Professional Documents

Culture Documents

Perforated Type Cable Tray: Raceway Ducts

Perforated Type Cable Tray: Raceway Ducts

Uploaded by

Akash VakkayilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Perforated Type Cable Tray: Raceway Ducts

Perforated Type Cable Tray: Raceway Ducts

Uploaded by

Akash VakkayilCopyright:

Available Formats

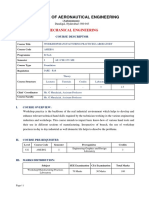

PERFORATED TYPE CABLE TRAY

RACEWAY DUCTS

WIDTH (W) 50 mm to 600 mm

HEIGHT (H) 25 mm to 150 mm

THICKNESS (T) 1.2 mm, 1.6 mm,2mm2.5 mm & 3 mm

LENGTH(L)

2500 mm / 3000 mm & 2444 mm (for Aluminum)

MOC

MS Steel, Stainless Steel, Aluminum

TRAY COVER AND CLAMP

LADDER TYPE CABLE TRAY

FLAT COVER SLOPPY COVER

COUPLER PLATES

PERFORATED TYPE CABLE TRAY LADDER TYPE CABLE TRAY

WIDTH (W) 50 mm to 1200 mm WIDTH (W) 50 mm to 1200 mm

HEIGHT (H) 25 mm to 100 mm SIDE CHANNEL HEIGHT (H)50 mm to 150 mm

THICKNESS (T) 1.6 mm,2mm2.5 mm & 3 mm RUN WIDTH 30 mm to 50 mm

LENGTH (L) 2500 mm / 3000 mm RUN HEIGHT 10 mm to 20 mm

MOC MS Steel, Stainless Steel, Aluminum RUN C TO C 250 mm to 300 mm

THICKNESS (T) 1.6 mm,2mm2.5 mm & 3 mm

LENGTH (L) 2500 mm / 3000

MOC MS Steel, Stainless Steel, Aluminum

PERFORATED TYPE CABLE TRAY

RACEWAY DUCTS

WIDTH (W) 50 mm to 600 mm

HEIGHT (H) 25 mm to 150 mm

THICKNESS (T) 1.2 mm, 1.6 mm,2mm2.5 mm & 3 mm

LENGTH(L)

2500 mm / 3000 mm & 2444 mm (for Aluminum)

MOC

MS Steel, Stainless Steel, Aluminum

TRAY COVER AND CLAMP

LADDER TYPE CABLE TRAY

FLAT COVER SLOPPY COVER

COUPLER PLATES

PERFORATED TYPE CABLE TRAY LADDER TYPE CABLE TRAY

WIDTH (W) 50 mm to 1200 mm WIDTH (W) 50 mm to 1200 mm

HEIGHT (H) 25 mm to 100 mm SIDE CHANNEL HEIGHT (H)50 mm to 150 mm

THICKNESS (T) 1.6 mm,2mm2.5 mm & 3 mm RUN WIDTH 30 mm to 50 mm

LENGTH (L) 2500 mm / 3000 mm RUN HEIGHT 10 mm to 20 mm

MOC MS Steel, Stainless Steel, Aluminum RUN C TO C 250 mm to 300 mm

THICKNESS (T) 1.6 mm,2mm2.5 mm & 3 mm

LENGTH (L) 2500 mm / 3000

MOC MS Steel, Stainless Steel, Aluminum

APPROVAL

1 Elcon CLIENTS

Insert the spring nut anywhere along the continuous Support System

slotted channel. The rounded nut ends permit easy

insertion. 100% Adjustable | 100% Reusable | bNo Welding

No Drilling | No Special Tools

2 UTILITY CHANNEL

Thickness

2.5 mm

Finishes

MS. Plain, Stalled

Hot Dip Galvanised

Material

Mild Steel

3 Standard Length

2 & 6 mtr

Insert the bolt through the fitting and into the spring

nut. See illustration 5 for end view showing the nut

in place)

4

Additional channel sections can now be bolted to

G. I. EARTHING FLATS

the fitting already in place by following procedure

described in steps 1-3.

