Professional Documents

Culture Documents

Infor 02. Supply Chain Execution

Infor 02. Supply Chain Execution

Uploaded by

mjgarridohazCopyright:

Available Formats

You might also like

- Neuroscan 4.5 EditDocument343 pagesNeuroscan 4.5 Editonehitwonder2316No ratings yet

- Carestream Vue PACS and Vue Archive 12.1 Administration GuideDocument213 pagesCarestream Vue PACS and Vue Archive 12.1 Administration GuideJuanGabrielVillamizarNo ratings yet

- Iso 13374 1 en PDFDocument8 pagesIso 13374 1 en PDFRodrigo Raziel Bernal ChulinNo ratings yet

- Delphi 7 - ASTA v3.0 For Delphi 7 - ManualDocument684 pagesDelphi 7 - ASTA v3.0 For Delphi 7 - ManuallealmoleroNo ratings yet

- TopSURV OnBoard7.5 PDFDocument447 pagesTopSURV OnBoard7.5 PDFayadNo ratings yet

- Past4 Manual PDFDocument283 pagesPast4 Manual PDFFrancisco AraújoNo ratings yet

- Manual TestopiaDocument40 pagesManual TestopiaSilviya KichukovaNo ratings yet

- Unity Games Optimization Best Practices-V5 PDFDocument32 pagesUnity Games Optimization Best Practices-V5 PDFNikhil Mahajan100% (1)

- myDHL GuideDocument29 pagesmyDHL GuidetgdymqnbvnNo ratings yet

- Frontier AnalystWorkbook - 4Document39 pagesFrontier AnalystWorkbook - 4Leidy BernalNo ratings yet

- Stimulsoft Reports and Dashboards User Manual - enDocument1,259 pagesStimulsoft Reports and Dashboards User Manual - enBrunoNo ratings yet

- Echo Hoper MT221 Program 2 14-11-19Document71 pagesEcho Hoper MT221 Program 2 14-11-19Deyvi Moises Gonzales AmableNo ratings yet

- Worldship User GuideDocument44 pagesWorldship User GuideThakhin Kai BworNo ratings yet

- WinRiver User Guide International VersionDocument130 pagesWinRiver User Guide International VersionLucas DalsottoNo ratings yet

- j45 S4hanax BPD en Us 3Document52 pagesj45 S4hanax BPD en Us 3Marissa DrakeNo ratings yet

- S509 Alpha Analysis User's ManualDocument141 pagesS509 Alpha Analysis User's ManualAhmadou Yerima AbbaNo ratings yet

- Tutorial Banxia FrontierDocument40 pagesTutorial Banxia FrontierErizal SutartoNo ratings yet

- Sistem Otomatis Pengisian Teh Kemasan-1 (Hmi) OkDocument23 pagesSistem Otomatis Pengisian Teh Kemasan-1 (Hmi) OkObay SobariNo ratings yet

- Rocplane: Planar Sliding Stability Analysis For Rock SlopesDocument72 pagesRocplane: Planar Sliding Stability Analysis For Rock Slopesfreddy carrilloNo ratings yet

- Manual For Element Track: © 2003 - 2017 ... Naviter D.O.O. Last Modified 30/07/2017Document88 pagesManual For Element Track: © 2003 - 2017 ... Naviter D.O.O. Last Modified 30/07/2017Alejandro SantiagoNo ratings yet

- Semafora OntoBroker 6 - 3 Reference Manual 2020Document286 pagesSemafora OntoBroker 6 - 3 Reference Manual 2020berndatthegeigersNo ratings yet

- ProODO User Manual - EnglishDocument28 pagesProODO User Manual - EnglishGiorgi KotilaidzeNo ratings yet

- Case Notebook User GuideDocument142 pagesCase Notebook User GuideSeyi AiyegbusiNo ratings yet

- TomTom Go 60 ManualDocument124 pagesTomTom Go 60 ManualTrickyDicky2No ratings yet

- Ocpp-1 6Document130 pagesOcpp-1 6marsuNo ratings yet

- Lit 12013295Document90 pagesLit 12013295Pedro Quintero JimenezNo ratings yet

- US SequenceOptimizer UMDocument220 pagesUS SequenceOptimizer UMAzra PhendragonNo ratings yet

- Music Label User GuideDocument33 pagesMusic Label User GuideMarcial CalabuchNo ratings yet

- DynaLift 3 6 User Guide A4Document53 pagesDynaLift 3 6 User Guide A4Quy HoangNo ratings yet

- Import 8.00 USDocument41 pagesImport 8.00 USprakash sharmaNo ratings yet

- Porsche Mobile Charger Connect - Operating ManualDocument293 pagesPorsche Mobile Charger Connect - Operating ManualJayz JDKNo ratings yet

- WEBFLEET - Connect 1.56.0Document392 pagesWEBFLEET - Connect 1.56.0Aaron SolisNo ratings yet

- ct14 MANUAL TANDEMSDocument37 pagesct14 MANUAL TANDEMSjlNo ratings yet

- FastCAM v8-0 UpdateDocument68 pagesFastCAM v8-0 Updatekalyana sundaram guhanNo ratings yet

- CadTools Reference ManualDocument82 pagesCadTools Reference ManualrobinNo ratings yet

- Printed Manual: © 1999-2019 AGG SoftwareDocument50 pagesPrinted Manual: © 1999-2019 AGG SoftwareMaxime KIENOUNo ratings yet

- Gas Turb 11Document256 pagesGas Turb 11Santiago Herrera PalacioNo ratings yet

- GasTurb11 PDFDocument256 pagesGasTurb11 PDFMartin JavierNo ratings yet

- Yealink Teams Phone Edition User Guide V15.96Document49 pagesYealink Teams Phone Edition User Guide V15.96christianlegentil38No ratings yet

- Cornerstone OnDemandDocument48 pagesCornerstone OnDemandIgor JovanovićNo ratings yet

- Port To Port User ManualDocument57 pagesPort To Port User Manualredchaoz100% (1)

- Programt 1Document47 pagesProgramt 1Pejic GoranNo ratings yet

- Protocols Guide - English ManualDocument164 pagesProtocols Guide - English ManuallamiaNo ratings yet

- Past 4 ManualDocument280 pagesPast 4 ManualYAKOV MARIO QUINTEROS GOMESNo ratings yet

- WinOLS User ManualDocument204 pagesWinOLS User Manualfrankhonda1100% (5)

- Reference Manual: Paleontological StatisticsDocument278 pagesReference Manual: Paleontological Statisticsgary chotaNo ratings yet

- Fabric OS TroubleshootingDocument120 pagesFabric OS TroubleshootingSayan GhoshNo ratings yet

- Fos 740 TroubleshootingDocument120 pagesFos 740 TroubleshootingGGNo ratings yet

- Nabertherm Kiln Operating Manual - F Range PDFDocument56 pagesNabertherm Kiln Operating Manual - F Range PDFmetaxwareNo ratings yet

- WedgeLink Software Keyboard Wedge Users GuideDocument63 pagesWedgeLink Software Keyboard Wedge Users Guideestefania A.CNo ratings yet

- Ctpat BP 2006Document56 pagesCtpat BP 2006Legend AnbuNo ratings yet

- Switch User Guide - ENDocument150 pagesSwitch User Guide - ENvoa1No ratings yet

- Web Based Email SystemDocument133 pagesWeb Based Email SystemaboodkingsizeNo ratings yet

