Professional Documents

Culture Documents

TWAS-Tender Addendum - Structural

TWAS-Tender Addendum - Structural

Uploaded by

nvnagarajuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TWAS-Tender Addendum - Structural

TWAS-Tender Addendum - Structural

Uploaded by

nvnagarajuCopyright:

Available Formats

STRUCTURAL NOTES

LEGEND STRUCTURAL STEEL POST-INSTALLED ANCHORS

1. UNLESS NOTED OTHERWISE, STRUCTURAL STEEL SHALL CONFORM TO CSA G40.21, ROLLED WIDE FLANGE 1. POST-INSTALLED ANCHORS SHALL INCLUDE ADHESIVE ANCHORS (THREADED RODS, BOLTS

GROUT MASONRY SHAPES W, WT, HP, M AND S SHAPES TO ASTM A572 GRADE 50; CHANNEL AND ANGLES TO 350W: PLATES AND BARS TO 300W: OR REINFORCING BARS), EXPANSION ANCHORS, AND UNDERCUT ANCHORS INSTALLED INTO

HOLLOW STRUCTURAL SECTIONS TO CSA G40.20-04/G40.21-04 GRADE 350W CLASS H; STRUCTURAL PIPES TO ASTM A53, HARDENED CONCRETE OR MASONRY. SEE THE ANCHORAGE IN CONCRETE AND MASONRY

SPAN TYPE E OR S, GRADE B OR ASTM A500, GRADES B OR C, OR ASTM A501. ALL STRUCTURAL STEEL SHALL BE FABRICATED SPECIFICATION SECTION 05500 FOR ADDITIONAL REQUIREMENTS.

AND ERECTED IN CONFORMANCE WITH CISC SPECIFICATIONS.

GRATING GRADE 2. POST-INSTALLED ANCHORS SHALL ONLY BE USED WHERE INDICATED ON THE DRAWINGS.

2. UNLESS NOTED OTHERWISE, ALL STRUCTURAL STEEL COMPONENTS AND CONNECTIONS SHALL BE PAINTED CONTRACTOR SHALL OBTAIN APPROVAL FROM ENGINEER PRIOR TO USING POST-INSTALLED

HINGE LOCATION OR PROTECTIVE COATED IN ACCORDANCE WITH THE SPECIFICATIONS. ANCHORS FOR MISSING OR MISPLACED CAST-IN-PLACE ANCHORS.

3. ALL CONNECTIONS SHALL BE WELDED OR BOLTED IN ACCORDANCE WITH THE DETAILS, SPECIFICATIONS, AND 3. CARE SHALL BE TAKEN TO AVOID CONFLICTS WITH EXISTING REINFORCING STEEL AND OTHER

CHECKERED PLATE BEDROCK OR NATIVE SOIL CISC HANDBOOK. BOLTS SHALL BE ASTM A325M, 20mm MIN DIAMETER, BEARING TYPE BOLTS WITH THE EMBEDDED ITEMS WHEN DRILLING HOLES. HOLES SHALL BE DRILLED AND CLEANED PER THE

THREADS EXCLUDED FROM THE SHEAR PLANE UNLESS NOTED OTHERWISE. PRODUCT MANUFACTURER'S INSTRUCTIONS. ANCHORS SHALL BE INSTALLED PER THE PRODUCT

MANUFACTURER'S INSTRUCTIONS AT NOT LESS THAN MINIMUM EDGE DISTANCES AND/OR

4. SELECT LOCATIONS OF STRUCTURAL STEEL WORK OCCUR INSIDE EXISTING IN SERVICE STRUCTURES. SPACINGS INDICATED IN THE MANUFACTURER'S LITERATURE.

CONCRETE STEEL

5. PROPOSED SPLICE LOCATIONS SHALL BE DESIGNED BY A LICENSED PROFESSIONAL ENGINEER AND SUBMITTED 4. SUBSTITUTION REQUESTS FOR PRODUCTS OTHER THAN THOSE LISTED IN THE

FOR REVIEW AND APPROVAL. SEE STRUCTURAL STEEL SPECIFICATIONS. SPECIFICATION OR INDICATED ON THE DRAWINGS SHALL BE SUBMITTED TO ENGINEER FOR

REVIEW AND APPROVAL. PRODUCT ICC-ESR EVALUATION REPORTS SHALL BE INCLUDED

CEMENTITIOUS WATERPROOFING WITH THE SUBMITTAL PACKAGE. IF REQUESTED, CALCULATIONS PREPARED BY A

REGISTERED PROFESSIONAL ENGINEER USING METHODS AND PROCEDURES REQUIRED BY THE

4. STEEL LEGEND : BUILDING CODE MAY BE REQUIRED AS PART OF THE SUBMITTAL PACKAGE.

GENERAL

5. UNLESS NOTED OTHERWISE, THE MINIMUM EMBEDMENT PROVIDED FOR ADHESIVE ANCHORED

1. THE SPECIFICATIONS AND REQUIREMENTS INDICATED ON THIS SHEET ARE INTENDED AS A BASIC INDICATES TWO BOLT ATTACHMENT OF HORIZONTAL BRACING TO UNDERSIDE

REINFORCING BARS SHALL DEVELOP THE FULL TENSILE STRENGTH OF THE BAR.

SUMMARY OF THE MATERIAL, CONSTRUCTION AND INSPECTION REQUIREMENTS FOR THE PROJECT. OF BEAM. SHIM AS REQUIRED. BOLTS TO BE 20mm DIAMETER A325.

ADDITIONAL, MORE STRINGENT REQUIREMENTS ARE GIVEN IN THE PROJECT SPECIFICATIONS. IN 6. INSPECTION WILL BE PROVIDED FOR ALL POST-INSTALLED ANCHORS.

THE EVENT OF A CONFLICT BETWEEN THE REQUIREMENTS INDICATED ON THIS SHEET AND THOSE INDICATES ANGLE OR PLATE TO BE WELDED ON THREE SIDES

IN THE PROJECT SPECIFICATIONS, THE PROJECT SPECIFICATIONS SHALL GOVERN.

INDICATES FOUR BOLT ATTACHMENT OF MONORAIL TO UNDERSIDE OF SUPPORT

2. FOR LOCATIONS AND DIMENSIONS OF ALL EMBEDMENTS, SLEEVES, CURBS, OPENINGS AND DEPRESSIONS BEAM. SPACER OR STANDOFF DETAIL AS REQUIRED. STAINLESS STEEL

NOT SHOWN ON THE STRUCTURAL DRAWINGS, SEE ARCHITECTURAL, CIVIL, MECHANICAL PROCESS, SITE,

PLUMBING, HVAC AND ELECTRICAL DRAWINGS. CONTRACTOR SHALL VERIFY AND COORDINATE REQUIREMENTS 1 INDICATES NONSTANDARD FRAMING CONNECTION 1. STAINLESS STEEL BOLTS SHALL CONFORM TO ASTM F593, ALLOY GROUP 1 OR 2, UNLESS

AND LOCATIONS OF ABOVE ITEMS WHETHER SHOWN ON THE STRUCTURAL DRAWINGS OR NOT. NOTED OTHERWISE. MINIMUM YIELD STRENGTH SHALL BE 310 MPa.

xxx INDICATES HORIZONTAL OR VERTICAL BRACING CONNECTION DETAIL

3. EMBEDDED ITEMS, SUCH AS PIPE SLEEVES, CONDUITS AND INSERTS SHALL BE IN PLACE BEFORE 2. STAINLESS STEEL PLATES SHALL CONFORM TO ASTM A240, TYPE 316L.

CONCRETE IS POURED. SEE ARCHITECTURAL, CIVIL, MECHANICAL PROCESS, SITE, PLUMBING, HVAC INDICATES MOMENT CONNECTION

AND ELECTRICAL DRAWINGS FOR ITEMS REQUIRING SLEEVES AND EMBEDMENT IN CONCRETE 3. STAINLESS STEEL STRUCTURAL SHAPES SHALL CONFORM TO ASTM A1069 OR ASTM A276,

WHICH ARE NOT SHOWN IN THE STRUCTURAL DRAWINGS. TYPE 316L.

VERTICAL BRACING IS SHOWN ON PLANS THUS:

4. ALL STRUCTURAL RELATED SHOP DRAWINGS SHALL BE SUBMITTED, REVIEWED AND APPROVED BY THE

ENGINEER OF RECORD PRIOR TO FABRICATION. EXTENDING UP FROM THE ELEVATION INDICATED. SOIL AND FOUNDATIONS

5. THE APPLICABLE BUILDING CODE IS THE ONTARIO BUILDING CODE (OBC), 2012. EXTENDING DOWN FROM THE ELEVATION INDICATED. 1. ALL EARTHWORK AND FOUNDATION CONSTRUCTION SHALL BE IN ACCORDANCE WITH THE SPECIFICATIONS.

6. THE LATEST EDITION OF ALL REFERENCE STANDARDS SHALL BE USED. EXTENDING UP AND DOWN FROM THE ELEVATION INDICATED. 2. TO FACILITATE SCHEDULING, AT LEAST 48 HOURS ADVANCE NOTICE SHALL BE GIVEN TO THE ENGINEER

PRIOR TO THE REQUIRED INSPECTIONS.

7 STANDARD DETAILS ARE INTENDED TO BE TYPICAL AND SHALL APPLY TO PLANS AND SECTIONS

THROUGHOUT THE PROJECT, UNLESS NOTED OTHERWISE ON DRAWINGS. 5. STRUCTURAL STEEL SHOP AND ERECTION DRAWINGS SHALL BE SIGNED AND SEALED BY THE FABRICATOR'S 3. FOUNDATION CONSTRUCTION SHALL NOT BEGIN UNTIL THE INSPECTIONS HAVE BEEN COMPLETED AND THE

ONTARIO PROFESSIONAL ENGINEER LICENSED IN ONTARIO. CONTRACTOR NOTIFIED TO PROCEED.

CAST-IN-PLACE CONCRETE 6. CONNECTIONS SHALL BE DESIGNED AS PER SPECIFICATION REQUIREMENTS BY A PROFESSIONAL 4. UNLESS NOTED OTHERWISE, BACKFILL SHALL NOT BE PLACED AGAINST WALLS WHICH SUPPORT A

ENGINEER LICENSED IN ONTARIO. CONCRETE SLAB OR WALKWAY UNTIL THE TOP SLAB OR WALKWAY HAS BEEN PLACED IN ITS ENTIRETY AND

ALL CONCRETE HAS REACHED ITS DESIGN STRENGTH.

7. CARBON STEEL OR GALVANIZED STEEL ANCHOR RODS AND ANCHOR BOLTS SHALL CONFORM TO ASTM F1554 GRADE 55.

1. A MINIMUM 28 DAY COMPRESSIVE STRENGTH (f'c) of 30 MPa (UNLESS NOTED OTHERWISE) WAS UTILIZED IN THE DESIGN OF

STRUCTURAL, REINFORCED CONCRETE. HOLES FOR ANCHOR RODS AND ANCHOR BOLTS IN COLUMN BASE PLATES SHALL BE AS FOLLOWS:

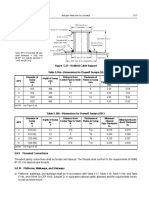

BOLT/ROD 19mm TO 25mm - 8mm OVERSIZE ULS AND SLS VALUES FOR HP 310x79 STEEL PILES

2. CEMENT SHALL CONFORM TO CSA 23.1 TABLE 7. TYPE MSb, HSb AS APPROPRIATE. BOLT/ROD 25mm TO 50mm - 13mm OVERSIZE

BOLTS/RODS OVER 50mm - 25mm OVERSIZE ESTIMATED PILE TIP FACTORED AXIAL AXIAL FACTORED AXIAL TENSILE

3. ALL CONCRETE CONSTRUCTION SHALL CONFORM TO THE ONTARIO BUILDING CODE (OBC) CSA A23.1/A23.2, COMPRESSIVE COMPRESSIVE TENSILE REACTION AT SLS

CSA A23.3 AND CSA A23.4 INCLUDING BAR BENDS AND HOOKS, UNLESS NOTED OTHERWISE. AT THE CONTRACTOR'S OPTION, OVERSIZE HOLES LARGER THAN THOSE LISTED ABOVE MAY BE DEPTH BELOW

ELEVATION RESISTANCE AT REACTION AT RESISTANCE AT (kN)

USED, PROVIDED THAT 10mm PLATE WASHERS ARE ALSO USED AND FIELD WELDED WITH A 8mm EXISTING GROUND ULS (kN) SLS (kN) ULS (kN)

4. THE LOCATION OF ALL CONSTRUCTION JOINTS AND OTHER TYPES OF JOINTS, OTHER THAN SPECIFIED OR FILLET TO THE BASE PLATE ALONG A MIN OF 3 SIDES. SURFACE (m) (m)

SHOWN ON THE PLANS, SHALL BE SUBMITTED TO THE ENGINEER FOR REVIEW AND APPROVED BY THE ENGINEER

PRIOR TO PLACING CONCRETE. 8. REFERENCE STANDARDS: SEE PILE

VARIES (*) 750 600 270 180

STRUCTURAL STEEL : CAN/CSA S16-14 LIMIT STATES DESIGN OF STEEL PLAN

5. ALL OPENINGS, PIPE SLEEVES, CONDUITS, INSERTS AND OTHER EMBEDDED ITEMS SHALL BE IN PLACE CARBON STEEL WELDING : CSA W59 WELDED STEEL CONSTRUCTION.

NOTE: SEE PILE PLANS, SPECIFICATION AND GEOTECHNICAL REPORT FOR FOUNDING LEVEL OF PILES

BEFORE CONCRETE IS PLACED. IT IS THE CONTRACTOR'S RESPONSIBILITY TO COORDINATE

ARCHITECTURAL, CIVIL, MECHANICAL PROCESS, STRUCTURAL, PLUMBING, HVAC, ELECTRICAL PLANS FOR

ITEMS REQUIRING SLEEVES AND EMBEDMENT IN CONCRETE WHICH ARE NOT INDICATED IN SECTIONS OR

FLOOR PLANS. NO PIPES OR SLEEVES SHALL PASS THROUGH STRUCTURAL MEMBERS, UNLESS SHOWN ON MASONRY LOADING CRITERIA

STRUCTURAL DRAWINGS OR MECHANICAL PROCESS DRAWINGS OR AS APPROVED BY THE ENGINEER.

