Professional Documents

Culture Documents

Simple To Sophisticated: Products For Pumping Systems

Simple To Sophisticated: Products For Pumping Systems

Uploaded by

Nguyen Tien TrinhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Simple To Sophisticated: Products For Pumping Systems

Simple To Sophisticated: Products For Pumping Systems

Uploaded by

Nguyen Tien TrinhCopyright:

Available Formats

Simple to sophisticated

Products for pumping systems

From simple to sophisticated

Our comprehensive global product and service offering

helps pump system manufacturers find the right products

and solutions to build reliable and energy efficient pumping

solutions, all from a single supplier.

Contents

4 Doing more than meeting expectations

6 Change thinking on pump efficiency

More than the best efficiency point

8 Solutions for water hammer

10 Solutions for pumping challenges, a spotlight on drives

12 Pumping solutions, from simple to sophisticated

14 Low and medium voltage AC drives offer tremendous

energy savings

16 AC motors, demonstrated pumping dependability

18 Synchronous reluctance motor and drive packages,

efficiently efficient

20 Low voltage products bring it all together

21 Softstarters deliver controlled and cost effective motor

startup and stopping

22 Measurement products provide a look inside

23 PLCs enable flexible and scalable control

24 Global life cycle services offer more than just spare parts

26 This is ABB

2 Products for pumping systems | Simple to sophisticated

AC drives offer efficient and reliable solutions for increased pump efficiency and energy savings.

Simple to sophisticated | Products for pumping system 3

Doing more than meeting expectations

In addition, our customers are being asked to provide

Our customers share similar concerns pumping solutions that:

when they select product suppliers for

− Provide the control to operate at the best efficiency point

their pumping systems: − Help them develop engineering recommendations to

− They want product solutions based on experience improve pump performance and to extend pumping system

− They demand reliability equipment life cycles

− They demand quality − Are more energy efficient and reduce energy consumption

− They insist on performance and that increase their customer’s return on investment

− And they want the best value − Use the latest automation technology and application

knowledge

− Reduce maintenance demands by using reliable,

dependable high quality products backed by global

warranties

− Provide condition-based predictive and preventive

maintenance programs and schedules, backed by globally

available service

4 Products for pumping systems | Simple to sophisticated

Our product offering and global life cycle Our offering includes:

services help our customers address all − Pre-sales engineering

− Global life cycle services

of these concerns. − Connectivity and communication ready devices

We have an extensive offering of automation, motor, and − Low and high voltage AC motors

connectivity products and the application experience to put − Low and medium voltage AC drives

together the best product solutions for our customers. The − Softstarters

offering includes premium efficiency low voltage AC motor − Programmable logic controllers (PLC)

and drive packages that reduce installation space and lower − Measurement products

energy consumption by as much as 50 to 60 percent, to − Low voltage products

programmable logic controllers and measurement products

that help ensure your pumping system operates reliably, 24/7.

ABB products are backed by our global manufacturing

capacity where the same high quality materials and production

processes ensure each product’s quality. A global life cycle

services network provides our customers with a wide range of

services from in-classroom training to spare parts contracts.

Simple to sophisticated | Products for pumping system 5

Change thinking on pump efficiency

More than the best efficiency point

Traditionally, pumping efficiency has focused on the best

efficiency point (BEP) of the centrifugal pump. However, what

does that mean when pumping systems are operated with

variable speed output?

Pump efficiency and BEP Fixed speed and reduced flow

The BEP of a centrifugal pump is defined as the operating point When fixed speed pumping motors are operated at reduced

of highest efficiency, but also the point where velocity, and capacity, ie, at a flow significantly less than BEP and at a

therefore pressure, is equal around the impeller and volute. higher head, the fixed vane angles will cause eddy flows

The corresponding BEP for variable speed follows the Affinity within the impeller, casing, and between the wear rings. The

laws. radial thrust on the rotor will increase, causing higher shaft

stresses, increased shaft deflection, and potential bearing and

Centrifugal pumps should be selected and normally operated mechanical seal problems while radial vibration and shaft axial

at or near the manufacturer’s design specific speed for the movement will also increase.

rated conditions of head and flow best efficiency point.

