Professional Documents

Culture Documents

HMM Infra TC

HMM Infra TC

Uploaded by

raisingh085Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HMM Infra TC

HMM Infra TC

Uploaded by

raisingh085Copyright:

Available Formats

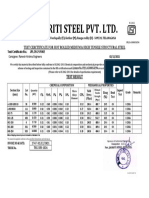

JINDAL STEEL & POWER LIMITED

Post Box No. 16, Kharsia Road, Raigarh(Chhattisgarh)-PIN 496001 INDIA

Registered Office : Post Box No. 6, O.P. Jindal Marg , Hisar (Haryana)

Corporate Office : Jindal Centre, 12 Bhikaji Cama Place, New Delhi- 110066 INDIA

Phone: (07762) 227001-227010; Fax : 07762-227021-227022;Gram : PIG IRON

Email : qcrailmill@jspl.com

TEST CERTIFICATE FOR HOT ROLLED MEDIUM & HIGH TENSILE STRUCTURAL STEEL

Test Method : Tensile : IS 1608 ; Bend : IS 1599 ; Impact : IS 1757 ; Chemical : ASTM E 415 / IS 8811

Test Certificate No. : 0000520473 Date : 16.03.2022 Time : 01:51:35

Customer: M/s HMM INFRA

VILL-MANDOUR,AMBALA-NARAINGARH ROADAMBALA,PIN-134003 Haryana Page 1 of 1

We certify that the material described below fully conforms to IS 2062:2011. Chemical composition and mechanical properties of the product as tested in accordance with the scheme of testing and inspection

contained in the BIS certification marks licence No. CM/L-8558192 are as indicated below against each Heat Number.

Process of Manufacture : EAF/NOF-LRF-CCM-Hot Rolling ( PLEASE REFER TO IS:2062:2011 FOR DETAILS OF SPECIFICATION REQUIREMENT) Supply Condition : As Rolled

TEST RESULTS Deoxidation : Killed

Heat No. Pcs/ Weight Chemical Analysis Mechanical Properties

Bndl in MT LA/PA %C %S %P %Si %Mn %AL %Cu %V %Nb %Ti %Mo %Ni %B %Cr N2 CE P YS UTS %EL Bend Test

**

% MPa MPa Mand Dia

Min - - - - - - - - - - - - - 250 410 23

Max 0.22 .045 .045 0.40 1.50 - - - - - - - 0.41 - - -

(Section Depth(mm) X Fl.Width(mm) X Fl.Thk(mm) X WEB Thk(mm) X Sectional Weight/Mtr) & Grade MC400X100X50.1 & IS2062 E250BR

2124661 14 8.193 LA 0.17 0.006 0.010 0.15 0.52 0.023 0.005 0.001 0.001 0.002 0.005 0.01 0.0068 0.25 P 341 482 29 Satisfactory(2.0T)

2124661 PA 0.16 0.008 0.012 0.16 0.52 0.025 0.006 0.002 0.002 0.002 0.006 0.01 0.0072 0.25 P 341 485 29 Satisfactory(2.0T)

2124663 5 2.926 LA 0.16 0.009 0.011 0.15 0.51 0.033 0.006 0.000 0.001 0.003 0.006 0.01 0.0068 0.25 P 304 473 28 Satisfactory(2.0T)

2124663 PA 0.19 0.011 0.010 0.18 0.55 0.030 0.005 0.001 0.002 0.001 0.006 0.01 0.0074 0.28 P 304 476 28 Satisfactory(2.0T)

2124666 1 0.584 LA 0.17 0.009 0.012 0.14 0.53 0.028 0.006 0.001 0.001 0.002 0.006 0.02 0.0066 0.26 P 340 472 30 Satisfactory(2.0T)

2124666 PA 0.18 0.009 0.018 0.20 0.55 0.029 0.009 0.001 0.002 0.002 0.009 0.01 0.0074 0.27 P 342 464 29 Satisfactory(2.0T)

Section Total : 20 11.703

(Section Depth(mm) X Fl.Width(mm) X Fl.Thk(mm) X WEB Thk(mm) X Sectional Weight/Mtr) & Grade NPB 358.0X172.2X13X8.1X57 & IS2062 E250BR

3124282 1 0.517 LA 0.15 0.009 0.013 0.18 0.77 0.025 0.005 0.002 0.001 0.002 0.002 0.005 0.02 0.0063 0.28 P 299 456 28 Satisfactory(2.0T)