1. CONCRETE MASONRY UNITS SHALL CONFORM TO CSA-A165 WITH A MINIMUM COMPRESSIVE STRENGTH

6. ALL EXPOSED EDGES AND CORNERS, UNLESS NOTED OTHERWISE, SHALL BE CHAMFERED 25mm EXCEPT OF 15 MPa (NET AREA). THE TOTAL MASONRY ASSEMBLAGE SHALL HAVE A MINIMUM COMPRESSIVE 1. DEAD LOAD ................................................................... CALCULATED

THE TOP EDGE OF WALLS AND SLABS WHICH ARE TO BE TOOLED. STRENGTH F'm OF 15 MPa FOR HOLLOW CONCRETE BLOCK MASONRY AND 7.5 MPa FOR SOLID OR GREEN ROOF DEAD LOAD .................................. 2.25 kN/m²

GROUTED CONCRETE BLOCK MASONRY PER CSA S304.

7. ALL CONSTRUCTION JOINTS TO EXISTING CONSTRUCTION SHALL BE ROUGHENED TO 6 mm AMPLITUDE MINIMUM. 2. LIVE LOADS: (UNO)

2. MASONRY MORTAR SHALL CONFORM TO CSA-A179, TYPE S. WALKWAYS, PLATFORMS & STAIRS ................. 5.0 kN/m²

8. REFERENCE CODES AND STANDARDS: OPERATING & PROCESSING FLOORS .............. 7.5 kN/m²

ONTARIO BUILDING CODE 2012 3. MASONRY MATERIALS AND CONSTRUCTION SHALL CONFORM TO CSA-A371. CENTRIFUGE FLOOR ........................................... 7.5 kN/m²

CSA A23.1/A23.2 - CONCRETE MATERIALS AND METHODS OF CONSTRUCTION/TEST STORAGE, GENERAL ........................................... 15.0 kN/m²

METHODS AND STANDARD PRACTICES FOR CONCRETE. 4. ALL BOND BEAMS AND ANY BLOCK CELLS CONTAINING EMBEDMENT, REINFORCING STEEL, ANCHORS, CHEMICAL STORAGE ROOM .............................. 15.0 kN/m²

CSA A23.3 - DESIGN OF CONCRETE STRUCTURES. ETC., SHALL BE FILLED WITH GROUT. BOND BEAM REINFORCEMENT TO BE CONTINUOUS ELECTRICAL & CONTROL ROOM FLOORS ....... 12.0 kN/m²

AC1 350M - CODE REQUIREMENTS FOR ENVIRONMENTAL ENGINEERING STRUCTURES AT CORNERS AND INTERSECTIONS. ROOF LIVE ............................................................. 1.0 kN/m² MINIMUM (NO REDUCTION TAKEN)

(FOR LIQUID-RETAINING STRUCTURES) ALL FLOORS NOT INDICATED ............................ 5.0 kN/m²

AC1 350.1M - SPECIFICATION FOR TIGHTNESS TESTING OF ENVIRONMENTAL ENGINEERING 5. SEE ARCHITECTURAL, CIVIL/STRUCTURAL, ELECTRICAL AND MECHANICAL DRAWINGS FOR EMBEDDED GREEN ROOF ........................................................ 2.55 kN/m²

CONCRETE CONTAINMENT STRUCTURES (FOR LIQUID-RETAINING STRUCTURES) ITEMS NOT SHOWN HEREIN AND TO VERIFY SIZE AND LOCATION OF ALL OPENINGS. BEFORE EXECUTING

CSA A23.4 - PRECAST CONCRETE MATERIALS AND CONSTRUCTION. 3. LATERAL EARTH PRESSURE: OVERBURDEN

ANYTHING HEREIN SHOWN, THE CONTRACTOR SHALL EXAMINE ACTUAL JOB CONDITIONS AND REPORT NON SATURATED............................................... REFER GEOTECH REPORT

TO THE ENGINEER ANY ERROR, OMISSION OR DISCREPANCY AFFECTING THE WORK.

SATURATED....................................................... REFER GEOTECH REPORT

REINFORCING STEEL

6. ALL REINFORCING BARS TO BE CONTINUOUS WITH LAP AS SHOWN ON THE

"TYPICAL MASONRY WALL REINFORCING" STANDARD DETAIL SHEET. 4. LATERAL SURCHARGE ........................................ EQUIVALENT OF 600 mm OF SOIL WHERE

ADJACENT TO ROADWAY

1. ALL REINFORCING BAR SHALL BE GRADE 400R, DEFORMED, CAN/CSA-G30.18, EXCEPT GRADE 400W

WHERE WELDING IS INDICATED OR SPECIFIED. 19 kN/m²

5. COMPACTIVE SURCHARGE LOAD ..................... 19 kN/m² AT FINISH GRADE ELEVATION

EXISTING STRUCTURES DECREASING LINEARLY AT SAME RATE AS

2. WELDED WIRE FABRIC SHALL CONFORM TO CSA G30.5.

BACKFILL LOAD INCREASES. FOR WALLS

3. CONCRETE COVER IS CLEAR DISTANCE BETWEEN BAR AND CONCRETE SURFACE. CONCRETE COVER 1. THE DRAWINGS DEPICT WORK AT EXISTING STRUCTURES. ALL DIMENSIONS AND ALL DEPICTIONS 2500mm OR LESS IN HEIGHT USE CRITERIA

SHALL CONFORM TO CONCRETE COVER STANDARD DETAIL, UNLESS NOTED OTHERWISE. SHALL BE FIELD VERIFIED BY THE CONTRACTOR PRIOR TO ORDERING MATERIALS, STARTING FOR COMPACTIVE SURCHARGE.

FABRICATION, OR STARTING CONSTRUCTION.

4. SPLICING OF REINFORCEMENT FOR WALLS, FOOTINGS AND SLABS SHALL BE AS SHOWN ON THE 6. HYDROSTATIC FLUID PRESSURE ....................... 10 kPa/m

"TYPICAL CONCRETE DETAILS" SHEETS, UNLESS NOTED OTHERWISE. WHEN BARS OF DIFFERENT 2. THE CONTRACTOR SHALL BE RESPONSIBLE FOR ANY DAMAGE, REPAIRS OR STRUCTURAL

SIZE LAP TO EACH OTHER, SPLICE LENGTH FOR THE LARGER BAR SHALL BE USED. MODIFICATIONS THAT ARE REQUIRED DUE TO DEMOLITION BEYOND THE LIMITS IDENTIFIED ON THE

DRAWINGS. 7. DESIGN FLOOD ELEVATION .................................. EL 76.000m

5. UNLESS INDICATED OTHERWISE, ALL DOWELS SHALL HAVE THE SAME SIZE AND SPACING AS THAT

OF THE REINFORCING STEEL TO WHICH THEY ARE SPLICED AND SHALL HAVE A MINIMUM LAP PER 3. REINFORCEMENT FOR ANY EXISTING CONCRETE OR MASONRY ELEMENT SHALL NOT BE DAMAGED UNLESS THE

NOTE NO. 4 ABOVE, UNLESS NOTED OTHERWISE. ELEMENT IS TO BE DEMOLISHED. WHEN LOCATING EXISTING REINFORCEMENT IS REQUIRED, IT SHALL BE

LOCATED USING NON-DESTRUCTIVE METHODS. WHERE NON DESTRUCTIVE METHODS ARE UNSUCCESSFUL, CLIMATIC DATA

6. NO WELDING OF REINFORCING BARS SHALL BE PERMITTED, UNLESS APPROVAL IS OBTAINED FROM CONTRACTOR SHALL USE LOCAL SELECTIVE DRILLING TO VERIFY REINFORCING STEEL LOCATIONS. CONCRETE AND

MASONRY SHALL BE REPAIRED AT ALL LOCATIONS OF SELECTIVE PROBING WITH IN-KIND REPAIR MORTARS. 1. REFERENCE LOCATION : TORONTO, ONTARIO

THE ENGINEER PRIOR TO CONSTRUCTION.

REINFORCING STRANDS IN EXISTING PRESTRESSED CONCRETE SHALL NOT BE CUT, UNLESS INDICATED ON THE

DRAWINGS OR OTHERWISE AUTHORIZED BY THE ENGINEER. THE CONTRACTOR SHALL BE RESPONSIBLE FOR ANY WIND : 1/10 0.34 Iw (SLS) = 0.75 SEISMIC : Sa (0.2) = 0.22 Sa (0.5) = 0.13

DAMAGE, REPAIRS OR STRUCTURAL MODIFICATIONS THAT ARE REQUIRED DUE TO DAMAGE OF CONCRETE, MASONRY HOURLY: 1/50 0.44 Iw (ULS) = 1.25 Sa (1.0) = 0.067 Sa (2.0) = 0.021

PGA = 0.120

ALUMINUM OR REINFORCEMENT THAT HAS BEEN IDENTIFIED ON THE DRAWINGS TO REQUIRE FIELD VERIFICATION.

RAIN : ONE DAY (1/50) = 97mm POST-DISASTER - ALL NEW BUILDINGS

4. SEE DEMOLITION AND SALVAGE SPECIFICATION 02050 FOR CONCRETE DEMOLITION AND MODIFICATIONS. SITE CLASS : D (ALL BUILDINGS AND STRUCTURES)

SNOW : Sr = 0.40 kPa Is (ULS) = 1.25

1. UNLESS NOTED OTHERWISE, ALUMINUM ALLOY IN ALL ALUMINUM STRUCTURAL MATERIALS SHALL Ss = 0.90 kPa Is (SLS) = 0.9 COMMON WALL FRAME IS DESIGNED FOR R =2

BE 6061-T6. PIPE AND TUBING MATERIAL FOR HANDRAIL AND GUARDRAIL SHALL BE ALLOY 6061-T6. 5. EXISTING PIPING, CONDUIT, LIGHTING FIXTURES AND OTHER APPURTENANT ITEMS MAY BE IN DIRECT VICINITY OF WORK,

SOME SERVICES WILL NEED TO REMAIN IN SERVICE AND SOME SERVICES MAY REQUIRE RELOCATION. SEISMIC COEFFICIENT = 0.12

FROST DEPTH: 1200mm TWAS BUILDING STRUCTURE IS DESIGNED FOR R =2

2. ALL ALUMINUM SURFACES IN CONTACT WITH CONCRETE OR DISSIMILAR METALS SHALL BE SEISMIC COEFFICIENT = 0.12

COATED OR COVERED WITH A HEAVY COAT OF EPOXY ENAMEL TO PREVENT ALUMINUM - 6. PROVIDE SHORING / BRACING OF EXISTING STRUCTURE AFFECTED BY REMOVAL.

DESIGN WIND PRESSURE FOR CLADDING DESIGN:

R:\d0978721\3D-S-Std Dtls.rvt

CONCRETE REACTION OR ELECTROLYTIC ACTION. 1.25 kPa (SLS) LIMITED DUCTILITY CONCENTRICALLY BRACED FRAME,TENSION

7. CORE DRILLING AND SAW CUTTING SHALL NOT BE PERFORMED UNLESS INDICATED ON THE DRAWINGS OR APPROVED

BY ENGINEER. 2.1 kPa (ULS) COMPRESSION BRACES

3. WELDED ALUMINUM CONSTRUCTION SHALL CONFORM TO CAN/CSA S157 STRENGTH DESIGN IN ALUMINUM.

4. ALL ALUMINUM WELDING SHALL CONFORM TO THE PROVISIONS OF CSA W59.2. 8. SHARP PROJECTIONS OF CUT OR SHEARED EDGES OF FERROUS METALS SHALL BE GROUND TO A RADIUS AS

NEEDED TO ENSURE SATISFACTORY COATING ADHERENCE.

ASHBRIDGES BAY TREATMENT PLANT

WAS THICKENING FACILITY AND SOUTH SUBSTATION UPGRADES

FRANK QUARISA, P. ENG. JOHN P. KELLY, P. ENG.

ACTING DIRECTOR, STRUCTURAL STANDARD NOTES

12/5/2018 10:31:49 PM

DIRECTOR, DESIGN & CONSTRUCTION

WASTEWATER TREATMENT MAJOR INFRASTRUCTURE STRUCTURAL

DESIGN: DK DRAFTING: NK CHECK: DT CONTRACT No. 19ECS-MI-01AB

SCALE: NTS DRAWING

1 DEC 2018 ISSUED FOR TENDER DT

No. DATE REVISIONS INITIAL SIGNED DATE: DEC 2018 NUMBER: 1001-2019-01-240 SG001

CONC SLAB

BEYOND

T

T/15,40mm MIN

T/2 T/2 EQ EQ

225 16 GAUGE WIRE TIED AROUND

CONC SLAB

10M BAR AND TIED AROUND

BEYOND

WATERSTOP

WIDEN BEAM POCKET REGULAR REINFORCING BARS

CONC BEAM

T/3 T/3 T/3

AT BOT AND SIDES TO PARALLEL TO JOINT AT 500mm

T/2 T/2

150 WATERSTOP PREVENT INTERFERENCE C TO C, TYP

T

BETWEEN WATERSTOP

T

LEAVE ROUGH

AND BEAM REINF EXP JT EXP JT

EQ EQ

6mm AMPLITUDE

CONC BEAM

T/15,20mm MIN

WATERSTOP

SECTION

40mm (MIN)

t/2

T=>450 75mm (MIN)

VAIRES

75mm (MIN) KEY NOT REQ'D AT

T/3 T/3 T/3

T<450 BOT AND SIDES

t

T=>450

OF BEAM POCKET

t/2

KEY NOT REQ'D AT

BOT AND SIDES SLABS WALLS TOP OF WALLS

T

OF BEAM POCKET

EQ EQ PLASTIC WATERSTOP, 10M CONTINUOUS REINFORCING

75mm (MIN) TYP BAR TIED ALONG EDGE OF

T/15,40mm MIN

TOP OF WALLS SLABS 75mm (MIN) 75mm (MIN) WATERSTOP WITH 16 GAUGE

REGULAR REINFORCING WIRE OR STEEL CLIPS AT

BARS, TYP 500mm C TO C, TYP

150

WATERSTOP

LEAVE ROUGH

EQ

T/3 T/3 T/3

T/3 T/3 T/3

6mm AMPLITUDE

T T 10M CONTINUOUS REINFORCING BAR WALL SECTION SLAB SECTION

40

*

TIED ALONG EDGE OF WATERSTOP

T/15,40mm MIN

T/15,40mm MIN

T

EQ

WATERSTOP WITH 16 GAUGE WIRE OR

T/3 T/3 T/3 T/3 T/3 T/3 225 WATERSTOP STEEL CLIPS AT 500mm C TO C, TYP

WATERSTOP ANCHORAGE 3

75 COVER

REGULAR REINFORCING BARS, TYP NTS -

T/15, 20mm MIN WATERSTOP EQ EQ

REINFORCING TIE 10M BAR TO

T=>450 STEEL WOOD BLOCKING

WITH U BOLTS @

t/2

THIS ALTERNATIVE MAY BE USED WHERE T=>450 500mm C TO C

VARIES

REQUIRED COVER IS 75mm OR GREATER SECTION

T=<450

t

ALIGN CL OF CONCRETE WALL TIE WIRES TO FASTEN

t/2

BULB WITH CL WS T&B @ 500mm MAX

BASE OF WALLS SLABS CORNERS OF EXPANSION W/ CONT EDGE OF WATERSTOP

JOINT WALL REINFORCEMENT TIED W/STEEL CLIPS

BASE OF WALLS WALLS NOTES:

FORMWORK 16 GAUGE TIED AROUND 10M BAR PLASTIC WATERSTOP WALL GROUT

1. REINFORCING STEEL IS CONTINUOUS THROUGH ALL CONSTRUCTION JOINTS. AND REGULAR REINFORCING BARS

SUIT

TO

PLASTIC WATERSTOP SET PARALLEL TO JOINT 500mm C TO C, "STAY-FORM"

2. WATERSTOPS SIZE SHALL BE 150mm FOR WALLS AND SLABS 450mm THICK OR FIRMLY IN PLACE BEFORE TYP

LESS, AND SHALL BE 225mm FOR WALLS AND SLABS THICKER THAN 450mm. PLACING CONCRETE

CL OF WS

PLAN/SECTION

HT TO

SUIT

JOINTS WITHOUT WATERSTOPS 1 TYPICAL JOINTS WITH WATERSTOPS 2 WATERSTOP ANCHORAGE FOR FIRST PLACEMENT 5

- SLAB

NTS - NTS - REINFORCEMENT

NTS

CONCRETE

SLAB

FOR ALL WATER HOLDING NOTES:

AND DRY BELOW GRADE

STRUCTURES, PROVIDE

INJECTO WATERSTOP 8 1. STARTER WALL REQUIRED FOR ALL CONSTRUCTION JOINTS WITH

EMBEDMENT AS SHOWN WET FACE OF WALL OR SLAB WATERSTOPS, UNLESS SPECIFICALLY NOTED OTHERWISE.

