Professional Documents

Culture Documents

Good Manufacturing Practice (GMP) : History, Structure and Its Significance

Good Manufacturing Practice (GMP) : History, Structure and Its Significance

Uploaded by

Marco El ShaddollOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Good Manufacturing Practice (GMP) : History, Structure and Its Significance

Good Manufacturing Practice (GMP) : History, Structure and Its Significance

Uploaded by

Marco El ShaddollCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/349489015

Good Manufacturing Practice (GMP): History, structure and its significance

Article in International Journal of Drug Regulatory Affairs · December 2020

DOI: 10.22270/ijdra.v8i4.439

CITATIONS READS

0 111

2 authors, including:

S P Yamini Kanti

University of Szeged

4 PUBLICATIONS 0 CITATIONS

SEE PROFILE

All content following this page was uploaded by S P Yamini Kanti on 28 September 2021.

The user has requested enhancement of the downloaded file.

Abhimanyu et.al International Journal of Drug Regulatory Affairs. 2020; 8(4): 47-54

Available online on 15 Dec, 2020 at https://ijdra.com/index.php/journal

International Journal of Drug Regulatory Affairs

Published by Diva Enterprises Pvt. Ltd., New Delhi

Associated with Delhi Pharmaceutical Sciences & Research University

Copyright© 2013-20 IJDRA

Review Article

Good Manufacturing Practice (GMP): History, structure and its significance

Abhimanyu Rampal*, S P Yamini Kanti

Dept. of Applied Chemistry, Amity University Noida Sector-126, Uttar Pradesh, India 201301

Abstract

Good Manufacturing Practice (GMP) is set of guidelines enforced by USFDA under 21 CFR. Every Manufacturer of Food,

Cosmetics, Pharmaceuticals products, Medical Devices & Dietary products should follow these guidelines in order to be sure that their

product is safe and effective to be put in the market and for use by general population. The parameters of GMP for different Categories

may vary but there is only one aim & that is to prevent any kind of harm that can occur to the final user of the product.

Keywords: GMP, USFDA, EUROPE, CANADA, TGA, ANVISA

Article Info: Received 22 Oct. 2020; Review Completed 11 Nov. 2020; Accepted 11 Nov. 2020

Cite this article as:

Rampal A, Yamini Kanti SP. Good Manufacturing Practice (GMP): History, structure and its significance.

International Journal of Drug Regulatory Affairs [Internet]. 15 Dec 2020 [cited 15 Dec 2020]; 8(4):47-54. Available

from:

http://ijdra.com/index.php/journal/article/view/439

DOI: 10.22270/ijdra.v8i4.439

*Corresponding author Tel.: +91-9953402923;

E-mail address: abhimanyurampal5@gmail.com (Abhimanyu Rampal).

1. Introduction

There were many tragic events happened around the formation of Federal Food, Drug & Cosmetics Act

world with respect to the safety & efficacy of drugs of 1938 & after that, the companies for the very first

which lead to the deaths of many people. After all these time were required to prove the safety of their

incidents FDA felt the urgent need to propose some products to FDA, before marketing them directly

guidelines in order to ensure that the product coming to (3).

the market and to the users should be regulated by GMP 3. Case Study of 1941 – A Company introduced

(1). Sulfathiazole tablets which were contaminated by

Phenobarbital, a Sedative and with the consumption

Some of the events which led to Birth of Good’s

of this tablet nearly 300 people were killed, & with

Manufacturing Practices are as Mentioned below –

such large no. of deaths, it persuaded FDA to make

1. Case study of 1901- there were children suffering revisions in their guidelines for Quality

from Diphtheria & they were given an antitoxin for Assurance/Control & Manufacturing (4).

their treatment which was prepared from Horse 4. Case Study of Thalidomide, 1957 – It was

Serum. All of the children who received that introduced in West Germany, Europe as over the

treatment died cause of Tetanus as the serum was counter drug for Anxiety, Morning Sickness &

infected with Tetanus and case the led to the Trouble in Sleeping. When the Regulatory

Biologics Control Act which was introduced in Authorities gave Permission to sell this Drug for the

1902. According to this act, it regulates the safety & said symptoms, they didn’t have any idea about its

purity of Vaccines, Sera’s & Biological products side effects.

(2). After sometime, pregnant women started consuming

2. Case Study of 1937 – another tragedy happened this drug for their associated Symptoms which

during this year, which killed almost 107 children. further resulted in their babies were born with

An elixir formulation of Sulfanilamide was deformed pair of limbs & after this incident the

formulated to be used by Children for Gonorrhea & congress realized that this drug was Teratogenic & it

strap throat. But later, after the deaths of many was removed from the Market (5).

children, they discovered that liquid formulation After all these incidents, the government came to

contains a poison which is was the same chemical realize that the quality & safety testing done at the

which is used as antifreeze and this case led to the end point is not enough and the same check should

e-ISSN: 2321-6794 [47]

Abhimanyu et.al International Journal of Drug Regulatory Affairs. 2020; 8(4): 47-54

be done at each step so that the product meets all its maintained and usage of correct materials, suitable

standards. equipment & premises is encouraged (6).