3124282 PA 0.18 0.005 0.015 0.22 0.79 0.023 0.007 0.001 0.002 0.001 0.009 0.02 0.0082 0.31 P 307 439 28 Satisfactory(2.0T)

Section Total : 1 0.517

Total : 21 12.220

The material conforms to the standard rolling tolerances as IS 12779

The above section(s) is / are equivalent to the following section(s) respectively : ,MC400X100X50.1,UB 356X171X57

** Gauge Length = 5.65sqrt(So) ,LA:LadleAnalysis,PA:ProductAnalysis,P:Product

Purchase Oder No. & Date : 822/04.02.2022

Despatch Advice No : 27373915

Truck/Wagon No.: RJ47GA1233

Created by :JAYANAND_RUBM Printing Date 04.04.2022 & Time 15:46:23

FORMAT No. F13 (8.6.0-05) /02.08.2017 (SK Ojha) (Rakesh Yadav)

Authorised signatory (Mechanical Lab) Authorised signatory (Chemical Lab)

You might also like

- Executive Coaching Workbook PDFDocument19 pagesExecutive Coaching Workbook PDFDiego Fortes100% (4)

- MTC-2 - Service STRCDocument1 pageMTC-2 - Service STRCHema NandhNo ratings yet

- Sumaja MTC 40 RNDDocument1 pageSumaja MTC 40 RNDRINL GZB0% (1)

- Cert ACERO INOX 316L PDFDocument1 pageCert ACERO INOX 316L PDFCarlos RomeroNo ratings yet

- Test Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811Document1 pageTest Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811akash_smhs0% (1)

- 300 C SailDocument2 pages300 C Sailchandrabhushan kushwahaNo ratings yet

- Page 1 of 1: Test Certificate No. 0000141878Document1 pagePage 1 of 1: Test Certificate No. 0000141878Vishwanathan NagarajanNo ratings yet

- 10MMDocument1 page10MMStructures ProductionNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh Mehta100% (1)

- Test Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesDocument1 pageTest Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesSuman Jana100% (1)

- Page 1 of 9: Test Certificate No. 0000145263Document9 pagesPage 1 of 9: Test Certificate No. 0000145263Vishwanathan NagarajanNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOBilal Luhar100% (2)

- JSW Steel LimitedDocument1 pageJSW Steel LimitedVenkatesh KumarNo ratings yet

- Infracem - WK-19Document1 pageInfracem - WK-19Sirajul IslamNo ratings yet

- Jyoti Steel Industries: Test Certificate As Per en 10204-3.1Document1 pageJyoti Steel Industries: Test Certificate As Per en 10204-3.1Gagat GongatNo ratings yet

- Fo MTCDocument2 pagesFo MTCDeepakNo ratings yet

- MOE Simplex - 24.06.2016 PDFDocument4 pagesMOE Simplex - 24.06.2016 PDFSabyasachi BangalNo ratings yet

- 6X1830 HR CoilDocument1 page6X1830 HR CoilBhavik PanchalNo ratings yet

- 20MM - 63.150 TonDocument1 page20MM - 63.150 TonRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- JSW Steel MTCDocument5 pagesJSW Steel MTCNelson 2428No ratings yet

- S355J2 Plate MTCDocument2 pagesS355J2 Plate MTCHarminder Kumar100% (1)

- Global Aluminium Private Limited: M/S. Wonjin Autoparts India PVT LTD, ChennaiDocument1 pageGlobal Aluminium Private Limited: M/S. Wonjin Autoparts India PVT LTD, ChennaiSonu Singh100% (1)

- 0707711343Document2 pages0707711343venkata krishna reddy MorthlaNo ratings yet

- Hebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEDocument1 pageHebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEAnonymous TPoO5u8MeNo ratings yet

- TMT Fe-550D, 500DDocument9 pagesTMT Fe-550D, 500DRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Sample Test Certificate (24.12.2022)Document1 pageSample Test Certificate (24.12.2022)PalaniyandiNo ratings yet

- Barbed Wire MTC - 230912Document1 pageBarbed Wire MTC - 230912dmtcl selcp1No ratings yet

- Test Certificate: CM/L-NO:5200036277Document10 pagesTest Certificate: CM/L-NO:5200036277TARUNKUMARNo ratings yet

- 1jsl Ltd. TPI 3 (31803) MMDocument2 pages1jsl Ltd. TPI 3 (31803) MMPratik KarekarNo ratings yet