Fixed speed and excess flow

In a fixed speed pumping application Any pump operated at excess capacity, ie, at a flow

significantly greater than BEP and at a lower head, will surge

BEP is “fixed.” When flow modulation and vibrate, creating potential bearing and shaft seal problems

is required, throttling or bypassing is as well as requiring excessive power. Additionally, it may also

used. This is not the most efficient way infringe net positive suction head (NPSH) leading to cavitation

and erosion of the impeller.

to operate, both in energy use and

mechanical stress (reliability) of the

system.

6 Products for pumping systems | Simple to sophisticated

BEA and variable speed drives

Many pump systems require variable flow

A pumping system’s best efficiency area (BEA) considers

to meet changing process demands. The variable speed operation and optimization of the pumping

most common methods for controlling system as a whole. BEA helps to understand the benefits of

a variable flow system is a control valve, running pumps at variable speeds. This is achieved by using

drives to control the speed of the pumping system’s motors.

bypass line or a variable speed drive. BEA takes hydraulic losses of the system into account, and is

based on the specific energy use of the total pumping system

(kWh/m3). BEA realistically shows the advantages of operating

Valve control the pump at lower rotational speeds. These advantages

Controlling the pump with a valve forces the pump “back on include:

the curve” away from the pump’s BEP, resulting in wasted

energy across the valve and at the pump. In addition the − Lower total system mechanical stress

pump’s reliability is reduced. − Less stress on pump bearings, shaft and sealing system

− Longer pump life span

Bypass control − Reduced cavitation

Bypassing the excess fluid allows the pump to operate at or − Reduced risk of pump failure

near BEP, however the energy used to move the excess fluid − Good specific energy for a wide operational flow range with

is wasted. either single or multiple pumps

Variable speed drive control

Variable speed drives are the most efficient method for

controlling flow. Because the drives control the speed of

the motor directly based on actual demand, a more efficient

match to the actual system requirements is more easily

achieved, increased energy savings are easily possible,

and stress on the pumping system as a whole is reduced.

Variable speed operation also changes the thinking about

BEP, introducing instead the pumping system’s best efficiency

area, where the specific energy (kWh/m3) can be kept at the

minimum possible value.

The most efficient method to control

the system is a variable speed drive.

The drive provides the best solution

for optimum pump efficiency and

reduced energy consumption.

Simple to sophisticated | Products for pumping system 7

Solutions for water hammer

The term water hammer comes from the pressure surge’s

hammering effect on a system. Water hammer is also known as

liquid hammer since the phenomenon can occur in other liquids.

This phenomenon is the result of a rapid increase in pressure

(typically in a closed loop system) when the liquid velocity is

suddenly changed.

The effect occurs due to a force applied to move and add All of these events can result in a change in the liquid velocity

pressure to a liquid (which is virtually incompressible) thereby within the pumping system.

creating dynamic energy that is transmitted instantly across

the system. When liquid moves, stops, or changes velocity Actions for controlling water hammer:

abruptly, the dynamic energy amplifies the normal system − Protect the pump by installing non-return check valve on

pressure creating a sudden pressure surge, or spike. When discharge piping to isolate the pump in the event of its

the pressure surge accelerates and approaches the speed sudden stoppage or reversal of its rotation in an upset

of sound, the surge becomes an acoustic resonance with condition. This device should be installed regardless.

a sound wave. The pressure surge is amplified many times − Open or close valves gradually (results in stress to system

greater than the normal system pressure. This pressure surge and wasted energy)

can be extremely destructive to system components ie, − Install surge suppressor, or pulsation dampener (highly

pump, piping and valves. engineered solution)

− Using a gradual, controlled start/stop of the pumping

In a centrifugal or roto-dynamic pumping system the sudden system prevents water hammer. This is the most effective

change may be the result of: method for controlling water hammer.

