Professional Documents

Culture Documents

Course Code: MET 406 Gths/Rs - 19 / 7659 Eighth Semester B. E. (Mechanical Engineering) Examination

Course Code: MET 406 Gths/Rs - 19 / 7659 Eighth Semester B. E. (Mechanical Engineering) Examination

Uploaded by

Mubarika SabirOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Course Code: MET 406 Gths/Rs - 19 / 7659 Eighth Semester B. E. (Mechanical Engineering) Examination

Course Code: MET 406 Gths/Rs - 19 / 7659 Eighth Semester B. E. (Mechanical Engineering) Examination

Uploaded by

Mubarika SabirCopyright:

Available Formats

Course Code : MET 406 GTHS/RS – 19 / 7659

Eighth Semester B. E. ( Mechanical Engineering ) Examination

AUTOMATION IN PRODUCTION

Time : 3 Hours ] [ Max. Marks : 60

Instructions to Candidates :—

(1) All questions carry marks as indicated against them.

(2) Due credit will be given to neatness and adequate dimensions.

(3) Assume suitable data and illustrate answers with neat sketches.

1. (a) What are the objectives of automated flow line ? Explain different types

of the part feeding devices. 5 (CO 1)

(b) A 10 station transfer line is used to produce a component. The ideal cycle

time is 1.2 min, breakdown occurs with a frequency 0.12 breakdown / cycle

and average down time per line stop 7.0 min. The scrap rate is 6% and

starting casting for the component costs Rs. 3.60 each and it will cost

Rs. 60/ hour or Rs. 1 / min to operate the transfer line. Cutting tool cost

Rs. 0.60/ workpart.

Find :

(i) Production rate

(ii) No. of hours required to meet a demand of 1000 units.

(iii) Line efficiency

(iv) Cost per item produced on line. 5 (CO 1)

OR

2. Chart defines the precedence relationship and work element times for a new shop floor

model. Calculate minimum numbers of workstations required to minimize balance delay,

assuming one worker per station. The repositioning time is 0.1 min and uptime proportion

assumed to be 1.1 min. Construct the precedence diagram.

Work Te (min) Immediate Work Te (min) Immediate

Element Predecessors Element Predecessors

1 0.5 — 6 0.6 3

Contd.....

GTHS/RS - 19 /7659 Contd.

2 0.3 1 7 0.4 4 , 5

3 0.7 1 8 0.5 3 , 5

4 0.2 2 9 0.3 7 , 8

5 0.1 2 10 0.6 6 , 9

Assign the work elements to stations using LCR and RPW methods. Compare the balance

delay for the solutions. 10 (CO 1)

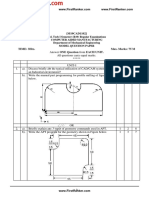

3. What is meant by interpolation algorithms in CNC programming ? Write the CNC part

program for the given work part as shown in figure. All dimensions are in mm.

10 (CO 2)

4. Answer any Two questions :—

(a) What are the different types of robot manipulator configurations ? Explain

with technical characteristics and applications. 5 (CO 3)

(b) What is the purpose of actuators in robotic system ? Explain the three

types of drives used in robot joints. 5 (CO 3)

(c) Describe the robot technical features for assembly robot with working of

RCC structure. 5 (CO 3)

5. (a) Discuss the following with reference to AGVS :—

(1) AGVS types and applications

(2) Traffic control and safety

(3) Vehicle acquisition distance. 5 (CO 4)

GTHS/RS - 19 /7659 2 Contd.

(b) The length of an AS / RS is 150 m and its height is 60 m. Horizontal

and vertical travel speeds are 80 m / min and 35 m / min respectively. The

P and D time is 0.80 min. Determine the average single – command and

dual – command transaction times for the storage system. What will be the

vertical travel speed that will make the system square – in – time ? For this

change, determine the expected single – command and dual – command transaction

times for the storage system. 5 (CO 4)

6. Answer any Two questions :—

(a) Describe the different inspection techniques used in modern industries ; also

explain the role of coordinate measuring machine in inspections. 5 (CO 5)

(b) Describe the concept of Group Technology in manufacturing. Explain product

flow analysis with rank order cluster algorithm. 5 (CO 5)

(c) What are the components of FMS ? Discuss in detail the technical planning

requisite for material handling system in FMS. 5 (CO 5)

7. (a) Explain different functional elements in CIM. 5 (CO 5)

(b) What is computer aided process planning ? Discuss the types in detail.

