Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

6 viewsParts Guide Book - Shearing

Parts Guide Book - Shearing

Uploaded by

nguyendando1) The document provides grinding allowance specifications for various models of shearing machine blades, including dimensions for allowance A and B.

2) It notes there are limitations for machine adjustment values in parentheses and that lower blade grinding is not recommended for some models due to blade height adjustment methods.

3) The grinding of lower blades is also not recommended for DCT models as it could lead to unbalanced blade mounting and potential damage if shims are dropped during cutting.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- ANZSMM 2018 NZ Guidance Notes - 19feb2018Document8 pagesANZSMM 2018 NZ Guidance Notes - 19feb2018Andrew ArahaNo ratings yet

- Bridge Abutment Pier Design As Per IRCDocument41 pagesBridge Abutment Pier Design As Per IRCjibendra mishra88% (43)

- GST9 Manual Final V2Document2 pagesGST9 Manual Final V2Steven MillerNo ratings yet

- 4.steel Reinforcement To Concrete (PT I)Document11 pages4.steel Reinforcement To Concrete (PT I)Arun RunNo ratings yet

- Screw Cortical Iso 5835 Ha4.5Document1 pageScrew Cortical Iso 5835 Ha4.5Karan ChadhaNo ratings yet

- Bar Mark Location of Bar Bar Shape Dia Space No of Bar Sr. No. Cutting LengthDocument3 pagesBar Mark Location of Bar Bar Shape Dia Space No of Bar Sr. No. Cutting LengthEr Biswajit SahaNo ratings yet

- Tabla de FileteDocument1 pageTabla de FileteRicardo PonceNo ratings yet

- Flat Belt Width PDFDocument2 pagesFlat Belt Width PDFanon_564740741No ratings yet

- Amada Thick Turret Technical DataDocument2 pagesAmada Thick Turret Technical DataAFAB Machinery and Tools LtdNo ratings yet

- Fin Wt. Surface Area Solid Fins: 0.039 3.5 0.049 4.4 Ratio 0.80Document3 pagesFin Wt. Surface Area Solid Fins: 0.039 3.5 0.049 4.4 Ratio 0.80BoilerNo ratings yet

- Project: Cadangan Klinik Kesihatan 4 Dengan Kuarters, Pengkalan Hulu, Hulu Perak, Perak (Ibs Sepenuhnya)Document9 pagesProject: Cadangan Klinik Kesihatan 4 Dengan Kuarters, Pengkalan Hulu, Hulu Perak, Perak (Ibs Sepenuhnya)faiz salimNo ratings yet

- Kids Overall Kik-P107953Document1 pageKids Overall Kik-P107953IE DEPARTMENTNo ratings yet

- DRAW - Bapak Rofiqi - Duri Kosambi - CengkarengDocument17 pagesDRAW - Bapak Rofiqi - Duri Kosambi - CengkarengDrafter VinitecNo ratings yet

- Stability Result 15275 MT - Initial StowageDocument1 pageStability Result 15275 MT - Initial StowageLife with Our planetNo ratings yet

- Blast Loads For Axen TEG PackageDocument6 pagesBlast Loads For Axen TEG PackageWinsonLimHuiWahNo ratings yet

- Dieset Fuel Tank T5302Document1 pageDieset Fuel Tank T5302Abu ZahidNo ratings yet

- LF Series: Low Frequency, Rugged, Elastomer Shock & Vibration Isolation MountsDocument4 pagesLF Series: Low Frequency, Rugged, Elastomer Shock & Vibration Isolation MountsCarlos Torres OliverosNo ratings yet

- Ceramic Encased: SeriesDocument5 pagesCeramic Encased: SeriesRavi RokkamNo ratings yet

- 2020-08-26-Kfaa-Floor Load Detail PDFDocument1 page2020-08-26-Kfaa-Floor Load Detail PDFhemanthsridharaNo ratings yet

- TAILENGSC4 - 2023 - L3 - Properties of Mine Tailings For Static Liquefaction AssessmentDocument40 pagesTAILENGSC4 - 2023 - L3 - Properties of Mine Tailings For Static Liquefaction Assessmenteng_civil_dayanaNo ratings yet

- HB-3M-2 Nominal Performance Characteristic Curve Torque vs. CurrentDocument1 pageHB-3M-2 Nominal Performance Characteristic Curve Torque vs. CurrentPrathmesh MahajaniNo ratings yet