− Across-the-line starting

− Abrupt stop from base speed

− Rapid change in speed

− Sudden opening and closing of valves

8 Products for pumping systems | Simple to sophisticated

In order to provide the gradual Electro-mechanical controlled start

Our Baldor/Dodge division has a unique electro-mechanical

deceleration of the pump, sufficient solution for high horsepower low speed pumping applications

motor torque needs to be available. where a controlled start and stop is necessary, eg irrigation,

To address the motor torque/controlled circulating water and flood control pump systems.

stop ABB offers three solutions, AC Softstarters

drives, electro-mechanical controlled ABB softstarters with torque control are designed for pumping

start (CST) and softstarters. applications. The PSE and PST range of softstarters with torque

control have a stopping algorithm that provides full control

over the pump’s torque during the pump’s deceleration ramp.

AC drives

In addition to the many pump specific features provided in our

AC drives, reliable and precise torque control is a standard

feature. Technology like ABB’s direct torque control (DTC)

ensures the needed torque is available in the motor while

stopping the pump.

Simple to sophisticated | Products for pumping system 9

Solutions for pumping challenges,

a spotlight on drives

Built-in technology in ABB AC drives does more than just control

the speed and torque of AC motors. Pump specific functions

provide solutions for many common pumping challenges while

improving the pumping system’s energy efficiency, mechanical

reliability and availability.

PID control: Process feedback, rather than a set speed pressure. Pumping restarts when the pressure falls below the

reference, lets the drive calculate the required motor speed or set level.

torque based on pre-configured process parameters like flow,

pressure, level, etc. Pump auto change

In multi-pump systems, the drive alternates between available

Pump cleaning/anti-jam pumps ensuring each has an equal duty cycle.

Used to prevent solids from building up on pump impellers and

piping, this function consists of a programmable sequence of Pump priority

forward and reverse runs of the pump to shake off any residue Used in pumping systems where the flow rate varies based

on the impeller or piping. This is especially useful with booster on a schedule or demand. For example, the drive can be

and wastewater pumps, and can be set to run automatically at configured to use larger pumps during high demand times

scheduled intervals, at startup or when the drive detects the and switches to smaller pumps when the demand is less,

impeller needs cleaning. optimizing system efficiency.

Level control Flow calculation

Using a level or pressure sensor connected to the drive’s Drives with a built-in flow calculation function very accurately

analog or digital inputs, the drive varies the flow into the determine the process’ flow rate without requiring an external

container ensuring the desired level is maintained. Level flow meter. This calculation is suitable for applications where

control also works with a series of drives connected in a flow data is not used for invoicing.

master/follower configuration, known as multi-pump.

Flow monitoring

Sleep and boost When configured, the drive monitors the flow (calculated or

When demand falls and the motor speed is reduced, the drive actual) and generates an alarm or fault if the flow falls below

detects the changes over time and starts the sleep mode. or rises above defined limits. This function helps detect leaks

It stops unnecessary pumping but continues to monitor in the system.

Pumping in water and wastewater systems

ABB’s ACQ810 AC drive for water and wastewater

applications is designed with many built-in

pump specific functions to meet the demanding

requirements found in the water industry.

− 0.37 to 400 kW

− 0.5 to 535 hp

− 200 to 480 V AC

10 Products for pumping systems | Simple to sophisticated

Multi-pump control Oil and gas pumping

Communicating together, ABB drives efficiently control parallel Designed specifically for the unique demands of the oil and

pumps to meet the required variable flow demands. Stable gas industry, dedicated control programs help improve the

process conditions are maintained while optimizing the speed performance of:

and number of pumps required.

− Electro submersible pumps (ESP)

Soft pipe filling − Progressive cavity pumps (PCP)

Pressure peaks damage pipe work and aggravate leaks. The − Rod pumps

drive ramps the pump speed slowly, avoiding pressure peaks − Booster pumps

when filling systems.

Harmonic reduction

Energy savings calculator Drives with built-in harmonic reduction ensure total harmonic

Drives with energy savings calculators show used and saved distortion (THD) levels remain less than 5 percent.

energy by the motor, and can display this information in terms

of kWh, currency or volume of saved CO2 emissions. Power loss ride through

Drives with this feature are able to remain in control during

Flow and pressure protection short periods of power loss. This also helps prevent

Cavitation occurs when pumping pressure falls and the fluid mechanical shocks when power is restored.

being pumped is vaporized by the change in pressure at

the impeller. This results in harmful gas bubbles that cause Built-in motor protection

damage to the pumping system. The drives detect when the Along with pump specific functions, ABB drives also provide

flow rate or the pressure in the pumping system changes, many built-in motor protection functions as well. These

and can increase or decrease pumping to correct the flow or include:

pressure, helping to prevent cavitation.