- Westlaw Guide For Paralegals: Retrieving Documents On WestlawDocument56 pagesWestlaw Guide For Paralegals: Retrieving Documents On WestlawpoptonesNo ratings yet

- Printed Manual: © 1999-2019 AGG SoftwareDocument50 pagesPrinted Manual: © 1999-2019 AGG SoftwareBudhi HermawanNo ratings yet

- ArtiFast-User-GuideDocument46 pagesArtiFast-User-GuideSlobaBgdNo ratings yet

- Api GuideDocument37 pagesApi Guidetiso_feriNo ratings yet

- Anyrail 4 Manual English: © 2011 Drail Modelspoor SoftwareDocument102 pagesAnyrail 4 Manual English: © 2011 Drail Modelspoor SoftwareNevzat ÖrnekNo ratings yet

- Programming the Intel Galileo: Getting Started with the Arduino -Compatible Development BoardFrom EverandProgramming the Intel Galileo: Getting Started with the Arduino -Compatible Development BoardRating: 5 out of 5 stars5/5 (1)

- Pollution Prevention: Methodology, Technologies and PracticesFrom EverandPollution Prevention: Methodology, Technologies and PracticesNo ratings yet

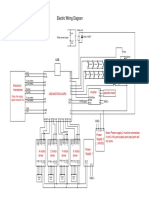

- Electric Wiring DiagramDocument1 pageElectric Wiring DiagramJoe Pañol RmzNo ratings yet

- Tumkur University: Department of Studies and Research in Computer ApplicationsDocument20 pagesTumkur University: Department of Studies and Research in Computer Applicationsnishanth gowda18No ratings yet

- TESTO-6651-6600 VOL2-1-20.en - EsDocument20 pagesTESTO-6651-6600 VOL2-1-20.en - EsEliana Guzman PachecoNo ratings yet

- Report On Hand Gesture Controlled WheelchairDocument4 pagesReport On Hand Gesture Controlled WheelchairPRERNA SONINo ratings yet

- Topalian JavaScript Robot AI 002 by Christopher TopalianDocument44 pagesTopalian JavaScript Robot AI 002 by Christopher TopalianCollegeOfScriptingNo ratings yet

- 2.the OSI Security ArchitectureDocument28 pages2.the OSI Security ArchitectureEzekiel PondeNo ratings yet

- Expert Systems With Applications: Tülin InkayaDocument10 pagesExpert Systems With Applications: Tülin InkayaMILLENIA WINADYA PUTRINo ratings yet

- Universal A/C Remote Control: Wall K-650EDocument2 pagesUniversal A/C Remote Control: Wall K-650EFajar PrasetyoNo ratings yet

- Department of IT Webinar-1 - Jan-June2021Document1 pageDepartment of IT Webinar-1 - Jan-June2021Shana KaurNo ratings yet

- Digital Logic Design: VHDL Coding For Fpgas Unit 6Document15 pagesDigital Logic Design: VHDL Coding For Fpgas Unit 6Srinivas CherukuNo ratings yet

- 07 Spanning Tree - Details - v6 0Document162 pages07 Spanning Tree - Details - v6 0Shabd PrakashNo ratings yet

- Genius 7000XRF ManualDocument67 pagesGenius 7000XRF ManualAlexNo ratings yet

- Final Details For Order #112-0320599-3449832: Shipped On August 7, 2017Document1 pageFinal Details For Order #112-0320599-3449832: Shipped On August 7, 2017krishna tejaNo ratings yet

- CHAPTER V Normal DistributionDocument33 pagesCHAPTER V Normal DistributionHera SmileNo ratings yet

- 1b. Distribution Components Systems and Operations PDFDocument25 pages1b. Distribution Components Systems and Operations PDFAnonymous 4k3M837gKNo ratings yet

- Auxiliary Heater (AHE) Diagnosis, Basic KnowledgeDocument1 pageAuxiliary Heater (AHE) Diagnosis, Basic Knowledgeمحمد يونسNo ratings yet

- Drs Operating ManualDocument64 pagesDrs Operating ManualWolaé Mathurin Edmond AmegandjinNo ratings yet

- NIRAnalyserFeed AnalyzerDocument2 pagesNIRAnalyserFeed AnalyzersiddiramuluredaboinaNo ratings yet

- Game CrashDocument9 pagesGame CrashfennoufelNo ratings yet

- MachineExpertBasic V1.2 SP1 ReleaseNoteDocument30 pagesMachineExpertBasic V1.2 SP1 ReleaseNoteRamesh NarayananNo ratings yet

- Сервис Мануал На Английском Samsung Ua32eh500r Шасси u73aDocument173 pagesСервис Мануал На Английском Samsung Ua32eh500r Шасси u73aiuri63No ratings yet

- 02 - Catch The Beetle 2022 NEWDocument2 pages02 - Catch The Beetle 2022 NEWKunj PatelNo ratings yet

- 115 ABAP For SAP HANA Interview Questions & AnswersDocument22 pages115 ABAP For SAP HANA Interview Questions & Answersabdul.shaikNo ratings yet

- ClassnotesDocument4 pagesClassnotesgamersandroid2014No ratings yet

- A New Class Of: Compact UltrasoundDocument24 pagesA New Class Of: Compact UltrasoundThiết bị Điện Tử Y SinhNo ratings yet

- B327 PT3 TMA Form - Branches - FALL 2023-24Document1 pageB327 PT3 TMA Form - Branches - FALL 2023-24adel.dahbour97No ratings yet

- Application Form For Industrial and Clinical Attachments AllowanceDocument2 pagesApplication Form For Industrial and Clinical Attachments AllowanceLellah VasikiNo ratings yet

Infor 02. Supply Chain Execution

Infor 02. Supply Chain Execution

Uploaded by

mjgarridohazCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Infor 02. Supply Chain Execution

Infor 02. Supply Chain Execution

Uploaded by

mjgarridohazCopyright:

Available Formats

Infor Supply Chain

Execution 10.3

Product Brief

Infor Supply Chain Execution 10.3 Product Brief

Table of contents

Reinvent supply chain execution ..................................................................................................... 4

The proven solution ......................................................................................................................... 5

Warehouse Management—Core functions ..................................................................................... 5

Appointment and dock door scheduling ....................................................................................... 5

Receiving ..................................................................................................................................... 6

ASN/EDI ....................................................................................................................................... 6

Storage (Putaway) ....................................................................................................................... 7

Crossdocking ............................................................................................................................... 8

Order processing, carrier rating and routing, and wave planning ................................................ 8

Order processing ..................................................................................................................... 8

Product selection ..................................................................................................................... 8

Wave management .................................................................................................................. 9

Picking ........................................................................................................................................ 10

RF directed picking ................................................................................................................ 10

RF assisted picking ................................................................................................................ 10

Cluster picking........................................................................................................................ 10

Layer picking .......................................................................................................................... 10

Batch picking .......................................................................................................................... 10

Order picking .......................................................................................................................... 10

Dynamic picking ..................................................................................................................... 11

Serialized and catch weight picking ....................................................................................... 11

Speed pick and consolidation picking .................................................................................... 11

Production line picking ........................................................................................................... 11

Voice picking – Powered by leading Vocollect voice technology .......................................... 11

Paper-based picking .............................................................................................................. 11

Packing ...................................................................................................................................... 12

Shipping ..................................................................................................................................... 12

Loading .................................................................................................................................. 12