- Specifications 7.1: Table 7-1. Transmission Data Table 7-2. Internal Gear RatiosDocument6 pagesSpecifications 7.1: Table 7-1. Transmission Data Table 7-2. Internal Gear RatiosMarcelo Ramos SaldanhaNo ratings yet

- 351W SpecsDocument6 pages351W Specsikram42789No ratings yet

- Katalog Baylan Vodomjer 1-2Document1 pageKatalog Baylan Vodomjer 1-2Edin Dervishi100% (1)

- Specifications For Plates: Specification GradeDocument15 pagesSpecifications For Plates: Specification Gradeppd9890No ratings yet

- Project Data: Project Name Project Number Author Description Date 26-Dec-23 Design Code AISC 360-16Document19 pagesProject Data: Project Name Project Number Author Description Date 26-Dec-23 Design Code AISC 360-16kheang amgNo ratings yet

- 7" Liner Cement Calculation Proposal: Marvin Peter Bjservices (M) SDN BHDDocument1 page7" Liner Cement Calculation Proposal: Marvin Peter Bjservices (M) SDN BHDshahaljawaie87No ratings yet

- BabbittDocument2 pagesBabbitterhan08No ratings yet

- Thermal Insulation Calculation at Sandwich Panels With PolyurethaneDocument4 pagesThermal Insulation Calculation at Sandwich Panels With Polyurethanesumanth.n nNo ratings yet

- High Speed Steel Drills: High Performance Cutting ToolsDocument44 pagesHigh Speed Steel Drills: High Performance Cutting ToolsRam SinghNo ratings yet

- Riser CalculationsDocument7 pagesRiser CalculationsmanishsahuNo ratings yet

- Side View Back View Recommended Footprint: CONSMA001 1.0Document1 pageSide View Back View Recommended Footprint: CONSMA001 1.0myfutn-re8512No ratings yet

- 120-Kld Stp-Structure Section DWGDocument1 page120-Kld Stp-Structure Section DWGTech MongerNo ratings yet

- Hoja de Producción Rev.01Document24 pagesHoja de Producción Rev.01Juan carlos Vargas victoriaNo ratings yet

- Steel Standards: ASTM A252 ASTM A500 CSA G40.21Document1 pageSteel Standards: ASTM A252 ASTM A500 CSA G40.21Candra YuniartoNo ratings yet

- Connector: 0.5mm Pitch/connectors For FPCDocument2 pagesConnector: 0.5mm Pitch/connectors For FPCJoão Paulo Da S NogueiraNo ratings yet

- A/t A1/t1+ (A/l-A1/l1) / (A2/l2-A1/l1) (A2/t2-A1/t1) (Linear Interpolation Formula)Document6 pagesA/t A1/t1+ (A/l-A1/l1) / (A2/l2-A1/l1) (A2/t2-A1/t1) (Linear Interpolation Formula)phan hoang diepNo ratings yet

- How To Evaluate For PAUTDocument6 pagesHow To Evaluate For PAUTphan hoang diep100% (1)

- Sect 10 Appendix 1fs Engine Ce303Document7 pagesSect 10 Appendix 1fs Engine Ce303laura MtNo ratings yet

- P3449 B01 PCB StackupDocument2 pagesP3449 B01 PCB Stackupsrikarbharadwaj0No ratings yet

- Cat Trailer 1 Trailer Catalog en Part43Document1 pageCat Trailer 1 Trailer Catalog en Part43soicanhavefriendsNo ratings yet

- InnerDocument4 pagesInnerSinu RaoNo ratings yet

- Motor Kubota Oc-Serie (Epa Tier 4)Document13 pagesMotor Kubota Oc-Serie (Epa Tier 4)Kevin Ricardo Mendoza AmadorNo ratings yet

- DISEÑO de Cerchas de Acero TallerDocument25 pagesDISEÑO de Cerchas de Acero TallerJose SierraNo ratings yet

- Oetiker SV Dn3Document6 pagesOetiker SV Dn3HIDRAFLUIDNo ratings yet

- Parker Inline Check ValvesDocument1 pageParker Inline Check ValvesTri Chandra WibowoNo ratings yet

- Technical Fiche Profile H65 Rev 13Document2 pagesTechnical Fiche Profile H65 Rev 13Satendra ThakurNo ratings yet