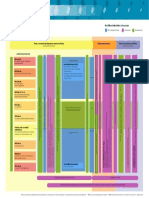

Sections of GMP Pharmaceuticals GMP in India is known as Schedule M,

a part of Drug & Cosmetics Act, 1940. Schedule M is

Before Initiating any procedure, it is required that it

required to be followed by manufacturers operating

should be properly defined and the necessary

Pharmaceutical Manufacturing Units. Schedule M

requirements & facilities are provided. Only trained

comprises of 2 parts (7)-

personnel should be allowed in practice, approved

procedures should be used, Availability of storage & Part 1 – GMP for Premises & Materials

transport facilities & proper records should be

Well maintained Good Design Equipments

Regularly monitoring the choice of cleaning

material & equipment

Adequately trained personnel and their protective

GMP clothing

(Good’s Manufacturing Practices)

Important Components Maintaining Standard operating procedures and

other documentation

Quality control of Packaging, Raw materials, and

finished product

Figure 1. Important components of GMP

It further includes: SOPs

Reference Sample

General Requirements

Reprocessing & Recovery

Production area

Validation & Process Validation

Ancillary area

Product Recall

Personnel

Distribution Record

Warehouse

Market complaints & Adverse Reaction

Quality Control Area

Manufacturing operations & Controls Site Master file

Health, Clothing & Sanitation of workers

Part 1A- Requirements for Manufacturing of Parenteral

Raw Material & Ophthalmic Preparations

Equipment

Labels & other Printed Materials Part 1B- Requirement for Manufacturing of Oral Solid

Documentation & Records Dosage Form (Tablets & Capsules)

Sanitation in the Manufacturing premises Part1C- Specific Requirements for Manufacturing of

Self inspection & internal quality audit Oral Liquids

Quality control system

Part1D- Specific Requirements for Manufacture of

Specifications

External Preparations

Master Formula Record

Batch Processing Record Part 2 – Requirement for Plant & Equipment (7)

Packaging Record

e-ISSN: 2321-6794 [48]

Abhimanyu et.al International Journal of Drug Regulatory Affairs. 2020; 8(4): 47-54

General requirements Production, Ancillary & Personnel, their Health,

Warehouse Area Clothing & Sanitation

Equipment, Raw Quality control system and area

materials, reference

sample

GMP Manufacturing operations &

controls

Validation & Process Validation

Sanitation in manufacturing

Reprocessing & Recovery

premises

Labels & other printed materials, Documentation &

Product Recall records,

Market Complaints & Adverse Reaction Specifications, Master formula record, Batch

Processing record, Packaging record, SOPs, Site

master file, Distribution Record

Figure 2. shows the combined components of GMP

1. General Requirements (7) joints to avoid accumulation of dust. The

walls should be smooth so that they can be

The Building & Premises which is to be used for

properly cleaned periodically.

the manufacturing, processing, packaging,

All the cleaning and painting records of

warehousing, testing & labeling should be –

the building should be maintained

Provided with adequate space to work & regularly.

to orderly arrange all the materials &

equipment & should also allow movement

of personnel. 2. Water System (7)

Compatible with the other operations that

can be carried out in the same area. Availability water treatment system must be there

Avoid all chances of mix-ups between so as to get purified water to carry out all the

different drugs, raw materials, operations except washing and cleaning. The water

intermediates, contamination & cross shall be stored in tanks and these tanks should be

contamination. cleaned periodically to ensure that water is free

The premises should be constructed in a from any microbial growth, & records should be

way to prevent insects, pests, rodents & maintained.

birds entry. The walls of the rooms should 3. Disposal of waste (7)

be smooth & free from cracks and should

allow easy painting and disinfection. The Disposal of waste from the premises should be

The premises should be well Air- in accordance with the requirement of Environment

Conditioned in all the areas where it is Pollution Control Board. All Bio-medical waste

required, properly lighted, ventilated & shall be destroyed as per biomedical waste Rules,

should have air handling units to maintain 1996.

temperature, humidity inside the building. There should be proper rules & provisions for the

Proper drainage system should be there in safe storage of waste materials awaiting disposal.

building, open channels shall be avoided Hazardous, flammable & toxic substance should be

& timely cleaning & disinfection should stored in suitably designed areas.

be done. All the records should be maintained time to time.

The walls & floors of the manufacturing 4. Warehouse Area (7)

unit should be free from the cracks & open

e-ISSN: 2321-6794 [49]

Abhimanyu et.al International Journal of Drug Regulatory Affairs. 2020; 8(4): 47-54

Warehouse area should be designed in such a way

that they shall be clear, dry & maintained.

8. Sanitation & Health (7)

Temperature should be maintained at all times, the

area should remain free from rodents, pests, & well

All the personnel should undergo medical

equipped with proper bins & platforms.

examination for full body; they should be free from

There should be a separate warehouse area for raw

any diseases like skin, communicable or

materials and excipient and the area must be

contagious, tuberculosis, before employment.

designed so that there is sufficient place for

A physician must be appointed for the health

different materials & products for starting &

checkup of all the personnel or assessing their

packaging materials, API & finished products,

health status.

intermediates, products in quarantine, products

Staff handling the Beta-Lactum antibiotics should

released, rejected, recalled & returned spare parts

be tested for Penicillin sensitivity, & those

of machines & equipment.

handling cytotoxic substance, potent drugs & sex

Narcotics, Psychotropic drugs & substance should

hormones should be examined by physician

be stored in safe & secure areas to avoid any

periodically for any kind of adverse effects, &

hazardous situation.

these personnel should be employed in these

Sampling & storage of sterile materials should be

sections on rotation to safeguard their health.

done in Aseptic area.