Shipping paperwork ............................................................................................................... 13

Shipping ................................................................................................................................. 13

Inventory control......................................................................................................................... 13

Multi-owner support ............................................................................................................... 14

Cycle counting........................................................................................................................ 14

Inventory adjustments ............................................................................................................ 15

Inventory status changes ....................................................................................................... 15

Inventory relocation ................................................................................................................ 15

Inter-facility transfers .............................................................................................................. 15

Returns to vendor .................................................................................................................. 15

Transaction logging ................................................................................................................ 15

Infor Supply Chain Execution 10.3 Product Brief 2

Warehouse Management—Advanced functions ........................................................................... 16

Paper and RF support ................................................................................................................ 16

System-directed forward pick replenishment ............................................................................. 16

Multiple code date tracking ........................................................................................................ 16

Serial number tracking (In, Out, End-to-End) ............................................................................ 16

Advanced kitting ......................................................................................................................... 17

Bill of materials (BOM), assembly work plans, and instructions ............................................ 17

Kit creation ............................................................................................................................. 17

Labor and task management ................................................................................................. 17

Cycle counting and loading standards ................................................................................... 18

Labor standards allowance enhancements ........................................................................... 18

Labor standards travel time enhancements ........................................................................... 18

Task-directed management ................................................................................................... 19

Transportation Management (TM) ......................................................................................... 19

Infor Third Party Logistics (3PL) Billing .................................................................................. 21

Infor 3PL Billing: ..................................................................................................................... 21

The Infor technology difference ..................................................................................................... 22

Infor Ming.le ............................................................................................................................... 22

Infor 10x Experience .................................................................................................................. 24

Infor BI Dashboards ................................................................................................................... 24

Infor Motion™ Warehouse Director ........................................................................................... 25

Infor Reporting ........................................................................................................................... 25

Infor Motion SCE Warehouse Operator ..................................................................................... 26

Usability...................................................................................................................................... 26

Infor ION ........................................................................................................................................ 26

Infor ION Workflow ..................................................................................................................... 26

Infor ION Event Management .................................................................................................... 27

Infor ION Pulse........................................................................................................................... 27

Infor ION Technology Connector ............................................................................................... 27

See results ..................................................................................................................................... 27

About Infor.................................................................................................................................. 27

Infor Supply Chain Execution 10.3 Product Brief 3

Positive impact: reduced expenses, improved productivity, and increased revenue are the

most recognized business results experienced by Infor® Supply Chain Execution customers.

With over 600 customers and more than 1,500 implementations, Infor presents the worldwide

community with an unmatched portfolio of solutions deployed in a diverse collection of

customer accounts, while maintaining unparalleled financial strength. Infor’s ability to

implement and support Supply Chain Execution solutions with customers, and positively

impact their business in over 40 countries around the world, sets the benchmark for the

industry.

Reinvent supply chain execution

In today’s competitive economy, you must deliver the perfect order in full, the first time and

every time, to win and retain customers, and drive sales. While you face these external

customer pressures, distribution operations are also forced to look for ways to reduce costs

and ramp up productivity. To accomplish this, you need a single fulfillment solution that will

provide you with real time inventory visibility at your fingertips, allowing you to meet or

exceed your customers unique demands, adapt to regularly changing requirements, and

where necessary, provide detailed tracking for accurate customer invoicing. You also need

productivity tools to keep work flowing to the warehouse staff consistently and efficiently, and

accurately measure your workforce in real-time against dynamic time standards. The

success of a business is dramatically influenced by the ability to grow without increasing

labor and transportation costs, and control expenses by optimizing the use of all of their key

resources.

Infor® Supply Chain Execution (Infor SCE) is the first solution that lets you view and manage

your supply chain execution activities as a coherent whole to eliminate bottlenecks and

improve all-around efficiency. Infor SCE combines warehouse management, labor

management, transportation management, and third-party logistics (3PL) billing in a unified

solution, built on a single technology with a common user interface. Today, many systems

are disjointed and offer inconsistent information, which makes it impossible to make

important decisions quickly and easily. With Infor Supply Chain Execution, you can simplify

complexity, automate repetitive processing, and control your exceptions— doing more with

less. You’ll be able to run your supply chain like a single, well-tuned machine that can satisfy

your customers every time.

A best-in-class supply chain execution solution can help your company thrive in a

challenging economy by providing better visibility into people, inventory processes, and

freight optimization through technology advancements like service-oriented architecture

(Infor ION®), mobility, social collaboration, voice, and radio frequency.

Infor Supply Chain Execution is your foundation for flawless order fulfillment. The solution

optimizes your distribution environment by utilizing resources to improve efficiency, labor

performance, inventory, freight, and order accuracy. By optimizing your distribution

environment, you can realize measurable, ongoing savings that can account for 10% to 25%

or more of your product handling costs and 5% to 20% or more of your freight costs.

Combining warehouse management capabilities and fully integrated radio frequency (RF) or

voice technology provides an opportunity to streamline your supply chain, specifically your

distribution operations. By improving data capture accuracy and reducing product touches in

the supply chain, your employees become more productive, order accuracy increases,

damages are reduced, and quality control activities become less necessary. Your employees

become more efficient and your warehouse becomes more flexible and productive, all of

which contribute to your bottom line. In short, with Infor SCE you’ll be able to optimize your

supply chain and maximize your investment.

Infor Supply Chain Execution 10.3 Product Brief 4

The proven solution

Infor Supply Chain Execution allows more than 600 customers—including the leading third-

party logistics providers (3PLs), four of the largest car manufacturers, leading consumer

packaged goods, manufactures and retailers—to automate their distribution activities. Infor

SCE is designed for a variety of industries, including 3PL, cold storage, public warehousing,

retail, wholesale, pharmaceutical, grocery, industrial distribution, manufacturing, consumer

packaged goods (CPG), food and beverage, industrial machinery and equipment, high tech,

and aerospace and defense.

Designed to perform the complex, business-critical operations demanded of a modern

fulfillment operation, Infor Supply Chain Execution helps companies reduce costs by

increasing throughput and productivity, and by optimizing freight costs. With this solution, you

can effectively address inventory management, labor management, work and task

management, cross docking and flow thru, freight tendering, freight optimization, value-

added services, voice-directed distribution, billing for 3PLs, and distribution.

Warehouse Management—Core functions

Whether your facilities account for 20,000 or 1,000,000+ square feet of warehousing

space, Infor Supply Chain Execution’s configurable and flexible solution meets the

demands of the modern supply chain. Infor SCE includes the following core functions:

Appointment and dock door scheduling

You can schedule inbound and outbound appointments with the Appointment Scheduler. An

authorized user can create an appointment schedule, review existing appointments, assign

time slots and dock doors to each specific appointment, and assign the associated carrier and

trailer numbers. Just as in other areas of Infor SCE, you can review the Appointment

Scheduler in graphical format and then drill down into more granular details about existing

appointments or the availability of dock doors. Color-coding on each graph provides a clear

visual indication as to whether a door or time slot has reached the appointment capacity. The

data is accessible at your fingertips; more data is available with a simple click.

You can update the status of each trailer to account for each action that affects the trailer,

including trailer check-in, trailer unload start and stop, trailer load start and stop, and trailer

check-out.. Each subsequent status change is logged with dates and times to ensure that a

proper audit trail is recorded. Each entry in this log helps you measure your success when

unloading and loading trailers, and also helps you meet service level agreements with both

customers and carriers.