− Motor thermal protection

Energy optimization − Motor stall protection

The drive monitors the load on the motor shaft and optimizes − Phase loss detection

the motor’s flux to ensure the minimum amount of energy is − Motor ground fault protection

used to satisfy the pump system needs.

Energy consumption monitoring

The drive monitors the energy consumption of both the drive

and the pump’s motor. The drive saves 12 months of data,

and can be configured to generate alarms when the energy

consumption rises significantly compared to past consumption.

Pumping in HVAC systems

Pumps are used throughout heating, ventilation and

air conditioning (HVAC) systems. And when these

systems are used in commercial buildings, there are

increased requirements that the system must meet.

ABB drives for HVAC provide built-in solutions for

these increased requirements.

− Meets HVAC EMC requirements

− Meets HVAC harmonics standards

− Native BACnet for integration with building

management systems

− IP21 and IP54 protection

− Built-in timers

− Built-in calendar and clock ACH550 drives for HVAC.

Simple to sophisticated | Products for pumping system 11

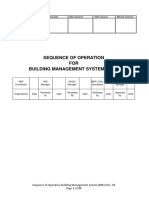

Pumping solutions,

from simple to sophisticated

Manual motor starter Softstarter Low voltage AC drives

and contactor

Motor Motor Motor Motor Motor

Remote monitoring options

GSM, GPRS, 3G GSM, GPRS, 3G

AC500-eCo CP600 HMI

PLC

AC drive AC drive Remote

monitoring

adapter

Motor Flow meter Motor Motor

12 Products for pumping systems | Simple to sophisticated

Advanced solutions with PLC and measurement products

PS501 Control Builder Plus

programming station

Industrial Ethernet

HMI AC500 PLC

AC drive

MCCB Motor

Network

analyzer AC drive Softstarter

S500 Remote I/O

Flow meter

Temperature

sensor

Contactors and softstarter

with manual motor starter

Automation network

Motor MV AC drive Industrial Ethernet

Electrical hardwire

Simple to sophisticated | Products for pumping system 13

Low and medium voltage AC drives

offer tremendous energy savings

Using ABB AC drives to control motor speed and torque in

pumping systems not only helps greatly reduce lifetime energy

costs, but also improves system reliability. The wide range of

built-in pump control technology helps our customers build

smarter pumping systems.

Pump specific applications built-in to the drives offer Single drives, 200 to 690 V

solutions for common challenges such as multi-pump − 0.37 to 5,600 kW

control, flow and pressure monitoring, PID control, level − 0.5 to 7,500 hp

control and cavitation protection. Energy use and saved

CO2 information let our customers easily keep track of Multidrives, 380 to 690 V

their savings. − 1.5 to 5,600 kW

− 2 to 7,500 hp

The drives help you easily follow

your return on investment and energy

savings by calculating:

− Saved MWh

− Money saved (in local currency)

− CO 2 reduction

14 Products for pumping systems | Simple to sophisticated

ABB medium voltage AC drives extend drive control and Single drives, 2.3 to 10 kV

energy saving benefits to larger pumping systems. From − 250 kW to 72 MW (higher on request)

reducing network voltage dips when starting pumps − 335 to 96,500 hp (higher on request)

to soft starting and stopping, these features reduce

mechanical stresses on the pumping system. Multidrives, 3.1 to 3.3 kV

− 3 to 36 MW

− 4,020 to 48,240 hp

Soft starting solutions, 2.3 to 10 kV

− 250 kW to 72 MW (higher on request)

− 335 to 96,500 hp (higher on request)

Simple to sophisticated | Products for pumping system 15

AC motors, demonstrated pumping

dependability

Motors are the driving force for pumping systems. Reliability

and efficiency are key factors in their choice. Our motors

are designed with this in mind and are backed by global

manufacturing and life cycle services.