IN DRAWINGS - (INTERIOR OF WATER HOLDING

END OF EXISTING WALL OR SLAB

STRUCTURES) 2. FOR WALLS WITH SINGLE MAT OF REINFORCING, LOCATE WATERSTOP

STD LAP LENGTH HOLE DIAMETER AS RECOMMENDED (EXTERIOR OF DRY BELOW ON LIQUID FACE, 25mm CLEAR OF REINFORCING.

BY ADHESIVE MANUFACTURER 1000 UNO

3

9

GRADE STRUCTURES)

3 0

2 3. SECURE WATERSTOP IN-PLACE AS SPECIFIED.

T/2, SEE NOTE 3

4. PROVIDE DEDICATED VIBRATOR TO CONSOLIDATE CONCRETE ON

REBAR DOWELS/ EITHER SIDE OF WATERSTOP.

1

ADHESIVE ANCHORS

T/2

"T"

SEE DRAWINGS FOR

WALL BASE CONSTRUCTION JOINT

3

3

1

SIZE AND SPACING 4

"T"

6

2

NTS -

NEW WALL OR EXISTING REINFORCING

SLAB EXTENSION LIMITED EDGE DISTANCE ADHESIVE ANCHOR

DRY FACE

NEW WALL OR SLAB

STD LAP LENGTH REINFORCING BAR DOWELS,

FACE OF EXISTING WALL OR SLAB

ROUGHEN SURFACE OF EXISTING FORMED CONTINUOUS WET FACE OF WALL OR SLAB POURED JOINT FILLER

EMBEDMENT AS SHOWN TO WITHIN 15mm OF

.

EXISTING REINFORCING CONCRETE TO FULL 6mm GROOVE, SEE GROUTING (INTERIOR - WATER EXP JT

IN DRAWINGS AMPLITUDE AND CLEAN PROCEDURE HOLDING STRUCTURES) TOP OF SLAB

4

20 DET 1

(EXTERIOR - DRY BELOW

GRADE STRUCTURES)

WALL - PLAN PROVIDE 50mm DEEPx100mm WIDE 15

1

3

CONTINUOUS KEY IN

20

SEE NOTES ABOVE EXISTING CONCRETE

15mm CHAMFER,

EXISTING CONCRETE TYP

4

WET FACE

MIN

75

20

1

5

UNLIMITED EDGE DISTANCE EXTERIOR EXPOSED

SURFACE TO 600mm

3

BELOW GRADE

T/2

1

3

PREMOLDED JOINT

"T"

ABOVE GRADE SLABS FILLER (SELF EXPANDING

2

6

CORK) TYPE EACH SIDE

75 TYP

DRY FACE EXISTING CONCRETE OF WATERSTOP

DET 1 EXP JT SEALANT

NOTES: CONTINUOUS INJECTION WATERSTOP

50 2

SAW-CUT SURFACE OF CONCRETE NEW CONCRETE WATERSTOP SYSTEM

1. FOLLOW ADHESIVE MANUFACTURER'S INSTRUCTIONS FOR INSTALLATION OF ANCHORS. DRY FACE BACKUP

TO 50mm DEPTH THEN CHIP TO REMOVE AS RECOMMENDED

2. USE EMBEDMENT AS SHOWN IN DRAWINGS, EXCEPT USE MANUFACTURER'S MINIMUM MATERIAL

50mm DEEP x CONT KEYWAY FULL DEPTH BY MANUFACTURER

RECOMMENDED EMBEDMENT IF GREATER. OF SLAB. TAKE CARE NOT TO DAMAGE PREMOLDED

3. LOCATE DOWELS CENTRED IN WALL OR SLAB UNLESS OTHERWISE NOTED ON DRAWINGS. WHERE EXISTING REINFORCEMENT. JOINT FILLER

2 ROWS OF DOWELS INDICATED, STAGGER SPACING & LOCATE ALTERNATING DOWELS AT MINIMUM CONSTRUCTION JOINT

GROUTING PROCEDURE:

EDGE DISTANCE FROM OPPOSITE FACES. SLAB - SECTION ENLARGED DETAIL 1

4. EDGE AND EMBEDMENT DISTANCE AS RECOMMENDED BY ADHESIVE ANCHOR MANUFACTURER. 1. WAIT UNTIL NEW CONCRETE MINIMUM 28 DAYS OLD PRIOR TO GROUTING GROOVE.

NOTES:

2. ROUGHEN AND CLEAN SURFACES OF GROOVE WITH POWER WIRE BRUSH OR SANDBLASTING.

1. ENSURE PROPER QUALITY CONTROL DURING CONCRETE PLACEMENT AND 3. SATURATE AREA FOR 24 HOURS PRIOR TO GROUTING.

MAKE THE JOINT WATERTIGHT. 4. DRY PACK WITH TYPE II NON-SHRINK GROUT.

5. USE STEEL HAMMER AND STEEL TOOL TO DENSELY PACK GROUT INTO GROOVE. PREMOLDED JOINT FILLER

2. RUN INJECTO HOSE WATERSTOP INTO ADJACENT WALLS / SLABS AS REQUIRED

6. WATER CURE GROUT FOR 4 DAYS MINIMUM. (SELF EXPANDING CORK)

TO ENSURE WATERTIGHT STRUCTURE.

7. ENSURE QUALITY WORKMANSHIP SUCH THAT THE JOINT IS WATERTIGHTAS PERFORMANCE TYPE

REQUIREMENT.

SLAB ON GRADE

ADHESIVE DOWEL/ANCHOR 6 CONNECTION OF NEW CONCRETE TO EXISTING 7 CONNECTION OF NEW CONCRETE TO EXISTING 8

NOTE:

ATTACH PREMOLDED JOINT FILLER WITH 65mm GALVANIZED NAILS

- - -

R:\d0978721\3D-S-Std Dtls.rvt

NTS NTS NTS @ 300mm SPACING EMBEDDED IN FIRST SLAB POUR.

SLAB EXPANSION JOINT TREATMENT 9

-

NTS

ASHBRIDGES BAY TREATMENT PLANT

WAS THICKENING FACILITY AND SOUTH SUBSTATION UPGRADES

FRANK QUARISA, P. ENG. JOHN P. KELLY, P. ENG.

ACTING DIRECTOR, STANDARD DETAILS 1

5/16/2019 11:16:29 AM

DIRECTOR, DESIGN & CONSTRUCTION

WASTEWATER TREATMENT MAJOR INFRASTRUCTURE STRUCTURAL

DESIGN: DK DRAFTING: NK CHECK: DT CONTRACT No. 19ECS-MI-01AB

2 MAY 2019 ISSUED FOR TENDER DT

SCALE: NTS DRAWING

1 DEC 2018 ISSUED FOR TENDER DT

No. DATE REVISIONS INITIAL SIGNED DATE: FEB 2019 NUMBER: 1001-2019-01-241 SM501

A2

75 MIN A2 A3 E2 E2 E3

75 MIN 75 MIN 75 MIN

75 MIN B 75 MIN B B A2 NOTE C

75 MIN 75 MIN 75 MIN 75 MIN 75 MIN

B B B

WALL 2

WALL 2

75 MIN

75 MIN

NOTE C NOTE C WALL 3 WALL 2 WALL 3

NOTE A NOTE A NOTE A NOTE A NOTE A NOTE C

75 MIN

75 MIN

WALL 3

WALL 2 WALL 2

E1

E1

ALTERNATE HOOK NOTE D NOTE E

A1

NOTE E

A1

NOTE D

B

WALL 2 DIRECTION

A2 A3 WALL 1 WALL 1 WALL 1

A1

A1

NOTE D WALL 1 NOTE A (ALT)

B

NOTE A

NOTE A NOTE A (ALT)

B

NOTE D Z-BAR SPACERS AT 15M BAR x 1300 LONG

WALL 1 NOTE A 200 mm CENTERS EACH EACH CORNER IN CENTER

75 MIN

WALL 1 E = WHERE SPECIFICALLY NOTED ON THE DRAWINGS, ADDITIONAL

75 MIN

DIRECTION. MINIMUM

CORNER REINFORCEMENT SHALL BE PLACED IN BOTH FACES OF THE

75 MIN

NOTE A

75 MIN

ONE ROW. FABRICATE

INDICATED CORNER OVER THE FULL HEIGHT. ADDITIONAL CORNER

FROM 10M OR HEAVIER

REINFORCEMENT SHALL BE OF THE SAME SIZE AND SPACING AS THE

BARS. TIE TO OUTSIDE

MAIN CORNER REINFORCEMENT. PLACE ADDITIONAL REINFORCEMENT

A = VERTICAL CONSTRUCTION JOINT NEAREST TO WALL CORNER. B = OPTIONAL SPLICE LOCATION UNLESS SPECIFICALLY NOTED ON LAYER OF REINFORCING.

ALTERNATELY WITH, AND EQUAL DISTANCE BETWEEN, MAIN CORNER

PLAN DRAWINGS. SPLICE LENGTH SHALL NOT BE LESS THAN THAT REINFORCEMENT.

A (ALT) = ALTERNATE VERTICAL CONSTRUCTION JOINT NEAREST TO REQUIRED FOR TOP BARS AS SHOWN IN TABLE ON THIS SHEET. USE

WALL CORNER IN T WALL JOINT WHICH DOES NOT REQUIRE WATERSTOP. SPLICE LENGTH FOR THE LARGER OF THE TWO BARS BEING SPLICED. E X = DISTANCE FROM INSIDE CORNER FACE TO TERMINATION OF

ADDITIONAL CORNER REINFORCEMENT IN SIMILARLY NUMBERED WALL.

C = STANDARD HOOK

Ax = DISTANCE FROM INSIDE CORNER FACE TO NEAREST VERTICAL E X SHALL NOT BE LESS THAN 0.20 THE CLEAR SPAN DISTANCE

CONSTRUCTION JOINT IN SIMILARLY NUMBERED WALL. Ax SHALL D = TYPICAL CORNER REINFORCEMENT. SIZE SHALL MATCH MEASURED HORIZONTALLY BETWEEN THIS CORNER AND THE NEXT OR

NOT BE LESS THAN DIMENSIONS INDICATED BY THESE DETAILS; LARGEST ADJACENT WALL HORIZONTAL REINFORCEMENT; 0.40 THE CLEAR SPAN DISTANCE OR CANTILEVERED DISTANCE

NOR GREATER THAN INDICATED ON PLAN DRAWINGS; BUT IN ANY SPACING SHALL MATCH MINIMUM ADJACENT WALL MEASURED VERTICALLY, WHICHEVER IS SMALLER, BUT NOT LESS

CASE SHALL NOT EXCEED 9000 mm IN LIQUID CONTAINMENT HORIZONTAL REINFORCEMENT SPACING. THAN 1000 mm.

STRUCTURES OR 12000 mm IN OTHER STRUCTURES. IN T WALL CONTRACTORS OPTION: (TYPICAL REQUIRED UNLESS ADDITIONAL REINFORCEMENT

JOINTS WHICH DO NOT REQUIRE WATERSTOP, A1 MAY BE ZERO. NOTES: E BAR TAILS MAY BE SPLICED USING LAPPED SPLICE LENGTHS FOR SPECIFICALLY INDICATED AT OPENINGS ON DRAWINGS

TOP BARS. SPLICES SHALL NOT BE LOCATED IN THE CORNER AREA

1. VERTICAL REINFORCING NOT SHOWN COMMON TO BOTH WALLS AND SHALL CLEAR HOOK ENDS BY 100 mm MIN.

MAIN REINFORCEMENT FOR ALL STRUCTURES 2. THESE DETAILS SHALL BE APPLICABLE TO ALL WALL

CORNERS UNLESS NOTED OTHERWISE ON THE DRAWINGS (SPECIFICALLY NOTED ON THE DRAWINGS)

SPACERS ADDITIONAL REINFORCING

TYPICAL HORIZONTAL CORNER REINFORCING 1 ADDITIONAL REINFORCEMENT 2

FOR WALL REINFORCEMENT 3

AT ISOLATED RE-ENTRANT CORNERS 4

NTS -

NTS - NTS - NTS -

SLAB BARS WALL WALL

NOTE 2

SUSPENDED WALL BARS

SLAB NOTE 3

NOTE 5

SUSPENDED

SUSPENDED MAT BARS SLAB

SLAB 15M BAR x 1300LONG D B D B

NOTE 2

MAT FOUNDATION SLAB BARS EACH CORNER IN CENTER

NOTE 2 SLAB BARS NOTE 1 D FOR CONCRETE THICKNESS EXTRA BARS EQUAL IN TOTAL AREA TO REGULAR REINFORCING CUT BY

NOTE 6 300 OR LESS, OPENING. PLACE ONE HALF TOTAL AREA TO EACH SIDE OF OPENING

NOTE 2

EACH FACE FOR CONCRETE AND IN THE SAME TRANSVERSE POSITION AS REGULAR REINFORCING.