Appointment scheduling in Infor Supply Chain Execution

Infor Supply Chain Execution 10.3 Product Brief 5

Receiving

With Infor Supply Chain Execution, you can automate and accelerate your receiving

processes, clearly identify inventory, and improve tracking capabilities. Infor SCE allows you

to receive material with or without inbound orders, advanced shipment notices (ASNs), and

pre-assigned tag/container ID labels (for example, Serial Shipping Container Code/SSCC

labels), keeping your receiving processes flexible. The solution also supports workstation

and/or RF receiving methods, providing the functional and technical support to accurately

and efficiently operate across diverse distribution environments.

ASN/EDI

An ASN may be used to communicate information about the material being received prior to

its arrival. Advanced notice provides an opportunity for better visibility and tracking, planning

of resources, and can streamline the receiving process. While ASNs typically arrive via

electronic data interchange (EDI), they may also be manually entered by you or your

vendor, or imported using a standard Excel spreadsheet as another EDI alternative. The

receiving process begins with information about the expected material. Infor SCE provides

you with the flexibility to receive using varying levels of pre-receipt notice, from none at all

(basic receiving), to some (inbound order receiving), to detailed (ASN receiving), to very

detailed (pre-tagged barcode ID receiving), to fully automated with RFID receiving. Plus, you

can define ASNs specifically for the receipt of returned products.

Desktop ASN receiving in Infor Supply Chain Execution

Once you enter the appropriate information such as purchase order number, ASN number,

tag, or container ID for the type of receiving being performed, Infor SCE creates an inventory

record detailing when, where, and by whom the receipt is performed. Based on the

configuration of each product, operators can approve defaulted attributes or be required to

enter attributes for the product being received for instance, product ownership, user-defined

attributes, lot numbers, serial numbers, catch weight data (including options for summary,

detailed, gross/net/tare weight), expiration/best-before-end (BBE) dates, and status/hold

codes. Infor Supply Chain Execution provides extensive tracking of manufacture, expiration,

and receipt dates to support future material selection, product rotation, and order fulfillment

activities.

Infor Supply Chain Execution 10.3 Product Brief 6

Barcoded pallet ID labels are most often affixed to product as you receive it. You can use

pre-printed generic labels or take advantage of the print -on-demand feature for rich user-

defined formatting. Receipts are put away directly following receipt, or are staged and then

put away by a different operator. Infor Supply Chain Execution supports consolidation of

product during receipt by pallet, multiple products per pallet, or rainbow pallets identifying the

sorting or routing of product by destination zone.

For environments where container exchange tracking is required, Infor SCE allows

customers to track various container types (e.g. CHEP or PECO pallets, totes, cages, Euro

Pallets, etc.) for ASNs and shipment orders. The result of the container tracking is a running

balance by trading partner.

For lot, food, and/or temperature-controlled warehouses, Infor Supply Chain Execution

provides multiple options to enforce validation and facilitate capture of key details during

receiving. During receiving, lot and lot masking configuration can ease capturing of the

multiple lot and date fields, and lot/date validations can enforce receipt of non-expiring (or

soon to expire) inventory. The solution has the flexibility to capture information about the

trailer and load.

Information available to be captured includes: temperature of trailer (nose, middle, and tail),

cleanliness, seal number and status, free form notes, average temperature, and LPN specific

temperature for received and shipped goods.

Using Infor SCE, you get the same results with either desktop or RF receiving. Whether you

are using RF equipment today or looking to switch to it in the future, the solution provides

you with the flexible receiving capabilities you need to smoothly transition your business from

one environment to the next.

By following the basic Infor SCE receiving principles, and configuring rules, validations, and

data capture requirements for your operation; you can improve the consistency and

efficiency of your operation. Accurate and efficient receiving is a vital initial step to managing

a successful warehouse.

Storage (Putaway)

Infor Supply Chain Execution empowers you to configure storage or putaway strategies.

Whether driven by product or location attribute, velocity, forward pick proximity, or a

combination of factors, Infor SCE automatically recommends storing material in the best

location according to your defined rules. And whether using paper putaway lists, RF

terminals, or voice, your putaway rules and storage capabilities maximize one of the most

valuable resources in your warehouse: space.

User-configurable rules define a putaway algorithm, which automatically recommends

storage locations that optimize storage capacity, facilitate item consolidation (based on

inventory attributes) and adhere to product handling requirements. Infor Supply Chain

Execution supports a wide variety of storage location types, each with configurable

characteristics. For example, you can identify locations designed for specific types of

product rotation (such as FIFO, LIFO, and bulk) or temperature- controlled zones such as

freezer, cooler, ambient, and dry. You can create zones with locations for containing bulk

materials, using single and double deep racks, flow racks, cantilever racks, shelving,

push-back racks, bulk tanks, carousels, and automatic storage and retrieval (ASRS) to

accommodate all your facility’s storage requirements.

In addition to space optimization, operational efficiencies are taken into account when

defining putaway rules. Putaway rules can be configured to account the following: filling

forward pick locations, cross dock opportunities, placement in closest proximity to forward

pick location for an item, putting away single LPN with multiple lots and/or multiple items,

from receiving location (e.g. place closest to receiving door), pick and drop location

handling, hold status, and more.

While putaway transactions are most often triggered post-receiving, often sites require a

Infor Supply Chain Execution 10.3 Product Brief 7

secondary putaway (or auto- move) transaction or automatic status changes to be time-

triggered for situations such as curing or blast-freezing, for temperature controlled items.

Infor SCE supports putaway and item configurations to automate the routing and status

change needed for such situations.

When you use Infor Supply Chain Execution to automate your putaway process, you’ll

reduce unused storage space, use your workforce more efficiently, and maximize value in

your warehouse operation.

Crossdocking

Crossdocking is the process by which items are either picked or moved directly from the

inbound dock to the outbound dock, eliminating the need for storage and replenishment

processes. Crossdocking increases your inventory velocity, which in turn reduces your

staffing and equipment needs, space requirements, and inventory carrying costs, and

ensures you keep material flowing seamlessly through your warehouse and out to

customers.

Standard crossdocking follows a three-step process: receiving, crossdock handling, and

shipping. You can use another form of crossdocking trans-shipment for inbound freight or

product meant to flow thru your facility without being recorded as inventory (often used in

deconsolidation and consolidation centers). Or you can use opportunistic cross docking to

monitor shortages or back orders and match inbound product with outstanding demand.

By reducing product touches and the time it takes to fill outbound orders, you reduce

damages, supply chain costs, and the overhead associated with your distribution

operation..

Order processing, carrier rating and routing, and wave planning

Your warehouse faces the formidable task of selecting the right product to meet order

demand every day. Infor Supply Chain Execution provides a robust set of tools to help you

flawlessly fulfill orders and exceed customer expectations.

Order processing

Infor Supply Chain Execution accepts orders through integration with the host system,

through desktop entry, via import using an Excel spreadsheet (EDI alternative) or through

the web-based SCM Portal order entry. Once outbound orders are in the system, Infor

Supply Chain Execution provides you with all the tools you need to facilitate the order

fulfillment process. The order fulfillment process includes tracking specific status changes of

the order beginning with order creation, through allocation and wave planning, picking

confirmation, staging, packing, loading and the final shipment confirmation.

Product selection

Infor Supply Chain Execution allows you to configure how inventory is selected to fill an

outbound order, transfer order, or replenishment request. You configure and define the

allocation strategies to select the most efficient method to search your facility for appropriate

product to fulfill the shipment request.