ABB low voltage IEC and Baldor Reliance NEMA AC IEC Process performance motors

motors offer robust and reliable performance for a wide − IEC frame sizes 71 to 450, up to 1,000 kW

variety of pumping applications. The motor selection − Efficiency classes IE2, IE3 and IE4

includes induction motors, permanent magnet motors,

synchronous reluctance motors, and motors for explosive General performance motors

atmospheres. − IEC frame sizes 56 to 355, up to 355 kW

− Efficiency class IE2

Explosion proof motors, all protection types

− IEC frame sizes 71 to 450, up to 1,000 kW

− NEMA frame sizes 48 to 5810, 0.25 to 800 hp

NEMA Severe duty motors

− NEMA frame sizes 42 to 6800, up to 5,000 hp

− NEMA Premium efficiency; Energy Efficient

16 Products for pumping systems | Simple to sophisticated

The powerful range of ABB high voltage IEC and medium Cast iron HXR motors

voltage Baldor Reliance NEMA AC induction and − IEC sizes 355 to 560, 100 to 2,250 kW

synchronous motors are designed to operate reliably

no matter how challenging the pumping system. The Modular induction motors

standardized construction for horizontal and vertical − IEC sizes 400 to 1,000, 140 to 23,000 kW

motors feature innovative insulation and optimized rotor,

stator and fan designs. This, along with over a century Process performance cast iron motors

of electric motor design, helps ensure low life cycle − IEC sizes 315 to 450, 110 to 750 kW

operating costs and reliable operation. − NEMA sizes 143T to 6800, 1 to 5,000 hp

Synchronous motors

− IEC sizes 0710 to 2500, 1 to 60 MW

Simple to sophisticated | Products for pumping system 17

Synchronous reluctance motor and drive

packages, efficiently efficient

When motor bearings and windings heat up, energy is lost, and

reliability is lowered. Our synchronous reluctance motor (SynRM)

and drive packages offer a new rotor design that significantly

increases efficiency and improves system reliability, all without

the use of rare earth magnets.

High output SynRM motor and drive package IE4 SynRM motor and drive package

Reduce energy

losses by up to

40%

Induction High output synchronous IE2 Induction IE4 Synchronous

motor reluctance motor motor reluctance motor

The high output SynRM motor can be up to two IEC frame Losses in the IE4 (super premium efficiency) SynRM motors

sizes smaller when compared to traditional induction motors. are cut up to 40% compared to IE2 motors. This helps pump

This space savings helps design more compact pumping system designers to meet the ever increasing demands for

systems. more efficient pumping systems.

Alternatively, replacing an induction motor with the same The IE4 SynRM motors are available with the same output

frame size high output SynRM motor is a convenient way to size combinations compared to traditional induction motors.

increase a pumping systems’s power. This allows existing pumping systems to be upgraded easily

for increased system efficiency.

Synchronous reluctance motors require the use of an ABB drive, they

cannot be run direct-on-line.

18 Products for pumping systems | Simple to sophisticated

Simple to sophisticated | Products for pumping system 19

Low voltage products bring it all together

Sometimes, the small things make the biggest difference.

In pumping systems, every switch, breaker, fuse or contactor

needs to be just as reliable as any other part of the system.

That’s the driving idea behind every one of ABB’s low voltage

products.

Low voltage products connect the electrical system and

provide protection for pumping systems. From circuit

breakers, contactors, relays and switches to surge

protection and residual current devices, the range of

products helps our customers create the best solution for

their pumping needs.

Circuit breakers

− Air circuit breakers

− High performance and miniature circuit breakers

− Moulded case circuit breakers

Control products

− Arc guard systems

− Contactors

− Manual motor starters

− Electronic relays

Fusegear

− Switch fuses

− Fuse switch disconnectors

− Fuse bases

− Fuse links

− Fuse monitors

Switches

− Switch-disconnectors

− Change-over switches

− Transfer switches

Enclosures

− Main distribution boards

Other modular DIN rail products

− Residual current devices

− Surge protective devices

− Electricity meters

− Socket outlets

20 Products for pumping systems | Simple to sophisticated

Softstarters deliver controlled and cost

effective motor startup and stopping

In pumping systems, it’s not always the motor starting that can

be challenging. Direct motor stops can quickly wear out valves,

gaskets and pipe connections. ABB softstarters offer convenient

and reliable solutions.