NOTE 1 THICKNESS > 300

ONE EXTRA BAR EACH CORNER PER LAYER OF REGULAR

WALL

NOTE 2

REINFORCING (SEE TABLE BELOW). PLACE IN SAME

TRANSVERSE POSITION AS REGULAR REINFORCING.

NOTE 1 NOTE 2

NOTE 4 THICKNESS BAR LENGTH

NOTE 1 OF CONCRETE BAR SIZE RECT OPNG CIRC OPNG

WALL NOTES: <300 mm 10M 1000 mm D+300 mm

SLAB BARS 300 mm TO 450 mm 15M 1000 mm D+300 mm

WALL BARS NOTE 3 >450 mm 20M 1200 mm D+300 mm

B

NOTE 1, SUSPENDED 1. EMBEDMENT LENGTH L = CLASS A LAP LENGTH

TYP SLAB (OTHERS BARS) BUT NOT LESS THAN A STANDARD B=THE REQUIRED LENGTH FOR LAPPED SPLICE

MAT BARS HOOK. FOR TOP BARS AS SHOWN ON THIS SHEET

NOTE 2 NOTE 2

SUSPENDED MAT FOUNDATION 2. CLASS B LAP UNLESS NOTED OTHERWISE.

SLAB

NOTE 2

SLAB BARS 3. DOWELS TO MATCH SLAB REINFORCEMENT UNLESS FOR OPENINGS FOR RECTANGULAR OPENINGS FOR CIRCULAR OPENINGS

NOTED OTHERWISE. 300 mm <= D <= 500 mm 500 mm < D <= 1400 mm 500 mm < D <= 1400 mm

4. DOWELS TO MATCH SLAB REINFORCEMENT UNLESS

WALL NOTED OTHERWISE.

NOTE 1, 5. APPLY DETAILS TO EXTERIOR WALL WITH UP TO (TYPICALLY REQUIRED UNLESS ADDITIONAL REINFORCEMENT SPECIFICALLY INDICATED AT OPENINGS ON DRAWINGS)

TYP 30mm OF FOOTING PROJECTION.

6. PROVIDE SLAB BOTTOM BARS WITH STANDARD

REINFORCING AT WALL AND SLAB INTERSECTIONS 5 HOOKS WHERE INDICATED. TYPICAL EXTRA REINFORCING AT OPENINGS 500mm TO <= 1400mm 6

NTS - NTS -

CAST THIS WALL/SLAB SECTION FIRST

. .

450 TYP

LENGTH OF LAPPED SPLICES JOINT TREATMENT

9

NOTES:

225 TYP EXP JT

FOR REINFORCEMENT (MM) CONCRETE COVER FOR REINFORCEMENT EXTEND HORIZ REINF SEE PLAN SM501

TO 50mm FROM JOINT 1. FOR WALLS / SLABS WITH THICKNESS OF 250mm THRU 600mm.

(UNLESS NOTED OTHERWISE ON THE DRAWINGS) EXPANSION JOINT FOR 250mm WALLS / SLABS LOCATE DOWELS 100mm FROM FACE OF WALL / SLAB

12 TYP

(f'c=30MPa) 400 MPa REINFORCING BAR LOCATION MINIMUM COVER (mm) FILLER MATERIAL INSTEAD OF T/2 INDICATED.

EXTERIOR FACE 25 CLR

CAST AGAINST AND PERMANENTLY EXPOSED TO EARTH MIN

CLASS A / 75 2. 25mm DIA x 900mm SMOOTH COATED BAR DOWELS. LOCATE AT 300mm MAX

CLASS B FROM TOP AND 600mm FROM BOTTOM OF WALL / SLAB AND AT 600mm MAX SPACING.

SEE NOTE 1

THICKNESS

WALL/SLAB

DEVELOPMENT LENGTH FORMED OR TOP SURFACES EXPOSED TO WEATHER OR 50 (FOR 20mm AGGREGATE) ALIGN AND TIE-IN-PLACE TO REINF. COATING SHALL CONSIST OF A CORROSION

BAR BAR SATURATED AIR, SUBMERGED IN WATER OR IN CONTACT

50 TYP

SIZE SIZE 60 (FOR 40mm AGGREGATE) RESISTANT COATING PLUS A LUBRICANT COATING AS SPECIFIED.

T

WITH EARTH, INCLUDING STIRRUPS, TIES OR SPIRALS

T/2

*TOP BARS OTHERS *TOP BARS OTHERS OTHER LOCATIONS: 3. GALVANIZED STEEL PIPE SLEEVE 33.4 ODx3.38 FILLED WITH GREASE.

BARS IN BEAMS OR GIRDERS, INCLUDING 40

STIRRUPS AND COLUMN SPIRALS OR TIES 4. CONNECT WALL WATERSTOP WITH BASE SLAB WATERSTOP.

INTERIOR (WATERSIDE) 3mm CLOSURE PLATE

10M 390 300 500 400 10M FACE OF WALL / SLAB WELDED AT END

SLABS AND WALLS (DRY CONDITION): 50 CLR 5. ENSURE PROPER QUALITY CONTROL DURING CONCRETE PLACEMENT.

40 GREASE THIS HALF OF BAR, SEE NOTE 3 VIBRATE SURROUNDING WATERSTOP THOROUGHLY.

15M 550 420 710 550 15M 20M AND LARGER

15M AND SMALLER SHEAR BARS, 150 TYP

20M 670 520 870 670 20M 25 2-10M HAIRPINS AT EACH DOWEL,

SEE NOTE 2 6. PROVIDE WATERTIGHT EXPANSION JOINT AS PERFORMANCE REQUIREMENT.

LOCATE 100mm CLR ABOVE AND BELOW

25M 1080 830 1400 1080 25M TYP REINF DOWELS. TIE TO 15M VERTICALS, TYP

NOTE: TOLERANCES FOR CONCRETE COVER AND THE FABRICATION AND PLACEMENT OF REINFORCEMENT 7. PROVIDE INJECTO WATERSTOP OR RETROFIT WATERSTOP WHERE PVC WATESTOP

30M 1280 990 1660 1280 30M SHALL CONFORM TO CSA A23.1. 225mm PLASTIC WATERSTOP, IS NOT FEASIBLE.

PLAN BOND TO WATERSTOP IN BASE SLAB,

35M 1530 1180 1990 1530 35M SEE NOTE 4

* TOP BARS ARE HORIZONTAL BARS SO PLACED THAT MORE THAN 300mm OF CONCRETE IS CAST IN THE

MEMBER BELOW THE BAR. HORIZONTAL BARS IN WALLS ARE TO BE PROVIDED WITH LAP LENGTHS AS

REQUIRED FOR TOP BARS. VERTICAL BARS MAY BE CONSIDERED AS OTHER BARS.

* DEVELOPMENT LENGTHS ARE EQUAL TO CLASS "A" SPLICES.

R:\d0978721\3D-S-Std Dtls.rvt

* PROVIDE CLASS "B" SPLICE UNO.

LAP SPLICES AND CONCRETE COVER FOR REINFORCEMENT 7 WALL/SLAB EXPANSION JOINTS 8

NTS - NTS -

ASHBRIDGES BAY TREATMENT PLANT

WAS THICKENING FACILITY AND SOUTH SUBSTATION UPGRADES

FRANK QUARISA, P. ENG. JOHN P. KELLY, P. ENG.

ACTING DIRECTOR, STANDARD DETAILS 2

5/16/2019 11:16:29 AM

DIRECTOR, DESIGN & CONSTRUCTION

WASTEWATER TREATMENT MAJOR INFRASTRUCTURE STRUCTURAL

DESIGN: DK DRAFTING: NK CHECK: DT CONTRACT No. 19ECS-MI-01AB

2 MAY 2019 ISSUED FOR TENDER DT

SCALE: NTS DRAWING

1 DEC 2018 ISSUED FOR TENDER DT

No. DATE REVISIONS INITIAL SIGNED DATE: FEB 2019 NUMBER: 1001-2019-01-242 SM502

TREAD 25 OFFSET

15M@150 T&B, EW

15M@300

UNLESS NOTED

RISER

OTHERWISE

10M NOSING BAR,

TYP

250 UNLESS FOR ABRASIVE

NOTED NOSING SEE

OTHERWISE ARCITECTURA 225 UNLESS NOTED OTHERWISE

L DRAWINGS

50 CLEAR UNLESS NOTED OTHERWISE

B

S

LAS

C LAP 15M@150 DOWEL UNLESS NOTED OTHERWISE

15M@150 UNLESS NOTED OTHERWISE

AT LANDING MIDDLE

B

ASS

CL AP

L

200

300

15M@150 UNLESS

NOTED OTHERWISE

15M@150 DOWEL UNLESS

NOTED OTHERWISE

SECTION BOTTOM

TYPICAL CONCRETE STAIR REINFORCING 1

NTS -

ANCHOR BOLT AND SLEEVE IF

REQD BY EQUIPMENT FURNISHED

SEE PLANS

40 MIN TO EDGE OF BASE PL

IF ANCHOR BOLTS

100 MIN 20mm CHAMFER-DELETE IF

40 GROUT (MIN)

BASE PL AS REQD < 200

"B" BAR CURB IS UNDER MASONRY

ARE REQD

BY EQUIPMENT 10M@300 DWLS MAX WALL

FURNISHED W/ STD HOOKS, TYP SEE NOTE 1

AREA OF 2

"A" BARS EF SEE PROCESS/MECH DWGS

15M@300 (MAX) EW 25mm CHAMFER ADD 1 + 15Mx1200 15M@300, EF

SEE NOTE 4 FOR PIPE DETAILS, TYP

DIAGONAL AT EA

SEE PLAN

(600 MAX)

REPLACE OR REMOVE

EXIST FLOOR COVERING CORNER FOR

EA LAYER OF REINF 12 DIA U-BOLT

AS REQD FOR REHAB 15M@300

CONSTRUCTION 45°

AREA OF 2 "B" BARS TYP

300 MAX

TOP LAYER REINF

150 MIN

15M AT MID-HEIGHT CONC SLAB

EACH FACE, EACH SIDE BUILD UP OR REINFORCE

OF BASE (4 SIDES) PIPE AT SUPPORT LOCATIONS

WINDOW, OF OPENING W/

SLAB THK - 50

DOORWAY MATCHING DOWELS, AS NEEDED

OR EXTEND FULL STORY

(150 MAX)

HEIGHT

75

LOUVERS 200 WIDE PLATE, 12 THICK

.

LEAVE ROUGH "A" BAR 6

(NEW CONSTRUCTION) 2400mm MAX FOR ALL AIR PIPES AND FOR

SLAB THICHNESS

WIDTH IF OPENING LOCATED ABOVE STD HOOK LIQUID PIPES UP TO 610 DIA,

7

5

2

1

SLAB ON GRADE, 15M 25 THICK FOR 750-1050 DIA,

MINUS 50

STD HOOK, TYP FLOOR SLAB DIAGONAL EF REQD AND 32 THICK FOR 1050-1200 DIA

AS REQUIRED

AREA OF 2 "A" BARS EF REQD CURB WIDTH LESS THAN OR EQUAL TO 200mm LIQUID PIPES

BELOW OPENING, PROVIDE

OPENING AND 5mm PL MATCHING DOWELS FROM 150 DIA SCHEDULE

LOWER LEVEL WALLS FOR 40 STEEL PIPE

TYP

SLEEVE W/ SEEP RING IF

250

50

SQ

ADHESIVE ANCHOR INTO CONC ELEVATED FLOOR

REQD BY EQUIPMENT FURNISHED FOR EXISTING CONSTRUCTION

OPENINGS SEE PLANS 25 PL

PL 6x100x100 MIN, WELD TO

>200 20mm CHAMFER-DELETE IF

SLEEVE AND BOLT ELEVATION CURB IS UNDER MASONRY

EQUIPMENT BASE 3 WALL

NTS -

15M@200, EF

SEE PLAN

(600 MAX)

NOTE: NOTES:

6

WILSON ANCHOR SLEEVES MAY BE SUBSTITUTED FOR STEEL PIPE SLEEVES. 1. PROVIDE MINIMUM LAP. 25 GROUT

15M@200, EF

2. TYPICAL FOR ALL OPENINGS IN ALL CONCRETE WALLS UNLESS INDICATED

OTHERWISE ON PLANS. 25 DIA ADHESIVE

CONC SLAB

3. DO NOT WELD REINFORCEMENT TO PIPE SLEEVES AND INSERTS. ANCHORS

300 DEEP

4. IF THE WIDTH OF DOORWAY, LOUVERS, WINDOWS AND OTHER OPENINGS IS

MIN

GREATER THAN 2400 & LESS THAN 4500 PROVIDE 3-25M OR AREA OF 2A BAR EF,

WHICHEVER IS GREATER. LENGTH OF BAR = WIDTH OF OPENING + TWO TIMES 250 MIN FROM EDGE

THE LAP LENGTH UNO. OF CONC, TYP

75

MIN CLR DISTANCE

.

2 x OD OF LARGER

CONDUIT (60 mm MIN) STD HOOK

SLAB THK

CONC SLAB CURB WIDTH GREATER THAN 200mm

T/3

T

OR WALL NOTES:

1. EMBED CONDUITS ONLY WHERE ALLOWED BY

ELECTRICAL DRAWINGS AND SPECIFICATIONS.

BASE OF WALL OPENING REINFORCING 4 NOTE:

NOTE:

T/3

NTS -

ALL STEEL MATERIALS SHALL BE HOT-DIP GALVANIZED.

2. PLACE CONDUIT ONLY IN SHADED AREA. 1. PROVIDE ADDITIONAL LAYER OF REINFORCING EACH VENT HOLES FOR GALVANIZING SHALL BE THE MINIMUM

FACE, IF CURB WIDTH EXCEEDS 200. SIZE NECESSARY. HOLES SHALL BE LOCATED IN THE

3. FOR CONDUIT REQUIREMENTS SEE THE

T/3

BOTTOM BASE PLATE AND ALSO LOCATED IN THE TOP

ELECTRICAL DRAWINGS AND SPECIFICATIONS.

OF THE PIPE, ADJACENT TO THE CURVED PLATE.

R:\d0978721\3D-S-Std Dtls.rvt

TYPICAL CONCRETE CURB 5

CONDUIT PLACING 7 NTS - STEEL COLUMN PIPE SUPPORT 7

NTS - NTS -

ASHBRIDGES BAY TREATMENT PLANT

WAS THICKENING FACILITY AND SOUTH SUBSTATION UPGRADES

FRANK QUARISA, P. ENG. JOHN P. KELLY, P. ENG.