Each rule consists of a prioritized list of selection types and search options that influence

product selection when processing a particular rule. Search options such as full pallet, full

case, full layer, clean partials, and clean locations allow you to control whether Infor Supply

Chain Execution looks for product to fill orders most efficiently or trades some efficiency to

clean up partial pallets and free up locations. Plus, you can configure defaults at the SKU,

order, customer, and customer/SKU level to control a product’s required code date usage

(for example, manufacture, expiration, receipt, and best before), product age sequencing

(FIFO, FEFO or LIFO), and remaining life window (shelf life in days specific to a customer’s

demands) in order to fill a particular order line.

Infor Supply Chain Execution 10.3 Product Brief 8

Infor Supply Chain Execution’s configurable strategies ensure you select the right product for

the right order at the right time, in the most efficient manner while meeting your customer’s

specific requirements.

Wave management

Once you have selected a group of orders manually or via the wave planning query filter, you

can group orders into waves. A wave includes one or more orders that are planned and

released together. You can pre-configure wave query filters with user-defined order attributes

to group orders together—to facilitate regular wave release processing. When planning

waves, you can query and select which orders to include in a wave, by establishing wave

constraints such as setting minimum and maximum values for orders, lines, cube, and weight

capacities. Wave selections can be saved for frequent re-use as well as placed on a

schedule. Wave planning filters may be established using traditional query building methods

or using graphical wave building.

Graphical wave planning in Infor Supply Chain Execution

The data elements that make up the filter criteria used within wave planning include all of the

shipment order header, detail, and product information. Wave filters may use literal

references like “today” or “tomorrow b/n 1pm – 3pm”. When the wave filters are saved and

reused in the future, the literal references require no date changes in order to collect orders

for the present day or time period. Additionally, the saved wave parameters permit

scheduling waves to run in the background on a regular timed basis, without human

intervention.

Once you build a wave, you can begin wave planning. During wave planning, Infor

Supply Chain Execution allocates material for the orders in a wave and generates

planned pick commands.

When evaluating the impact of a wave plan, you can drill down and review orders

before releasing pick commands. For example, you can:

• Determine if you have enough inventory to fill orders

• Display wave and/or order level labor estimates for processing time. Determine impact on

each, case and full pallet areas.

• Remove an order from a wave.

• Change and re-filter the wave.

After a wave is planned and approved, either manually or automatically, it is released for

picking. Pick commands generated during the planning process are activated and available

for operator assignment.

Infor Supply Chain Execution 10.3 Product Brief 9

The wave release process will trigger off multiple types of picks, associated labels and

picking lists. Picks that are configured for cartonization will follow configured cartonization

rules to drive a pick to pack process. Based on user-defined container characteristics—

including container priority, cube, dims, and weight—container selection rules evaluate the

picks for an order and select the most appropriately sized container(s) for each order. Pick-

to-tote, carton, and pallet environments may all realize gains in efficiency using container

selection rules. As you pick, scan, and confirm orders, the data is automatically captured and

available for packing slip, case / pallet manifest documents, and EDI notifications for

customers.

Picking

Released picks become available to operators once a wave has been released. Regardless

of the size of your facility, Infor Supply Chain Execution ensures efficient and accurate

picking of product for outbound orders. Orders are picked quickly and without errors,

following the most efficient work path. Accurate, timely picking helps you use space

efficiently and keep accurate inventory records, utilize your personnel and integrated

automation potential, and get orders to shipping docks faster. Because of the efficiency

Infor Supply Chain Execution provides, you can improve performance and cut costs in

moving material off the shelf and to your customer.

Infor Supply Chain Execution supports many pick methods, including:

RF directed picking

Users receive a pick task via a handheld or vehicle mount RF unit and complete the

transaction with RF.

RF assisted picking

Users pick via a pick list or labels and confirm picks on the RF. Label printing may be

initiated from a workstation or from the RF unit.

Cluster picking

A single operator picks multiple orders simultaneously, visiting each location one time during

one route through the pick path, and often picking to a tote, container or shipping box.

Layer picking

Users are directed to pallet locations vs. case pick locations when order line quantities

will clean a pre-defined layer quantity.

Batch picking

Operators aggregate item quantities, pick bulk quantities, and deliver picks to a batch

processing location where the bulk quantity is separated into individual order

quantities.

Order picking

Operators select a specific order to pick, and the RF directs the user through the order line

items and quantities for pick confirmation.

Infor Supply Chain Execution 10.3 Product Brief 10

Dynamic picking

Often used for full case or full pallet picking in floor locations. Users receive an RF directed

pick to a specific location and the user confirms the exact LPN or Case Id that will be picked.

The RF will validate the pick matches the order line’s rotation requirements and complete the

transaction.

Serialized and catch weight picking

Operations that require tracking of specific information such as serial numbers or catch

weights will drive picking operators to capture appropriate levels of serial and/or catch

weights. Validations are enforced based on item configurations to ensure accuracy in this

picking process.

Speed pick and consolidation picking

When multiple orders call for large quantities of the same items, wave planners can

establish a speed pick process which releases consolidated wave quantity picks into a

designated dynamic forward speed pick location. Individual order quantities are then picked

from this speed pick location. This process can be used for outbound fulfillment (often

called dynamic pick), as well as in production environments calling for pallets of raw

materials feeding multiple production lines.

Production line picking

Warehouses that are managing inbound raw materials for production typically require many

of the features of outbound fulfillment (e.g. production rotation, lot capture, and efficient RF

picking). In addition to those available features, the solution provides advanced capabilities

to support manufacturing environments that require a staged consolidation area for multiple

or single production lines, auto-replenishment feed process, automatic consumption of

materials at pick line, operator initiated task retrieval for picks to/from specific staged area or

production line, and more.

Voice picking – Powered by leading Vocollect voice technology

Infor Supply Chain Execution integrates directly to Vocollect’s Voice Direct (Voice Artisan)

software, which supports multiple pick methods using voice technology. Users receive pick

commands through a voice headset and confirm pick commands verbally, providing a

hands-free picking method.

Paper-based picking

Users pick via a pick list or labels and confirm the pick on the workstation.

Infor Supply Chain Execution provides the capabilities configurable by work zone for users to

choose how pick commands are communicated. Infor Supply Chain Execution has been

integrated with a variety of material handling equipment (MHE), including automated storage

and retrieval systems, carousels, sorters, A- frames, voice equipment and pick to light.

Integration can take many forms, from a simple routing barcode printed on a container label,

to TCP/IP socket level messaging integration. Whatever the level of interaction between

operator and equipment, Infor Supply Chain Execution can integrate your warehouse

equipment and personnel picking tasks.

With RF you can use task management to automatically assign tasks (picks, putaways,

replenishments, and cycle counts) to operators by priority, location, and sequence order. You

can also interleave various types of picking with other tasks based on the operator’s work

profile as configured by an authorized user. Since workers in many warehouses spend 50-

60% of their time traveling, task interleaving—which can reduce travel time by 10-20% can

lead to a significant reduction in the number of warehouse employees needed. Using task

interleaving, Infor Supply Chain Execution leads the picking operator through the warehouse

on the most efficient path, within a given priority level. For instance, a forklift operator might

be sent to drop off a pallet in a storage location on the way to his next picking location.