- Operation Breakdown: Style # Department Customer Desc. Season Fall 14Document18 pagesOperation Breakdown: Style # Department Customer Desc. Season Fall 14Saint's saintNo ratings yet

- Submersible Stainless Steel Rewindable Motor: Quality For Your BorewellDocument6 pagesSubmersible Stainless Steel Rewindable Motor: Quality For Your BorewellSherin PaulNo ratings yet

- DA04 Data SheetDocument2 pagesDA04 Data Sheetquotes13No ratings yet

- Alveolate Motor: SpecificationsDocument1 pageAlveolate Motor: Specificationssieged_rj3165No ratings yet

- 26.0 + - 0.2 0.1 (Length) 2.5 + 0.1 0.0 (SW)Document1 page26.0 + - 0.2 0.1 (Length) 2.5 + 0.1 0.0 (SW)Karan ChadhaNo ratings yet

- Fatigue Relevant DiagramsDocument2 pagesFatigue Relevant DiagramsrxaxsxaxNo ratings yet

- Sample Project EstimateDocument218 pagesSample Project EstimateMichael Jorge Bernales0% (1)

- Spray Metal Polished Rod With Wrench Flats: Product DescriptionDocument3 pagesSpray Metal Polished Rod With Wrench Flats: Product DescriptionJAVIER EDUARDO MANTILLA BUITRAGONo ratings yet

- Aluminium Alloy 2014 - 2014A - Aircraft MaterialsDocument3 pagesAluminium Alloy 2014 - 2014A - Aircraft MaterialscelsribeiroNo ratings yet

- Drawing 4D 1870mm (REV) TB. Bomas Surya (LH) (NEW TIMOTHY PROPELLER 2020)Document1 pageDrawing 4D 1870mm (REV) TB. Bomas Surya (LH) (NEW TIMOTHY PROPELLER 2020)Alan Sebastian100% (1)

- WBLFF Dec 2018Document15 pagesWBLFF Dec 2018CHRISTY MELENIE HILLMONDNo ratings yet

- Conventional: Original Design (Current Rate - July 2014) HC Precast System (Current Rate - July 2014)Document2 pagesConventional: Original Design (Current Rate - July 2014) HC Precast System (Current Rate - July 2014)Khairul AnuwrNo ratings yet

- Torque Motor Kubota D1703Document17 pagesTorque Motor Kubota D1703Marcelo Gustavo Fuentes ValdiviaNo ratings yet

- Drilling Machine and TypesDocument15 pagesDrilling Machine and TypesFaisNo ratings yet

- I. Berilah Tanda Silang (X) Pada Huruf A, B, Atau C Di Depan Jawaban Yang Paling Benar!Document3 pagesI. Berilah Tanda Silang (X) Pada Huruf A, B, Atau C Di Depan Jawaban Yang Paling Benar!Nopz_naiZ9686No ratings yet

- CNC Programming "Milling": Module ObjectivesDocument37 pagesCNC Programming "Milling": Module Objectiveshasan alsarrafNo ratings yet

- Dialog4 Deckel FP1Document23 pagesDialog4 Deckel FP1peterNo ratings yet

- Machine Maintenance Log SampleDocument24 pagesMachine Maintenance Log SampleJimmy Dereta100% (1)

- Adobe Scan Feb 16, 2024Document7 pagesAdobe Scan Feb 16, 2024Manyathela HopaneNo ratings yet

- Economic Growth and Demographic Transition in Third World Nations A Chaos and Complexity Theory Perspective 1st Edition Efika Ule Erçetin (Editor)Document43 pagesEconomic Growth and Demographic Transition in Third World Nations A Chaos and Complexity Theory Perspective 1st Edition Efika Ule Erçetin (Editor)gladys.chesla584100% (9)

- Wood Species and WHR They R UsedDocument10 pagesWood Species and WHR They R UsedOluwaseun AdetayoNo ratings yet

- First Summative Test in Tle 6 Fourth Quarter: Francisco F. Illescas Elementary SchoolDocument6 pagesFirst Summative Test in Tle 6 Fourth Quarter: Francisco F. Illescas Elementary SchoolSofia ZafraNo ratings yet

- Module-3 Aircraft Hardware Materials Systems Processes: Basic Hand Tools Used in AviationDocument10 pagesModule-3 Aircraft Hardware Materials Systems Processes: Basic Hand Tools Used in AviationDinesh ChandranNo ratings yet

