16442

DISTRIBUTION BOARDS

PART 1 - GENERAL

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of Contract, including General and special Conditions

(General requirements), apply to work of this section.

B. Basic electrical materials and methods, section 16050 applies to work of this section.

1.2 DESCRIPTION OF WORK

A. Work includes providing all materials, equipment, accessories, services and tests

necessary to complete and make ready for operation, all distribution boards in

accordance with Drawings and Specifications.

1.3 QUALITY ASSURANCE

A. Manufacturers: Firms regularly engaged in the manufacture of distribution boards of

the types and capacities required, whose products have been in satisfactory use in

similar service for not less than 5 years.

B. Standards Compliance: Comply with requirements of applicable local codes, IEC

60439, IEC 60947 pertaining to distribution boards.

1.4 SUBMITTALS

A. Product Data: Submit manufacturer's data for distribution boards including size,

enclosures, and electrical ratings and characteristics.

B. Shop Drawings: Submit dimensional layouts on architectural background drawings.

C. Selectivity Study

Submit to the Engineer a relay and C.B. selectivity study.

The Current-time characteristics must be plotted on a log-log papers showing that the

choice of the C.B. settings are correct for full selective system..

D. Short circuit and voltage drop calculation

Submit a comprehensive short circuit study as well as voltage drop calculation based on

the actual impedance values of the electrical components such as supply short circuit

level at the 111 KV (shall not be less than 500 MVA), transformer per unit impedance,

bus bars and cables impedances....etc.

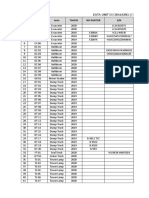

E. Load balance

submit a detailed load list verifying the load balance across the phased of each board.

PART 2 - PRODUCTS

MVP RIYADH HOTEL

DISTRIBUTION BOARDS

Date: MAR., 2008. Rev. : 1 16442 - 1

AHC Co.

2.1 RECOMMENDED MANUFACTURER

Refer to list of recommended manufacturers.

2.2 GENERAL REQUIREMENTS

A. Distribution boards shall be type tested and shall comply fully with the requirements of

IEC 60947, standards.

B. All interior components shall be mounted on a rigid fabricated chassis capable of being

removed and/or reversed for ease of wiring.

C. Distribution boards shall be provided with a suitable earth bar and neutral bar, with

adequate provision for the connection of a circuit protective conductor for each

outgoing way.

D. Terminals for the neutral conductor shall allow the individual connection of conductors

having a current carrying capacity equal to the full current carrying capacity of the

phase conductor.

E. When the means of isolating the distribution board from the incoming supply is not to

be mounted immediately adjacent to the board, means shall be provided in the

distribution board to indicate whether or not the supply is "ON".

F. Unless otherwise specified on the schedules or drawings, distribution board cases shall

be fabricated from zinc-coated or heavily rust-proofed heavy gauge sheet steel and be of

all-welded construction. They shall be adequately braced or stiffened, by folding or

otherwise, to form a completely rigid enclosure. Exterior corners and edges shall be

rounded so as to give a smooth overall appearance.

G. Distribution boards shall have a side-hung hinged front cover, attached by means of lift-

off hinges, and fitted with cylinder type locking handles. Covers shall be braced or

folded in such a manner as to prevent distortion or whip, and shall be fitted with dust-

proofing gaskets or edge seals.

H. Distribution board cases shall provide a degree of protection IP 42.

I. Distribution board cases shall be of such dimensions that adequate space is available for

manoeuvering and connecting the incoming and outgoing cables.

J. Distribution boards shall be arranged for top or bottom or top and bottom entry

according to the requirements specified on the drawings or in the schedules.

K. Distribution boards shall be provided with detachable end plates as specified in the

schedules or drawings.

L. Each distribution board shall be provided with a durable circuit chart fixed to the inside

of the cover or immediately adjacent and bearing typewritten details, in plain language,

of the circuits supplied by each of the ways. The chart shall be on heavy weight paper

or thin card, and shall be protected by means of a rigid transparent plastic cover, it shall

be mounted in such a way that it can easily be removed for correction or alteration, then

replaced. The size of the chart shall be such that there is adequate space of recording all

of the required information and, in any case, shall not be less than A5 (210 mm x 148

mm).

MVP RIYADH HOTEL

DISTRIBUTION BOARDS

Date: MAR., 2008. Rev. : 1 16442 - 2

AHC Co.

M. Each way in the distribution board shall be clearly numbered to correspond with the

numbering on the circuit chart.