Infor Supply Chain Execution 10.3 Product Brief 11

An RF device displays the pick, presenting the operator with the pick location,

recommended pallet ID, item, quantity, destination, and any user -defined pick information.

Once at the pick location, the operator verifies the pick information and confirms the removal

of product from the pick location via barcode scan. The location of picked inventory is

updated in real time, reflecting the product removal from the pick location. An RF operator

completes a pick command by delivering picked inventory to the destination displayed on

the RF terminal and then confirms delivery by scanning the barcode at the destination

location.

Infor Supply Chain Execution also allows operators to place picked product into a user-

defined container for example, a pallet, tote, or carton rather than delivering it directly to a

destination location. With this feature, operators can build pallets or fill cartons with picks for

orders from various pick locations before delivering completed containers to destination

locations. Destination locations for picked product can include staging, packing, dock doors,

exit, and drop locations.

Using the Infor Supply Chain Execution picking functions, your warehouse can experience a

reduction in picking errors and an increase in inventory accuracy. Whatever your warehouse

size or configuration, Infor Supply Chain Execution ensures your product is moving efficiently

through the supply chain, providing real-time feedback on every step of facility operations.

Packing

Packing requirements vary widely and can encompass any type of packing container. Infor

Supply Chain Execution supports user-configurable container types with a variety of

attributes, including dimensional and weight constraints. You can specify container types

using defined cartonization rules and determine the sequence of evaluation. Material for an

order is progressively added to a container until another container of the same or larger size

is necessary.

In addition to offering pre-picking cartonization, Infor Supply Chain Execution also provides

post-picking functions for packing material into containers. The pack container merge/unpack

RF functions (for moving product between or out of containers) facilitate consolidation of

product and containers, allowing the final packed shippable container to be accurately

reflected.

When Infor Supply Chain Execution is deployed with Infor Small Parcel Shipping (Infor SPS)

component, your warehouse will have the advantage of a tightly coupled warehouse

management and small parcel execution system to support your parcel rating and shipping

needs from North American shipping locations. Infor SPS provides operations with parcel

rate shopping, carrier compliant label generation, carrier rate calculations for domestic and

international shipments, carrier tracking number capture, LTL shipment rating, and carrier

electronic manifesting. Having one tightly integrated solution, supporting a multiple parcel

carrier environment for small parcel shipping provides a tremendous advantage to our

customers.

Shipping

Infor Supply Chain Execution manages your warehousing processes from the moment an

order is created until the order is shipped. The solution not only makes shipping faster and

more accurate, it makes it flexible enough to adapt to change. The shipping process involves:

Loading

The load maintenance function associates a specific trailer with the dock door location

where it is positioned. Once you identify the location, you can load the trailer using the RF

load function. To load, scan each shippable unit (outermost container) for a

stop/shipment/order. To confirm loading of each piece, scan the trailer or dock door location

barcode. As loading proceeds, the number of pieces remaining counts down until all pieces

have been loaded. Once loading is complete, you can ship the trailer.

Infor Supply Chain Execution 10.3 Product Brief 12

Shipping paperwork

Users trigger the generation and printing of shipping paperwork from PC workstations. Infor

Supply Chain Execution provides multiple documents at various levels of detail, including:

• Pack list—Printed per shippable container (details the contents of that container)

• VICS Bill of lading—Printed per shipment (group of orders to the same consignee

address)

• Master bill of lading—Printed per shipment pool (group of shipments to a pool point)

Shipping

Your final step in shipping product is to perform a “ship complete” transaction using either a

workstation or RF terminal. This indicates the product has left the facility and should be

deducted from inventory and recorded as shipped. Infor Supply Chain Execution provides

you with multiple ways to perform this function, including mass ship orders, mass ship pick

details, single order ship, shipping a wave, and shipping a load (all units loaded onto a

trailer). For situations where an order line is shipped short, short ship reason codes can be

attached to an order to record the reason an order is shipped short. This often is vital in a

3PL environment to properly communicate and retain details about unique situations.

Inventory control

Knowing the type, location, and quantity of inventory in your warehouse network is crucial for

you to meet fulfillment demands and establish a plan for your operations. With Infor Supply

Chain Execution, you have access to real-time information at multiple levels of your

distribution network. This includes summarized enterprise-level inventory and ownership level

across all warehouses down to granular details like specific warehouse, owner, location, lot,

serial number, item, and license plate.

Using the facility viewer, your warehouse layout is rendered graphically based on location xyz

coordinates. This facility viewer gives users search and drill down access to real -time

inventory. Drill down into empty locations, damaged inventory or held locations. Search for

inventory by item or item/lot. The facility viewer, along with other on-line inquiries (workstation

and / or RF) and reporting options, give your operations quick and flexible inventory visibility.

Inventory visibility at your fingertips

Infor Supply Chain Execution 10.3 Product Brief 13

Inventory control features include:

Multi-owner support

Infor Supply Chain Execution offers a flexible approach to managing enterprises with

multiple owner/partner requirements. Sample operational needs for multi-ownership

functions include:

• 3PL customer analysis and billing

• Vendor management inventory

• Consignment inventory

• Divisional warehousing and distribution

With Infor Supply Chain Execution multi-owner functions, you can track inventory from the

time it is received through to outbound order shipment. You can co-mingle products or

separate them by warehouse zone as each operation dictates. You can transfer ownership

from one owner to another, or reclassify inventory within one ownership account. This type of

tracking provides operations with full visibility of transactional history, space utilization, and

inventory balances for its clients.

The multi-owner configurations support owner-specific workflows and rules to enforce the

disciplines and processes required in multi-owner environments. With flexible and

configurable options, Infor Supply Chain Execution has turned the challenge of handling

multiple-owner operations into a distinct competitive advantage for our customers.

Cycle counting

Infor Supply Chain Execution controls the process of cycle counting, regularly improving our

customer’s inventory accuracy beyond 99%. Cycle counts can be generated in a variety of

ways, including:

• Automatic cycle count by area

• Automatic cycle count by item and location (for bulk environments) or by item and

location and LPN

• Discrepancy cycle counts—when a picking discrepancy is recorded for a location, Infor

Supply Chain Execution automatically generates a cycle count for the location.

• Manually scheduled cycle counts—Cycle counts may be generated by owner, item,

location, location level, zone, or area.

• Demand cycle counts—An RF operator can scan a location and initiate a cycle count; the

count is automatically assigned to the operator. Or you can choose blind cycle counts, in

which the operator is not shown the current system quantity. If a count reported by an

operator does not exactly match the warehouse management quantity, the operator can

choose to recount or complete the count. Recounting can continue until the operator

confirms completion of the count.

• If a quantity discrepancy is confirmed, Infor Supply Chain Execution checks the quantity

and value authorization levels for the operator/cycle class. When verified and approved,

cycle count adjustments update inventory balances in real time. If the user is not

authorized to complete automatic adjustments, the discrepancy is logged to allow a

supervisor to determine next steps, which may include additional counts and/or

completing an adjustment transaction. As in other areas of operation, Infor Supply Chain

Execution Management supports both RF and paper list methods of cycle counting.

• Supervisor cycle counts.

• Zero-cross checks—prompts automatic confirmation of remaining quantity in a location

during normal operations (for example, picks).

Infor Supply Chain Execution 10.3 Product Brief 14

Inventory adjustments

Infor Supply Chain Execution allows operators, with the proper authorization, to adjust

the quantity of inventory. For each modification, the system logs a validated reason

code and uploads all inventory adjustments to the host system.