- Handrail Wall Bracket - 3419-NSHDocument1 pageHandrail Wall Bracket - 3419-NSHWahyu Candra WardanaNo ratings yet

- GLO Catalogue Vol - 01Document34 pagesGLO Catalogue Vol - 01Om Walunj100% (1)

- Mechanical Work Shop Lab ReportDocument9 pagesMechanical Work Shop Lab ReportOG HackNo ratings yet

- Makita Chain Mortiser Model 7104L Parts DiagramDocument2 pagesMakita Chain Mortiser Model 7104L Parts DiagramplymplanNo ratings yet

- Material Price ListDocument4 pagesMaterial Price ListPraveen Varma VNo ratings yet

- Fresadora B40pte B40e 2 PDFDocument70 pagesFresadora B40pte B40e 2 PDFRaul Alanoca ColqueNo ratings yet

- Color Chart: 100% Recycled Polyester Fiber Acoustic PanelDocument11 pagesColor Chart: 100% Recycled Polyester Fiber Acoustic PanelElizabeth Molina GuzmanNo ratings yet

- Main Catalogue 2014 / 2015: Innovative Tools Universal AccessoriesDocument50 pagesMain Catalogue 2014 / 2015: Innovative Tools Universal AccessoriesLiviu MihailescuNo ratings yet

- Brigada Eskwela Form 4 Daily Attendance of VolunteerDocument1 pageBrigada Eskwela Form 4 Daily Attendance of VolunteerMOMMY GAMERNo ratings yet

- Aluminium DoorsDocument2 pagesAluminium DoorsSumit LathwalNo ratings yet

- Technology and Livelihood Education: Electrical Installation and MaintenanceDocument17 pagesTechnology and Livelihood Education: Electrical Installation and MaintenanceJoshua Asoy100% (1)

- Carb / Epa: Key Requirements For Regulatory ComplianceDocument3 pagesCarb / Epa: Key Requirements For Regulatory CompliancesacdawoodNo ratings yet

- Popular Mechanics Encyclopedia 12Document264 pagesPopular Mechanics Encyclopedia 12Marco VazquezNo ratings yet

- Drills and Drilling Machines-1Document27 pagesDrills and Drilling Machines-1Tafadzwa E ChigwazaNo ratings yet

- Cambridge IGCSE: Design & Technology 0445/31Document24 pagesCambridge IGCSE: Design & Technology 0445/31Yuvraaj MadhaviNo ratings yet

- WTO - Mazak Program - HQ - QTN - QTS - enDocument32 pagesWTO - Mazak Program - HQ - QTN - QTS - ensimonNo ratings yet

- Module 2 Part 1 QTR 1 1Document17 pagesModule 2 Part 1 QTR 1 1harlanecarlsNo ratings yet

Parts Guide Book - Shearing

Parts Guide Book - Shearing

Uploaded by

nguyendando0 ratings0% found this document useful (0 votes)

6 views1 page1) The document provides grinding allowance specifications for various models of shearing machine blades, including dimensions for allowance A and B.

2) It notes there are limitations for machine adjustment values in parentheses and that lower blade grinding is not recommended for some models due to blade height adjustment methods.

3) The grinding of lower blades is also not recommended for DCT models as it could lead to unbalanced blade mounting and potential damage if shims are dropped during cutting.

Original Description:

Parts guide book_Shearing

Original Title

Parts guide book_Shearing

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) The document provides grinding allowance specifications for various models of shearing machine blades, including dimensions for allowance A and B.

2) It notes there are limitations for machine adjustment values in parentheses and that lower blade grinding is not recommended for some models due to blade height adjustment methods.

3) The grinding of lower blades is also not recommended for DCT models as it could lead to unbalanced blade mounting and potential damage if shims are dropped during cutting.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

6 views1 pageParts Guide Book - Shearing

Parts Guide Book - Shearing

Uploaded by

nguyendando1) The document provides grinding allowance specifications for various models of shearing machine blades, including dimensions for allowance A and B.

2) It notes there are limitations for machine adjustment values in parentheses and that lower blade grinding is not recommended for some models due to blade height adjustment methods.