N. Each distribution board shall be provided with an engraved plastic label on the outside

of the front cover, bearing the designation of the board and its reference number, if any,

as given on the drawings or in the schedules. The label shall be fixed in position by

chromium-plated set screws. Each such label shall be not less in size than 100 mm x 30

mm, and shall bear the required inscription in white on a black background, using letters

and/or digits not less than 5 mm high.

2.3 WORKS TESTS

A. All assemblies shall be tested in accordance with the requirements of IEC 60439

standard Part 1, plus requirements of associated standards.

B. Works tests shall include inspection of all wiring and a complete electrical functioning

test.

C. Protection relays shall be tested by primary current injection with currents equal to

overload, short-circuit and earth fault conditions.

D. Works tests shall be done in the presence of the engineer.

2.4 FIELD TESTING

A. ASSEMBLES

All assemblies shall be subjected to the routine tests as defined in IEC, standards. after

installation on site. Test Certificates shall be provided.

B. FUNCTIONAL UNITS

All functional units shall be checked for correct mechanical operation.

C. PROTECTION CIRCUITS

All protection circuits with in relays used shall be tested for correct operation by

secondary injection of test currents. This shall be carried out at currents equivalent to

overload, short-circuit and earth fault conditions.

D. CURRENT TRANSFORMERS

Where specified in the schedules, protection circuits using current transformer (CT)

operated relays shall be tested by primary injection of current to prove the transformer

ratio.

2.5 COMMISSIONING

A. Following the satisfactory conclusion of inspections and tests on completed sections of

the Works, each switchgear assembly shall be duly commissioned and left in full

working order. The term "Commissioning" shall be deemed to include:

(i) The energizing of functional device circuits and equipment which have

previously been inspected, tested, found to be satisfactory and capable of being

energized with compete safety.

MVP RIYADH HOTEL

DISTRIBUTION BOARDS

Date: MAR., 2008. Rev. : 1 16442 - 3

AHC Co.

(ii) The starting up of all electrically powered plant and equipment, including that

supplied and installed under other contracts, and as specified in the schedules.

(iii) The verification of the performance of each distribution board relative to all

such plant and equipment by the carrying out, where required, of further tests

and the making of all necessary adjustments so as to obtain optimum

performance.

(iv) The proving of all interlock operations in all possible combinations and the

operation of all control systems, metering and indications to meet the

performance requirements specified.

PART 3 - EXECUTION

3.1 INSPECTION

A. Examine conditions under which distribution boards and enclosures are to be installed,

and notify Engineer in writing of conditions detrimental to proper completion of work.

Do not proceed with work until unsatisfactory conditions have been corrected.

3.2 INSTALLATION

A. Install distribution boards as indicated, in accordance with manufacturer's written

instructions, requirements of applicable Standards, and in accordance with recognized

industry practices to ensure that installation complies with requirements and serves

intended function.

B. Coordinate as necessary to interface installation of distribution boards with other works.

C. Tighten connectors and terminals, including screws and bolts and equipment earthing

connections, in accordance with equipment manufacturer's published torque tightening

values for equipment connectors.

D. Fasten enclosures firmly to walls and structural surfaces, ensuring that they are

permanently and mechanically anchored. Provide all angle units and accessories for

proper mounting.

E. Provide properly wired electrical connections for distribution boards within enclosures.

F. Double lugging is not permitted.

G. Fill out distribution boards circuit directory card upon completion of installation work.

H. Provide equipment earthing connections sufficiently tight to assure a permanent and

effective ground for distribution boards.

3.3 FIELD QUALITY CONTROL

A. Upon completion of installation of distribution boards and after circuiting has been

energized, demonstrate capability and compliance of panelboard with requirements.

Where possible, correct malfunctioning units at site, then retest to demonstrate

compliance; otherwise, remove and replace with new units and retest.

B. Prior to energization of electrical circuitry, check all accessible connections to

manufacturer's tightening torque specifications.

MVP RIYADH HOTEL

DISTRIBUTION BOARDS

Date: MAR., 2008. Rev. : 1 16442 - 4

AHC Co.

C. Prior to energization of distribution boards, check with ground resistance tester

phase-to-phase and phase-to-ground insulation resistance levels to ensure requirements

are fulfilled.

D. Prior to energization, check distribution boards for electrical continuity of circuits, and

for short circuits.