ACTING DIRECTOR, STANDARD DETAILS 3

5/16/2019 11:16:30 AM

DIRECTOR, DESIGN & CONSTRUCTION

WASTEWATER TREATMENT MAJOR INFRASTRUCTURE STRUCTURAL

DESIGN: DK DRAFTING: NK CHECK: DT CONTRACT No. 19ECS-MI-01AB

2 MAY 2019 ISSUED FOR TENDER DT

SCALE: NTS DRAWING

1 DEC 2018 ISSUED FOR TENDER DT

No. DATE REVISIONS INITIAL SIGNED DATE: FEB 2019 NUMBER: 1001-2019-01-243 SM503

FOR ALL WATER HOLDING

AND BELOW GRADE 1400 MAX ROUGHEN SURFACE OF

STRUCTURES, SEE 7 EXISTING SLAB/WALL

TYP OPENING OPENING TO FULL 6mm

SM501 CONCAVE GROUT PLUG

MINIMUM AMPLITUDE,

40 CLR

CLEAN AND SOAK PRIOR

EXISTING STRUCT

TO POURING CONCRETE

SLAB

200mm DIA SCH 40 HOT DIP

GALVANIZED STEEL PIPE,

GRIND SMOOTH, FILL WITH

30MPa CONCRETE

MIN

.

25

2-12mm DIA DRAINAGE HOLES

EACH SIDE AT 150mm FROM

FINISH GRADE

1200

20 CLR

15M@200 EW SLAB/WALL THICKNESS TO 16mm DIAMETER x 450mm THREADED ROD

T&B, TYP 90mm, 40 25mm SLOPE, TYP

MATCH EXISTING (150mm MIN) ADHESIVE ANCHORS, CENTER IN SLAB/WALL,

SEE NOTE 2 ALL AROUND

AT 200mm SPACING ALL AROUND PERIMETER GROUT PLUG,

OF OPENING, DRILL AND EPOXY 150mm FINISH SMOOTH

25

CURE CONCRETE AS SPECIFIED FOR PATCHING, MINIMUM INTO EXISTING CONCRETE CONC WALL

DO NOT REMOVE SUPPORTING FORMS AND DO (3 ANCHORS MINIMUM EACH SIDE OF OPENING).

N GROUT OR FILL

NOT LOAD UNTIL CONCRETE ATTAINS REINF WITH 15M@200 EW, T&B, MI CONC FILL FINISHED GRADE

FULL 28 DAY DESIGN STRENGTH 50 SLOPE

40mm CLEAR, FOR ALL OPENINGS

ANGLE

LARGER THAN 300mm 6

CHIP SIDES OF EXISTING OPENING BACK 250mm DIA SCH 40 6

50

TO 3:12 SLOPE AS SHOWN ROUGHEN FOR ALL WATER HOLDING STEEL PIPE, GRIND

MIN

100

IN

SURFACE TO FULL 6mm MINIMUM AND BELOW GRADE SMOOTH, FILL WITH

40

AMPLITUDE, CLEAN AND SOAK PRIOR TO STRUCTURES, SEE 7 CONC, GALV, PAINT

1070

POURING CONCRETE FILL LEAVE END EXISTING STRUCTURAL AS SPECIFIED

REINFORCEMENT AS SHOWN SM501 CONCRETE SLAB OR WALL 6

CONC SLAB

30MPa CONCRETE

1800

FILL

SLOPE

ANGLE

MIN

250

GRANULAR BASE

CONC SLAB

SURROUNDING

SONOTUBE, TYP

90mm, PL 12x300x300

CLEAR

CLR

150

SEE NOTE 2 2 ADDITIONAL CENTERED

75

15mm DIA RING BAR WELDED ALL PROVIDE 100 WIDE x 50 DEEP 15M@400 EA SIDE, ON PIPE

AROUND TO EXISTING REINFORCEMENT 600 MAX CONT KEY ALL AROUND FOR TYP

EACH SIDE OPENING WALL THICKNESS > 300mm NOTES: 12x50 FLANGE

ALL AROUND

NOTES:

CURE CONCRETE AS SPECIFIED FOR 1. PROVIDE KEY FOR ALL FILL WHERE FILL SLOPE ANGLE

PATCHING, DO NOT REMOVE TO WALL OR SLAB IS LESS THAN 45 DEGREES. 1. HOT DIPPED GALVANIZED AFTER FABRICATION.

SUPPORTING FORMS AND DO NOT LOAD REINF WITH 15M@200 EW, 450

40mm CLEAR, FOR ALL OPENINGS 2. FOR EXTERIOR STEEL BOLLARD SEE CIVIL DWGS.

UNTIL CONCRETE ATTAINS FULL 28 DAY 2. LENGTHEN 90mm BLOCKOUT AS REQUIRED TO MAINTAIN MIN DIA

DESIGN STRENGTH LESSER THAN 300mm

50mm MINIMUM THICKNESS OF GROUT OR CONCRETE FILL.

CHIP SIDES OF EXISTING OPENING BACK FOR ALL WATER HOLDING

TO 3:12 SLOPE AS SHOWN ROUGHEN AND BELOW GRADE INTERIOR BOLLARD DETAIL EXTERIOR BOLLARD DETAIL

SURFACE TO FULL 6mm MINIMUM STRUCTURES, SEE 7

AMPLITUDE, CLEAN AND SOAK PRIOR TO

POURING CONCRETE FILL LEAVE END SM501 EXISTING STRUCTURAL

REINFORCEMENT AS SHOWN CONCRETE SLAB OR WALL CONC OR GROUT FILL KEY 2 STEEL BOLLARD 3

NTS - -

NTS

SS L89x89x6.4 W/

SS 10mm DIA CONCRETE

15mm DIA RING BAR WELDED ALL PROVIDE 100 WIDE x 50 DEEP STUD ANCHORS @400 C/C x

AROUND TO EXISTING REINFORCEMENT 300 MAX CONT KEY ALL AROUND FOR 150mm LONG

EACH SIDE WALL THICKNESS > 300mm SAW-CUT 25mm DEEP AND CHIP TO REMOVE

OPENING

FINISH SLAB OR WALL UNDER REMOVED EXISTING CONCRETE AS REQUIRED.

CONCRETE TO MATCH EXISTING ADJACENT USE CARE NOT TO DAMAGE EXISTING 25mm

CONCRETE FINISH, REPAIR ROUGH OR ADJACENT CONCRETE SURFACES TO REMAIN SLOPE

DAMAGED SURFACES SEE NOTE 3

EXISTING SLAB/WALLS OPENING REPAIR 1

NTS -

EXISTING CONCRETE

EXISTING

EXISTING TO REMAIN

REINFORCING

NEW OPENING CONCRETE

SAW-CUT

LINE

OPENING

REMOVED

NEW

CONCRETE CORE DRILL 50mm DIAMETER HOLE, 40mm DEEP, AND

CHIP AND GRIND TO REMOVE EXISTING REINFORCING CONCRETE EDGE PROTECTOR 7

GRIND SURFACE CUT BACK EXISTING AND EQUIPMENT ANCHORS TO 40mm MIN BELOW TOP -

OF EXISTING CONCRETE TO REMAIN, CLEAN AND SOAK, NTS

SMOOTH AFTER BAR 25mm AND FILL HOLE WITH

GROUT HAS CURED NON-SHRINK NON-FERROUS AND DRY-PACK WITH NON-SHRINK GROUT

PRIOR TO SAW CUTTING NEW OPENING

GROUT

DRILL SUFFICIENT NUMBER OF 25mm DIA

HOLES IN ALL CORNERS TO PREVENT PLAN NOTES: 600 DIA

OVERCUTTING, TYP

1. REMOVE CONCRETE OUT TO SOUND CONCRETE. DEPRESSION

NEW

EXISTING WALL ELEVATION / SLAB PLAN DETAIL CUT BACK EXISTING 2. IF CHIPPING INTO THE SURFACE OF THE EXISTING SLAB OR WALL AND PART OF IT IS

OPENING BAR 25mm AND FILL TO REMAIN, MAKE EDGES PERPENDICULAR TO THE SURFACE. DO NOT FEATHER EDGES.

EXISTING GRIND 20mm

HOLE WITH

NOTES: CONCRETE CHAMFER

NON-SHRINK NON- 3. REPAIR AS PER SPECIFICATION SECTION 03920 CONCRETE SURFACE REPAIR, TYPE OF REPAIR TO SUIT SET FLOOR DRAIN

FERROUS GROUT DEPTH OF CUT. RIM 12mm LOWER

1. LOCATE ANY EXISTING UTILITIES THAT COULD

BE AFFECTED WITH DEMOLITION. REPORT TO THE THAN ADJACENT

ENGINEER IF ANY UTILITIES ARE FOUND. REMOVED 4. DEMONSTRATE METHODS FOR REPAIR USING ACTUAL MATERIALS, METHODS, AND CURING SLAB ELEVATION

CONCRETE PROCEDURES REQUIRED BY MATERIAL MANUFACTURERS, CONSULT WITH BONDING AGENT SLOPE

2. STAY WITHIN LIMITS OF OPENING, DO NOT OVERCUT. MANUFACTURERS AND REPAIR GROUT MANUFACTURER ON TECHNIQUES.

TYP

GRIND SURFACE

3. BURN BACK EXPOSED REINFORCING 25mm AND DRY SMOOTH AFTER 5. MAKE AREA WATER TIGHT FOR BELOW GRADE APPLICATION AND WATER RETAINING

EXISTING STRUCTURE.

PACK WITH NON SHRINK GROUT. GROUT HAS CURED

REINFORCING

4. SIZE AND LOCATION OF ALL OPENING MUST BE

PLAN / SECTION

APPROVED BY ENGINEER PRIOR TO BEGINNING

CUTTING OPERATION.

NEW OPENING IN EXISTING WALLS/SLABS 4 NEW OPENING IN EXISTING WALLS/SLABS 5 CONCRETE DEMOLITION OF EXISTING PADS/SUPPORTS 6 FLOOR DRAIN 8

R:\d0978721\3D-S-Std Dtls.rvt

- - NTS - NTS -

NTS NTS

ASHBRIDGES BAY TREATMENT PLANT

WAS THICKENING FACILITY AND SOUTH SUBSTATION UPGRADES

FRANK QUARISA, P. ENG. JOHN P. KELLY, P. ENG.

ACTING DIRECTOR, STANDARD DETAILS 4

12/5/2018 10:31:52 PM

DIRECTOR, DESIGN & CONSTRUCTION

WASTEWATER TREATMENT MAJOR INFRASTRUCTURE STRUCTURAL

DESIGN: DK DRAFTING: NK CHECK: DT CONTRACT No. 19ECS-MI-01AB

SCALE: NTS DRAWING

1 DEC 2018 ISSUED FOR TENDER DT

No. DATE REVISIONS INITIAL SIGNED DATE: DEC 2018 NUMBER: 1001-2019-01-244 SM504

25mm MIN GROUT

MINIMUM EMBEDMENT

SEE TABLE OR AS

JAMB SCHEDULE LINTEL SCHEDULE BOLT

ALL AROUND

SHOWN IN SECTION

EMBEDMENT

JAMBS MASONARY LINTEL SCHEDULE (UNO)

BLOCK

BLOCK BUILDING WALL LINTEL REMARKS

THICKNESS OPENING SIZE

BUILDING WALL THICKNESS OPENING SIZE NUMBER OF BARS PER BAR

REMARKS

(mm) (mm) TYPE/SIZE DEPTH BOT TOP HEADED BOLT NOTE:

(mm) (mm) REINFORCED REINFORCED ANCHOR SIZE EMBED

.

SIZE (mm) REINF REINF

CELLS CELL BOLT MINIMUM BOLT SPACING SHALL BE 12

12 100 BOLT DIAMETERS WITH A MINIMUM EDGE

EAST 240 <4000 3 1 15M 240 <2000 MASONRY 400 2-15M 2-10M DISTANCE OF 6 BOLT DIAMETERS AND

16 100 WITH A MINIMUM OF 150mm TO END OF WALL

TWAS WEST 240 <4000 3 1 15M 240 2000 T0 4000 HSS254x254x12.7 - - - SUPPORTED ON COLUMN 20 125

MAIN EAST 22 150

BUILDING SOUTH 240 <4000 3 1 15M 240 >4000 HSS254x254x12.7 - - - SUPPORTED ON COLUMN

24 175

INTERIOR 190 <4000 3 1 15M 240 WINDOW (W-10A) HSS254x254x12.7 - - - BEARING ON MASONRY

240 <2000 MASONRY 400 2-15M 2-10M -

TWAS MAIN

BUILDING 240 2000 T0 4000 HSS254x254x12.7 - - - SUPPORTED ON COLUMN

WEST

TYPICAL MASONRY ANCHOR BOLT 3

240 >4000 HSS254x254x12.7 - - - SUPPORTED ON COLUMN -

NTS

NOTES:

240 <2000 MASONRY 400 2-15M 2-10M FOR W13 USE HSS LINTEL

1. WALL HEIGHT IS DISTANCE FROM BOTTOM OF MASONRY WALL TO THE LOCATION

OF TOP LATERAL SUPPORT. SOUTH 240 >4000 HSS254x254x12.7 - - - SUPPORTED ON COLUMN 240

2. THE SCHEDULED REINFORCING SHALL BE PLACED WITH ONE BAR AT EACH FACE 240 WINDOW (W5/W10) HSS254x254x12.7 - - - BEARING ON MASONRY

OF THE WALL. ONLY ONE PAIR OF BARS SHALL BE PLACED IN EACH CELL.

INTERIOR 190 <2000 MASONRY 400 2-15M 2-10M - 190 GALV ANGLE

3. AN INTERIOR WALL IS A WALL IN WHICH NO PORTION OF THE WALL IS

EXPOSED TO THE EXTERIOR.