5

Tightening with a wrench locks the serrated teeth of the

nut into the iturned edges of the channel, to complete a All Sizes Earthing Flats are Hot Dip Galvanized

as per IS 4759 - 2629

strong, vise-like connection.

You might also like

- Proposed 2-Storey Residential House-FootingDocument1 pageProposed 2-Storey Residential House-FootingZiur18100% (1)

- Slab Design Excel SheetDocument5 pagesSlab Design Excel SheetersivarajNo ratings yet

- Stoody 104Document1 pageStoody 104JUAN DAVID ESPITIANo ratings yet

- Metal Cable TrayDocument2 pagesMetal Cable TrayGaurav KoliNo ratings yet

- Steel Cable Ladder Trays (Steel S235 Jrg2) : Rail TypesDocument3 pagesSteel Cable Ladder Trays (Steel S235 Jrg2) : Rail TypesLeland SharafNo ratings yet

- E Line TlsDocument42 pagesE Line TlsmarchentoNo ratings yet

- Cable Management SystemsDocument53 pagesCable Management SystemsMohammed MustafaNo ratings yet

- 1 Cable Tray CatalogueDocument33 pages1 Cable Tray CatalogueAkash VakkayilNo ratings yet

- Elbow TEE: Part No Wide (MM) Hight (MM) Length (MM) (MM)Document1 pageElbow TEE: Part No Wide (MM) Hight (MM) Length (MM) (MM)REZANo ratings yet

- Type Sct25 Cable Trunking: Standard Length: 2.4M, Other Lengths Such As 3M Available Upon RequestDocument6 pagesType Sct25 Cable Trunking: Standard Length: 2.4M, Other Lengths Such As 3M Available Upon RequestHAFIZNo ratings yet

- Cable Support System (Part 3 - Ladder)Document131 pagesCable Support System (Part 3 - Ladder)Dera Nyilong Dera NyilongNo ratings yet

- Stoody 104TJ SAW005Document1 pageStoody 104TJ SAW005Juaros LeonNo ratings yet

- Ficha Técnica SSR y SSRWDocument3 pagesFicha Técnica SSR y SSRWAlberto Lennin CarrilloNo ratings yet

- Stoody 105Document1 pageStoody 105JUAN DAVID ESPITIANo ratings yet

- Emerald: CatalogueDocument22 pagesEmerald: CatalogueHuma JavedNo ratings yet

- Typical Girder/Beam DetailsDocument1 pageTypical Girder/Beam DetailsKaren JoyNo ratings yet

- Architectural: Department Subject Title: Drafted byDocument1 pageArchitectural: Department Subject Title: Drafted byJasper MayorNo ratings yet

- SWL 1.5 Tons Master Link: Door Side Lateral and Back Sides Floor SidesDocument1 pageSWL 1.5 Tons Master Link: Door Side Lateral and Back Sides Floor SideshshobeyriNo ratings yet

- Unitray ProductDocument53 pagesUnitray ProductSaravanan KsNo ratings yet

- KT Penstock PDFDocument24 pagesKT Penstock PDFKmi GutierrezNo ratings yet

- Part3 Ladder 24-7-19 CompressDocument132 pagesPart3 Ladder 24-7-19 CompressNhut Bang NguyenNo ratings yet

- Motor's Bearing DetailsDocument9 pagesMotor's Bearing DetailsValipireddy NagarjunNo ratings yet

- Retaining Wall-1Document6 pagesRetaining Wall-1Rajendra BadjatyaNo ratings yet

- Fencing Tech SpecDocument8 pagesFencing Tech SpecMaina MathengeNo ratings yet

- Magnetic Float Level Switch - KleevDocument2 pagesMagnetic Float Level Switch - KleevRAMZI ALJILANYNo ratings yet

- Imcc 2Document4 pagesImcc 2Valipireddy NagarjunNo ratings yet

- Imcc 3Document4 pagesImcc 3Valipireddy NagarjunNo ratings yet

- Steel Grating Weight Welded 22x50Document2 pagesSteel Grating Weight Welded 22x50Cane CirpoNo ratings yet

- Imcc 4Document4 pagesImcc 4Valipireddy NagarjunNo ratings yet

- Technical Bid 10078223 - 2023 07 04 20 20 23Document1 pageTechnical Bid 10078223 - 2023 07 04 20 20 23constructionenergoNo ratings yet