All personnel should be trained well for personal

The area should be regularly checked for any kind

hygiene & should be well observed if they are

of leakage or breakage of containers.

following all the instructions or not. Smoking,

All the records should be maintained from time to

Drinking, keeping food, medicines & drinks should

time.

not be allowed in the production, storage,

laboratory & other areas.

5. All staff should report about their illness to their

Ancillary Areas(7)

supervisor, if they have any.

All the premises shall be cleaned & maintained

There should be separate rooms for Refreshment,

periodically to ensure that they are free from waste,

Rest, Changing, Storing clothes & washing for

dust etc.

personnel’s. Toilets should be separate for males &

There should be proper space for working & in-

females.

storage space to avoid mix-ups & contamination.

These Ancillary areas should be separate from

other areas & shall not lead directly to the

manufacturing units.

9. Materials, Equipments, Packaging materials

Periodically cleaning and disinfecting records

should be maintained.

As per the starting materials specification shared by

QC, to the purchasing department, they order

materials to be used for the production purpose.

6. Quality Control Area (7)

They usually make orders with a supplier who is

approved by QA, QC & production department.

These areas should be designed to avoid any kind

All the material that is received from the suppliers

of mix-ups & cross contamination, there should be

should be stored separately from each other & after

proper space for test samples, reference standard,

checking all the materials, each one is labeled as

reagents & records.

quarantine with code no., material name, lot no. &

Separate area for Physico-chemical, biological,

date received. (8).

microbiological analysis. Periodically cleaning

All the labels for quarantine, released & rejected

should be done. Airlocks & Laminar air flow

should be in different colors so as to avoid any kind

should be there in microbiology section.

of errors. All the equipment used for production

should conform the specified quality parameters

7. (9).

Personnel (7)

They should be designed in a way so that it’s easy

to clean up. The material of the equipment should

All the manufacturing procedures & testing of

be well polished, smooth, no difficult corners,

products should be performed under the uneven joints, to avoid contamination & difficulty

supervision of competent technical staff, which has in cleaning. The material of the equipment should

the required qualification and experience in the

be non-reactive in nature with the products so as to

same.

avoid any reaction or contamination. Packaging

Staff for Quality Assurance & Quality Control

material which comes in direct contact with

section should be qualified & experienced in the

product should be of high grade quality so that it

same. All the duties for the technical staff & does not cause any contamination (10).

personnel responsible for QA/QC shall be laid &

followed by them strictly. Adequate no. of

personnel’s should be employed with proportion to

10. Validation (9)

the workload in the premises

e-ISSN: 2321-6794 [50]

Abhimanyu et.al International Journal of Drug Regulatory Affairs. 2020; 8(4): 47-54

Validation is an important part of GMP and it Through Documentation we can regulate all the

should be performed as per the protocols. All the procedures which are related to medicinal products.

results & conclusions of validation process should Common types of documents which are used in

be recorded, documented & maintained. industries are as mentioned below-

All the processes & procedures that had gone under

validation should be revalidated time to time to SOP (Standard Operating Procedures)

ensure that they can give the desired results. –this is a document in which step by step

All the buildings & premises design should comply instruction of all process and procedures

with the specifications of Design & they should are mentioned.

operate in accordance to their design specification. Test Method- it provides step by step

instruction for testing materials, products,

task, supplies etc.

11. Self-Inspection & Quality Audits (7) Policies – all the aspects of GMP o be

complied by the Manufacturer in the

A team should be made by the management premises.

including staffs who are experts in their respective Site Master File – it includes all the

fields. These teams can perform self inspection in information related to the Manufacturing

the production & Quality control area time in a site.

timely manner or on special occasions to make sure Quality Handbook – it includes all the

that the manufacturer is carrying out all the rules & regulations which are to be

procedures in accordance with GMP. followed by the company.

These self inspection or quality audits can help in Batch Record – it includes step by step

detecting any shortcoming in GMP implementation instruction for the entire task related to

& corrective measures can be taken within time. production area & these records are

The procedure of self-inspection should be well basically maintained by manufacturing

documented including results, conclusions, unit.

evaluation & the corrective actions. Batch Processing Records – its

There should be proper written instructions for – documentation of each processed batch of

1. Premises with personnel facilities the product & it complies with the

2. Personnel approved master formula.

3. Storage facility for raw material & finished - Before processing every new batch, it

products should be verified that the instrument

4. Documentation & the working station is properly

5. Quality control clean & clear of previous products &

6. Sanitation & Hygiene suitable for use.

7. Complaints - While processing every new batch,

8. Validation & Re-validation program following information should be

9. Procedures for recall recorded by a designated person

employed for the operations –

a) Product name

12. Complaints & Product Recalls (7) b) Number of the batch which is

being manufactured.

All the complaints related to the quality of the c) Operator’s name or the

product must be very carefully reviewed & person responsible for

recorded & there should be a written procedure for checking the process at each

carrying out this process. step.