MASONRY

200

4. AT LOCATIONS WHERE WALLS CANTILEVER ABOVE THE TOP LATERAL SUPPORT,

THE WALL HEIGHT FOR ABOVE SCHEDULE SHALL BE THE GREATER OF THE TYP

HEIGHT IN NOTE 1 OR DOUBLE THE DISTANCE FROM LATERAL SUPPORT TO 6

LOCATE CENTERED

THE TOP OF THE WALL. NOTES: 8 20-300 GALV HSS OR ON VERT REINF GROUT

HSS GALV OR MASONRY CELLS

5. REINFORCE JAMBS AS INDICATED UNLESS NOTED OTHERWISE ON THE DRAWINGS. 1. BEAR ALL LINTELS A MINIMUM 600mm AT EACH END. MASONRY LINTEL, LINTEL

2. REINFORCED LINTELS AS INDICATED UNLESS NOTED OTHERWISE ON THE DRAWINGS. VARIES SEE LINTEL

15 SCHEDULE GALV ANGLE GALV L203x102x13

* HSS = HOLLOW SQUARE SECTION 300 LONG@ 600 C/C,

MASONRY WALL TYP (T&B, EF)

200x175x8

GALV BENT PL 8 20-300

INSIDE OUTSIDE

BRICK VENEER SUPPORT DETAIL 9 HSS TO MASONRY WALL DETAIL 10

NTS - NTS -

SPLICE LENGTH

FLOOR SLAB

WEB MAY BE REMOVED DOUBLE CURTAIN MASONRY

150 MIN CONC FOR 400 DIA PIPE AND SMALLER

200 MIN CONC FOR 400 DIA PIPE AND LARGER

TO FACILITATE REINF GROUT WALL REINF SHOWN. SINGLE

PLACEMENT OF FULL FILLED CORES CURTAIN REINF SIMILAR

HEIGHT REINF, TYP (SEE JAMB REINF SCHED) EXCEPT CENTERED IN WALL

TOP REINF, SEE SCHEDULE

LINTEL DEPTH

GROUT SOLID

SEE SCHED

STIRRUPS WHERE INDICATED

IN SCHEDULE

CONCRETE

NOT TO EXCEED MAX ENCASEMENT

SPACING OF VERTICAL REINF OPENING SEE LINTEL

SCHEDULE

(SEE SCHEDULE) PIPE DIA AS

SPECIFIED

JAMB - PLAN

10M@300 TIES

2-10M EF

TYPICAL MASONRY JAMB PLAN AND SCHEDULE 1 TYPICAL MASONRY LINTEL SECTION AND SCHEDULE 2

NTS - NTS - CONCRETE PIPE ENCASEMENT 4

NTS -

DOWELS W/MECHANICAL

DOWEL SIZE AND SPACING THREADED CONNECTORS 10mm DIA SST ADHESIVE

FOR FUTURE CONSTRUCTION PROTECTIVE CAPS ANCHORS@300mm OC,

TO MATCH MASONRY WALL

REINFORCING STAGGER FOR 600mm

SEE ARCHITECTURAL 115 CENTERS EA SIDE, 150

MASONRY WALL, 150mm PLASTIC WATERSTOP SEE NOTE 3

DWGS FOR JOINT MAX

FOR SIZE AND CTRD IN WALL OR SLAB

TREATMENT

LOCATION SEE

ARCH DWGS, TYP

MAX

150

W BEAM MORTAR JOINT ADJUSTABLE ANCHOR IN

W/ CAULK (TYP) DOVETAIL SLOT AT

20

400mm CTRS

FOR REINFORCEMENT

SEE DETAIL 5 OF SM503 CONCRETE FILLED

40 30

200+/-

CELLS (TYP)

5 50-300

CL

5 50-300 WALL OR

30 40

20mm DIA THREADED ROD

6

SLAB

M

ANCHOR @ 1200 OC

AX

2.66mm SST

FINGER TIGHTEN NUT & 10x125 SQ PLATE WATERSTOP

CONTINUOUS

TACK WELD TO ANCHOR PROTECTORS

20

CONT L203x102x13 LLV, DOVETAIL SLOT

BOND BEAM AND HALF W/ 70mm DIA HOLE, TYP

LEAVE CONTACT AREA 2.66mm SST

ROUGH BLOCK ABOVE, FULLY 125 PLATE CONTINUOUS

CONCRETE WALL

GROUTED

OR COLUMN

SEE NOTE 3

CORNER DETAIL

NOTES:

1. PROVIDE SEALANT AT ALL EDGES, CORNERS

CONCRETE CURB UNDER MASONRY 5

TYPICAL NON-LOAD BEARING TYPICAL NON-LOAD BEARING MASONRY AND JOINTS.

MASONRY WALL AT STEEL BEAM WALL AT CONCRETE WALL OR COLUMN WATERSTOP PROTECTOR

R:\d0978721\3D-S-Std Dtls.rvt

NTS - 6 7 8 2. PROVIDE WATERTIGHT 2.66mm SST CLOSURE

- - - PLATE AT FREE ENDS.

NTS NTS

3. WHERE APPLICABLE, ADJUST SPACING OF

ANCHORS TO CLEAR REBAR MECHANICAL

THREADED CONNECTORS.

ASHBRIDGES BAY TREATMENT PLANT

WAS THICKENING FACILITY AND SOUTH SUBSTATION UPGRADES

FRANK QUARISA, P. ENG. JOHN P. KELLY, P. ENG.

ACTING DIRECTOR, STANDARD DETAILS 5

5/16/2019 11:16:31 AM

DIRECTOR, DESIGN & CONSTRUCTION

WASTEWATER TREATMENT MAJOR INFRASTRUCTURE STRUCTURAL

DESIGN: DK DRAFTING: NK CHECK: DT CONTRACT No. 19ECS-MI-01AB

2 MAY 2019 ISSUED FOR TENDER DT

SCALE: NTS DRAWING

1 DEC 2018 ISSUED FOR TENDER DT

No. DATE REVISIONS INITIAL SIGNED DATE: FEB 2019 NUMBER: 1001-2019-01-245 SM505

CMU WALL AND MAIN REINFORCING SCHEDULE

100

.

BAR POSITIONERS @ BOND BEAM REINFORCEMENT

1200mm VERT CTRS, TYP

MAIN VERTICAL REINFORCEMENT

EQ EQ

CONT WALL REINF CONCRETE SLAB,

INTO CONC BEAM COLUMN OR BEAM BLOCK GROUTING BARS PER MAX SPACING

BUILDING WALL BAR MAIN HORIZONTAL

STD HOOK THK (NOTE 6) REINFORCED SIZE

OF VERT

REINFORCEMENT

12 (TYP)

CONTINUOUS CELL (NOTE 7) REINF

DOVETAIL SLOT CONCRETE BEAM

REINF FULL HEIGHT OR SLAB

WEB MAY BE REMOVED TO EAST 240 R 1 15M 600

IN GROUT FILLED

FACILITATE PLACEMENT

.

CORES (SEE SCHEDULE) TWAS 600

OF FULL HEIGHT REINF, WEST 240 R 1 15M

TYP BOND BEAM MAIN -

ADDITIONAL TYPICAL REINF CAULK AND BACKER

BUILDING

SPLICE LENGTH

AT WALL ENDS ROD BOTH SIDES SOUTH 240 R 1 15M 600

TYPICAL CONTROL JOINT

WHERE INDICATED ON PLANS DWL SIZE TO MATCH INTERIOR 190 R 1 15M 600

NOTES: VERT WALL REINF CONCRETE BLOCK

DOVETAIL ANCHOR 300mm

BOND BEAM REINFORCEMENT (CUT AS REQ'D) ELEVATOR

LONG @ 800mm CTRS NORTH 240 F 1 15M 600 -

1. GROUT ONLY THE CELLS W/ REBARS UNLESS MORTAR INTO HEAD JOINT SHAFT

THE WALL IS NOTED TO BE FULLY GROUTED. BOND BEAM AT LAST

FULL COURSE WEST 190 R 1 15M 600

CONCRETE BLOCK 2. FOR VERTICAL REINF, SEE SCHEDULE, UNO. ELECTRICAL

BUILDING

SOUTH 190 R 1 15M 600 -

TWAS ROOF 240 R 1 10M 600

PARAPET

TYPICAL LOAD BEARING MASONRY ELECTRICAL

(SINGLE CURTAIN REINFORCEMENT SHOWN) TYPICAL NON-LOAD BEARING MASONRY ROOF

190 R 1 10M 600 -

WALL AT CONCRETE BEAM OR SLAB 2

MASONRY WALL CORNER REINFORCING WITH CONTROL JOINTS 1 -

WALL AT CONCRETE BEAM OR SLAB 3 TWAS MAIN

NTS BUILDING/ 140 R 1 15M 600

- NTS - INTERIOR

NTS WALL STABILITY

SEE THE TYPICAL LOAD 2-15M IN BOND BEAM AT TOP OF WALL

BEARING MASONRY WALL SPLICE LENGTH & AT STRUCTURALLY CONNECTED GIRT, "W" 800

DETAIL THIS DRAWING FLOOR & ROOF LEVELS

NOTE 1 TYP NOTES:

LINTEL REINFORCING (TYP) 2-15M ABOVE LINTEL BLOCK

TYPICAL WALL REINF 1. WALL HEIGHT IS DISTANCE FROM BOTTOM OF MASONRY WALL TO THE LOCATION OF LATERAL SUPPORT.

(SEE SCHEDULE) & BELOW OPNG BEAM BOT W BEAM

(SEE SCHEDULE)

TOP OF WALL SEE NOTES 2 & 3 FLANGE

2 TYP WALL 2. AN INTERIOR WALL IS A WALL IN WHICH NO PORTION OF THE WALL IS EXPOSED TO THE EXTERIOR.

TYPICAL WALL REINF ABOVE &

BELOW VERTICAL OPENING VERTICAL BARS

SEE NOTE 1

.

15mm 3. AT LOCATIONS WHERE WALLS CANTILEVER ABOVE THE TOP LATERAL SUPPORT, THE WALL HEIGHT FOR THE

WHEN OPENING WIDTH EXCEEDS (FULL HT EA)

SIDE OF OPNG, ABOVE SCHEDULE SHALL BE THE GREATER OF THE HEIGHT IN NOTE 1 OR DOUBLE THE DISTANCE FROM

TYPICAL REINF SPACING

NOTE 1

SEE NOTE 4 LATERAL SUPPORT TO THE TOP OF THE WALL.

"H"

WHERE EXTENSION IS NOT 5

POSSIBLE, EXTEND BARS AS 4. IN ADDITION TO THE SCHEDULED REINFORCEMENT, WALLS SHALL HAVE A CONTINUOUS BOND BEAM WITH

BOND BEAM 5 AT LEAST 2-15M BARS AT OR NEAR THE TOP COURSE, SCHEDULED REINFORCEMENT AT OPENINGS,

FAR AS POSSIBLE AND

SPLICE LENGTH

PROVIDE STANDARD HOOK AND ALL OTHER HORIZONTAL AND VERTICAL REINFORCEMENT AS INDICATED ON THE STRUCTURAL AND

(TYP) 15M TOP ARCH ARCHITECTURAL DRAWINGS.

(TYP)

.

BARS, NOTE 5

100 .

25 MIN

TYPICAL WALL REINF AT EACH 300 5 5. SEE THE STRUCTURAL DRAWINGS FOR SPECIAL REINFORCEMENT AND BOUNDARY ELEMENTS IN HIGH STRESS

DEVELOPMENT

CORNER & AT END OF WALL SHEAR WALLS. ALL WALLS SHALL BE REINFORCED WITH THE MINIMUMS ABOVE, UNLESS NOTED OTHERWISE.

"D " 5

LENGTH

16mm THK x 300

2-15M (TYP) UNO LONG BENT PL @ 6. "F" INDICATES A FULLY GROUTED WALL, "R" INDICATES TO GROUT ONLY THE REINFORCED CELLS.

E1 300 L127x76x6.4x100mm

NOT 1200 OC

@ 1200 OC 7. "1" INDICATES A SINGLE BAR CENTERED IN WALL, "2" INDICATES DOUBLE CURTAIN REINFORCING,

FOUNDATION LINE WITH ONE BAR EACH FACE OF CELL.

BOND BEAM W/ FILL VOID W/ INSULATION FOR

2-15M CONT, TYP FIRE RATED WALLS, SEE

SAW CUT REINF SIM AS ARCH DWGS 8. SEE THE OTHER STRUCTURAL DRAWINGS FOR ADDITIONAL REINFORCEMENT DETAILS AT CONNECTIONS,

JAMB REINF (TYP) BLOCK FOR SHOWN FOR TOPS OF WALLS, JAMBS, LINTELS, ETC.

(SEE SCHEDULE) CIRCULAR OPNG RECTANGULAR

SOLID GROUT OPNG ABOVE 9. THE DETAILS ON THIS SHEET ARE APPLICABLE TO ALL CONCRETE MASONRY CONSTRUCTION.

DEVELOPMENT

SEE NOTE 4, SPECIAL NOTES, SECTIONS AND DETAILS SPECIFICALLY NOTED ON THE DESIGN DRAWINGS

NOTES:

LENGTH

TYP SHALL BE APPLICABLE IN LIEU OF THESE TYPICAL DETAILS, EXCEPT THAT REINFORCEMENT

HOOK

SHALL NOT BE LESS THAN THE TYPICAL REINFORCEMENT REQUIRED.

NOTES: 1. TYPICAL FOR ALL OPENINGS WITH (W, H, OR D) 600mm OR GREATER AND 1200mm 10. FOR MISCELLANEOUS APPURTENANCES INCLUDING EMBEDMENTS, BRACING, STEEL OR PRECAST

OR LESS , UNLESS NOTED OTHERWISE. SEE PLANS FOR LARGER OPENING. LINTELS, VENEER, FLASHING, WEEPS, INSULATION, SEALING, CAULKING AND EMBEDDED PIPE

1. EXTEND JAMB BARS FLOOR TO ROOF WHERE OPENING WIDTH EXCEEDS

400mm, OTHERWISE, EXTEND A DEVELOPMENT LENGTH OR 600mm MIN AND ELECTRICAL CONDUIT, SEE THE DESIGN DRAWINGS.

2. AT ADJACENT OPENINGS WITH LESS THAN 2400mm WALL BETWEEN, CONTINUE

PAST OPENING. HORIZONTAL REINFORCING TO 800mm BEYOND FURTHEST OPENING. NOTES:

11. MASONRY SHALL BE CONSTRUCTED WITH SLEEVES AS REQUIRED TO ACCOMMODATE PASSAGE OF

2. SEE STANDARD CONCRETE REINFORCING DETAILS FOR SPLICE LENGTH 1. ALL INTERIOR MASONRY WALLS WHICH ARE FULL HEIGHT SHALL BE PENETRATING PIPING, CONDUIT AND DUCT BANKS INDICATED ON THE CIVIL, MECHANICAL AND

3. AT OPENING LOCATED WITHIN 800mm OF CORNER, CONTINUE HORIZONTAL ELECTRICAL DRAWINGS.

IN CONCRETE. REINFORCING AROUND CORNER PER DETAIL SUPPORTED AT THE TOP BY THE STRUCTURE IN ACCORDANCE WITH

1 DETAILS ON THIS SHEET. AN EXCEPTION TO THIS RULE IS INTERIOR

3. MINIMUM HOOK EMBEDMENT SHALL BE 250mm FOR 15M AND SMALLER BARS, WALLS WITH HORIZONTAL INTERSECTING WALLS SPACED AT 2400mm 12. COORDINATE MASONRY DETAILS WITH MASONRY LINTEL AND JAMB REINFORCING DETAILS AND SCHEDULES.