- Hcis Class-1Document11 pagesHcis Class-1shate2099No ratings yet

- Mass Calculator: Sheet & PlateDocument4 pagesMass Calculator: Sheet & PlateShaikh Mohd QaisarNo ratings yet

- Type Sct50 Cable Trunking: Standard Length: 2.4M, Other Lengths Such As 3M Available Upon RequestDocument6 pagesType Sct50 Cable Trunking: Standard Length: 2.4M, Other Lengths Such As 3M Available Upon RequestHAFIZNo ratings yet

- ABESTANO Wall and Column Footing Details LDocument1 pageABESTANO Wall and Column Footing Details LAldrin Abestano Jr.No ratings yet

- SFDocument15 pagesSFHai PhanNo ratings yet

- Radiator Product CatalogDocument4 pagesRadiator Product CatalogSamer Abdulaziz SadaqaNo ratings yet

- Resistance WireDocument16 pagesResistance Wirets01759No ratings yet

- Large Diameter: Couplings OD355.6 - 816Document4 pagesLarge Diameter: Couplings OD355.6 - 816Joh SongthamNo ratings yet

- Pavillion Summaries of The Analysis and DesignDocument4 pagesPavillion Summaries of The Analysis and DesignPRAVEEN RAJBHANDARINo ratings yet

- Sample Slope Protection DetailDocument1 pageSample Slope Protection DetailChub BokingoNo ratings yet

- Abestano - Wall and Column Footing Details and SchedulesDocument1 pageAbestano - Wall and Column Footing Details and SchedulesAldrin Abestano Jr.No ratings yet

- Astral Wire Guard PipesDocument2 pagesAstral Wire Guard PipesKiran KumarNo ratings yet

- Alt Industrial Rolled Copper and Copper Alloy Products 2016 GBDocument22 pagesAlt Industrial Rolled Copper and Copper Alloy Products 2016 GBsrinuNo ratings yet

- Ms Leonidas S2Document1 pageMs Leonidas S2Sancho AcbangNo ratings yet

- General CapabilitiesDocument1 pageGeneral CapabilitiesBenito LópezNo ratings yet

- Vantrunk Cable Tray Brochure MinDocument46 pagesVantrunk Cable Tray Brochure Minram.gopal217620No ratings yet

- Denah AokiDocument5 pagesDenah AokiAndika PangestuNo ratings yet

- Aerial Catalog 2 - 8 Alumoweld PDFDocument1 pageAerial Catalog 2 - 8 Alumoweld PDFsb_al20No ratings yet

- Lugs and Connectors: Features - Advantages - BenefitsDocument14 pagesLugs and Connectors: Features - Advantages - BenefitsDELMAR QUIROGA CALDERONNo ratings yet

- Universal "DUPLEX" Electrode For Welding and Cladding of Austenitic/ferritic Microstruc-Ture StainlessesDocument2 pagesUniversal "DUPLEX" Electrode For Welding and Cladding of Austenitic/ferritic Microstruc-Ture StainlessesnurarifiantoNo ratings yet

- Strip Cladding StripsDocument20 pagesStrip Cladding StripsMahesh DeshmukhNo ratings yet

- Troughed - Design Guidelines and StandardsDocument6 pagesTroughed - Design Guidelines and StandardshaqjmiNo ratings yet

- Hardface NM oDocument1 pageHardface NM ojohndupNo ratings yet

- Carriageway Carriageway Paver Paver Block Paver Drain Paver DrainDocument1 pageCarriageway Carriageway Paver Paver Block Paver Drain Paver DrainANKESH SHRIVASTAVANo ratings yet

- Factors That Influence - PDF - XX PDFDocument43 pagesFactors That Influence - PDF - XX PDFharmlesdragonNo ratings yet

- Cable Tray Sleeper and Support Design 3Document5 pagesCable Tray Sleeper and Support Design 3Elmokadem EinsteinNo ratings yet

- Model LOC Model LOC: CeltronDocument3 pagesModel LOC Model LOC: CeltronmhemaraNo ratings yet