If any serious adverse event occurs from the use of d) Date & time of starting of any

any drug, it should be recorded & documented with procedure, intermediate

the concerned authority. stage & completion of

A well-structured SOP should be drafted in the process.

premises for recall of the products. e) Information about any

All the product recalls should be documented and material, equipment or

the necessary corrective actions are to be event used.

performed timely. f) Batch no. of the starting

material

g) Amount of product yielded at

13. Documentation (11) different stages of

procedure

For GMP & Quality Assurance, Documentation of h) Record of all the in-process

each and every process or procedure is an controls, results yielded &

important part. Quality Management system the name of person who

defines all the types of Documentation required. carried out all of them.

e-ISSN: 2321-6794 [51]

Abhimanyu et.al International Journal of Drug Regulatory Affairs. 2020; 8(4): 47-54

i) Record all the deviations 6. Stage 2 Audit –During this second audit, the

occurred in the procedure auditor checks whether the company is

from the master formula. following rules & regulation according to its

documentation and if they have identified any

Batch Packaging Record (12). - It non-compliance, then the auditor gives an

should be in accordance with the opportunity to the company to correct the

packaging instructions and it should be particular non-compliance.

maintained for every batch. - Review – Reviewing of the

- Before packaging each batch, it is implementation of regulation

made sure that the working station & according to the documents of

the equipment is clear of the waste of company.

previous the batch products - Corrective Action- if they identify

any non-conformity, then corrective

action has to be taken.

14. GMP Certification Process: INDIA (13) - Verification – verify that all the rules

& regulations are being followed by

1. Application – it’s the first step of GMP all the employees.

Certification. It includes basic information of

the company. The application needs to be

accepted by the certification body. 7. Granting of Certification – after checking all

2. Review of application – after receiving the the parameters for compliance, the certification

application, it should be reviewed by a team to body issues a certificate of compliance, valid

make sure it complies with the entire for 3 years.

requirement.

3. Quote & Agreement – After reviewing the 8. Surveillance Audit – After the certificate is

application, the quote is provided to the clients issued, once in every 6 months period, a

& gap analysis is carried out so as to cover all surveillance audit should be performed to

the clauses & quality standard sections. ensure that the company fulfills all the

4. Documentation Review - Checking of requirements of management system.

documents to make sure they comply with the

requirements. 9. Re-Certification –it’s done after every 3 years.

5. Stage 1 Audit –

- Review – Checking the documents, - Review – review that the company

procedures of your company in complies with the requirement of the

comparison to the compliance management system.

requirement. - Corrective Action- if they identify

- Corrective Action – Take proper any non-conformity, then corrective

corrective action in case of non- action has to be taken.

conformity. - Verification – compare all the

- Verification – Documents should be company’s documentation with the

verified according to the required compliance requirement.

standards.

Table 1. Worldwide Agencies Regulating GMP

S. Countries with Regulatory Agencies Product to be inspected

No.

1. Canada – Health Canada API’s and Finished products (14)

2. Australia (Therapeutic Goods Administration API’s and Finished products (15)

3. Brazil ( National Agency for Sanitary Finished Pharmaceuticals (16)

Surveillance, ANVISA)

4. United States Bulk Pharmaceutical Chemicals (17)

5. Europe API’s & Finished Formulation (18)

6. United Kingdom(Medicine and Healthcare Finished Pharmaceuticals (19)

Products Regulatory Agency, MHRA)

7. South Africa (Medicines Control Council) Finished Pharmaceuticals (20)

Table 2. GMP Guidance Documents Websites

S.No. Country/Agency Website

1. Europe https://ec.europa.eu/health/documents/eudralex/vol-4_en (21)

2. United States https://www.fda.gov/drugs/pharmaceutical-quality-

resources/current-good-manufacturing-practice-cgmp-regulations

e-ISSN: 2321-6794 [52]

Abhimanyu et.al International Journal of Drug Regulatory Affairs. 2020; 8(4): 47-54

(22)

3. International Conference of https://www.ema.europa.eu/en/ich-q7-good-manufacturing-practice-

Harmonization active-pharmaceutical-ingredients (23)

4. The Pharmaceutical https://picscheme.org/en/activites-gmdp-harmonisation (24)

Inspection Convention and

Pharmaceutical Inspection

Co-operation Scheme (PIC/S)

5. Canada https://www.canada.ca/en/health-canada/services/drugs-health-

products/compliance-enforcement/good-manufacturing-

practices/guidance-documents/gmp-guidelines-0001/document.html

(25)

Conclusion technical report series: 823, ISBN 92 4140823 6, ISSN

Geneva; 1992 .p. 0512- 3054.

GMP is a practice for production & testing of medicinal

7. Schedule M. good manufacturing practices and

products in order to assure that the general population

requirements of premises, plant and equipment for

gets medicinal products of excellent quality. There have

pharmaceutical products; 25.03.2012,

been different guidelines all over the world for

cdsco.nic.in/html/GMP/Schedule(GMP).pdf

regulating the quality of medicinal products but all of

them have the same goal of safeguarding the health of 8. PIC/S Secretariat (Ed.): guide to good manufacturing

patients as well as manufacturing good quality medicinal practice for medicinal products, Pharmaceutical inspection

products. convention/ pharmaceutical inspection co-operation

scheme PE 009-2 1 July 2004, Geneva.

