Professional Documents

Culture Documents

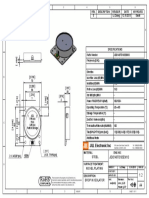

1999-1040006 Motor Without Pinon

1999-1040006 Motor Without Pinon

Uploaded by

shahnawazhusain2008Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1999-1040006 Motor Without Pinon

1999-1040006 Motor Without Pinon

Uploaded by

shahnawazhusain2008Copyright:

Available Formats

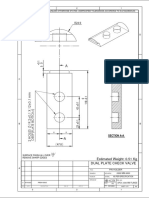

Refer to outsourcing procedure CCHAD-SP-0000010B.

N YAQIN CAI APG-PM 20070731

Is design information security level high (Y/N) ? ______________ Name / BU: _______________ /______________ Date:______

1 2 3 4 5 6 7 8 9 10

ALT. REF. DESCRIPTION DATE BY

C SRF#2116 COMMUTATOR SLEEVE ADDED.(SCN#04041029) 2004.12.13 LH ZH

D CRRN#3H/14974 ADD NOTE 8. 2007.07.31 YQ CAI

A

A

2.8 ±0.1 DIRECT PRINT CUSTOMER PART NO. ( 1st ROW ) , JOHNSON PART NO. ( 2nd ROW )

1.10 ±0.15

AND DATE CODE ( 3rd ROW ) ONTO KEEPER RING.

DATE CODE FORMAT REFER TO ESDC-038

"X"

B

B

"X"

ROTATION

1.5 ±0.1

30° ±2°

30° ±2°

SECTION "X"-"X" B 50.0 REF. 8.7173 (REF. DIA.)

7.0 ±0.3 0.2 B 0.12 B A

0.8 ±0.1

SPACER KEEPER RING 2 ~ M3.0 ( SEE NOTE 7 )

TAPPED HOLES

C C

-

A

11.0 ±0.2 11.0 ±0.2

R0.50

32.0 MAX.

25357353

22.0 ±0.15

1040006

3E276109

( 3.0 DEPTH )

3.2 ±0.2

C D

12.95 ±0.05

12.95 ±0.05

0.000

- 0.005

0.8 ±0.1

+

4.5 ±0.2

4.005

11.5 0.2

6.8 ±0.5

3.5 ±0.2 29.2 ±0.3 1.1 ±0.15

RED DOT ADDED

INDENT MARK INDICATES

POSITIVE TERMINAL DIM."B" 0.3 64.0 ±0.3 ( MEASURE FROM HOUSING FACE TO END CAP FACE )

0.10 S A S B C S DIM."A" 0.2 E

E

NOTES :

1. LENGTH OF SHAFT, DIM. "A" ____________92.0______________ mm. DWN. BY LW ZH CHK. BY APP. BY

2. FRONT EXTENSION, DIM. "B"______________23.5____________ mm,

MEASURED WITH SHAFT PUSHED AGAINST STEEL END CAP. Date (yyyymmdd) 2004/03/02 Date (yyyymmdd) Date (yyyymmdd)

3. DIRECTION OF ROTATION : ANTI-CLOCKWISE WHEN VEIWING

MOTOR OUTPUT END WITH POSITIVE VOLTAGE APPLIED TO

POSITIVE TERMINAL. Characteristics

MATERIAL :

FINISH :

A4

4. AXIAL END PLAY : 0.1 mm MAX. WHEN APPLYING 1 KG MAX. C pk Customer

FORCE TO THE OUTPUT SHAFT.

Key Product Significant General Tolerance ISO 2768-1 Class m (Unless specified) ALL DIMENSIONS ARE IN MILLIMETRES SCALE 1:1

5. TAPPED HOLES CAN ACCEPT MAX. USABLE MALE SCREW > 1.67 JOHNSON JOHNSON ELECTRIC GROUP OF COMPANIES TITLE F

F LENGTH OF 3.0 mm. ELECTRIC (" JOHNSON ELECTRIC ") MOTOR OUTLINE

6. DIMENSIONS MARKED WITH " " ARE THE SPECIAL

CHARACTRISTIC ITEMS REQUIRED BY CUSTOMER UNDER SP

> 1.33 This document is the Property of Johnson Electric and the information therein contained

is confidential. Unauthorised reproduction or other use thereof, whether directly or

(HC477XLLG)

CONTROL.(SAMPLE SIZE>= 5 PCS & CPK >=1.33)

7. RUNOUT OF PINION AT REF. DIA. 8.7173 TO BE 0.12 MAX., MEASURED >1.00 indirectly. in whole or in part, is strictly prohibited. All products made or otherwise DWG No. SHEET 1 OF 1

BY THE MASTER GEAR.

