Professional Documents

Culture Documents

Single Crystal Solidification: - Why Do We Want Single Crystals?

Single Crystal Solidification: - Why Do We Want Single Crystals?

Uploaded by

Manikandan Muthuvijayan0 ratings0% found this document useful (0 votes)

8 views4 pagesThis document discusses methods for producing single crystal solids. It describes that single crystals have improved mechanical properties over polycrystalline solids due to the lack of grain boundaries. It then explains two common methods: the floating zone method, which uses an induction coil to melt and solidify a rod into a single crystal, and Czochralski crystal growth, which is commonly used to produce silicon wafers by slowly pulling a single crystal from a melt.

Original Description:

Original Title

singlecrystal

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses methods for producing single crystal solids. It describes that single crystals have improved mechanical properties over polycrystalline solids due to the lack of grain boundaries. It then explains two common methods: the floating zone method, which uses an induction coil to melt and solidify a rod into a single crystal, and Czochralski crystal growth, which is commonly used to produce silicon wafers by slowly pulling a single crystal from a melt.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

8 views4 pagesSingle Crystal Solidification: - Why Do We Want Single Crystals?

Single Crystal Solidification: - Why Do We Want Single Crystals?

Uploaded by

Manikandan MuthuvijayanThis document discusses methods for producing single crystal solids. It describes that single crystals have improved mechanical properties over polycrystalline solids due to the lack of grain boundaries. It then explains two common methods: the floating zone method, which uses an induction coil to melt and solidify a rod into a single crystal, and Czochralski crystal growth, which is commonly used to produce silicon wafers by slowly pulling a single crystal from a melt.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

Single Crystal Solidification

• Why do we want single crystals?

– No grain boundaries leads to improved

mechanical properties.

• Reduces susceptibility to creep and cracking along

grain boundaries.

• Directional Solidification – e.g. Ni super-

alloy turbine blades

– 1960 – columnar crystals (Fig. 5.33)

– 1967 – single crystal (Fig. 5.33)

Single Crystal Solidification

• Floating Zone Method (Fig. 5.34)

– Goal → to grow single crystals or refine

polycrystalline metals (zone refining)

– To grow single crystal:

• Start with polycrystalline rod resting on single

crystal seed

• Induction coil is passed along the length of rod

• Single crystal seed grows maintaining orientation

Single Crystal Solidification

• Floating Zone Method (cont.)

– Refining polycrystalline metal

• Impurities are swept to one end of rod

– Can use multiple passes or create multiple zones

– Impurity rich region can be discarded

• Phase Diagram (see blackboard)

• Like segregation in casting

– Different composition across length of bar

• For k<1 solute (impurities) rejected by solid

– Less soluble in solid than in liquid

• Most impurities have k<1

– ↓ k, ↑ segregation

• Mass Balance (see black board)

Single Crystal Solidification

• Czochralski Crystal Growth – e.g. Si

wafers for microelectronics (Fig. 5.34)

You might also like

- Solidification and Crystalline Imperfection Part 1Document25 pagesSolidification and Crystalline Imperfection Part 1Aiman MutallidNo ratings yet

- Crystal Growth and Ore Texture SP4Document129 pagesCrystal Growth and Ore Texture SP4dennysikasepNo ratings yet

- Chapter 04Document37 pagesChapter 04Husna MustafaNo ratings yet

- Mineralogi Part.2 3Document10 pagesMineralogi Part.2 3Roges tomara mahesa100% (2)

- StrengtheningDocument22 pagesStrengtheningeddickNo ratings yet

- 2.1 Solidification, Imperfection (Defect) in Solids, and DiffusionDocument54 pages2.1 Solidification, Imperfection (Defect) in Solids, and Diffusionjun005No ratings yet

- Elastic and Plastic Deformation: - Metals Deform Both Elastically and PlasticallyDocument24 pagesElastic and Plastic Deformation: - Metals Deform Both Elastically and PlasticallyHarris DarNo ratings yet

- Failure Mechanism of MatterDocument66 pagesFailure Mechanism of MatterSiva Kumar SalumuriNo ratings yet

- Electronic Properties of Materials: Lecture - 3: Crystal DefectsDocument19 pagesElectronic Properties of Materials: Lecture - 3: Crystal DefectsKm. Rakibur RahmanNo ratings yet

- Chapter+4+ +Imperfections+in+CrystalsDocument25 pagesChapter+4+ +Imperfections+in+Crystalspramod_kNo ratings yet