Excellent quality can be achieved by properly planning 9. US food & Drug Administration. CFR code of federal

& implying of Quality Assurance system and complying regulation [Internet]. USA: FDA; 2019 [sept 19]. [cited 12

with GMP guidelines. august 2020]. Available from:

GMP can be effectively implemented only if we have https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/

knowledge about all the components of GMP starting CFRSearch.cfm?CFRPart=211

from the Premises till the product development step. 10. Huber. L. Validation of analytical methods and

procedures. 25.03.2012,

Acknowledgements labcompliance.com/tutorial/methods/default.aspx.

We would like to express our sincere gratitude to 11. Eudralex: 2012, Eudralex-Volume 4 Good manufacturing

International Journal of Drug Regulatory Affairs for practice (GMP) Guidelines, 23.03.2012,

their continuous support and guidance. ec.europa.eu/health/documents/Eudralex/vol-

4/index_en.htm.

Financial Disclosure statement: The author received no

12. WHOTR: Annex 2 Supplementary guidelines on good

specific funding for this work.

manufacturing practices for heating, ventilation and air-

Conflict of Interest conditioning systems for non-sterile pharmaceutical

The authors declare that there is no conflict of dosage forms. In; WHO expert committee on

interest regarding the publication of this article. specifications for pharmaceutical preparations Fortieth

report WHO technical report series 937, Geneva; 2006 .p.

References 45-84.

1. Learoyd.P. Good Manufacturing Practices or ‘GMP’ A 13. Absolute Quality Certification Pvt. Ltd., GMP

Brief Guide, NBS-Scientific and Technical Training STT- Certification, Available from:

040, Sept 2005. http://www.absolutecertification.com/GMP.aspx

2. Shadle.PJ. Overview of GMPs, BioPharm International [Accessed on 2 November 2020].

[internet]. 2004 [cited Nov 15, 2004]. Available from: 14. Government of Canada. Health Canada [Internet].

http://www.biopharminternational.com/biopharm/artile/art Canada: Health Canada; 2020 [sept 19]. [Cited 12 august

icleDetail.jsp?id=134225&pageID=2. Accessed: 27th 2020]. Available from: https://www.canada.ca/en/health-

January, 2007 canada.html.

3. FDA (overview) An Overview of FDA [Internet]. 2007 15. Australian Government. Therapeutic Good’s

[cited 17th august, 2020]. Available from: Administration [Internet]. Australia: TGA; 2020 [Cited 12

http://www.fda.gov/ oc/opacom/fda101/sld013.html august 2020]. Available from:

4. Time Line: Chronology of Drug Regulation in the United https://www.tga.gov.au/.

States [internet]. 2007 [cited 27th august 2020]. Available 16. Ministerio da saude. Agencia National de Vigilancia

from: http://www.fda.gov/cder/about/history/time1.html Sanitaria [Internet]. Brazil: ANVISA; 2020 [Cited 12

5. Immel.BK. A Brief History of the GMPs, Regulatory august 2020]. Available from:

Compliance Newsletter, Winter [internet]. 2007 [cited https://www.gov.br/anvisa/pt-br.

17th August, 2020]. Available from: 17. US Department of Health & Human Services. US food &

http://www.gmplabeling.com/catalog/news1105.pdf Drug Administration [Internet]. US: USFDA; 2020 [Cited

6. WHOTRS. WHO expert committee on specifications for 12 august 2020]. Available from:

pharmaceutical preparations: thirty-second report. WHO https://www.fda.gov/home

e-ISSN: 2321-6794 [53]

Abhimanyu et.al International Journal of Drug Regulatory Affairs. 2020; 8(4): 47-54

18. European Union. European Medicines Agency [Internet]. resources/current-good-manufacturing-practice-cgmp-

EU: EMA; 2020 [Cited 12 august 2020]. Available from: regulations

https://www.ema.europa.eu/en 23. European Medicines Agency.ICH Q7 [Internet]. GMP for

19. UK Government. Medicines & Healthcare products Active Pharmaceutical Ingredient. EU: EMA; 2020

Regulatory Agency [Internet]. GOV.UK: MHRA; 2020 [Cited 16 august]. Available from:

[Cited 12 august 2020]. Available from: https://www.ema.europa.eu/en/ich-q7-good-

https://www.gov.uk/government/organisations/medicines- manufacturing-practice-active-pharmaceutical-ingredients

and-healthcare-products-regulatory-agency 24. PIC/S. GM (D) P Harmonization [Internet]. GMP

20. South Africa Government. South African Health Products Standards; 2020 [Cited 16 august]. Available from:

Regulatory Authority. [Internet]. SAHPRA; 2020 [Cited https://picscheme.org/en/activites-gmdp-harmonisation

12 august 2020]. Available from : 25. Government of Canada. Health Canada [Internet]. Good

https://www.sahpra.org.za/ Manufacturing Practices guide for drug products. Canada:

21. European Commission. Medicinal Products [Internet]. Health Canada; 2020 [Cited 16 august]. Available from:

Eudralex-Volume 4. GMP Guidelines. [Internet]. EU: https://www.canada.ca/en/health-canada/services/drugs-