The wide range of softstarter solutions offers more PSR range

than just controlled motor starting and stopping. With − Compact

features such as fieldbus communication options, pump- − Can be used with manual motor starter

stop torque control, built-in bypass and flexible output − Up to 105 A, 600 V

connections, they offer flexibility for pump system

designers. PSE range

− Pump specific functionality

− Torque control

− Up to 370 A, 600 V

PST range

− Most advanced functionality

− Torque control with programmable functionality

− Up to 1,050 A, 690 V

Simple to sophisticated | Products for pumping system 21

Measurement products provide a look

inside

Acquiring accurate data on what is actually happening inside

a pumping system is critical for efficient and maximized flow.

Our measurement products make this data easily available.

ABB flow, temperature, pressure and level sensors as well Flow measurement products

as analytical measurement products provide the reliable − Self diagnostics

and accurate data needed to fine tune the performance − High accuracy

of your pumping systems. With a wide range of input − Quick and simple startup

and outputs they easily integrate into pumping systems.

Developed with over century of experience and backed by Pressure, temperature and level measurement products

worldwide sales and service, our measurement products − Long term stable measurements

provide pump system designers with the right data for − Designed for demanding environmental and operational

any pump system design. conditions

Analytical measurement products

− Simple setup

− Easy operation and maintenance

− Online diagnostics

22 Products for pumping systems | Simple to sophisticated

PLCs enable flexible and scalable control

Pumping systems can have very unique control challenges.

And when they do, our range of PLCs provides the flexibility

to meet these challenges.

The scalable ABB AC500 range of PLCs, which AC500-eCo

also includes a safety PLC, provides pump system − For small to medium applications

manufacturers with the flexibility and choices to meet − CPUs come with onboard digital and analog I/Os

the technical demands of pumping systems. A wide − Expandable

range of communication options provide connectivity to

all common industrial networks. Design and build your AC500

pump control applications with our Control Builder Plus − For mid to high end solutions

engineering tool. − Wide connectivity and real time Ethernet

− Complete set of internet services

− Very fast algorithm execution

− Decentralized I/O

− Available for harsh ambient conditions

CP600 operator panels:

− Wide range of touch panels (from 4.3” up to 15”)

− Graphic and web panels created with Panel Builder 600 or

the AC500 web server

− Completely integrated with AC500 PLC and Control Builder

Plus

− Alarms, trending and graphics fully integrated

− USB, Ethernet and serial communication ports

Simple to sophisticated | Products for pumping system 23

Global life cycle services offer more than

just spare parts

Our global service offering starts even Pre-sales engineering connects our technical engineers

with your engineers. They work together to understand your

before you decide to buy ABB products, unique product and integration requirements and together,

and continues through installation, determine and specify correctly dimensioned products.

commissioning, and daily operation to

the eventual recycling of the products. ABB global manufacturing, central

Our local and global technical support stocks and advanced logistics solutions

networks answer questions and solve ensure high availability and quick

problems quickly and efficiently. delivery, including spare parts.

Installation and commissioning

Pre-sales services Time and cost efficient installation and commissioning helps

Energy appraisals help you find out where and how you can get pumping systems up and running safely and quickly. We

save energy. offer a wide range of installation and commissioning services

to help you stay on schedule.

The appraisal, conducted on your site by trained ABB

engineers, documents types and powers of motors, control Preventive and predictive maintenance

methods used, and typical duty cycle characteristics. The Planned preventive maintenance helps you extend the return

information is used to produce a report showing possible on your investment. Our preventive maintenance programs let

energy savings, the estimated annual operational savings, and you tailor the best service to meet your needs. From product-

recommended products as well as payback period to achieve specific maintenance schedules to convenient preventive

these savings. maintenance spare parts kits, these services help you keep

your pumping systems running reliably.