5 (CO 6)

OR

8. (a) How MRP differs with the capacity planning (CP) ? Explain the input files

in MRP. 5 (CO 6)

(b) Describe in detail working phases of shop floor control. 5 (CO 6)

GTHS/RS - 19 /7659 3 105

You might also like

- Core and Vue - Js - 2021Document479 pagesCore and Vue - Js - 2021Yousef ElsaeedNo ratings yet

- Course Code: MET 406 Azby/Ms - 18 / 4656 Eighth Semester B. E. (Mechanical Engineering) ExaminationDocument23 pagesCourse Code: MET 406 Azby/Ms - 18 / 4656 Eighth Semester B. E. (Mechanical Engineering) ExaminationMubarika SabirNo ratings yet

- 15P701Document4 pages15P701rajakrishnanNo ratings yet

- Cim Model QBDocument3 pagesCim Model QBSoorya NarayananNo ratings yet

- Me 8 Sem Automation in Production Jun 2017Document4 pagesMe 8 Sem Automation in Production Jun 2017Zaky MalikNo ratings yet

- (3hours) : CompulsoryDocument7 pages(3hours) : CompulsorySaima ZainabNo ratings yet

- Qps 6Document10 pagesQps 6saikrishnaps31No ratings yet

- Advanced ManufacturingDocument5 pagesAdvanced Manufacturingmukesh3021No ratings yet

- Old Q.papers M.tech I SemDocument15 pagesOld Q.papers M.tech I SemallakagopichandNo ratings yet

- Me6703 CimsDocument2 pagesMe6703 Cimssyed1188No ratings yet

- 5902r09-Automation in ManufacturingDocument2 pages5902r09-Automation in ManufacturingDr-Asit Kumar ParidaNo ratings yet

- Automation in ManufacturingDocument8 pagesAutomation in ManufacturingPradeepkumarKatgiNo ratings yet

- Cim See 2015Document3 pagesCim See 2015vrushNo ratings yet

- Sathish S 18me731 2023 24 Cim Model 1Document3 pagesSathish S 18me731 2023 24 Cim Model 1srujangowdasj2002No ratings yet

- May, 2019 B.Tecb. Vi Semester CAM and Automation (ME-306-C)Document2 pagesMay, 2019 B.Tecb. Vi Semester CAM and Automation (ME-306-C)utkarshtyagi2307No ratings yet

- 15P701Document3 pages15P701rajakrishnanNo ratings yet

- Computer Aided ManufacturingDocument3 pagesComputer Aided ManufacturingVivek PatelNo ratings yet

- NR 422001 C Automation in ManufactureDocument8 pagesNR 422001 C Automation in ManufactureSrinivasa Rao GNo ratings yet

- Computer Integrated Manufacturing (Model QP) : CBCS SchemeDocument2 pagesComputer Integrated Manufacturing (Model QP) : CBCS SchemeMuwaizNo ratings yet

- ExamMEC4108 15 16Document4 pagesExamMEC4108 15 16Marvin kakindaNo ratings yet

- Nov Dec 2016Document3 pagesNov Dec 2016pecoxor808No ratings yet

- Thapar Institute of Engineering & Technology, Patiala: End Semester Examination (May 2019)Document4 pagesThapar Institute of Engineering & Technology, Patiala: End Semester Examination (May 2019)Forza HorizonNo ratings yet

- Automation EngineeringDocument16 pagesAutomation Engineeringsachin22221No ratings yet

- Question Paper Code:: Reg. No.Document2 pagesQuestion Paper Code:: Reg. No.ESWARANNo ratings yet

- MCHA1Document3 pagesMCHA1rajyalakshmi_mechNo ratings yet

- Suggestive QuestionDocument4 pagesSuggestive Questiondebojitpaul926No ratings yet

- TVEC Model Paper Programmable Logic ControllerDocument2 pagesTVEC Model Paper Programmable Logic ControllerSajith MadushankaNo ratings yet

- RT31055102020Document2 pagesRT31055102020elisha emilianNo ratings yet

- Cim QP 71012 PMDocument3 pagesCim QP 71012 PMAnonymous GEHeEQlajbNo ratings yet

- Answer All The Questions: From-To Data For The Parts Processed by The Machines Are Shown in The Table BelowDocument2 pagesAnswer All The Questions: From-To Data For The Parts Processed by The Machines Are Shown in The Table Belowbrahma2deen2chaudharNo ratings yet

- Me 8 Sem Automation in Productiion Summer 2018Document4 pagesMe 8 Sem Automation in Productiion Summer 2018Zaky MalikNo ratings yet