EMA; 2020 [Cited 16 august 2020]. Available from: health-products/compliance-enforcement/good-

https://ec.europa.eu/health/documents/eudralex/vol-4_en manufacturing-practices/guidance-documents/gmp-

22. USFDA. Current Good Manufacturing Practice guidelines-0001/document.html

Regulations [Internet]. Code of Federal Regulations. US:

USFDA; 2020 [Cited 16 august 2020]. Available from:

https://www.fda.gov/drugs/pharmaceutical-quality-

e-ISSN: 2321-6794 [54]

View publication stats

You might also like

- Pfizer Pharmaceutical CompanyDocument6 pagesPfizer Pharmaceutical CompanySaad UllahNo ratings yet

- Example Biological Evaluation Submission Form Iso 10993 Part 1 Rev2Document7 pagesExample Biological Evaluation Submission Form Iso 10993 Part 1 Rev2Jezreel ZaragosaNo ratings yet

- The Online Poker Starting Guide (Frank Miller) PDFDocument39 pagesThe Online Poker Starting Guide (Frank Miller) PDFDe_VinciNo ratings yet

- PharmaDoc Pharmacy AppDocument109 pagesPharmaDoc Pharmacy AppUsama Malik100% (1)

- ABM Applied Economics Module 1 Differentiate Economics As Social Science and Applied Science in Terms of Nature and ScopeDocument37 pagesABM Applied Economics Module 1 Differentiate Economics As Social Science and Applied Science in Terms of Nature and Scopemara ellyn lacson100% (6)

- Aurobindo Pharma Limited - 577033 - 062F202F2019 FDADocument7 pagesAurobindo Pharma Limited - 577033 - 062F202F2019 FDAChandan ShahNo ratings yet

- PA 28 181 ChecklistDocument1 pagePA 28 181 Checklistrobk182No ratings yet

- GstarCAD 2017 USER GUIDE ภาษาไทยDocument269 pagesGstarCAD 2017 USER GUIDE ภาษาไทยPhannachet RungsrikeawNo ratings yet

- MR4 - Franchise Agreement - Train - Rolling Stock Module - Publication Version PDFDocument156 pagesMR4 - Franchise Agreement - Train - Rolling Stock Module - Publication Version PDFAnand Raj DoraisingamNo ratings yet

- Comparison of The EC-GMP Guide Part I With The SFDA-GMP Guideline For Chinese CompaniesDocument7 pagesComparison of The EC-GMP Guide Part I With The SFDA-GMP Guideline For Chinese Companiesrambabukomati472No ratings yet

- Lecture 5 PharmacovigilanceDocument32 pagesLecture 5 Pharmacovigilancephoto copyhemnNo ratings yet

- 385 PDFDocument8 pages385 PDFIjdra Journal Jitendra BadjatyaNo ratings yet

- Biosimilars ManuDocument6 pagesBiosimilars ManuIshan GhaiNo ratings yet

- Critical Review of The TransCelerate Template ForDocument10 pagesCritical Review of The TransCelerate Template Forbdvd1007092No ratings yet

- Estimation of Tinidazole and Ciprofloxacin in Bulk and Pharmaceutical Dosage Forms by RP HPLC MethodDocument7 pagesEstimation of Tinidazole and Ciprofloxacin in Bulk and Pharmaceutical Dosage Forms by RP HPLC MethodIJAR JOURNALNo ratings yet

- FDA-ISO QMS Audit Checklist GreenlightDocument3 pagesFDA-ISO QMS Audit Checklist Greenlightada wangNo ratings yet

- Biological Assessment of Medical Devices Containing Nano MaterialsDocument109 pagesBiological Assessment of Medical Devices Containing Nano Materialsalmudena gomezNo ratings yet

- Commercial Report BFT 28 April 2023 S3640279Document11 pagesCommercial Report BFT 28 April 2023 S3640279suzana krkicNo ratings yet

- Global Anti-Bacterial Drugs Market Assessment & Forecast: 2015-2019Document13 pagesGlobal Anti-Bacterial Drugs Market Assessment & Forecast: 2015-2019Re-Presen-TingNo ratings yet

- Global Pharmaceutical MarketDocument13 pagesGlobal Pharmaceutical MarketdashNo ratings yet

- Medical Device Import PoliciesDocument4 pagesMedical Device Import PoliciesRavia SharmaNo ratings yet

- Literature Search ReportDocument44 pagesLiterature Search ReportEon RegulatoryNo ratings yet

- 21 CFR Part 111, Dietary Supplement CGMP - Background, Development, Content, Comparison To Drug CGMP, and The FutureDocument9 pages21 CFR Part 111, Dietary Supplement CGMP - Background, Development, Content, Comparison To Drug CGMP, and The Futuremelimaulani-1No ratings yet

- MDA/GL/08 September 2022 Second EditionDocument11 pagesMDA/GL/08 September 2022 Second EditionKS Wong100% (1)

- Iso Ieee 11073-10417-2017Document80 pagesIso Ieee 11073-10417-2017Amer AmeryNo ratings yet

- Review On Design For Medical DeviceDocument10 pagesReview On Design For Medical Deviceserhat yaşpalaNo ratings yet