24 Products for pumping systems | Simple to sophisticated

Quite often, analysis of process data provides helpful Training, available at ABB Universities,

information to pinpoint where unplanned maintenance actions

may be required. From PLC’s and drives monitoring process

online, and even at your site, makes sure

data, to our Life Expectancy Analysis Program (LEAP), your system engineers and maintenance

predictive, or condition-based maintenance services help you staff have the technical understanding

identify, budget and plan for your maintenance.

and familiarity to keep ABB products

Retrofit and upgrades running reliably.

Sometimes, existing equipment can be retrofitted or upgraded

with our latest products to help optimize your operation. This Services tailored to your needs

offers a cost efficient solution compared to replacing the Our services are offered on a contract basis and are designed

whole system. to meet your specific requirements. The contracts are flexible,

allowing you to add or remove services as your business

Ordering and tracking needs grow.

Our eBusiness systems make routine tasks like checking

stock availability, ordering and status tracking quick and easy.

Product documentation and other information are quickly

available.

Simple to sophisticated | Products for pumping system 25

This is ABB

As one of the world’s leading engineering companies, we help

our customers to use electrical power efficiently, to increase

industrial productivity and to lower environmental impact in a

sustainable way.

Many of the benefits we take for granted Power Products Division

− High Voltage Products

in our daily life, from electricity at the − Medium Voltage Products

touch of a switch to the consistent − Transformers

high quality of industrial goods, are

Power Systems Division

made possible by technology that was − Grid Systems

pioneered, improved and adapted − Network Management

by ABB over more than a century of − Power Generation

− Substations

innovation.

Formed in 1988 by the merger of two long-established

engineering groups, ABB has about 135,000 employees and

operations in more than 100 countries in every region of the

world.

Today, ABB is one of the world’s leading engineering

companies, helping customers to use electrical power

effectively and to increase industrial productivity in a

sustainable way.

26 Products for pumping systems | Simple to sophisticated

Discrete Automation and Motion Division Process Automation Division

− Low Voltage Drives − Full Service

− Motors and Generators − Open Control Systems

− PE and MV Drives − Measurement Products

− Robotics − Marine and Cranes

− Programmable Logic Controllers − Metals

− Minerals

Low Voltage Products Division − Oil, Gas and Petrochemical

− Breakers and Switches − Pulp and Paper

− Control Products − Service

− Enclosures and DIN-Rail Products − Turbocharging

− LV Systems

− Wiring Accessories

Simple to sophisticated | Products for pumping system 27

Contact us

3AUA0000115065 REV A 5.4.2012 #15696

For more information please contact your © Copyright 2012 ABB. All rights reserved.

Specifications subject to change without notice.

local ABB representative or visit:

www.abb.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- BMS Sequence of OperationDocument29 pagesBMS Sequence of Operationmohmmad alam Khan100% (1)

- Lab Policies Sysmex XN 450 XN 550 Lab 1532Document25 pagesLab Policies Sysmex XN 450 XN 550 Lab 1532Nguyen Tien Trinh100% (5)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- kHAO SAT MACH MAUDocument25 pageskHAO SAT MACH MAUNguyen Tien TrinhNo ratings yet

- Ho Ra MauDocument32 pagesHo Ra MauNguyen Tien TrinhNo ratings yet

- I 131Document14 pagesI 131Nguyen Tien TrinhNo ratings yet

- Product Data - Accuray D5Document7 pagesProduct Data - Accuray D5Nguyen Tien TrinhNo ratings yet

- CME210 2010 Qs 1292024007Document2 pagesCME210 2010 Qs 1292024007Nguyen Tien TrinhNo ratings yet

- PROJECT Mau Estimate TemplateDocument2 pagesPROJECT Mau Estimate TemplateNguyen Tien TrinhNo ratings yet

- PRODUCT DATA - AccuRay D5 (Floor Type)Document6 pagesPRODUCT DATA - AccuRay D5 (Floor Type)Nguyen Tien TrinhNo ratings yet

- Changing The Rotation Direction of Asynchronous Motor PurposeDocument7 pagesChanging The Rotation Direction of Asynchronous Motor PurposeMuhammad J SherwaniNo ratings yet