Inventory status changes

Infor Supply Chain Execution allows you to control the status of all inventories within the

warehouse. Inventory status may be changed for a lot, location, or pallet ID. Hold/status code

values are user-defined and numerous hold codes may be used in conjunction with one

another such as if a pallet is on QC hold and also requires to be held for curing. With this

example the QC hold can be released while the curing hold continues to exist independently.

Inventory relocation

Infor Supply Chain Execution allows both desktop and RF terminal operators to relocate

material. Operators may specify a location, or the system will select a location using

standard storage location selection rules. Moves can be imported into the system using an

Excel template to facilitate relocation of multiple products and within this process a release

time can be configured to forward schedule the release times of these tasks to RF and

voice units.

Inter-facility transfers

You can handle shipments between warehouses through inter- facility transfer order

processing. The process of releasing, picking, and shipping these orders is consistent with

regular customer order processing. Additionally, when the order inter-warehouse transfer

order is shipped, a corresponding ASN is created automatically in the destination warehouse,

allowing for ASN receipt reconciliation and in-transit tracking.

Returns to vendor

You can handle returns to vendors/suppliers through the use of return orders that are picked

and shipped similar to other outbound orders. You can also accumulate damaged or obsolete

inventory for a specific vendor in a logical (and/or physical) location until a time when the

vendor approves the return or when enough stock has been accumulated to complete a

shipment.

Transaction logging

Infor Supply Chain Execution logs every transaction that affects location, quantity, or status of

inventory, ensuring a comprehensive transaction audit trail you can query online. In addition

to inventory-related data, operator performance and wave plan/release timestamps are

recorded for reporting purposes with data tracking of original and new values. All warehouse

transactions are logged including, but not limited to:

• Receipts

• Putaways

• Picks

• Replenishments

• Order packing and ship confirmation

• Inventory moves

• Cycle count and physical inventory adjustments

• Inventory adjustments

For each transaction, Infor Supply Chain Execution tracks a wealth of data elements,

including transaction type, pallet ID, item, lot, lot attributes, hold code, quantity, order number,

order type, order line item, operator, date, and time. You can use the transaction log for

analysis, problem resolution, productivity reporting and measurements, and product recalls.

Infor Supply Chain Execution 10.3 Product Brief 15

Warehouse Management—Advanced functions

For more complex warehouse operations, Infor Supply Chain Execution may be configured

to support all of the basics outlined above, and a host of other advanced functions,

including:

Paper and RF support

Infor Supply Chain Execution supports RF and list-based functions (cycle counting, picking,

replenishment, and putaway) alone or simultaneously. You can configure by work zone,

whether that work zone relies on paper -driven activities or RF. Paper-based work

commands are printed on paper lists or on labels. RF work commands are posted to the RF

task management work queue. RF and paper-based operations may coexist in one facility.

Whether you are utilizing RF and automation equipment now, or plan on implementing these

components in the future, Infor Supply Chain Execution is poised to support your

warehousing environment and advance your logistics development.

System-directed forward pick replenishment

Infor Supply Chain Execution lets you keep key warehouse items in forward picking

locations for immediate access. The application automatically replenishes forward picking

locations, keeping these vital zones stocked to meet demand. For each forward pick

location, you can assign an item, minimum and maximum capacity, replenishment trigger,

units of measure, and more. These parameters control how much to stock of a chosen item,

what point to trigger the replenishment, and the UOM to be used for replenishment. Infor

SCE supports both dynamic replenishment (evaluated with each transaction at the location)

and batch replenishment (on-demand by authorized users). Whether replenishing a few

parts or entire cases of product, the solution uses your configured values to maintain

specified levels and ensure every location produces maximum benefit.

Multiple code date tracking

With perishable products such as foods, adhesives, paints, batteries, or pharmaceuticals,

the ability to capture and track code dates is a requirement for proper inventory

management and order fulfillment. The code date function in Infor Supply Chain Execution

provides you with the capability necessary to handle perishable inventory.

Infor Supply Chain Execution supports capture and maintenance of the expiration,

manufacture, best- by and deliver-by dates, allowing you to configure material aging

defaults for each product. You can capture these dates during receiving, predetermine

them based on ASN details or item defaults, and/or drive them off of other dates through

date code capture and conversion setup.

When fulfilling orders, you can use code date information to enforce product rotation for each

item selection. For each order line item, you can also specify code date criteria, including the

date (for example, manufacture or expiration), the minimum number of shelf-life days, and the

code date search method (FIFO or LIFO).

The code date function in Infor Supply Chain Execution helps you properly manage and

rotate your perishable inventory, and allows flexibility in the date and shelf-life requirements

for customer-specific and ship-to destination specific order allocation and fulfillment.

Serial number tracking (In, Out, End-to-End)

Many fulfillment operations require accurate tracking and monitoring of product serial

numbers. Infor Supply Chain Execution provides you with the serial number tracking

functions you need to handle critical data tracking requirements for these products and put

you in complete control of your inventory.

You can configure serial number tracking to support both inbound and outbound data capture

requirements. For inbound tracking, you enter/scan serial numbers as part of the receiving

process. For outbound tracking, you enter/scan serial numbers as part of the outbound

Infor Supply Chain Execution 10.3 Product Brief 16

pick/pack/ship process and include this information as part of the shipment confirmation to

support your customer’s warranty tracking requirements. You can configure Infor Supply

Chain Execution to allow operators to enter the required number of serial numbers and

validate against a pre-configured serialized format before performing further processes.

Other customers require tracking on both the inbound, outbound, and to the specific

warehouse location within the facility. Infor Supply Chain Execution may be configured to

support this end-to-end serial number requirement.

Infor Supply Chain Execution allows serial number tracking either the moment product is

received or when the product is allocated to an outbound order. Regardless of your

requirements, Infor Supply Chain Execution allows you to track numerous serial numbers for

all your critical fulfillment components.

Advanced kitting

Warehouses have evolved into fulfillment centers as demands for kitting and value-added

services (VAS) have increased. Infor Supply Chain Execution offers you a kitting solution,

allowing your warehouse to perform light manufacturing and assembly work. You can

institute postponement strategies, create kits for promotions, and manage processes based

on the bill of materials (BOM), assembly work plans, and assembly instructions provided to

warehouse staff.

Bill of materials (BOM), assembly work plans, and instructions

The advanced kitting function supports the BOM, assembly work plans and instructions

necessary for the kitting process. Infor Supply Chain Execution utilizes a BOM or a list of

required components (items) to create a finished product, along with the quantity of

components and any non-stock accessories. Infor SCE also supports a dynamic BOM,

downloaded with an order to denote unique component requirements for the order.

Kit creation

Each step of your work plan can have specific instructions for its kitting operation. Operators

input the number of kits that have been completed at each stage of the work plan, and

component stock is decremented based on bill of material quantities automatically.

Infor Supply Chain Execution not only allows operators to create finished kits from

components, it also keeps them supplied with necessary materials by automatically

checking component locations for replenishment opportunities. If necessary component

parts are not at a kitting area, operators can create pick commands to move the component

parts to the proper area. If the quantity in that location drops below the trigger quantity,

operators can create replenishment commands to restock the material.

Infor Supply Chain Execution records all instructions and guides your warehouse

operators through the entire kitting process, ensuring they create kits correctly and

quickly.