- Lecture 1Document38 pagesLecture 1Yong Hao Jordan JinNo ratings yet

- Australia Post Market Activity GuidelinesDocument31 pagesAustralia Post Market Activity Guidelinesspenceblack7999No ratings yet

- GMPJBK1 Scribd Uploaded JBK 001Document9 pagesGMPJBK1 Scribd Uploaded JBK 001Jaya Bir KarmacharyaNo ratings yet

- Registration Procedure of Marketing Authorization of Medicinal Product in MalaysiaDocument17 pagesRegistration Procedure of Marketing Authorization of Medicinal Product in MalaysiaFitrah Zulfikar MansyurNo ratings yet

- ImdrfDocument30 pagesImdrfborrellanoNo ratings yet

- Liquid Cream Production SystemDocument48 pagesLiquid Cream Production SystemUMIE UMAIRA KM-PelajarNo ratings yet

- A Comprehensive Study On Regulatory Requirements For Development and Filing of Generic Drugs GloballyDocument7 pagesA Comprehensive Study On Regulatory Requirements For Development and Filing of Generic Drugs GloballyAtikur RonyNo ratings yet

- Mdar1 - Adverse Event Report - 1 Oct 2018Document5 pagesMdar1 - Adverse Event Report - 1 Oct 2018Mary YamNo ratings yet

- Determination of Residue Aspects On Surface After Application of Imagard BIQUAT DisinfectantDocument8 pagesDetermination of Residue Aspects On Surface After Application of Imagard BIQUAT DisinfectantSurjeet SamantaNo ratings yet

- Regulatory Requirnment and Approval Procedure of Drugs in JapanDocument25 pagesRegulatory Requirnment and Approval Procedure of Drugs in Japansandeep bansalNo ratings yet

- AeroTrak - Plus - A100 31 35 50 51 55 - APC - User Manual 6016408 - USDocument74 pagesAeroTrak - Plus - A100 31 35 50 51 55 - APC - User Manual 6016408 - USRezaul KarimNo ratings yet

- 16 Notification For Clinical Research or Performance EvaluationDocument57 pages16 Notification For Clinical Research or Performance EvaluationrevathiNo ratings yet

- Slide 1Document6 pagesSlide 1marwaNo ratings yet

- Myanmar Food & DrugDocument28 pagesMyanmar Food & DrugYe MyintNo ratings yet

- Ms Opuntia BioeconomyDocument28 pagesMs Opuntia BioeconomyOrn-uma DaumNo ratings yet

- PHARMACEUTICAL INDUSTRY - REPORT Part 2Document47 pagesPHARMACEUTICAL INDUSTRY - REPORT Part 2Samra SiddiquiNo ratings yet

- Dietary Supplement RegulationDocument2 pagesDietary Supplement Regulationjbabu123No ratings yet

- VHP DCA Technical Data Sheet PDFDocument8 pagesVHP DCA Technical Data Sheet PDFMohammed AltafNo ratings yet

- Travel RestrictionsDocument16 pagesTravel RestrictionsaegeanxNo ratings yet

- UCLA FDA Inspection Guidance 1Document8 pagesUCLA FDA Inspection Guidance 1GeorgeNo ratings yet

- Pharmacovigilance and RMPDocument15 pagesPharmacovigilance and RMPЗухра ИбрагимоваNo ratings yet

- GS1 Anti-Counterfeiting White PaperDocument24 pagesGS1 Anti-Counterfeiting White PaperRashed MohammadNo ratings yet

- FDA Pesticides in Food Compliance GuideDocument40 pagesFDA Pesticides in Food Compliance Guidekristy yolibeth lopez banegasNo ratings yet

- Lifecycle of A MedicaldeviceDocument1 pageLifecycle of A MedicaldeviceJezreel ZaragosaNo ratings yet

- Bahrain New Regulation For Medical DeviceDocument2 pagesBahrain New Regulation For Medical Devicegulafsha1No ratings yet

- Strategic Management AmitDocument3 pagesStrategic Management AmitRahul BaranwalNo ratings yet

- Nigeria - Pharma Sector Profile - 032011 - Ebook - 0Document109 pagesNigeria - Pharma Sector Profile - 032011 - Ebook - 0Vishnu SharmaNo ratings yet

- Oig Process ValidationDocument11 pagesOig Process Validationbashira khalidyNo ratings yet

- Filed Order EQCE087085Document14 pagesFiled Order EQCE087085Local 5 News (WOI-TV)No ratings yet

- Ood Anufacturing Ractices in 21st Century: By:Ady Sadek M.SC., P.ChemDocument72 pagesOod Anufacturing Ractices in 21st Century: By:Ady Sadek M.SC., P.ChemRazvan Popa100% (1)

- Decription of The QM-Certification Procedure 13485 MDD EDocument5 pagesDecription of The QM-Certification Procedure 13485 MDD EJohn ThompsonNo ratings yet

- Srilaksmi 2017 Regulatory Requirements For Registration of API in US and EU PDFDocument17 pagesSrilaksmi 2017 Regulatory Requirements For Registration of API in US and EU PDFhira darNo ratings yet

- Classify Your Medical DeviceDocument3 pagesClassify Your Medical DeviceChris HartoyoNo ratings yet