8. CHECK ITEM : HI-POT 600VAC 500 □A MAX REQUIRE TO TEST 1s MIN.

Not

derived directly or indirectly from this document are proprietary to Johnson Electric.

□ Copyright Johnson Electric S. A. 2007 . All rights reserved.

1999-1040006

Required

1 2 3 4 5 6 7 8 9 10

rev 4

You might also like

- 6951-Anchor Bolt and Base Plate DesignDocument38 pages6951-Anchor Bolt and Base Plate DesignOmprakash Khodke100% (1)

- LENGTH .010 D E: Bombardier Standards ManualDocument4 pagesLENGTH .010 D E: Bombardier Standards ManualJohn CollinsNo ratings yet

- HAZOP HAZID Haliburton PDFDocument2 pagesHAZOP HAZID Haliburton PDFamirNo ratings yet

- New Employee Orientation ChecklistDocument3 pagesNew Employee Orientation ChecklistJessica WilliamsNo ratings yet

- CSR, Sustainability, Ethics & - Governance - Bernhard Bachmann (Auth.) - Ethical Leadership in Organizations - Concepts and Implementation (2017, Springer International Publishing)Document213 pagesCSR, Sustainability, Ethics & - Governance - Bernhard Bachmann (Auth.) - Ethical Leadership in Organizations - Concepts and Implementation (2017, Springer International Publishing)ZahirSyah100% (1)

- Ctagon O: Title: REV HRC Qty: 1 Pc/1 PCDocument1 pageCtagon O: Title: REV HRC Qty: 1 Pc/1 PCandhikabpNo ratings yet

- Me 359 HW 03 P 10 DRW 2Document2 pagesMe 359 HW 03 P 10 DRW 2api-576392651No ratings yet

- NHD C160100az RN GBWDocument12 pagesNHD C160100az RN GBWcizetawwwNo ratings yet

- Umpco: CAGE CODE No. 18076 Part NumberDocument4 pagesUmpco: CAGE CODE No. 18076 Part NumberFredNo ratings yet

- Cover CastingDocument1 pageCover CastingArman MominNo ratings yet

- Recommender PCB Layout: Header .100" Pitch, 2 Rows, StraightDocument1 pageRecommender PCB Layout: Header .100" Pitch, 2 Rows, StraightPhan Ngọc DuyNo ratings yet

- Commscope RVVPX308.14R3Document1 pageCommscope RVVPX308.14R3blackcobrarockerulNo ratings yet

- Ash 13.8 em 411B - AsbuiltDocument25 pagesAsh 13.8 em 411B - AsbuiltMr IlchamNo ratings yet

- Samtec ASP 134488 01 DatasheetDocument4 pagesSamtec ASP 134488 01 DatasheetamiteshtripathiNo ratings yet

- FM1484-117-0010!01!01 - Roller Chain Duplex Sprocket 1 1-2 21 TeethDocument1 pageFM1484-117-0010!01!01 - Roller Chain Duplex Sprocket 1 1-2 21 TeethReza JavadianNo ratings yet

- Z RZCZZZSZZN-RC, ST, 11635-BDocument1 pageZ RZCZZZSZZN-RC, ST, 11635-BGilbertoAndresDuarteNo ratings yet

- Standing Valve Ball TypeDocument2 pagesStanding Valve Ball TypeNattakorn sangmarkNo ratings yet

- Pin Holder - 0350Document1 pagePin Holder - 0350munish kanwarNo ratings yet

- NHD C12864B2Z RN FBW-2953355Document10 pagesNHD C12864B2Z RN FBW-2953355jon_scribd2372No ratings yet

- PDFDocument1 pagePDFNemekhbayar GanbatNo ratings yet

- PO178 - 20 10t X 20m Span + 5.2m Cantilever Gantry Crane - Part8Document1 pagePO178 - 20 10t X 20m Span + 5.2m Cantilever Gantry Crane - Part8ahmed saadNo ratings yet

- PO178 - 20 10t X 20m Span + 5.2m Cantilever Gantry Crane - Part8Document1 pagePO178 - 20 10t X 20m Span + 5.2m Cantilever Gantry Crane - Part8ahmed saadNo ratings yet

- Drawings Grid Holder BoxesDocument20 pagesDrawings Grid Holder BoxesStefano CasiniNo ratings yet

- 03 - PoutreDocument1 page03 - PoutreZakaria KchiriNo ratings yet

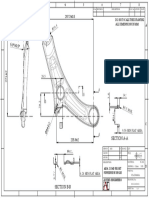

- Suspension ArmDocument1 pageSuspension ArmNsjsjsjieisNo ratings yet

- Tecnadyne PC10XDocument1 pageTecnadyne PC10Xdegek68399No ratings yet

- JQL Electronic Inc: JID0148T0165EM10Document1 pageJQL Electronic Inc: JID0148T0165EM10RAJATHNo ratings yet