E. Adjust operating mechanisms for free mechanical movement.

F. After energization, check phase balancing and adjust accordingly.

G. Touch-up scratched or marred surfaces to match original finishes.

END OF SECTION 16442

MVP RIYADH HOTEL

DISTRIBUTION BOARDS

Date: MAR., 2008. Rev. : 1 16442 - 5

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- How To Design A Flat Roof PDFDocument3 pagesHow To Design A Flat Roof PDFMaria Rose Giltendez - BartianaNo ratings yet

- Waterside Buddhist Shrine Case StudyDocument2 pagesWaterside Buddhist Shrine Case StudyVaishnavi Konde DeshmukhNo ratings yet

- Steel Design Final Project - Tradeoffs For All Structural MembersDocument87 pagesSteel Design Final Project - Tradeoffs For All Structural MembersEmmanuel Lazo100% (6)

- MDB Specs PDFDocument9 pagesMDB Specs PDFAbdElrahman AhmedNo ratings yet

- Low Voltage SwitchgearDocument9 pagesLow Voltage SwitchgearsallammohamedNo ratings yet

- SWGR & MCC, 9611Document5 pagesSWGR & MCC, 9611Ma.socorro SaballaNo ratings yet

- BuswaysDocument5 pagesBuswaysAli SaifNo ratings yet

- Switchboards SECTION 16441Document12 pagesSwitchboards SECTION 16441NATHANNo ratings yet

- Spec MDBDocument16 pagesSpec MDBDolyNo ratings yet

- Package SubstationDocument9 pagesPackage SubstationuddinnadeemNo ratings yet

- 66kv Lightning ArresterDocument9 pages66kv Lightning ArresterbinodeNo ratings yet

- Spec Sub-Distributions PanelsDocument11 pagesSpec Sub-Distributions PanelsDolyNo ratings yet

- Section 16900 - Electrical Work (Low Voltage Switchboards)Document11 pagesSection 16900 - Electrical Work (Low Voltage Switchboards)Kurt Darryl SabelloNo ratings yet

- Panel BoardDocument7 pagesPanel BoarduddinnadeemNo ratings yet

- Va 26 24 16Document6 pagesVa 26 24 16adrian karl bonaNo ratings yet

- 26 2416 PanelboardsDocument10 pages26 2416 PanelboardsMena Amir KhairyNo ratings yet

- Cable Trays For Electrical Systems-Rev05Document8 pagesCable Trays For Electrical Systems-Rev05Mohamed Hamed100% (1)

- BuswayDocument5 pagesBuswayuddinnadeemNo ratings yet

- 26 2413 Main Distribution Board PDFDocument18 pages26 2413 Main Distribution Board PDFMena Amir KhairyNo ratings yet

- Wiring DevicesDocument4 pagesWiring DevicessallammohamedNo ratings yet

- MV Switchgear 11 KV VCB Rev-0Document16 pagesMV Switchgear 11 KV VCB Rev-0ISHA SINGHNo ratings yet

- E16406Document11 pagesE16406HOFFERNo ratings yet

- Spec For 33kv SystemDocument27 pagesSpec For 33kv SystemkjfenNo ratings yet

- Engineering SpecificationDocument4 pagesEngineering SpecificationAhmed MenshawyNo ratings yet

- Panelboards SpecificationsDocument7 pagesPanelboards SpecificationsBladimir MichelNo ratings yet

- A Guid To HVACDocument11 pagesA Guid To HVACHamad GulNo ratings yet

- QCP-E-04 - Cable Install Proc - Issue 1Document10 pagesQCP-E-04 - Cable Install Proc - Issue 1Mohamed AliNo ratings yet

- SECTION 16464 Switchgear, Low Voltage (600 Volts and Below)Document12 pagesSECTION 16464 Switchgear, Low Voltage (600 Volts and Below)no nameNo ratings yet

- 16310-Dry-Type Transformer 13.8 KVDocument5 pages16310-Dry-Type Transformer 13.8 KVAli SaifNo ratings yet

- Asc Ps SP 4000Document22 pagesAsc Ps SP 4000Jasm MutingNo ratings yet

- 16320Document9 pages16320uddinnadeemNo ratings yet

- 16441Document7 pages16441uddinnadeemNo ratings yet

- Enclosed Switches and Circuit Breakers-Rev05Document7 pagesEnclosed Switches and Circuit Breakers-Rev05Mohamed HamedNo ratings yet

- Technical Specifications For Power Distribution Board (PDB)Document14 pagesTechnical Specifications For Power Distribution Board (PDB)sri_lnt50% (2)

- Sandwhich BusductDocument5 pagesSandwhich BusductHarmandeep Ahluwalia100% (1)

- 494107293Document4 pages494107293Billy BrownNo ratings yet

- SECTION 16312 Unit Substation, SecondaryDocument9 pagesSECTION 16312 Unit Substation, Secondaryno nameNo ratings yet

- DC Poweer Distribution Switch BoardDocument9 pagesDC Poweer Distribution Switch BoardpvenkyNo ratings yet