Labor and task management

Within Infor Supply Chain Execution, you can direct, track, measure, and report on all labor-

related activities within your operation. Infor SCE includes the following features designed to

provide your operation with tools to drive and monitor labor efficiencies:

• Task dispatch strategies to proactively direct activity in the warehouse

• Task interleaving setup, including task type, priority, and proximity-based

• Task queue monitoring and management

• Time and attendance, including time in-for-day, out-for-day, indirect and direct activity

tracking via desktop or RF

• User and operational activity monitoring and performance reporting

Infor Supply Chain Execution 10.3 Product Brief 17

When you deploy the advanced labor management functionality, you get additional

capabilities, including:

• Labor planning and forecasting

• The ability to capture configurable labor standards (engineered standards or reasonable

expectancies) and operational complexities, including equipment uniqueness, operational

steps, travel restrictions, warehouse and location orientations, conditional variations, and

personal fatigue and delay (PF&D) allowances

• Interactive viewing by RF users of both standard expectations (goal time) and actual

times for each task performed; as well as summary inquiry capability

• Individual and group-level performance tracking versus standards

• Interactive facility and travel viewer

Cycle counting and loading standards

Labor standards are now supported for the following warehouse activities when performed

using RF:

• Assisted cycle counting

• Directed cycle counting

• Supervisor cycle counting

• Production cycle counting

• Assisted loading

• Directed loading

Standards for these activities have been preloaded into the labor management module and

can be used as-is or modified to fit your operating procedures.

Labor standards allowance enhancements

In addition to the percent-based allowance, tiered allowances can now be added based on

the number of hours worked in the shift, the average weight handled per hour during their

shift, and the specific shift that is being worked. This gives four different types of

allowances that can be configured:

• Flat percent—The allowance is based on a percent of the standard time calculated.

• Time worked—Hour ranges can be specified and a different allowance percent specified

for each.

• Weight handled—Tiered ranges of average weight handled can be specified and a

different allowance percent specified for each.

• Shift—A different allowance percent can be given depending on which shift the user is

working on.

Labor standards travel time enhancements

This enhancement allows the travel time calculation to more closely reflect the actual user

travel time by calculating different average equipment speeds when the user is traveling

within an aisle that requires lower travel speed or when the user is traveling a short

distance down an aisle that limits full acceleration. Each equipment profile contains an

attribute that specifies what is considered a short versus long distance. In addition, each

aisle can be configured as supporting a fast or slow speed. The travel time calculation

analyzes each segment of travel and calculates the time based on the attributes for each

segment of the travel path.

Infor Supply Chain Execution 10.3 Product Brief 18

With the built-in labor management capability of Infor Supply Chain Execution, your

operational management can dynamically monitor staff performance against engineered

labor standards and management expectations. Achievable goals can be set and

consistently monitored to drive operational improvements rather than using subjective

measurements of performance. Measuring productivity is multi-faceted; Labor Management

System implementations have shown dramatic improvement when it comes to labor

utilization, efficiency of staff, and adherence to proper work methods being performed on

the warehouse floor. Infor SCE’s labor management provides the framework to help drive

your warehouse operations to new productivity levels.

Infor Supply Chain Execution provides your operation with vital tools that allow you to better

utilize labor, facilitate operational process and performance improvements, increase overall

efficiency, and lower overall costs.

Task-directed management

Infor Supply Chain Execution provides automatic direction to operators using the task

management function. Based on operators’ profiles and ability to be assigned and complete

work in certain locations, and the priority of the work to be completed, an available task

from the work queue is automatically assigned to an operator. Supervisors can adjust an

operator’s task management profile to optimize skill sets, and to assign each operator the

necessary permissions to perform tasks in specific work zones.

Each time an operator working under task management becomes available for work, Infor

Supply Chain Execution evaluates the work queue to choose the next “best most efficient”

task available based on the user’s profile. The operator’s task management profile is used

to determine the operator’s primary task type. From the population of tasks available to a

particular operatorthe solution then determines the highest-priority task the operator can

service with their equipment type. Interleaving can also be enabled to efficiently drive your

workforce like for example interleaving putaways with pallet picks.

With Task management you’ll optimize your workforce and receive maximum benefit from

Infor Supply Chain Execution.

Transportation Management (TM)

The fulfillment requirements of many customers go beyond picking and shipping within the

four walls of a distribution center. Infor Supply Chain Execution has a robust set of

transportation management features built in, including shipment carrier tendering, carrier

communications, carrier rating, and shipment optimization. The solution takes advantage of

Infor’s proven Transportation Planning optimization engine to drive aggregation and multi-

stop shipment optimization.

The TM tendering capabilities are fully configurable to meet your operations unique carrier,

tendering, selection and optimization priorities. Based on configurable carrier tendering

rules, shipments can have carriers assigned manually or tendering can be automated.

Automated carrier tendering supports electronic carrier notifications (EDI, email, and carrier

web user access), facilitates sequential carrier tendering based on pre-defined timeout

rules, and provides a secure carrier user interface providing carrier access and visibility to

loads.

TM Rating and Routing is also fully configurable with carrier selection rules, rate contracts,

routing guides, and can determine optimal carriers based on negotiated carrier rate

contracts and configured routing guides. Carriers can be ranked for manual selection and

sequential tendering.

The automated optimization process supports aggregation and multi-stop shipment load

planning utilizing Infor’s proven advanced transportation planning algorithms.

Infor Supply Chain Execution 10.3 Product Brief 19

Consolidating Transportation Management within one supply chain execution environment

provides tremendous advantages as all outbound order management activities are driven

by one single source With the flexibility to automate the tendering, rating and routing steps,

Infor Supply Chain Execution can help reduce labor costs due to the time savings involved

with transportation planning, and can significantly drive down freight costs up to 20%

annually, using advanced load optimization.

Shipment Route

Carrier shipment load visibility

Infor Supply Chain Execution 10.3 Product Brief 20

Infor Third Party Logistics (3PL) Billing

Accurate billing for storage, handling, and miscellaneous charges is a critical component for

many customers. This includes 3PL companies, as well as customers looking to track

operating costs by division. Infor Supply Chain Execution includes a robust and exhaustive

solution to simplify management of your billing and invoicing requirements.

Infor 3PL Billing supports centralized billing across multiple facilities, presenting a

consolidated view to your company and customers. You can create charges based on

configurable rating rules, group charges together into invoices tailored to each individual

customer (or division), generate detail and consolidated invoices, post invoices to an

accounting package, and report on historical revenue and costing comparisons.

Infor 3PL Billing:

• Reduces missed charges by automating transactional billing for storage, handling, and

accessorial charges.

• Provides a configurable and flexible rating engine supporting a variety of attributes

including carrier, vendor, ship-to customer, transportation mode, item groups, UOM,

weights, and quantity.

• Captures miscellaneous charges at time of transaction or as a special charge.

• Automates recurring storage charges with flexible user defined billing periods and rules

(Anniversary, Split Month, First/Last of Month, etc.). Charges are calculated using

quantity, weight, and / or cube based rates and real-time inventory levels.

Infor Supply Chain Execution 10.3 Product Brief 21

• Summary and detail invoices can be printed, emailed, or faxed more quickly to help

reduce days of sales outstanding.

• Provides a standard for exporting invoice data to an xml file which can then be imported

into your accounting package.

The Infor technology difference

Infor Supply Chain Execution is built on industry-leading technology providing you with cutting

edge capabilities. . Infor invests heavily in research and development, keeping our customers