- VLSI Technology 1Document87 pagesVLSI Technology 1SriramNo ratings yet

- Manufacturing Processes (ME361) Lecture 3 and 4Document32 pagesManufacturing Processes (ME361) Lecture 3 and 4Randhir KyNo ratings yet

- Chap5 FinalDocument49 pagesChap5 Finalamanuelfitsum589No ratings yet

- Unit1 - 6 - Solidfication - CoolingDocument30 pagesUnit1 - 6 - Solidfication - CoolingPrajesh KrishnaNo ratings yet

- CH 01 - Metal StructureDocument36 pagesCH 01 - Metal StructureBelgium WafflesNo ratings yet

- Physical Properties of MineralsDocument73 pagesPhysical Properties of MineralsNishant MeenaNo ratings yet

- Engineering Geology (BFC21303) : MineralsDocument24 pagesEngineering Geology (BFC21303) : MineralsHaiqal RafiqNo ratings yet

- Module 4 Defects in Solids and Strengthening MechanismDocument45 pagesModule 4 Defects in Solids and Strengthening MechanismMuhammadFaishalFadhlurahmanNo ratings yet

- What Is A Mineral?Document7 pagesWhat Is A Mineral?Noor NadiahNo ratings yet

- Geol-Mineral IdentificationDocument64 pagesGeol-Mineral Identificationapi-219086016No ratings yet

- Manufacturing Technology (ME361) Lecture 2: Shantanu BhattacharyaDocument21 pagesManufacturing Technology (ME361) Lecture 2: Shantanu BhattacharyaSahil SundaNo ratings yet

- Def by Slip TwinDocument39 pagesDef by Slip Twinakanksha.ja779No ratings yet

- Deformation & StrengthDocument35 pagesDeformation & StrengthcolorofstoneNo ratings yet

- Mineralogi Part.2 2Document8 pagesMineralogi Part.2 2Roges tomara mahesaNo ratings yet

- Slip Systems and TwinningDocument33 pagesSlip Systems and TwinningAyush ShahNo ratings yet

- Semi 2Document16 pagesSemi 2Shashwat ShuklaNo ratings yet

- CzochralskiDocument4 pagesCzochralskininnette1No ratings yet

- Chem 434F-1206F Lecture 8 Short 2007Document49 pagesChem 434F-1206F Lecture 8 Short 2007GaGoAlishkaLiubaNo ratings yet

- Lecture 04 Atomic ArrangementsDocument22 pagesLecture 04 Atomic Arrangementsantoine demeireNo ratings yet

- mt101 Part2Document46 pagesmt101 Part2Prateek 4-Yr B.Tech.: Metallurgical Engg., IIT(BHU)No ratings yet

- Engineering Geology (Ersc-2007) 2014Document233 pagesEngineering Geology (Ersc-2007) 2014yeshi janexoNo ratings yet

- Crystal Growth and Wafer PreparationDocument18 pagesCrystal Growth and Wafer PreparationraghudatheshNo ratings yet

- 5 Crystalline Defects, Different Crystals From An IngotDocument8 pages5 Crystalline Defects, Different Crystals From An IngotAhmad AbdNo ratings yet

- Historical Geology - L2 The Rock Cycle and Earth MaterialsDocument70 pagesHistorical Geology - L2 The Rock Cycle and Earth MaterialsArlette Lucía Ramírez PérezNo ratings yet

- M.E VLSI Technology UNIT IDocument64 pagesM.E VLSI Technology UNIT IMahendra BabuNo ratings yet

- Chapter 7 - Dislocations and Strengethening MechanismsDocument50 pagesChapter 7 - Dislocations and Strengethening MechanismsmikeengineeringNo ratings yet

- Lecture 5 - Crystal Defects-Dislocations - 2 PDFDocument53 pagesLecture 5 - Crystal Defects-Dislocations - 2 PDFArpit Pradhan100% (1)

- THE SOLID STATE Class 12 RevisionDocument88 pagesTHE SOLID STATE Class 12 Revisionhakuna matata100% (2)

- Nucleation Processes in Recrystallization: History and Current StatusDocument32 pagesNucleation Processes in Recrystallization: History and Current StatusRohit ShintreNo ratings yet

- 1 Week 2 Minerals LabDocument5 pages1 Week 2 Minerals Labakshaynew2011No ratings yet

- Final Metal and Alloys1Document22 pagesFinal Metal and Alloys1saharaliarainNo ratings yet

- Crystall GrowthDocument41 pagesCrystall Growthmailstonaik100% (1)