3) The grinding of lower blades is also not recommended for DCT models as it could lead to unbalanced blade mounting and potential damage if shims are dropped during cutting.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

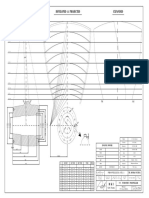

Blade Grinding Allowance for Shearing Machine

Machine Cutting Grinding allowance Grinding allowance

Blade

Model Specification A (mm) B (mm)

Upper 0.5 (1.0) The value with ( ) : there is a limitation

3.2t / 4.5t

S Lower 0.75 (1.5) for the machine adjustment

Shear Upper 1.0 (1.0)

6.5t / 13t

Lower 1.5 (1.5)

NS Upper 0.5 (1.0)

ALL

Shear Lower 0.75 (1.5)

ALL Upper 2.5 1.0

A A

(except3045/4045) Lower 1.5 2.0

M

Shear Upper 1.5 1.0 B

3045 / 4045

Lower 1.5 2.0

R Upper 2.5 1.0

ALL

Shear Lower 3.0 3.5

P Upper 2.5 1.0

ALL

Shear Lower 3.0 3.5

B

ALL Upper 2.0 4.5

(except 6016) Lower 3.0 4.5

H

Shear Upper 2.0 4.5

6016 A A

Lower 3.0 0.0

B

PH Upper 2.0 4.5

ALL

Shear Lower 3.0 4.5

DCT Upper 1.5 0.0

ALL

Shear Lower 1.5 0.0

Upper 1.0 0.0

ALL(except 6.5 / 3.5)

Lower 1.0 0.0 B

ATF Upper 1.5 0.0

1365

Shear Lower 1.5 0.0

Upper 2.0 0.0

2035 / 1335

Lower 2.0 0.0

ESH Upper 2.0 (2.0)

ALL

Shear Lower 2.0 (2.0)

1)There is a tolerance of grinding allowance A and B for blade shape.

2)There is a grinding allowance of lower blade for S,NS and ESH shear, but we do not recommend to grind

them. Because the adjustment of the blade height is shim adjustment.

3)We do not recommend that the gringing of DCT lower blade. If the blade has a deep chipping, need to

grind a lot. And need to put a thicker shim under the blade. If the customer cut a thicker material,

brade mounting will be unbalanced.

Then if the shim is dropped during cutting, surface of the blade mounting part will be damaged.

You might also like

- ANZSMM 2018 NZ Guidance Notes - 19feb2018Document8 pagesANZSMM 2018 NZ Guidance Notes - 19feb2018Andrew ArahaNo ratings yet

- Bridge Abutment Pier Design As Per IRCDocument41 pagesBridge Abutment Pier Design As Per IRCjibendra mishra88% (43)

- GST9 Manual Final V2Document2 pagesGST9 Manual Final V2Steven MillerNo ratings yet

- 4.steel Reinforcement To Concrete (PT I)Document11 pages4.steel Reinforcement To Concrete (PT I)Arun RunNo ratings yet

- Screw Cortical Iso 5835 Ha4.5Document1 pageScrew Cortical Iso 5835 Ha4.5Karan ChadhaNo ratings yet

- Bar Mark Location of Bar Bar Shape Dia Space No of Bar Sr. No. Cutting LengthDocument3 pagesBar Mark Location of Bar Bar Shape Dia Space No of Bar Sr. No. Cutting LengthEr Biswajit SahaNo ratings yet

- Tabla de FileteDocument1 pageTabla de FileteRicardo PonceNo ratings yet

- Flat Belt Width PDFDocument2 pagesFlat Belt Width PDFanon_564740741No ratings yet

- Amada Thick Turret Technical DataDocument2 pagesAmada Thick Turret Technical DataAFAB Machinery and Tools LtdNo ratings yet

- Fin Wt. Surface Area Solid Fins: 0.039 3.5 0.049 4.4 Ratio 0.80Document3 pagesFin Wt. Surface Area Solid Fins: 0.039 3.5 0.049 4.4 Ratio 0.80BoilerNo ratings yet

- Project: Cadangan Klinik Kesihatan 4 Dengan Kuarters, Pengkalan Hulu, Hulu Perak, Perak (Ibs Sepenuhnya)Document9 pagesProject: Cadangan Klinik Kesihatan 4 Dengan Kuarters, Pengkalan Hulu, Hulu Perak, Perak (Ibs Sepenuhnya)faiz salimNo ratings yet

- Kids Overall Kik-P107953Document1 pageKids Overall Kik-P107953IE DEPARTMENTNo ratings yet