- Aux View Parts Drawing PackageDocument5 pagesAux View Parts Drawing PackageIbadurrahman IbadNo ratings yet

- NHD-24064WG-ATMI-VZ#: Graphic Liquid Crystal Display ModuleDocument11 pagesNHD-24064WG-ATMI-VZ#: Graphic Liquid Crystal Display ModuleMiguel VanegasNo ratings yet

- 9311-60214 PDDDocument1 page9311-60214 PDDsathis13me44No ratings yet

- Drawing 8760017 - REV - CDocument5 pagesDrawing 8760017 - REV - Cvlachos1821No ratings yet

- Conn MC 2127rev.b Web00Document1 pageConn MC 2127rev.b Web00changiz2220No ratings yet

- .Shuttle B11IE11 B1XIEXX RevADocument23 pages.Shuttle B11IE11 B1XIEXX RevAKun FayakunNo ratings yet

- SS13 PDFDocument1 pageSS13 PDFArturo NarvaezNo ratings yet

- Indec MotorDocument12 pagesIndec MotorErnestoNo ratings yet

- Raft For 145 146 149 150Document33 pagesRaft For 145 146 149 150Dharnendra P Bhavsar100% (4)

- 21-601-000 46kV, 250kV BIL, 150ADocument1 page21-601-000 46kV, 250kV BIL, 150AAngel StragliatiNo ratings yet

- Item 1 - Ficha Tecnica IBOP Upper Canrig 1250 ACDocument6 pagesItem 1 - Ficha Tecnica IBOP Upper Canrig 1250 ACanghelo marquezNo ratings yet

- Crossover Flange 3-18, 2k (R-31) X 3-12 Eue BoxDocument1 pageCrossover Flange 3-18, 2k (R-31) X 3-12 Eue BoxAndi TrionoNo ratings yet

- E1340 05 PDFDocument1 pageE1340 05 PDFSunil Ranjan MohapatraNo ratings yet

- NHD C0216CZ FSW FBW 3V3Document10 pagesNHD C0216CZ FSW FBW 3V3meeramytuNo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12 - Revised 2.0Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12 - Revised 2.0Faris QoceyNo ratings yet

- Outside Diameter: B Cp041085 Class "3" Change To Class "1" 2004/03/02 LW ZH C CP051829 NOTE 1 CHANGED. 2005/10/24 Yq CaiDocument1 pageOutside Diameter: B Cp041085 Class "3" Change To Class "1" 2004/03/02 LW ZH C CP051829 NOTE 1 CHANGED. 2005/10/24 Yq Caishahnawazhusain2008No ratings yet

- 27° A A C 120° .090 .005 Cast .015 DBC: Revisions Zone Rev. Description Date Approved 0 New Sketch 7/17/17 PRB 1Document1 page27° A A C 120° .090 .005 Cast .015 DBC: Revisions Zone Rev. Description Date Approved 0 New Sketch 7/17/17 PRB 1nidhal kotorsiNo ratings yet

- 523-XXX - Coupling Cut SheetDocument1 page523-XXX - Coupling Cut SheetRavishankarNo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12asuncionNo ratings yet

- 81-03-0053-00e (General Arrangement Cd42-T1a Stainless Steel Screw Cap Transmitter Assembly) Rev ADocument1 page81-03-0053-00e (General Arrangement Cd42-T1a Stainless Steel Screw Cap Transmitter Assembly) Rev AsudeepjosephNo ratings yet

- Keypad DatasheetsDocument5 pagesKeypad DatasheetsHardav RavalNo ratings yet

- Toshiba 36a43Document19 pagesToshiba 36a43eduardo granadoNo ratings yet

- FMC - Rønland Bixlozone Project: Stamp Area For Code 1, 2 or 3Document30 pagesFMC - Rønland Bixlozone Project: Stamp Area For Code 1, 2 or 3Alejo SilvaNo ratings yet

- YjhhhjjDocument1 pageYjhhhjjmusang berjanggutNo ratings yet

- Sealed Tactile Switch B3WNDocument2 pagesSealed Tactile Switch B3WNMuhamad PriyatnaNo ratings yet

- VVPX306R-V5 VVPX306R-V5.MR: 30 210 (Inside)Document1 pageVVPX306R-V5 VVPX306R-V5.MR: 30 210 (Inside)Ikie BarieNo ratings yet

- Spreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 20-Nov-2019 116 CHG - R68 A F CDocument7 pagesSpreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 20-Nov-2019 116 CHG - R68 A F CKhan EngrNo ratings yet

- 1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Document7 pages1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Tamer. ThekingNo ratings yet