- En 8Document3 pagesEn 8ajaykrishnaaNo ratings yet

- Mittal Corp Limited Test Certificate FinalDocument1 pageMittal Corp Limited Test Certificate FinalMehmet SoysalNo ratings yet

- Atul 30,36-LoescheDocument16 pagesAtul 30,36-LoescheSales ITANo ratings yet

- Ssi Report 50-2Document18 pagesSsi Report 50-2Shubham MauryaNo ratings yet

- Indian Standards Chemical Composition and Mechanical Properties of SteelDocument7 pagesIndian Standards Chemical Composition and Mechanical Properties of SteelUmesh KingerNo ratings yet

- SAIL CatalogueDocument37 pagesSAIL Cataloguekoushikdey_20110% (1)

- TC No-1451Document1 pageTC No-1451Structures ProductionNo ratings yet

- SS304-1 2THK PDFDocument1 pageSS304-1 2THK PDFrajNo ratings yet

- 622888Document1 page622888DeepakNo ratings yet

- Round Bar 60mm, Square Bar 50 MM - MTCDocument1 pageRound Bar 60mm, Square Bar 50 MM - MTCMohammad Adil0% (1)

- Acc Moe REPORT PDFDocument4 pagesAcc Moe REPORT PDFSabyasachi BangalNo ratings yet

- MOE Test Result of Acc ConcreteDocument4 pagesMOE Test Result of Acc ConcreteSabyasachi BangalNo ratings yet

- Book 2Document68 pagesBook 2nm_rangaNo ratings yet

- Img 0001Document1 pageImg 0001Harish RanaNo ratings yet

- TC-ST52 MSLDocument1 pageTC-ST52 MSLVijay BhureNo ratings yet

- Material Test Certificate: M/s Alstom Projects India LimitedDocument1 pageMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleNo ratings yet

- Zhengbang Super Alloy Ltd.: BS EN 10204.3.1/产品质量证明Document1 pageZhengbang Super Alloy Ltd.: BS EN 10204.3.1/产品质量证明Sales HBS SolutionsNo ratings yet

- TC 1419 McnallyDocument2 pagesTC 1419 McnallymtlhwhNo ratings yet

- IS 4923 Chemical CompositionDocument1 pageIS 4923 Chemical CompositionTulasidas MalajiNo ratings yet

- Offshore A312A358 R2Document1 pageOffshore A312A358 R2Prathamesh OmtechNo ratings yet

- HR 6MM X 2.5 X 6 Mtrs (5) - SHELLDocument1 pageHR 6MM X 2.5 X 6 Mtrs (5) - SHELLGurumoorthy RajavijayanNo ratings yet

- BF20112602 English MTC PDFDocument2 pagesBF20112602 English MTC PDFSvetlana VujovićNo ratings yet

- Rajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1Document1 pageRajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1qualityNo ratings yet

- PSP TCDocument7 pagesPSP TCPSP kanpurdehatNo ratings yet

- Commented - 8' PIPE TCDocument1 pageCommented - 8' PIPE TCAqib Khan VCSPNo ratings yet

- Bhushan Power & Steel Limited: Mill Test CertificateDocument1 pageBhushan Power & Steel Limited: Mill Test CertificateKamal PriyanNo ratings yet

- Amnd No 2 IS 6911Document16 pagesAmnd No 2 IS 6911Rakesh Soti (JSHL-QUALITY)No ratings yet

- J.K.Cement Works-Muddapur J K Super Cement: END of ReportDocument12 pagesJ.K.Cement Works-Muddapur J K Super Cement: END of ReportSiddhesh Kamat MhamaiNo ratings yet

- Blind Rivet Quality Certification ReportDocument1 pageBlind Rivet Quality Certification ReportZain Abedeen0% (1)

- IS 14246-1995 Galvalume SheetDocument10 pagesIS 14246-1995 Galvalume SheetkumarchemNo ratings yet

- Page 2 of 6: Test Certificate No. 0000052877Document1 pagePage 2 of 6: Test Certificate No. 0000052877pranesh kadam100% (2)

- 18 MTR Painting ReportDocument7 pages18 MTR Painting Reportraisingh085No ratings yet

- Is 1477 1 1971Document26 pagesIs 1477 1 1971raisingh085No ratings yet

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- Welder Samples Courier To L&T Sachin RM Samples Courier To L&T Sachin Welder Samples Courier To NABLDocument30 pagesWelder Samples Courier To L&T Sachin RM Samples Courier To L&T Sachin Welder Samples Courier To NABLraisingh085No ratings yet