- Earthing Transformer PDFDocument13 pagesEarthing Transformer PDFNelson SarriasNo ratings yet

- Cat UPS 1000izDocument25 pagesCat UPS 1000izokovalskiNo ratings yet

- Tech - Spec. LA For WBSEDCL Sept.07, ArresterDocument6 pagesTech - Spec. LA For WBSEDCL Sept.07, ArresterThanh NguyenNo ratings yet

- SPEC 262416 PanelboardsDocument7 pagesSPEC 262416 Panelboardsabdulbasit88No ratings yet

- Switch Disconnectors (Isolator)Document3 pagesSwitch Disconnectors (Isolator)sallammohamedNo ratings yet

- Specifications For Motor Control CentersDocument5 pagesSpecifications For Motor Control CentersNATHANNo ratings yet

- 16410-Enclosed Switches and Circuit BreakersDocument4 pages16410-Enclosed Switches and Circuit BreakersAhmed Sherif IsmailNo ratings yet

- SECTION 16480 Motor Control Centers Part 1 - General 1.1 DescriptionDocument7 pagesSECTION 16480 Motor Control Centers Part 1 - General 1.1 Descriptionno nameNo ratings yet

- Erection Testing and CommissioningDocument30 pagesErection Testing and CommissioningEngr Muhammad Abu BakrNo ratings yet

- Oil Immersed TransformerDocument8 pagesOil Immersed TransformerAbdul JabbarNo ratings yet

- Electrical SpecsDocument5 pagesElectrical Specshadjie ansayNo ratings yet

- Molded Case Circuit Breakers PDFDocument7 pagesMolded Case Circuit Breakers PDFMohamedAhmedFawzyNo ratings yet

- SwitchboardsDocument6 pagesSwitchboardsbate chinsauba (bate963)No ratings yet

- E-10 Panel BoardsDocument6 pagesE-10 Panel BoardsBfboys EdissonNo ratings yet

- LT ACDB Rae BareliDocument41 pagesLT ACDB Rae BareliPrashant TrivediNo ratings yet

- SECTION 15241 Mounting and Isolation of Mechanical and Electrical SystemsDocument23 pagesSECTION 15241 Mounting and Isolation of Mechanical and Electrical SystemsfatREVITNo ratings yet

- Medium Voltage Cables Rev01Document8 pagesMedium Voltage Cables Rev01Mohamed HamedNo ratings yet

- SECTION 16462 Distribution SwitchboardsDocument13 pagesSECTION 16462 Distribution Switchboardsno nameNo ratings yet

- Technical Specification For Lightning ArrestorsDocument7 pagesTechnical Specification For Lightning ArrestorsAravind Reddy0% (1)

- Section 262416 - PanelboardsDocument14 pagesSection 262416 - PanelboardssamirNo ratings yet

- 262416-Panelboards Rev 2Document7 pages262416-Panelboards Rev 2Hany NassimNo ratings yet

- 16342-Metal Clad MV SWGRDocument14 pages16342-Metal Clad MV SWGRuddinnadeemNo ratings yet

- 16461-Dry Type TransformerDocument8 pages16461-Dry Type TransformeruddinnadeemNo ratings yet

- 11kv SWGR SpecsDocument87 pages11kv SWGR SpecsMekonnen Shewarega100% (1)

- Tips Standard-SDocument7 pagesTips Standard-SsallammohamedNo ratings yet

- High Voltage 345 400kV XLPE Power CableDocument4 pagesHigh Voltage 345 400kV XLPE Power CablesallammohamedNo ratings yet

- Sound, Music and Public Address SystemDocument19 pagesSound, Music and Public Address SystemsallammohamedNo ratings yet

- Sec-03-01 R0 FinalDocument9 pagesSec-03-01 R0 FinalsallammohamedNo ratings yet

- Circuit BreakersDocument11 pagesCircuit BreakerssallammohamedNo ratings yet

- Testing and CommissioningDocument10 pagesTesting and Commissioningsallammohamed100% (1)

- Low Voltage SwitchgearDocument9 pagesLow Voltage SwitchgearsallammohamedNo ratings yet

- Instruments and MeteringDocument5 pagesInstruments and MeteringsallammohamedNo ratings yet

- Static Uninterruptible Power SupplyDocument8 pagesStatic Uninterruptible Power SupplysallammohamedNo ratings yet

- Raceways, Boxes and FittingsDocument10 pagesRaceways, Boxes and FittingssallammohamedNo ratings yet