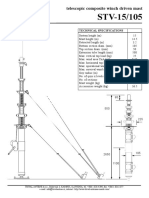

- Mastil 15mDocument2 pagesMastil 15mce4rwsNo ratings yet

- Standard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsFrom EverandStandard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsNo ratings yet

- Hilti Drilling & DemolitionDocument40 pagesHilti Drilling & DemolitionkhuNo ratings yet

- Millers Falls 1949 CatalogDocument89 pagesMillers Falls 1949 Catalogcrm102bNo ratings yet

- Bahasa Inggris Teknik Part2Document30 pagesBahasa Inggris Teknik Part2Nur IslamianingrumNo ratings yet

- CNC HistoryDocument26 pagesCNC HistoryBas RamuNo ratings yet

- Fixing of GratingDocument2 pagesFixing of GratingenggmohanNo ratings yet

- Report Benchwork DrillingDocument14 pagesReport Benchwork DrillingKhairunnisaSyahirah100% (2)

- Draft Handbook On Welding TechniquesDocument77 pagesDraft Handbook On Welding Techniquessssf-doboj100% (2)

- Aspl 2011 PDFDocument29 pagesAspl 2011 PDFRajkumar ANo ratings yet

- Ball-Peen Hammer - WikipediaDocument4 pagesBall-Peen Hammer - WikipediaAkarsh TpNo ratings yet

- Pliers: Pliers Are Hand Tools, Designed Primarily For Gripping Objects by Using LeverageDocument4 pagesPliers: Pliers Are Hand Tools, Designed Primarily For Gripping Objects by Using LeverageAli Mohd100% (2)

- Is 6735 1994Document14 pagesIs 6735 1994sarath6725No ratings yet

- JJ104 Workshop Technology Chapter4 Drilling Drill BitsDocument24 pagesJJ104 Workshop Technology Chapter4 Drilling Drill BitsAh Tiang50% (2)

- DIY CNC Router Build Fixed Gantry, Steel - Wade'O DesignDocument11 pagesDIY CNC Router Build Fixed Gantry, Steel - Wade'O DesignRed ErickNo ratings yet

- Jis B 0203 e 1982 PDFDocument14 pagesJis B 0203 e 1982 PDFrichard alexander santacruz wallesNo ratings yet

- History: Parts DescriptionDocument9 pagesHistory: Parts DescriptionClaudiu RotariuNo ratings yet

- Tri Fixx TextDocument216 pagesTri Fixx TextChitikala RajeshNo ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- Welding ReportDocument15 pagesWelding ReportSamNo ratings yet

- Catalog KennametalDocument749 pagesCatalog KennametalTrí PhạmNo ratings yet

- Cracks in WeldsDocument19 pagesCracks in Weldsjesycuban100% (1)

- Lab Report CNC LatheDocument6 pagesLab Report CNC LathePeter Van der Put0% (1)

- Assignment Engine BlockDocument7 pagesAssignment Engine Blocksaad100% (1)

- Fanuc Series 0 MB Fanuc Series 00 MB Operator S ManualDocument540 pagesFanuc Series 0 MB Fanuc Series 00 MB Operator S ManualRicardoPagésMarínNo ratings yet

- Mithshubishi Tool Catalogue - Full PDFDocument2,040 pagesMithshubishi Tool Catalogue - Full PDFdvb018No ratings yet

- Technical Information For Kipp ProductsDocument6 pagesTechnical Information For Kipp ProductsSannohashi MFGNo ratings yet

- Specification For Subsea Flange FittingDocument16 pagesSpecification For Subsea Flange FittingMuzammil Makandar100% (1)

- Chemical Machining ProcessesDocument2 pagesChemical Machining ProcessesMuhammadHamzaNo ratings yet

- Advanced Finishing ProcessesDocument15 pagesAdvanced Finishing ProcessesADWAITH G SNo ratings yet

- Ad1 80-10 Aydinlatma Di̇reği̇ PDFDocument1 pageAd1 80-10 Aydinlatma Di̇reği̇ PDFSinan SuleymanovNo ratings yet

- BWMP CD - MeDocument8 pagesBWMP CD - MeWossenu MekonnenNo ratings yet