- Is 15531 2004Document13 pagesIs 15531 2004Mehmet SoysalNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To Informationraisingh085No ratings yet

- Is 9175 7 1986Document16 pagesIs 9175 7 1986raisingh085No ratings yet

- Welding Electrode CalculationsDocument1 pageWelding Electrode Calculationsraisingh085No ratings yet

- Three Phase Controlled RectifiersDocument90 pagesThree Phase Controlled RectifiersBolisetti DheerajNo ratings yet

- Classes and Objects: © 2017 Wipro Confidential 1Document35 pagesClasses and Objects: © 2017 Wipro Confidential 1Preethi A ECENo ratings yet

- Textile Internship - Usha YarnsDocument49 pagesTextile Internship - Usha YarnsROHAN GIREESHNo ratings yet

- MR SecGH Grp1 LeverAyushDocument12 pagesMR SecGH Grp1 LeverAyushSoumya HalderNo ratings yet

- Country Report On LondonDocument10 pagesCountry Report On LondonKhushboo Khanna100% (1)

- Target GamesDocument7 pagesTarget Gamesapi-245732877No ratings yet

- DLL Mathematics 6 q4 w6Document7 pagesDLL Mathematics 6 q4 w6Abegail CorpuzNo ratings yet

- 1.3. Consider The Bond-Portfolio Problem Formulated in Section 1.3. Reformulate The ProblemDocument4 pages1.3. Consider The Bond-Portfolio Problem Formulated in Section 1.3. Reformulate The ProblemVIKRAM KUMARNo ratings yet

- SM-Personal Finance-Unit1to3Document176 pagesSM-Personal Finance-Unit1to3Priyanshu BhattNo ratings yet

- Guasch-Espasa Brill 2015 PDFDocument21 pagesGuasch-Espasa Brill 2015 PDFERIKA VIVIANA MOLINA BALAGUERANo ratings yet

- BIO Genetics Eukaryote TranscriptionDocument23 pagesBIO Genetics Eukaryote TranscriptionAnonymous SVy8sOsvJDNo ratings yet

- Pre Issue ManagementDocument19 pagesPre Issue Managementbs_sharathNo ratings yet

- The Verb To BeDocument1 pageThe Verb To Bek.havleovaNo ratings yet

- Class 9 Science Worksheet - Matter in Our Surroundings - 1Document2 pagesClass 9 Science Worksheet - Matter in Our Surroundings - 1Sumedha Thakur100% (1)

- SCREW THREADS, BOLTS and NUTS PDFDocument10 pagesSCREW THREADS, BOLTS and NUTS PDFhrhgk50% (2)

- BIOL UA16 v201903Document2 pagesBIOL UA16 v201903Pam HNo ratings yet

- Policy - Task 2 ContentDocument6 pagesPolicy - Task 2 ContentJadhav AmitNo ratings yet

- PS: Patient Safety and Risk ManagementDocument5 pagesPS: Patient Safety and Risk Managementnoor88No ratings yet

- Lesson Plan in TLE 10Document31 pagesLesson Plan in TLE 10jan rose samsonaNo ratings yet

- Table of ASCII CharactersDocument2 pagesTable of ASCII CharactersVü PhämNo ratings yet

- En - S8018II Spec SheetDocument3 pagesEn - S8018II Spec SheetAndrea PaoNo ratings yet

- Oxygen Scavenger Boiler Water TreatmentDocument6 pagesOxygen Scavenger Boiler Water TreatmentDarius DsouzaNo ratings yet

- Car Sticker Policy PDFDocument11 pagesCar Sticker Policy PDFMohsin KhanNo ratings yet

- Republic Act No. 10591) An Act Providing For A Comprehensive Law On Firearms and Ammunition and Providing Penalties For Violations ThereofDocument2 pagesRepublic Act No. 10591) An Act Providing For A Comprehensive Law On Firearms and Ammunition and Providing Penalties For Violations ThereofLiMaLi ClitarNo ratings yet

- Articulo-Watson Crick PDFDocument2 pagesArticulo-Watson Crick PDFAjedrez ItineranteNo ratings yet

- FBS Pre TestDocument4 pagesFBS Pre TestEvelyn Santos100% (1)

- Persia and The Persian Question Volume IDocument275 pagesPersia and The Persian Question Volume IhbatesNo ratings yet

- Query ManualDocument37 pagesQuery ManualstraNo ratings yet

- Vocabulary Extra Unit 3Document3 pagesVocabulary Extra Unit 3MariaInesMartinefskiNo ratings yet