SM506

300mm FOR 20M BARS AND 350mm FOR 25M BARS. OR LESS APART (CLEAR).

13. NON-CONTACT LAP SPLICES SHALL NOT BE USED.

4. LOCATE VERTICAL BARS CENTERED IN 2 ADJACENT CELLS IN 200mm WALLS,

4. AT EACH VERTICALLY REINFORCED CELL, PROVIDE A SINGLE DOWEL AND EACH FACE IN SINGLE GROUT CELL IN 300mm WALLS. LAP 48 BAR DIAMETERS 2. PROVIDE ABOVE DETAIL WHEN WALL DOES NOT CLEAR BEAM BOTTOM

CENTERED IN THE CMU WALL, UNO. LAP SPLICE LENGTH FOR DOWEL WITH MATCHING FOUNDATION DOWELS. FLANGE.

SHALL BE BASED ON A SINGLE REINF WALL, EVEN IF JAMB OR MAIN LENGTH OF LAP SPLICES

VERTICAL REINF IS DOUBLE CURTAIN. DOWEL BAR SIZE SHALL MATCH

SIZE OF JAMB OR MAIN VERTICAL REINF.

5. LOCATE 15M ARCH BARS CENTERED IN 200mm WALLS, AND EACH FACE IN 300mm WALLS. FOR REINFORCEMENT (mm)

INTERIOR MASONRY

MASONRY OPENING REINFORCING 200mm CMU

MASONRY OPENING REINFORCING 4 5 WALL TOP SUPPORT TO BEAM FLANGE 6

BAR SIZE

NTS - - NTS - SINGLE REINF

NTS

10M 525

15M 650

BAR POSITIONERS @ 1200mm

TYPICAL REINF FULL HEIGHT IN 20M 1175

VERTICAL CTRS, TYP .

12

GROUT FILLED CORE EACH SIDE

CONCRETE BLOCK OF CONTROL JOINT.

MINIMUM CMU WALL REINFORCING SCHEDULE 7

NTS -

FILL VOID WITH FIRESAFE

INSULATION CONT @ FIRE

RATED WALLS, 450 FILL VOID WITH FIRESAFE

450 INSULATION CONT @ FIRE RATED

CONTROL JOINT MATERIAL PREFORMED COMP FILL VOID W/

.

WALLS, PREFORMED COMP VARIES ROOF DECK

WITH BACKER ROD OR TAPE CLOSURE OTHERWISE INSULATION FOR

ROOF DECK CLOSURE OTHERWISE

AND CAULK BOTH SIDES FIRE RATED WALLS, (300mm MAX)

SEE ARCH DWGS,

NOTES: TYP

5

7

6

2

1. LADDER TYPE REINFORCEMENT IS DISCONTINUOUS AT JOINT. 50% OF BOND BEAM 300mmx4.18mm 5

25 MIN

300mmx4.18mm BOND BEAM W/

REINFORCEMENT IS DISCONTINUOUS AT JOINT. (8 GAGE) PL

50mm RETURN (8 GAGE) PL 2-15M CONT, TYP

2. CONTROL JOINT IS CONTINUOUS FULL WALL HEIGHT. @ EA END 5

5 TYP W BEAM

3. SPACE CONCRETE MASONRY CONTROL JOINTS AT NO GREATER THAN 10500mm CENTERS 5 NOTE:

TYP

AND LOCATE WITHIN 4800mm OF CORNERS UNLESS OTHERWISE NOTED. LOCATE CONTROL 5 L 127x76x6.4x150mm

JOINTS AT LEAST ONE HALF THE OPENING WIDTH AWAY FROM OPENINGS, BEYOND THE EA SIDE PROVIDE THIS CONNECTION WHEN

L127x76x6.4x150mm WALL IS 300mm OR LESS FROM BEAM

JAMBS ON EITHER SIDE OF THE OPENING, AND AT LEAST 200mm FROM ANCHORS

CONNECTING ANOTHER STRUCTURAL MEMBER OR NON-STRUCTURAL COMPONENT TO THE WALL REINF CENTERLINE OTHERWISE, SUPPORT

WALL. BEARING PLATES, CLIP ANGLES, OR OTHER STRUCTURAL CONNECTION ELEMENTS L127x76x6.4x150mm BOND BEAM W/ WALL TO METAL DECK AS DETAILED

SHALL NOT STRADDLE CONTROL JOINTS. HORIZ LEG TO PROJECT 2-15M CONT, TYP ON THIS SHEET.

OUTWARDS IF WALL IS

.

15mm

NOTES:

4. SEE ARCHITECTURAL DRAWINGS FOR LOCATION OF VENEER CONTROL JOINTS. A MIN OF 90mm FROM

EDGE OF PL 1. ABOVE CONNECTION TO BE SPACED @ 1200mm OC MAX. 16mm THK x 300 LONG BENT PL

.

.

65mm

@ 1200 OC, SEE NOTE

2. ABOVE DETAIL TO BE USED WHEN WALL IS MORETHAN 300mm

CLEAR FROM ADJACENT BEAM.

WALL PARALLEL TO DECK SPAN WALL PERPENDICULAR TO DECK SPAN

R:\d0978721\3D-S-Std Dtls.rvt

125 .

20M@1200 HEADED ANCHOR

BOLT AT GROUTED CELLS

TYPICAL CONCRETE MASONRY CONTROL JOINT 8

NTS - INTERIOR MASONRY WALL SUPPORT AT TOP TO DECK 9 INTERIOR MASONRY WALL TOP SUPPORT TO BEAM 10

NTS - -

NTS

ASHBRIDGES BAY TREATMENT PLANT

WAS THICKENING FACILITY AND SOUTH SUBSTATION UPGRADES

FRANK QUARISA, P. ENG. JOHN P. KELLY, P. ENG.

ACTING DIRECTOR, STANDARD DETAILS 6

5/16/2019 11:16:31 AM

DIRECTOR, DESIGN & CONSTRUCTION

WASTEWATER TREATMENT MAJOR INFRASTRUCTURE STRUCTURAL

DESIGN: DK DRAFTING: NK CHECK: DT CONTRACT No. 19ECS-MI-01AB

2 MAY 2019 ISSUED FOR TENDER DT

SCALE: NTS DRAWING

1 DEC 2018 ISSUED FOR TENDER DT

No. DATE REVISIONS INITIAL SIGNED DATE: FEB 2019 NUMBER: 1001-2019-01-246 SM506

150 MIN 75 75 EXISTING

150 MIN 75 75 65 65 CONCRETE STEEL BEAM NUMBER NUMBER

STEEL 2L 100x90x10x370 90 EXISTING CONCRETE OF ROWS OF ROWS

STEEL BEAM EXISTING CONCRETE WALL OR SHAPE DEPTH

(BACK TO BACK) W/ 6-20mm WALL OR BEAM OF ANCHORS OF BOLTS

50

WALL OR BEAM BEAM

DIA SST STUD TYPE

ADHESIVE ANCHORS 30 W 200 2 2

W 250 2 2

SEE NOTE 2

SEE NOTE 2

90 , MIN

W 300 2 2

250

90 MIN

65

BEAM DEPTH

150 MAX

SEE NOTE 1

TYP

65

COPE BOTTOM

BEAM DEPTH

50

STEEL BEAM

250 OR 300

FLANGE FOR BEAM

65,

150

175 MIN INSTALLATION SECTION

MIN

150

EMBED

PLATE 20x350x(BEAM DEPTH + 50)

100 2-20mm DIA A325 STEEL PLAN

(TYP) BOLTS (PROVIDE SHORT

HORIZONTAL SLOTTED BEAM SECTION

25

175 , MIN

TYP

HOLES IN BEAM WEB) STEEL L 150x100x10x75 W/ 20mm DIA BOLT OR

30

150

2-20mm DIA SST STUD TYPE EMBED CONCRETE ANCHORS,

ADHESIVE ANCHORS SEE NOTES

75

(70 LENGTH FOR 100 BEAM) STANDARD SHORT

150 MIN 75 75

50

90 SLOTTED HOLES FOR 20mm 65mm FOR

STEEL 2L 100x90x10x215 EXISTING CONCRETE STEEL BEAM

DIA A307 BOLTS, NUTS, 200mm BEAM DEPTH

SPACING

(BACK TO BACK) W/ 4-20mm WALL OR BEAM

30 LOCKNUTS & WASHERS,

DIA SST STUD TYPE

75

100 TIGHTEN SNUG TIGHT

TYP

ADHESIVE ANCHORS

MIN

150

30

CLIP BOTTOM OF AND BACK OFF 1/2 TURN

SEE NOTE 2

TYP ANGLE 75mm@45°

90 , MIN

50

3-20mm DIA A325 STEEL BOLTS 6mm PLATE AT DBL L100x75x8X135 LONG

60

(PROVIDE SHORT HORIZONTAL THROUGH-BOLT LONG LEG ADJACENT

SLOTTED HOLES IN BEAM WEB) CONNECTION TO BEAM WEB

175, 200 OR 225

BEAM DEPTHS

TYP

65

NOTES:

80 40

COPE BOTTOM

25

150

FLANGE FOR BEAM 1. 65mm DIMENSION TYPICAL EXCEPT 50mm FOR 100mm BEAMS. 25 RETURN

INSTALLATION 6

T&B, TYP

2. DO NOT CUT EXISTING CONCRETE BEAM TOP REINFORCING DURING DRILL-IN ANCHOR

INSTALLATION. FIELD LOCATE BEAM REINFORCING PRIOR TO FABRICATION. ADD LENGTH

TO CLIP ANGLES AS REQUIRED TO LOWER ANCHORS TO CLEAR REINFORCING WHILE ELEVATION

MAINTAINING SPACING AND EDGE DISTANCE AS SHOWN.

3. WHERE BOTH ENDS OF BEAM ARE ATTACHED TO A WALL, PROVIDE LONG HORIZONTALLY

TYP

30

NOTES:

MIN

150

100 SLOTTED HOLES IN BEAM WEB AT ONE END. TIGHTEN NUTS SNUG TIGHT, BACK OFF 1/2

STEEL BEAM 175 MIN

TYP TURN, AND LOCK WITH DOUBLE NUT.

EMBED 1. THIS DETAIL TO BE USED ONLY WHERE SPECIFICALLY INDICATED OR APPROVED.

2-20mm DIA A325 STEEL 4. GALVANIZE STEEL SECTIONS. ANGLES, PLATES & BOLTS, IF GALV. STEEL BEAMS/COLUMNS

CLIP BOTTOM OF

BOLTS (PROVIDE SHORT ARE SHOWN IN DRAWINGS. 2. THROUGH-BOLT WHEREVER POSSIBLE FOR AS MANY FASTENERS AS POSSIBLE PER

ANGLE 75mm@45°

HORIZONTAL SLOTTED HOLES CONNECTION.

IN BEAM WEB) 5. USE SST BOLTS FOR EMBEDDED BOLTS IN CONCRETE.

3. EPOXY/VE ANCHORS WITH MIN 150mm EMBEDMENT AT EXTERIOR CONNECTIONS ONLY

BEAM/WALL CONNECTION STEEL 1

WITH ENGINEER APPROVAL ON SITE. PROVIDE SPECIAL INSPECTION AT ALL ANCHORS.

NTS -

RETROFIT BEAM CONNECTION 3

COL + 25, COL + 125 NTS -

MIN,

TYP

150 MIN

30

MIN,

TYP

MIN

30

A

SM507

A

COL + 150

COL +125

750 750 SM507

TYP

MIN

MIN

45

HSS HSS

COLUMN COLUMN 450 450

DUCT BANKS

200

TYP

200

750

PLAN PLAN

450

65mm FOR

COL + 25 COL + 125 MIN

MIN

W250 COLUMN,

30

B B HP310x79

. . 90mm FOR

W310 COLUMN, SM507 SM507

100mm FOR

450

W360 COLUMN

WHICHEVER

IS GREATER

COL + 25 OR

AB SPG + 75

COL + 125

750

4-20M, TYP

.

MIN

.

40 MIN,

TYP

W COLUMN

PLAN W COLUMN PLAN PLAN - TYPE B STEEL H - PILE

PLAN - TYPE A

W OR HSS

SEE COLUMN DUCT BANK 160 - TYPE A

W OR HSS 240 - TYPE B

NOTE 2 CONCRETE

COLUMN DUCT BANK

SURROUND

SUIT TO FIELD

750 - TYPE A

450 - TYPE B

SEE

40 40

NOTE 2 200 200

TYP TYP

TYP TYP

"t" SEE PLANS

"t" SEE PLANS

UNO (SST)

12mm MIN

12mm MIN

MIN

500

EMBED

TYP

400

TYP

75

500

SST ANCHOR

BOLTS, TYP

125

300

TYP 2-10M TIES

40mm NON-SHRINK GROUT SST ANCHOR 20M@300 2-10M TIES

AS SPECD, ROUND CORNERS BOLTS, TYP EW T&B HP310x79

ELEVATION W/ 20mm RADIUS TOOL

ELEVATION HP310x79

TYPE A TYPE B

NOTES:

1. UNLESS OTHERWISE NOTED, ANCHOR BOLTS SHALL BE 16mm DIA (MINIMUM) x REQUIRED WITH

SECTION A SECTION B

LEVELING NUTS AND 300mm MINIMUM EMBEDMENT AND BASE PLATES SHALL BE CENTERED ON COLUMN.

2. WELD SIZE SHALL BE DETERMINED BY THE THICKEST MEMBER JOINED; MINIMUM WELD SIZE SHALL NOTE: REFER TO CG201 AND CG202 FOR PILE CAP LOCATIONS.

BE 5mm FILLET FOR MATERIAL THICKNESS UP TO AND INCLUDING 15mm, 8mm FILLET FOR

THICKNESS OVER 20mm. ALL WELDS SHALL BE SINGLE-PASS WELDS.

R:\d0978721\3D-S-Std Dtls.rvt

3. ANCHOR BOLTS AND BASE PLATES TO BE STAINLESS STEEL UNLES NOTED OTHERWISE.

ELECTRICAL DUCTBANK PILE CAP 5

STEEL COLUMN BASE 4

- NTS CG201

NTS

CG202

ASHBRIDGES BAY TREATMENT PLANT

WAS THICKENING FACILITY AND SOUTH SUBSTATION UPGRADES

FRANK QUARISA, P. ENG. JOHN P. KELLY, P. ENG.