- Baldor Dodge IP and ISN CatalogueDocument79 pagesBaldor Dodge IP and ISN CatalogueRestuNo ratings yet

- Service Manual: Sigma Air Manager 16/8Document192 pagesService Manual: Sigma Air Manager 16/8Evandro Jva compressoresNo ratings yet

- Alesis - RA - 100 Reference Manual PDFDocument27 pagesAlesis - RA - 100 Reference Manual PDFPhasebookerNo ratings yet

- Comoros Study 170608222938Document123 pagesComoros Study 170608222938ABDELOUAHEB HAMIDINo ratings yet

- Datasheet MCO enDocument1 pageDatasheet MCO entuan triNo ratings yet

- Add Finisher Tray b1 PCDocument18 pagesAdd Finisher Tray b1 PCutilscNo ratings yet

- Sa210272 0000 0001Document2 pagesSa210272 0000 0001Nagaraj NeradhalaNo ratings yet

- Spare Parts Catalog: 16 S 2230 TO Material Number: 1367.002.045 Current Date: 26.04.2017Document80 pagesSpare Parts Catalog: 16 S 2230 TO Material Number: 1367.002.045 Current Date: 26.04.2017Wang Sze Shian100% (1)

- Kia Niro Ev Owners Manual My23Document507 pagesKia Niro Ev Owners Manual My23Did883No ratings yet

- LD7575 LeadtrendDocument18 pagesLD7575 LeadtrendTechnical sidhuNo ratings yet

- BYDT45C01 User ManualDocument125 pagesBYDT45C01 User ManualTimothy John MoraNo ratings yet

- Silicon Chip Magazine 2009-02 FebDocument108 pagesSilicon Chip Magazine 2009-02 FebcuradarsjrNo ratings yet

- IBM System x3650 M3 Server Models Include Intel Xeon 5600 Series Processors and Preloaded With SAP Discovery SoftwareDocument29 pagesIBM System x3650 M3 Server Models Include Intel Xeon 5600 Series Processors and Preloaded With SAP Discovery SoftwarenurdhiniNo ratings yet

- Surge Arrester Buyers Guide Edition 6 - Section PEXLIM QDocument7 pagesSurge Arrester Buyers Guide Edition 6 - Section PEXLIM QLuis Gerardo Noy DomínguezNo ratings yet

- Manual 2009 Mitsubishi Colt 113592Document449 pagesManual 2009 Mitsubishi Colt 113592Madalina ChitcarofNo ratings yet

- VN330SP PDFDocument10 pagesVN330SP PDFRoozbeh BahmanyarNo ratings yet

- Anemômetro - WindsonicDocument2 pagesAnemômetro - WindsonicFranklinNo ratings yet

- 176 fc5297 PDFDocument3 pages176 fc5297 PDFHamilton MirandaNo ratings yet

- Easa Sib Upn2008-S20080411011 1Document20 pagesEasa Sib Upn2008-S20080411011 1Marco TrankNo ratings yet

- File 41 ADocument178 pagesFile 41 AHamiltonNo ratings yet

- Reyes, Andrian G. Multi Dwelling Electrical Plan BSCE 2-1 Engineering UtilitiesDocument4 pagesReyes, Andrian G. Multi Dwelling Electrical Plan BSCE 2-1 Engineering UtilitiesAndrian ReyesNo ratings yet

- M101Document1 pageM101Eong Huat Corporation Sdn BhdNo ratings yet

- 12-2010 09a, Jf506eDocument17 pages12-2010 09a, Jf506eAleNo ratings yet

- Em 222 Digital Output: Technical SpecificationsDocument9 pagesEm 222 Digital Output: Technical SpecificationsFrancisco MartinezNo ratings yet

- Automotive Lamp CatalogueDocument29 pagesAutomotive Lamp CatalogueKavinda MadhusankaNo ratings yet

- CORE 8mm Video Scope - SpecDocument2 pagesCORE 8mm Video Scope - SpecKate KateNo ratings yet

- LD630Document1 pageLD630Luis Jonathan Bahamaca FernandezNo ratings yet