- Sambungan Rantai 220419 PDFDocument1 pageSambungan Rantai 220419 PDFArief FibonacciNo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12bunheng lonNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document8 pagesRCC92 Ribbed Slabs (Tables)lucianduNo ratings yet

- Pole Mounting Bracket PlateDocument1 pagePole Mounting Bracket PlateeyaingenieriayproyectosNo ratings yet

- Barril - 4267885-01-DDocument1 pageBarril - 4267885-01-Dcesar guerreroNo ratings yet

- Spreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 16-Aug-2014 116Document1 pageSpreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 16-Aug-2014 116mathewsujith31No ratings yet

- Cheat Sheet For Unknown Analysis (Chem 17)Document4 pagesCheat Sheet For Unknown Analysis (Chem 17)Emmalin MesinaNo ratings yet

- Phy Chapter Wise P1 P3Document277 pagesPhy Chapter Wise P1 P3sidharthNo ratings yet

- Lec 3 - AssumptionsDocument13 pagesLec 3 - AssumptionsPriyadharshan BobbyNo ratings yet

- VOL. 3. UFO Magazine India Officially Free PDFDocument83 pagesVOL. 3. UFO Magazine India Officially Free PDFExopolitika MagyarországNo ratings yet

- Belimo LM230A-S Data Sheet EngDocument4 pagesBelimo LM230A-S Data Sheet EngTeo Pei SanNo ratings yet

- Multiple ChoiceDocument26 pagesMultiple Choiceedgar_chieyahoocomNo ratings yet

- EBU EMMC Security Rev1.1 - Non ConfidentialDocument15 pagesEBU EMMC Security Rev1.1 - Non ConfidentialGeorgeNo ratings yet

- Ethiopian Urban Design Manual - Final Ind 1-TS Reviewed - 100516Document192 pagesEthiopian Urban Design Manual - Final Ind 1-TS Reviewed - 100516WorkuMamo100% (1)

- Holistic Risk Man in SMEsDocument17 pagesHolistic Risk Man in SMEsHenny ZahranyNo ratings yet

- MCQ - SHRM1 - DR Tripathi JPDocument5 pagesMCQ - SHRM1 - DR Tripathi JPjaitripathi26No ratings yet

- QMM Assignment 2Document2 pagesQMM Assignment 2Ambika Sharma0% (1)

- CS F342-11 PDFDocument24 pagesCS F342-11 PDFsky_davisNo ratings yet

- How To Get Rich Without Being LuckyDocument9 pagesHow To Get Rich Without Being LuckybrijsingNo ratings yet

- BINUS University Binus Online Learning: y 2x y XDocument3 pagesBINUS University Binus Online Learning: y 2x y XSiti N HallimahNo ratings yet

- Calf RacDocument72 pagesCalf RacEmerson Ipiales GudiñoNo ratings yet

- Critical Thinking For Analysis and EvaluationDocument13 pagesCritical Thinking For Analysis and EvaluationPuja DhawanNo ratings yet

- Strengthening of RC Column With Externally Bonded Steel BarsDocument5 pagesStrengthening of RC Column With Externally Bonded Steel BarsInternational Journal of Innovative Science and Research Technology100% (1)

- OLYMPUS Stream Software PDFDocument20 pagesOLYMPUS Stream Software PDFFALRepresentaionesNo ratings yet

- Narco Analysis and Brain MappingDocument17 pagesNarco Analysis and Brain MappingManbaniKaurOhriNo ratings yet

- CIE 2010 Handbook For Centres - IGCSE - O-Levels - A-LevelsDocument124 pagesCIE 2010 Handbook For Centres - IGCSE - O-Levels - A-Levelssafwan120% (1)

- Ecological CrisisDocument6 pagesEcological CrisisSolomon SamNo ratings yet

- Table of Specification - Urdu: Mcqs 30 30 40%Document7 pagesTable of Specification - Urdu: Mcqs 30 30 40%AdnanNo ratings yet

- Vocabulary TeachingDocument44 pagesVocabulary TeachingNi Made Ivana Swastiana100% (1)

- Mohammed Murshid: Work ExperieanceDocument2 pagesMohammed Murshid: Work ExperieanceMurshid MurshiNo ratings yet

- Engexam - info-FCE Listening Practice Test 4 PrintableDocument2 pagesEngexam - info-FCE Listening Practice Test 4 PrintableLorenzo MassiNo ratings yet

- Turbidity Sensor SKU SEN0189-DFRobotDocument4 pagesTurbidity Sensor SKU SEN0189-DFRobotBlak Dia MondNo ratings yet

- Sociology Project: Topic - A Discourse On Theories of SocializationDocument19 pagesSociology Project: Topic - A Discourse On Theories of SocializationSumukh TiwariNo ratings yet