- Gokwe Food System Summary Report 2022Document20 pagesGokwe Food System Summary Report 2022Anna BrazierNo ratings yet

- Good Manufacturing Practice (GMP) : History, Structure and Its SignificanceDocument7 pagesGood Manufacturing Practice (GMP) : History, Structure and Its SignificanceShivam VinothNo ratings yet

- Lannao, Arren Joyce J. Bsche V Good Manufacturing Practices (GMP) Good Laboratory Practices (GLP)Document1 pageLannao, Arren Joyce J. Bsche V Good Manufacturing Practices (GMP) Good Laboratory Practices (GLP)Jagna LannaoNo ratings yet

- What Are Gmps AnywayDocument4 pagesWhat Are Gmps Anywaymelfer100% (2)

- Vol 2Issue9September2014PharmaTutorPaper-1Document13 pagesVol 2Issue9September2014PharmaTutorPaper-1Anand KumarNo ratings yet

- Current Good Manufacturing Practices (cGMP) for Pharmaceutical ProductsFrom EverandCurrent Good Manufacturing Practices (cGMP) for Pharmaceutical ProductsNo ratings yet

- Calculation of Natural Gas Isentropic ExponentDocument8 pagesCalculation of Natural Gas Isentropic ExponentsekharsamyNo ratings yet

- Trickle Up-Mali Case StudyDocument40 pagesTrickle Up-Mali Case StudyPoverty Outreach Working Group (POWG)No ratings yet

- KPM V TrajanoDocument2 pagesKPM V Trajanojodelle11No ratings yet

- Level 2 Unit 7Document10 pagesLevel 2 Unit 7Yigal AlonNo ratings yet

- Version 6.0Document14 pagesVersion 6.0socialboy002No ratings yet

- Value Relevance of Accounting Information of Listed New Economy Firms in Nigeria-An Empirical Investigation Using Ohlson ModelDocument18 pagesValue Relevance of Accounting Information of Listed New Economy Firms in Nigeria-An Empirical Investigation Using Ohlson ModelNguyễn Hữu QuyNo ratings yet

- Certification of Testing: Manufacturer of World Class Direct Tension IndicatorsDocument1 pageCertification of Testing: Manufacturer of World Class Direct Tension IndicatorsJ. Fabián MenaNo ratings yet

- Alyssa Locken Resume Jan 2021Document3 pagesAlyssa Locken Resume Jan 2021api-544203584No ratings yet

- Duplex Filter and Duplex StrainerDocument2 pagesDuplex Filter and Duplex StrainerMuthuNo ratings yet

- Circuits Virtual LabDocument2 pagesCircuits Virtual LabPaula GómezNo ratings yet

- Practice Development Guide and Evaluation Rubric - Unit 3 - Phase 4 - Practical Component - Simulated PracticesDocument7 pagesPractice Development Guide and Evaluation Rubric - Unit 3 - Phase 4 - Practical Component - Simulated PracticesMaria Jose Ramos BarcoNo ratings yet

- Aviation News - December 2015Document84 pagesAviation News - December 2015serge.pungweNo ratings yet

- QW - 483 Registro Da Qualificação Do Procedimento de Soldagem (RQP)Document3 pagesQW - 483 Registro Da Qualificação Do Procedimento de Soldagem (RQP)sidnei carraschiNo ratings yet

- Chapter 7 - Strategy Implementation - NarrativeDocument14 pagesChapter 7 - Strategy Implementation - NarrativeShelly Mae SiguaNo ratings yet

- Palma Review of Dependency Theory World Development 1978Document44 pagesPalma Review of Dependency Theory World Development 1978Juan Hermidas100% (1)

- 1 14 321 XX GN de 007 Numering of Project DocumentDocument6 pages1 14 321 XX GN de 007 Numering of Project DocumentELPIDIO LUCERONo ratings yet

- 2 Replacement AnalysisDocument10 pages2 Replacement AnalysisKrishna BirlaNo ratings yet

- Acrysol rm-8w 3Document4 pagesAcrysol rm-8w 3Forever0% (1)

- Time and Distance Handwritten NotesDocument26 pagesTime and Distance Handwritten Notes20-20 online junctionNo ratings yet

- Spar Design of A Fokker D-VII - Aerospace Engineering BlogDocument8 pagesSpar Design of A Fokker D-VII - Aerospace Engineering Blogjohn mtz100% (1)

- Digital Media Project Proposal: Submitted To: DR Sawera ShamiDocument3 pagesDigital Media Project Proposal: Submitted To: DR Sawera ShamiJaveria JanNo ratings yet

- DP2269Document7 pagesDP2269GABRIEL AMORIM ARAUJONo ratings yet

- Test Bank For Advanced Accounting 2nd Edition HamlenDocument36 pagesTest Bank For Advanced Accounting 2nd Edition Hamlenacetize.maleyl.hprj100% (58)

- Ang Tibuok Mong KinabuhiDocument6 pagesAng Tibuok Mong KinabuhiJuliet PanogalinogNo ratings yet

- Indian Institute of Materials Management: Graduate Diploma in Public Procurement Paper No.5Document3 pagesIndian Institute of Materials Management: Graduate Diploma in Public Procurement Paper No.5shivamdubey12No ratings yet