- Cable TraysDocument6 pagesCable TrayssallammohamedNo ratings yet

- Earthing SystemDocument6 pagesEarthing SystemsallammohamedNo ratings yet

- Wires and CablesDocument7 pagesWires and CablessallammohamedNo ratings yet

- Basic Electrical Materials and MethodsDocument20 pagesBasic Electrical Materials and MethodssallammohamedNo ratings yet

- Project 2 ReportDocument26 pagesProject 2 Reportarjun kumarNo ratings yet

- Abrar AwolDocument153 pagesAbrar AwolErmias Assaminew AlmazNo ratings yet

- Symbol Plant-3d-Isometrics PDFDocument9 pagesSymbol Plant-3d-Isometrics PDFEvaldo BritoNo ratings yet

- Bending RadiusDocument16 pagesBending RadiussexmanijakNo ratings yet

- Formwork and Shoring Solutions: A.H. Harris & Sons, IncDocument8 pagesFormwork and Shoring Solutions: A.H. Harris & Sons, IncFrancisco GonzalezNo ratings yet

- Proe RH N Pro-ClassicDocument2 pagesProe RH N Pro-ClassicDak SerikNo ratings yet

- Complete Roofing CatalogueDocument24 pagesComplete Roofing CatalogueJuan MansillaNo ratings yet

- Itp Equipment (Static)Document5 pagesItp Equipment (Static)Rajeev KumarNo ratings yet

- Cover PageDocument1 pageCover PageJan Emilyn Chavez CatindigNo ratings yet

- Beam Design Excel SheetDocument1 pageBeam Design Excel SheetDinesh GowdaNo ratings yet

- Ce013 Cruz, Mark-Kiolo Final-SubmissionDocument61 pagesCe013 Cruz, Mark-Kiolo Final-SubmissionKiolo CruzNo ratings yet

- Detailed Specifications For Pneumatic Drill Pipe SpinnerDocument3 pagesDetailed Specifications For Pneumatic Drill Pipe SpinnerRakefsNo ratings yet

- BNBC HandbookDocument49 pagesBNBC Handbookarpondev83% (6)

- Reinforced Concrete Design Module 7 Subject: CE 74A-Reinforced Concrete DesignDocument25 pagesReinforced Concrete Design Module 7 Subject: CE 74A-Reinforced Concrete DesignJemson VictorioNo ratings yet

- Hailemeskel Tefera PDFDocument82 pagesHailemeskel Tefera PDFmekides napolionNo ratings yet

- Saddle SupportDocument12 pagesSaddle SupportrustamriyadiNo ratings yet

- Normal Concrete Mix DesignDocument4 pagesNormal Concrete Mix Designmurnal0% (1)

- Memorial Calculo EstaisDocument1 pageMemorial Calculo Estaispedro kaiserNo ratings yet

- EVAPCO Fill Offerings 1Document4 pagesEVAPCO Fill Offerings 1Walter J Naspirán CastañedaNo ratings yet

- Questions CE2203, CE2201Document13 pagesQuestions CE2203, CE2201titukutty6032No ratings yet

- Bs 7835 11Kv LSZH Single Core Screened CableDocument2 pagesBs 7835 11Kv LSZH Single Core Screened CablefoaadahmadNo ratings yet

- Disclosure To Promote The Right To Information: IS 3823 (1988) : Rolling Bearings - Static Load Ratings (PGD 13: Bearing)Document12 pagesDisclosure To Promote The Right To Information: IS 3823 (1988) : Rolling Bearings - Static Load Ratings (PGD 13: Bearing)karthikeyanNo ratings yet

- Geotechnical - Investigation - For Hokolitu - PV - Hybrid - Power - PlantDocument20 pagesGeotechnical - Investigation - For Hokolitu - PV - Hybrid - Power - PlantmessayNo ratings yet

- Session I - Gravity LoadsDocument129 pagesSession I - Gravity LoadsMarculus Jermaine Robinson100% (2)

- Data Unit Di Cibaliung (CSD) : NO Jenis Tahun No Kantor S/N No Lambung UnitDocument6 pagesData Unit Di Cibaliung (CSD) : NO Jenis Tahun No Kantor S/N No Lambung UnitKukuh Suryo AtmojoNo ratings yet

- Almeida Et Al. (2023) (SR) Ground Improvement Techniques Applied To Very Soft Clays State of Knowledge and Recent AdvancesDocument32 pagesAlmeida Et Al. (2023) (SR) Ground Improvement Techniques Applied To Very Soft Clays State of Knowledge and Recent AdvancesandreasgavrasNo ratings yet

- Flexural Response of SS Reinforced Concrete BeamDocument15 pagesFlexural Response of SS Reinforced Concrete BeamShakil AhmedNo ratings yet