- Research QuestionsDocument6 pagesResearch QuestionsiAmAlfaNo ratings yet

- Assignment - 1 - 18ME72 - CADMDocument1 pageAssignment - 1 - 18ME72 - CADMVinayak TevarannavarNo ratings yet

- AM-1 7th Sem Remid 14.05.19Document2 pagesAM-1 7th Sem Remid 14.05.19Raj PatelNo ratings yet

- Me 8 Sem Automation in Production Winter 2018Document4 pagesMe 8 Sem Automation in Production Winter 2018Zaky MalikNo ratings yet

- Questions 4 1Document95 pagesQuestions 4 1Anik PaulNo ratings yet

- Cim See 2013Document2 pagesCim See 2013vrushNo ratings yet

- Performance Modelling and Analysis of Manufacturing SystemsDocument2 pagesPerformance Modelling and Analysis of Manufacturing SystemsJithesh VNo ratings yet

- (M19CAD1102) I M. Tech I Semester (R19) Regular ExaminationsDocument2 pages(M19CAD1102) I M. Tech I Semester (R19) Regular Examinationsraja raoNo ratings yet

- 127BD052019 CAD QuestionDocument3 pages127BD052019 CAD QuestionKollan Manivardhan ReddyNo ratings yet

- Model QP Os Set 3 UpdatedDocument3 pagesModel QP Os Set 3 Updatednarenmadhavan5No ratings yet

- MF 7202 - Manufacturing Metrology and Quality Engineeringmay June 2016Document3 pagesMF 7202 - Manufacturing Metrology and Quality Engineeringmay June 2016THOMSON JACOBNo ratings yet

- Embedded Systems Model Question PaperDocument6 pagesEmbedded Systems Model Question PaperSubramanyaAIyerNo ratings yet

- PSG College of Technology, Coimbatore - 641 004 Semester Examinations, November 2018 Me (PT) - Industrial Engineering Semester: 3Document2 pagesPSG College of Technology, Coimbatore - 641 004 Semester Examinations, November 2018 Me (PT) - Industrial Engineering Semester: 3SaravananNo ratings yet

- Cad Cam Previous Paper JntukDocument4 pagesCad Cam Previous Paper JntukMD KHALEELNo ratings yet

- Sixth Sem. B.E. (Mechanical & I. & P. Engg.) Degree End Semester (Make-Up) EXAMINATIONS JULY 2006 Subject: Mechatronics (Mee-310/Ipe-310)Document2 pagesSixth Sem. B.E. (Mechanical & I. & P. Engg.) Degree End Semester (Make-Up) EXAMINATIONS JULY 2006 Subject: Mechatronics (Mee-310/Ipe-310)blackbirdNo ratings yet

- (3965) - 636 M.E. (E & TC) : (VLSI & Embedded Systems)Document14 pages(3965) - 636 M.E. (E & TC) : (VLSI & Embedded Systems)Manu SeaNo ratings yet

- BT-7/M-20 Non-Conventional Machining ME-415N: Roll No. .......................... Total Pages: 03Document3 pagesBT-7/M-20 Non-Conventional Machining ME-415N: Roll No. .......................... Total Pages: 03upenderNo ratings yet

- AMP Summer Question Paper (Msbte Study Resources)Document4 pagesAMP Summer Question Paper (Msbte Study Resources)Varad DateNo ratings yet

- Production AutomationDocument2 pagesProduction AutomationpreethamshetNo ratings yet

- 53211-mt - Advanced in CNC TechnologiesDocument2 pages53211-mt - Advanced in CNC TechnologiesSRINIVASA RAO GANTANo ratings yet

- Me6703 Computer Integrated Manufacturing Systems 4Document19 pagesMe6703 Computer Integrated Manufacturing Systems 4raja30gNo ratings yet

- L-4rr-l/EEE Date: 25/09/2022Document50 pagesL-4rr-l/EEE Date: 25/09/2022Nure Alam DipuNo ratings yet

- Apj Abdul Kalam Technological University: Answer Any Three Full Questions, Each Carries 10 MarksDocument2 pagesApj Abdul Kalam Technological University: Answer Any Three Full Questions, Each Carries 10 MarksvivekNo ratings yet

- EEE-ND-2021-CS 2411-OPERATING SYSTEMS-115487051-80395(CS2411-CS609)Document3 pagesEEE-ND-2021-CS 2411-OPERATING SYSTEMS-115487051-80395(CS2411-CS609)VIGNESH MNo ratings yet