- DRAW - Bapak Rofiqi - Duri Kosambi - CengkarengDocument17 pagesDRAW - Bapak Rofiqi - Duri Kosambi - CengkarengDrafter VinitecNo ratings yet

- Stability Result 15275 MT - Initial StowageDocument1 pageStability Result 15275 MT - Initial StowageLife with Our planetNo ratings yet

- Blast Loads For Axen TEG PackageDocument6 pagesBlast Loads For Axen TEG PackageWinsonLimHuiWahNo ratings yet

- Dieset Fuel Tank T5302Document1 pageDieset Fuel Tank T5302Abu ZahidNo ratings yet

- LF Series: Low Frequency, Rugged, Elastomer Shock & Vibration Isolation MountsDocument4 pagesLF Series: Low Frequency, Rugged, Elastomer Shock & Vibration Isolation MountsCarlos Torres OliverosNo ratings yet

- Ceramic Encased: SeriesDocument5 pagesCeramic Encased: SeriesRavi RokkamNo ratings yet

- 2020-08-26-Kfaa-Floor Load Detail PDFDocument1 page2020-08-26-Kfaa-Floor Load Detail PDFhemanthsridharaNo ratings yet

- TAILENGSC4 - 2023 - L3 - Properties of Mine Tailings For Static Liquefaction AssessmentDocument40 pagesTAILENGSC4 - 2023 - L3 - Properties of Mine Tailings For Static Liquefaction Assessmenteng_civil_dayanaNo ratings yet

- HB-3M-2 Nominal Performance Characteristic Curve Torque vs. CurrentDocument1 pageHB-3M-2 Nominal Performance Characteristic Curve Torque vs. CurrentPrathmesh MahajaniNo ratings yet

- Specifications 7.1: Table 7-1. Transmission Data Table 7-2. Internal Gear RatiosDocument6 pagesSpecifications 7.1: Table 7-1. Transmission Data Table 7-2. Internal Gear RatiosMarcelo Ramos SaldanhaNo ratings yet

- 351W SpecsDocument6 pages351W Specsikram42789No ratings yet

- Katalog Baylan Vodomjer 1-2Document1 pageKatalog Baylan Vodomjer 1-2Edin Dervishi100% (1)

- Specifications For Plates: Specification GradeDocument15 pagesSpecifications For Plates: Specification Gradeppd9890No ratings yet

- Project Data: Project Name Project Number Author Description Date 26-Dec-23 Design Code AISC 360-16Document19 pagesProject Data: Project Name Project Number Author Description Date 26-Dec-23 Design Code AISC 360-16kheang amgNo ratings yet

- 7" Liner Cement Calculation Proposal: Marvin Peter Bjservices (M) SDN BHDDocument1 page7" Liner Cement Calculation Proposal: Marvin Peter Bjservices (M) SDN BHDshahaljawaie87No ratings yet

- BabbittDocument2 pagesBabbitterhan08No ratings yet

- Thermal Insulation Calculation at Sandwich Panels With PolyurethaneDocument4 pagesThermal Insulation Calculation at Sandwich Panels With Polyurethanesumanth.n nNo ratings yet

- High Speed Steel Drills: High Performance Cutting ToolsDocument44 pagesHigh Speed Steel Drills: High Performance Cutting ToolsRam SinghNo ratings yet

- Riser CalculationsDocument7 pagesRiser CalculationsmanishsahuNo ratings yet

- Side View Back View Recommended Footprint: CONSMA001 1.0Document1 pageSide View Back View Recommended Footprint: CONSMA001 1.0myfutn-re8512No ratings yet

- 120-Kld Stp-Structure Section DWGDocument1 page120-Kld Stp-Structure Section DWGTech MongerNo ratings yet

- Hoja de Producción Rev.01Document24 pagesHoja de Producción Rev.01Juan carlos Vargas victoriaNo ratings yet

- Steel Standards: ASTM A252 ASTM A500 CSA G40.21Document1 pageSteel Standards: ASTM A252 ASTM A500 CSA G40.21Candra YuniartoNo ratings yet

- Connector: 0.5mm Pitch/connectors For FPCDocument2 pagesConnector: 0.5mm Pitch/connectors For FPCJoão Paulo Da S NogueiraNo ratings yet

- A/t A1/t1+ (A/l-A1/l1) / (A2/l2-A1/l1) (A2/t2-A1/t1) (Linear Interpolation Formula)Document6 pagesA/t A1/t1+ (A/l-A1/l1) / (A2/l2-A1/l1) (A2/t2-A1/t1) (Linear Interpolation Formula)phan hoang diepNo ratings yet