ACTING DIRECTOR, STANDARD DETAILS 7

5/16/2019 11:16:32 AM

DIRECTOR, DESIGN & CONSTRUCTION

WASTEWATER TREATMENT MAJOR INFRASTRUCTURE STRUCTURAL

DESIGN: DK DRAFTING: NK CHECK: DT CONTRACT No. 19ECS-MI-01AB

2 MAY 2019 ISSUED FOR TENDER DT

SCALE: NTS DRAWING

1 DEC 2018 ISSUED FOR TENDER DT

No. DATE REVISIONS INITIAL SIGNED DATE: FEB 2019 NUMBER: 1001-2019-01-247 SM507

REINFORCING

STEEL, TYP

ALUMINUM OR GENERAL NOTES:

THICKNESS

STEEL GRATING

SS 6mm PL WELDED 1. EXTEND GRATING CONTINUOUSLY OVER GATE GUIDES AND GATES 11. TYPE OF GRATING MATERIAL USED SHALL BE AS SHOWN ON PLANS

SLAB

BANDING BAR OR AS SPECIFIED. THIS STANDARD DETAIL INCLUDES 2 TYPES,

AT OPEN ENDED 2. NOTCH GRATING SUPPORTS AS REQUIRED. ALTHOUGH BOTH MAY NOT BE INCLUDED IN PROJECT.

SUPPORTS, TYP

3. GRATING SPAN SEE PLAN. 12. THE HORIZONTAL CLEARANCE BETWEEN THE GRATING AND

TRIM SS 6mm THICK GRATING SUPPORTS SHALL BE LESS THAN 6mm NOT

THICKNESS

4. WIDTH OF GRATING SECTIONS SHALL NOT EXCEED 900mm. GREATER THAN 13mm AND AS SPECIFIED.

GRATING

VERTICAL LEG AS CENTERED

20° REQD FOR GRATING

THICKNESS 5. SHOP DRAWINGS BASED ON FIELD DIMENSIONS SHALL BE 13. ALL GRATING SECTIONS, WHEN IN PLACE, SHALL ALWAYS BE

SUBMITTED TO THE ENGINEER PRIOR TO FABRICATION. FIRMLY ANCHORED TO THEIR SUPPORTS AS SPECIFIED.

6. MATERIAL FOR SUPPORTS OF STEEL AND ALUMINUM GRATING TO BE 14. MIN BEARING HORIZONTAL DIMENSIONS = 25mm FOR GRATING

SAME AS GRATING, EXCEPT METAL SUPPORTS THAT ARE TO BE DEPTH 57mm OR LESS, MIN BEARING HORIZONTAL

SS 10mmx150 EMBEDDED IN CONCRETE SHALL BE TYPE 316 STAINLESS STEEL. DIMENSION = 50mm FOR GRATING DEPTH GREATER THAN 57mm.

AL CHECKERED PL COVER, COUNTERSUNK

ANCHORS STEEL BEAMS

SEE PLANS FOR TYPE, SST BOLTS 7. UNLESS NOTED OTHERWISE ON PLANS, GRATING THICKNESS

SIM TO SM509 TYPE'A' @ 450 CENTERS BEARING BAR SHALL BE AS TABULATED IN "GRATING THICKNESS TABLE" FOR

APPLICABLE TRAFFIC.

6

MIN BEARING

DIMENSION, 8. BEARING BAR THICKNESS FOR GRATING TO BE 5mm MINIMUM.

SINGLE LAYER REINFORCING - SLAB THICKNESS LESS THAN OR EQUAL TO 200mm

SEE NOTE 14 GS-1 9. BAND ALL EDGES WITH 5mm x DEPTH OF BEARING BAR.

LIVE LOAD:UDL = 9.6 kPa -OR-

C = 4.5 kN/M

6mm BAR WELD TO SUPPORT 10. PROVIDE MISCELLANEOUS GRATING FASTENERS AS REQUIRED. TYPICAL DECK SLAB REINF DETAIL 3

THICKNESS

GRATING

BEAM, OMIT WHERE GRATING -

MINIMUM GRATING THICKNESS TABLE NTS

HINGES @ 600 IS CONT OVER SUPPORT BEAM

L65x65x8 ON 10mm PL TO BANDING BAR MAXIMUM ALUMINUM STEEL

SEATED SIDED SUIT HINGES

EQPT 6mm BAR TOE STOP ALL SPAN

ONLY

OPNG AROUND OPENINGS, 1050 32 25

L65x65x8 ON HINGE SIDE SUPPORTING BEAM, WELD TO GRATING

ONLY, SEE SLAB OPENING FOR SIZE AND END 1200 38 25

COVER

CLEAR

BEARING BAR

125

30mm

COVER TYPE "A", SIM CONDITIONS, SEE PLAN 1350 44 32

REINFORCING

GRATING 1500 51 32 STEEL, TYP

MIN BEARING 1650 51 38

DIMENSION, 1800 64 44

THICKNESS

NOTES: MIN BEARING GS-2 SEE NOTE 14 GRATING 1950 64 51

SLAB

DIMENSION,

1. INSTALL SST CHAIN. TACK WELD OR BOLT TO PL AND FRAME. -

CHAIN TO STOP PL AT 20° PAST VERTICAL. SEE NOTE 14 EQUIPMENT OPENINGS 2100 51

THICKNESS

GRATING

2. HINGES TO BE STAINLESS STEEL FULL MORTISE BUTT HINGES BANDING BAR

UDL = UNIFORMLY DISTRIBUTED LOAD

WITH STAINLESS STEEL BOLTS. SS 16mm ADHESIVE

ANCHORS @ 450 C = CONCENTRATED LOAD

3. MAX WEIGHT TO BE 35 kg. COMPOSITE

CENTERS, 150 MIN FLOOR DECK

4. SEE SM509 FOR LIFTING EYE DETAILS AND PLANS FOR TYPE. EMBEDMENT

5. FOR LOCATIONS OF AL CHECKERED PLATE SEE PROCESS

MECHANICAL DRAWINGS BEARING BAR

GRATING STEEL BEAMS

L100x75x8 LLV, UNO

GS-3 DOUBLE LAYER REINFORCING - SLAB THICKNESS ( > 200mm)

CHECKERED ALUMINUM HINGED FLOOR PLATE 1 STANDARD GRATING 2

- NTS -

TYPICAL DECK SLAB REINF DETAIL 4

NTS -

NTS

BOTTOM REINF SPLICE REINF CENTERED IN

LAP-SEE STANDARD SLAB FOR SIZE AND CENTER VALLEY OF STEEL

REINFORCING DETAILS SPACING, SEE PLANS DECKING OVER GIRDER

TYP FOR SHEAR STUDS

FOR REINF

20mm,

5 50-300 CONCRETE

CLR

SEE PLANS

KEY UNO

EQ EQ 5 50-300

NOTE 2

T/3

MAKE SURFACE SMOOTH

SEE,

NOTE 2

REINFORCING POUR STOP

SEE,

T

STEEL

T/3

.

THICKNESS

T7

2

4

1

.

COMPOSITE

SLAB

EQUAL EQUAL

.

FLOOR DECK

20 DIA HEADED

T/3

TOP SHEAR STUDS

REINF T

OP

R

N

IE

F

SHORE DECK SPLICE L

P

S

C

IE

20mm . JOIST

0

5

1

AT CJ EQUAL EQUAL

COMPOSITE FLOOR DECK OVERHANG GIRDER

50mm

EQUAL

5

2

8

6

EQUAL

5

2

8

6

BEAM SPACING - SEE PLAN NOTES:

1. TOTAL NUMBER OF OF SHEAR STUDS FOR FOR BEAM SHOWN ON FRAMING PLAN

BEAM SPCG - SEE PLAN

0

5

6

3

1

SPACE STUDS UNIFORMLY OVER THE LENGTH OF BEAM.

2. FOR SLAB AND DECKING DEPTH, SEE PLANS.

TYP DECK SLAB CONSTRUCTION JOINT 5

TYP DECK SLAB REINFORCEMENT SPLICE DETAIL 6 TYP DECK SLAB EDGE DETAIL 7 COMPOSITE BEAM DETAIL 8

NTS - - -

- NTS NTS

NTS

R:\d0978721\3D-S-Std Dtls.rvt

ASHBRIDGES BAY TREATMENT PLANT

WAS THICKENING FACILITY AND SOUTH SUBSTATION UPGRADES

FRANK QUARISA, P. ENG. JOHN P. KELLY, P. ENG.

ACTING DIRECTOR, STANDARD DETAILS 8

12/5/2018 10:31:54 PM

DIRECTOR, DESIGN & CONSTRUCTION

WASTEWATER TREATMENT MAJOR INFRASTRUCTURE STRUCTURAL

DESIGN: DK DRAFTING: NK CHECK: DT CONTRACT No. 19ECS-MI-01AB

SCALE: NTS DRAWING

1 DEC 2018 ISSUED FOR TENDER DT

No. DATE REVISIONS INITIAL SIGNED DATE: DEC 2018 NUMBER: 1001-2019-01-248 SM508

20mm x CONT

KEYWAY 6

35

9

1

6 3

5

2

13

1

9

8

22 5

7

3mm THICK x 35mm CONT

9

5

3

VARIES, SEE COVER SYMMETRICAL EDGE PL FOR 6 NEOPRENE GASKET

CONTRACTORS OPTION TO USE TYPE DETAILS ABOUT CL TYPE 'C' SEAL WELD

6

PLATE

THREADED DOWELS W/ MECHANICAL COVERS,

15M@300mm

10

THREADED CONNECTORS EDGE OF OPENING CHECKERED PL SEE DETAIL

DOWELS 6 6

1

COVER MAX

3

WELD AS

NOTED

CLR

MASONRY ANCHOR TYPE "C"

40

5 50-150 AS SPACER

SYSTEM TYP PL 3mm x 32 x CONT COVER PL

5 50-150

2/3 1/3 AL PL 10mmx75mm x CONT, 6mm STAINLESS STEEL

STIFFENER STIFFENER STOP 6mm FROM FACE OF FLAT HEAD SCREWS @

CONCRETE TOPPING SPG OR SPG OR

STIFFENER SUPPORT ANGLE EA END, 300 CENTERS

SLAB THICKNESS,

1

8

0

3 5

2 6

8

2

40x5 STRAP ANCHOR 300 MAX SPACING, SEE TABLE 150 MAX DRILL & TAP FOR 6mm

7

2

6

SEE PLANS

SUPPLIED BY STEEL STAINLESS STEEL SCREWS

FABRICATOR, INSTALLED 'W' COVER PLATE WIDTH

2

7

4

1

BY MASONRY CONTRACTOR NOTE:

THIS DETAIL APPLIES AT TYPE "C"

COVERS AND OTHER AIRTIGHT COVERS.

45

1

0

9

COMPOSITE TABLE

STEEL DECKING EDGE PLATE DETAIL

42x6x5 BAR CHANNEL OPENING SPAN STIFFENER MAX MAX PLATE

L 102x76x9.5 LLV x50mm LONG WELDED LENGTH `L' SIZE STIFFENER WIDTH `W'

BY STEEL FABRICATOR SPACING OPENING SPAN

20mm DIA ANCHOR BOLTS SEE PLAN

@ 300mm CENTERS, SEE NOTE 2 L<750 NONE - 1500

35 6 MAX

750<L<1050 L51x38x6.4 450 1200

10mmx20mm STAINLESS

1050<L<1200 L64x38x6.4 450 1200 10mm UNLESS 13 MAX STEEL FLAT BAR

WALL CONTINUOUS

3

9

OUTSIDE FACE NOTED,

6

OF MASONRY 1200<L<1350 L64x38x6.4 375 1200 SEE PLAN

40 42

CLR 2-TYP WALL 50 1350<L<1500 L76x51x6.4 450 1200

3

5

0

HORIZONTAL BARS

CONTINUOUS 1500<L<1650 L76x51x6.4 375 900 STIFFENERS

50

WHERE REQD,

NOTES: 1650<L<1800 L89x64x6.4 450 900 SEE DETAIL

50

AND TABLE

5

0

2

1800<L<1950 L89x64x6.4 375 750

100

1. WHERE DECKING SPAN IS PARALLEL TO WALL, LOCATE VALLEY

1

0

3

21950<L<2100 L102x76x6.4 375 750

OF DECKING CENTERED ON LEDGER ANGLE. STAINLESS STEEL L50x50x6

2100<L<2250 L102x76x6.4 300 600

2. PROVIDE HEADED ANCHOR BOLTS WITH 250mm EMBEDMENT FOR TYP

TO SUIT2

1

4

10mm DIA x 150mm STAINLESS 5

WALLS 300mm & THICKER. PROVIDE SMOOTH ANCHOR BOLTS MASONRY STEEL ANCHORS AT 450

WITH 75mm HOOK AS SHOWN FOR WALLS LESS THAN 300mm THICK. NOTES: CENTERS HOOK 50mm AS SHOWN

1. STIFFENERS TO BE PLACED LONG LEG VERTICAL.

NOTE: 2. SPAN DIRECTION OF PLATE TO BE PARALLEL TO STIFFENERS, AND SHALL

1. ALL WELD SHALL BE 5mm MINIMUM FILLET WELD. BE SHORT DIMENSION OF OPENING UNLESS NOTED OTHERWISE ON PLANS. COVER TYPE "A"

3. MAXIMUM ALLOWABLE UNIFORM DESIGN LOAD = 15kPa.

4. MAXIMUM WEIGHT OF COVER PLATE TO BE 55kg.

COMPOSITE FLOOR DECKING 5. COVER PLATES AND STIFFENERS ARE ALUMINUM PLATES AND ANGLES. OPENING SPAN 3

9

1

6 MAX

LEDGER SUPPORT ANGLE 1 MASONRY TO STEEL CONNECTION 2 6. ALL COVER PLATES TO HAVE A MINIMUM OF TWO EYES AS SHOWN IN SEE PLAN

- - LIFTING EYE DETAILS.

NTS NTS 7. FOR HINGED FLOOR PLATE SEE DETAIL 1 ON DRAWING SM508. 22 13

6mm STAINLESS STEEL

COVER STIFFENERS 13 MAX 3

9 3

1

5

20 FLAT HEAD SCREWS

10mm UNLESS WITH 2 SQ NUTS

NOTED, WELD TO L, ONE AT

SUPPORT COVER PLATE 25

0

1

SEE PLAN EA CORNER

OPENING ANGLE,

WIDTH SEE SCH 20mm DIAx100mm

.

4

3

7

'W' WALL, TYP LONG ROD STIFFENERS

EQ

WHERE REQD, 10mmx20mm

0

5

7

1

SEE DETAIL STAINLESS STEEL

AND TABLE FLAT BAR

75

0

5

3

65

TOP CHORD

0

4

2

1

EQ

OF METAL

0

5