- OS MODEL EXAMDocument2 pagesOS MODEL EXAMSurya NatarajanNo ratings yet

- RT 22022042017Document8 pagesRT 22022042017YasyrNo ratings yet

- Chadalawada Ramanamma Engineering College: Time: 3 Hours Max Marks: 70Document2 pagesChadalawada Ramanamma Engineering College: Time: 3 Hours Max Marks: 70BADAS POOJANo ratings yet

- Architecture-Aware Optimization Strategies in Real-time Image ProcessingFrom EverandArchitecture-Aware Optimization Strategies in Real-time Image ProcessingNo ratings yet

- Multicore DSP: From Algorithms to Real-time Implementation on the TMS320C66x SoCFrom EverandMulticore DSP: From Algorithms to Real-time Implementation on the TMS320C66x SoCNo ratings yet

- Web Application Question AnswersDocument5 pagesWeb Application Question Answersdhruvil mehtaNo ratings yet

- Logical Domains ManagerDocument4 pagesLogical Domains ManagerMbonk Wae LahNo ratings yet

- Topics Sheet - Automation Tester - TheTestingAcademyDocument29 pagesTopics Sheet - Automation Tester - TheTestingAcademyPraneet kumarNo ratings yet

- AI City Challenge 2024Document2 pagesAI City Challenge 2024Hridya NNo ratings yet

- 3 Objects and ClassesDocument10 pages3 Objects and ClassesAbdi sabaNo ratings yet

- JD For Electrician&apper PDFDocument2 pagesJD For Electrician&apper PDFVikash SharmaNo ratings yet

- AC PPTDocument28 pagesAC PPTPrajwal BirwadkarNo ratings yet

- FORC Book 1Document196 pagesFORC Book 1rohini mNo ratings yet

- Information Age TimelineDocument8 pagesInformation Age TimelineZPads0% (1)

- SQL ComparisonDocument13 pagesSQL ComparisonMADHAVNo ratings yet

- Iec 61850-90-5-2012-02 TRDocument154 pagesIec 61850-90-5-2012-02 TRSergio Blanco CorreaNo ratings yet

- Catalogue: SINCE 1989Document54 pagesCatalogue: SINCE 1989TOPOGRAFIA PUNTA ARENAS ALIWENNo ratings yet

- C For EveryoneDocument5 pagesC For EveryoneVrushabh WarkeNo ratings yet

- Python Like PRO Light ModeDocument36 pagesPython Like PRO Light ModehotfoodtaasteNo ratings yet

- Azul Zulu Ca Release Notes October 2024 Rev1.3Document61 pagesAzul Zulu Ca Release Notes October 2024 Rev1.3Géminis ZNo ratings yet

- Interview Questions - Manual and DB TestingDocument5 pagesInterview Questions - Manual and DB TestingSri Harsha PogulaNo ratings yet

- DarkplacesDocument44 pagesDarkplacesEsteban LeónNo ratings yet

- A Software Maintainability Attributes ModelDocument6 pagesA Software Maintainability Attributes ModelAmit MishraNo ratings yet

- Spring Boot ReferenceDocument692 pagesSpring Boot ReferencechivasNo ratings yet

- Hospital Management SystemDocument4 pagesHospital Management SystemJunaid AmirNo ratings yet

- Protecting Linux Systems With Oracle Ksplice Zero-Downtime UpdatesDocument4 pagesProtecting Linux Systems With Oracle Ksplice Zero-Downtime UpdatesPregador TochaNo ratings yet

- Cne6 Level 2 Quiz 1 (Refresher)Document6 pagesCne6 Level 2 Quiz 1 (Refresher)Saarguna WathyNo ratings yet

- Mega Chill ManualDocument7 pagesMega Chill ManualDee RajaNo ratings yet

- The Hi-End of Productivity: Multi-Core Flying Probe TesterDocument4 pagesThe Hi-End of Productivity: Multi-Core Flying Probe TesterkgjNo ratings yet

- P5G41T-M LX: SpesifikasiDocument3 pagesP5G41T-M LX: SpesifikasipatrickLstarNo ratings yet

- CSI 411 - Compiler - Lecture 3 PDFDocument16 pagesCSI 411 - Compiler - Lecture 3 PDFMd Tasriful HoqueNo ratings yet

- Lecture 5 - Functions of Combinational Logic CircuitDocument71 pagesLecture 5 - Functions of Combinational Logic CircuitDoctor Care100% (1)

- Configuration Management and ConnectorsDocument51 pagesConfiguration Management and ConnectorsJORGE ENRIQUE CRUZ BASABENo ratings yet

- A Voice Controlled Home Automation SystemDocument13 pagesA Voice Controlled Home Automation SystemBhushan BharatiNo ratings yet