- How To Evaluate For PAUTDocument6 pagesHow To Evaluate For PAUTphan hoang diep100% (1)

- Sect 10 Appendix 1fs Engine Ce303Document7 pagesSect 10 Appendix 1fs Engine Ce303laura MtNo ratings yet

- P3449 B01 PCB StackupDocument2 pagesP3449 B01 PCB Stackupsrikarbharadwaj0No ratings yet

- Cat Trailer 1 Trailer Catalog en Part43Document1 pageCat Trailer 1 Trailer Catalog en Part43soicanhavefriendsNo ratings yet

- InnerDocument4 pagesInnerSinu RaoNo ratings yet

- Motor Kubota Oc-Serie (Epa Tier 4)Document13 pagesMotor Kubota Oc-Serie (Epa Tier 4)Kevin Ricardo Mendoza AmadorNo ratings yet

- DISEÑO de Cerchas de Acero TallerDocument25 pagesDISEÑO de Cerchas de Acero TallerJose SierraNo ratings yet

- Oetiker SV Dn3Document6 pagesOetiker SV Dn3HIDRAFLUIDNo ratings yet

- Parker Inline Check ValvesDocument1 pageParker Inline Check ValvesTri Chandra WibowoNo ratings yet

- Technical Fiche Profile H65 Rev 13Document2 pagesTechnical Fiche Profile H65 Rev 13Satendra ThakurNo ratings yet

- Operation Breakdown: Style # Department Customer Desc. Season Fall 14Document18 pagesOperation Breakdown: Style # Department Customer Desc. Season Fall 14Saint's saintNo ratings yet

- Submersible Stainless Steel Rewindable Motor: Quality For Your BorewellDocument6 pagesSubmersible Stainless Steel Rewindable Motor: Quality For Your BorewellSherin PaulNo ratings yet

- DA04 Data SheetDocument2 pagesDA04 Data Sheetquotes13No ratings yet

- Alveolate Motor: SpecificationsDocument1 pageAlveolate Motor: Specificationssieged_rj3165No ratings yet

- 26.0 + - 0.2 0.1 (Length) 2.5 + 0.1 0.0 (SW)Document1 page26.0 + - 0.2 0.1 (Length) 2.5 + 0.1 0.0 (SW)Karan ChadhaNo ratings yet

- Fatigue Relevant DiagramsDocument2 pagesFatigue Relevant DiagramsrxaxsxaxNo ratings yet

- Sample Project EstimateDocument218 pagesSample Project EstimateMichael Jorge Bernales0% (1)

- Spray Metal Polished Rod With Wrench Flats: Product DescriptionDocument3 pagesSpray Metal Polished Rod With Wrench Flats: Product DescriptionJAVIER EDUARDO MANTILLA BUITRAGONo ratings yet

- Aluminium Alloy 2014 - 2014A - Aircraft MaterialsDocument3 pagesAluminium Alloy 2014 - 2014A - Aircraft MaterialscelsribeiroNo ratings yet

- Drawing 4D 1870mm (REV) TB. Bomas Surya (LH) (NEW TIMOTHY PROPELLER 2020)Document1 pageDrawing 4D 1870mm (REV) TB. Bomas Surya (LH) (NEW TIMOTHY PROPELLER 2020)Alan Sebastian100% (1)

- WBLFF Dec 2018Document15 pagesWBLFF Dec 2018CHRISTY MELENIE HILLMONDNo ratings yet

- Conventional: Original Design (Current Rate - July 2014) HC Precast System (Current Rate - July 2014)Document2 pagesConventional: Original Design (Current Rate - July 2014) HC Precast System (Current Rate - July 2014)Khairul AnuwrNo ratings yet

- Torque Motor Kubota D1703Document17 pagesTorque Motor Kubota D1703Marcelo Gustavo Fuentes ValdiviaNo ratings yet

- Drilling Machine and TypesDocument15 pagesDrilling Machine and TypesFaisNo ratings yet

- I. Berilah Tanda Silang (X) Pada Huruf A, B, Atau C Di Depan Jawaban Yang Paling Benar!Document3 pagesI. Berilah Tanda Silang (X) Pada Huruf A, B, Atau C Di Depan Jawaban Yang Paling Benar!Nopz_naiZ9686No ratings yet