- Post Mid LabDocument113 pagesPost Mid LabsnoopNo ratings yet

- Physical Properties of MineralsDocument10 pagesPhysical Properties of MineralsSumit SinghNo ratings yet

- Lec03 Plasticity P2Document35 pagesLec03 Plasticity P2Muna UnisaNo ratings yet

- CZ Wafer ProcessDocument20 pagesCZ Wafer ProcessRajkumari MishraNo ratings yet

- Processing of Aerospace Materials Part I (ME772) : Crystal Structures, Imperfections, Slip and Strain Hardening in MetalsDocument19 pagesProcessing of Aerospace Materials Part I (ME772) : Crystal Structures, Imperfections, Slip and Strain Hardening in MetalsB RITHIKANo ratings yet

- NotesDocument54 pagesNotesShaiha AshrafNo ratings yet

- Types of Grain BoundryDocument4 pagesTypes of Grain BoundryEmadSaeed44No ratings yet

- Imperfections in Solids & Diffusion Process: Assoc. Prof. Ir. Dr. Wong Yew HoongDocument103 pagesImperfections in Solids & Diffusion Process: Assoc. Prof. Ir. Dr. Wong Yew HoongVITHYAA RUHBINI GUNARAJANNo ratings yet

- Manufacturing Science and MetallurgyDocument47 pagesManufacturing Science and MetallurgyAppu bjNo ratings yet

- Module 5 VLSIDocument77 pagesModule 5 VLSIlordofthunder888No ratings yet

- MetallurgyDocument75 pagesMetallurgymmramachandranNo ratings yet

- Silicate Ceramics: - Soils, Rocks, Clays, and Sand Come Under The Silicate ClassificationDocument32 pagesSilicate Ceramics: - Soils, Rocks, Clays, and Sand Come Under The Silicate ClassificationsairamNo ratings yet

- Crystalline Properties of SolidsDocument24 pagesCrystalline Properties of SolidsMD. MEHEDI HASANNo ratings yet

- Week 2 2 IPE 2203-LecturesDocument44 pagesWeek 2 2 IPE 2203-LecturesMD Al-AminNo ratings yet

- BMM3643 CHP 1 Metal Casting Processes - Sand CastingDocument42 pagesBMM3643 CHP 1 Metal Casting Processes - Sand Castingemadaddin alezzaniNo ratings yet

- Matter and Minerals: Geology For EngineersDocument61 pagesMatter and Minerals: Geology For EngineersLinh VoNo ratings yet

- Cabochon Cutting - A Collection of Historical Articles on the Methods and Equipment Used for Working GemstonesFrom EverandCabochon Cutting - A Collection of Historical Articles on the Methods and Equipment Used for Working GemstonesRating: 5 out of 5 stars5/5 (2)

- Defence Research & Development Organisation: Naval Physical and Oceanographic LaboratoryDocument4 pagesDefence Research & Development Organisation: Naval Physical and Oceanographic LaboratoryManikandan MuthuvijayanNo ratings yet

- Unit IV Pilling Bedworth RatioDocument7 pagesUnit IV Pilling Bedworth RatioManikandan MuthuvijayanNo ratings yet

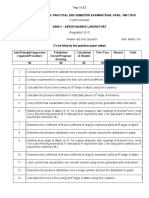

- Aim/Principle/Apparatus Required/procedure Tabulation/ Circuit/Program/ Drawing Calculation & Results Viva-Voce Record Total 30 30 20 10 10 100Document2 pagesAim/Principle/Apparatus Required/procedure Tabulation/ Circuit/Program/ Drawing Calculation & Results Viva-Voce Record Total 30 30 20 10 10 100Manikandan MuthuvijayanNo ratings yet

- Materials. The Constituent Materials of A Composite Have Significantly Different Properties. Further, ItDocument8 pagesMaterials. The Constituent Materials of A Composite Have Significantly Different Properties. Further, ItManikandan MuthuvijayanNo ratings yet

- Aim/Principle/Apparatus Required/procedure Tabulation/ Drawing Calculation/ Graph & Results Viva-Voce Record Total 25 25 30 10 10 100Document3 pagesAim/Principle/Apparatus Required/procedure Tabulation/ Drawing Calculation/ Graph & Results Viva-Voce Record Total 25 25 30 10 10 100Manikandan MuthuvijayanNo ratings yet

- Ae8512. Propulsion QuestionDocument3 pagesAe8512. Propulsion QuestionManikandan MuthuvijayanNo ratings yet