- CNC Programming "Milling": Module ObjectivesDocument37 pagesCNC Programming "Milling": Module Objectiveshasan alsarrafNo ratings yet

- Dialog4 Deckel FP1Document23 pagesDialog4 Deckel FP1peterNo ratings yet

- Machine Maintenance Log SampleDocument24 pagesMachine Maintenance Log SampleJimmy Dereta100% (1)

- Adobe Scan Feb 16, 2024Document7 pagesAdobe Scan Feb 16, 2024Manyathela HopaneNo ratings yet

- Economic Growth and Demographic Transition in Third World Nations A Chaos and Complexity Theory Perspective 1st Edition Efika Ule Erçetin (Editor)Document43 pagesEconomic Growth and Demographic Transition in Third World Nations A Chaos and Complexity Theory Perspective 1st Edition Efika Ule Erçetin (Editor)gladys.chesla584100% (9)

- Wood Species and WHR They R UsedDocument10 pagesWood Species and WHR They R UsedOluwaseun AdetayoNo ratings yet

- First Summative Test in Tle 6 Fourth Quarter: Francisco F. Illescas Elementary SchoolDocument6 pagesFirst Summative Test in Tle 6 Fourth Quarter: Francisco F. Illescas Elementary SchoolSofia ZafraNo ratings yet

- Module-3 Aircraft Hardware Materials Systems Processes: Basic Hand Tools Used in AviationDocument10 pagesModule-3 Aircraft Hardware Materials Systems Processes: Basic Hand Tools Used in AviationDinesh ChandranNo ratings yet

- Handrail Wall Bracket - 3419-NSHDocument1 pageHandrail Wall Bracket - 3419-NSHWahyu Candra WardanaNo ratings yet

- GLO Catalogue Vol - 01Document34 pagesGLO Catalogue Vol - 01Om Walunj100% (1)

- Mechanical Work Shop Lab ReportDocument9 pagesMechanical Work Shop Lab ReportOG HackNo ratings yet

- Makita Chain Mortiser Model 7104L Parts DiagramDocument2 pagesMakita Chain Mortiser Model 7104L Parts DiagramplymplanNo ratings yet

- Material Price ListDocument4 pagesMaterial Price ListPraveen Varma VNo ratings yet

- Fresadora B40pte B40e 2 PDFDocument70 pagesFresadora B40pte B40e 2 PDFRaul Alanoca ColqueNo ratings yet

- Color Chart: 100% Recycled Polyester Fiber Acoustic PanelDocument11 pagesColor Chart: 100% Recycled Polyester Fiber Acoustic PanelElizabeth Molina GuzmanNo ratings yet

- Main Catalogue 2014 / 2015: Innovative Tools Universal AccessoriesDocument50 pagesMain Catalogue 2014 / 2015: Innovative Tools Universal AccessoriesLiviu MihailescuNo ratings yet

- Brigada Eskwela Form 4 Daily Attendance of VolunteerDocument1 pageBrigada Eskwela Form 4 Daily Attendance of VolunteerMOMMY GAMERNo ratings yet

- Aluminium DoorsDocument2 pagesAluminium DoorsSumit LathwalNo ratings yet

- Technology and Livelihood Education: Electrical Installation and MaintenanceDocument17 pagesTechnology and Livelihood Education: Electrical Installation and MaintenanceJoshua Asoy100% (1)

- Carb / Epa: Key Requirements For Regulatory ComplianceDocument3 pagesCarb / Epa: Key Requirements For Regulatory CompliancesacdawoodNo ratings yet

- Popular Mechanics Encyclopedia 12Document264 pagesPopular Mechanics Encyclopedia 12Marco VazquezNo ratings yet

- Drills and Drilling Machines-1Document27 pagesDrills and Drilling Machines-1Tafadzwa E ChigwazaNo ratings yet

- Cambridge IGCSE: Design & Technology 0445/31Document24 pagesCambridge IGCSE: Design & Technology 0445/31Yuvraaj MadhaviNo ratings yet

- WTO - Mazak Program - HQ - QTN - QTS - enDocument32 pagesWTO - Mazak Program - HQ - QTN - QTS - ensimonNo ratings yet

- Module 2 Part 1 QTR 1 1Document17 pagesModule 2 Part 1 QTR 1 1harlanecarlsNo ratings yet