Professional Documents

Culture Documents

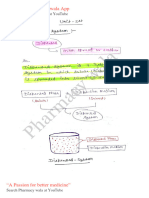

Sop of Tablet & CApsule

Sop of Tablet & CApsule

Uploaded by

Zeyad A AbdullahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sop of Tablet & CApsule

Sop of Tablet & CApsule

Uploaded by

Zeyad A AbdullahCopyright:

Available Formats

1.

0 OBJECTIVE

To lay down the Procedure for Manufacturing of Tablets & Capsules.

2.0 SCOPE

This SOP shall be applicable for Tablet & Capsule Manufacturing in the Production

department.

3.0 RESPONSIBILITY

3.1 Execution: Operator

3.2 Checking: Production Pharmacist & Above

4.0 ACCOUNTABILITY

HOD-Production/ Assigned Designee

5.0 PROCEDURE

5.1 PLANNING

The activities in manufacturing department should be planned according to the

production schedule by Production Executive or Production Manager for the respective

month, and specifically for the respective week.

5.2 OBTAINING THE BATCH DOCUMENT

According to plan production person shall generate Process order No. of respective

products and obtained the batch no. and batch documents from Q.A. department, for

this a request is to be raised to Q.A. department mentioning the Product Name and

Process order No. as required. After the generation of the batch documents by Q.A.

department, the production department should receive it form Q.A. department duly

signed by Q.A. Officer. The production person should also sign while receiving the

document after checking the pages, issue no, batch details etc.

5.3 REQUISITION TO THE STORES

The raw material requisition / Bill of material should be raised preferably in advance, to

issue of the raw materials for respective batches. The store person should make

necessary arrangements for the dispensing accordingly.

5.4 ISSUE OF RAW MATERIALS TO MANUFACTURING DEPARTMENT

The store officer, Production officer along with Q.A. Chemist if required should weigh

the raw materials as per the standard operating procedure for dispensing. After

weighing, the raw materials will be stored in a suitable container, in Day Store I till taken

for production. The duly filled requisition /Bill of material and BMR will remain along with

the dispensed raw materials.

5.5 RECEIPT OF DISPENSED MATERIAL BY MANUFACTURING DEPARTMENT

Before taking the material into the area the production person shall ensure the

cleanliness of the equipment & area and get the line clearance from Q.A. person. Then

take the raw material into the respective manufacturing area and all the weighed

materials will be checked against the requisition with calibrated balance. Also the other

details on dispensing label like product name, Material Name, Batch No. , Lot No. etc

will be checked.

5.6 ASSIGNING MFG. DATE & EXP. DATE

5.6.1 The Mfg. The date should be assigned as per the date of dispensing.

5.6.2 The expiry date should be assigned as per the shelf life mentioned in BMR or

considering the expiry date of active R.M.

5.7 PROCESSING

5.7.1 The material should be processed strictly as per BMR.

5.7.2 The operators should wear protective accessories like gloves, masks, muffs, ear

plugs, goggles etc. while processing, as per the requirements.

5.7.3 Each equipment should have the status label with signature of the pharmacist.

5.7.4 Operators and pharmacists should check the area and equipment cleanliness

before starting the manufacturing operations.

5.7.5 Environmental conditions like Temperature, Relative Humidity should be

maintained within the limits specified in the respective BMR.

5.7.6 Pharmacist should ensure that, sieves and screens are intact before and after the

processing. When any new sieve is received, it should be checked for its mesh size by

counting no. of perforations per linear inch. The mesh size should be checked against

the sieve no. punched on the edge of the sieve.

5.7.7 Pharmacist should personally monitor all the critical operations like Dry mixing,

Addition of binder, Wet mixing, Drying, Inlet and outlet temperature, Mixing time during

lubrication, Machine setting, In process parameters etc.

5.7.8 The material ready for further processing should be immediately weighed and

labeled accordingly and the weight should be recorded in the batch document.

5.7.9 All entries in BMR should be done immediately.

5.7.10 In process goods should be stored only in the area provided.

5.7.11 Standard Operating and Cleaning procedures should be strictly followed.

5.7.12 Any adverse incidence or spillage or deviation observed should be immediately

informed to the superiors.

5.7.13 All the safety instructions should be strictly followed.

6.0 ABBREVIATIONS

6.1 SOP: Standard Operating Procedure

6.2 BMR: Batch Manufacturing Record

6.3 Q.A.: Quality Assurance

6.4 HOD: Head of The Department

You might also like

- CRO and Sponsor - Integrated Application FormDocument4 pagesCRO and Sponsor - Integrated Application FormNaevisweloveuNo ratings yet

- Generic Menu CardDocument9 pagesGeneric Menu CardLode DeocadesNo ratings yet

- Guidance Template Qualified Persons Declaration Concerning Good Manufacturing Practice GMP - enDocument8 pagesGuidance Template Qualified Persons Declaration Concerning Good Manufacturing Practice GMP - enLook AheadNo ratings yet

- Philippines Sales and Promotion FDA OutlineDocument30 pagesPhilippines Sales and Promotion FDA OutlineAidee SmithNo ratings yet

- SOP ReconciliationDocument1 pageSOP ReconciliationFika CuiNo ratings yet

- SOP For Entry in and Exit From The Suspension Manufacturing - Pharmaceutical GuidelinesDocument2 pagesSOP For Entry in and Exit From The Suspension Manufacturing - Pharmaceutical GuidelinesAbou Tebba SamNo ratings yet

- Practical Challenges of Stability Testing On Nutraceutical FormulationsDocument10 pagesPractical Challenges of Stability Testing On Nutraceutical FormulationsTayyab Tahir MinhasNo ratings yet

- Project Report PDFDocument41 pagesProject Report PDFAKRAMA HASANNo ratings yet

- Chemrite Grout NSDocument2 pagesChemrite Grout NSghazanfar0% (1)

- What Is BMR (Batch Manufacturing Record) ?Document2 pagesWhat Is BMR (Batch Manufacturing Record) ?Yousif100% (1)

- Issuing Date Doc No: Effective Date Department Next Review Date SectionDocument5 pagesIssuing Date Doc No: Effective Date Department Next Review Date SectionAmer Abu RahmahNo ratings yet

- Annex 9: Guide To Good Storage Practices For PharmaceuticalsDocument12 pagesAnnex 9: Guide To Good Storage Practices For PharmaceuticalsRyan Noel Perez de TagleNo ratings yet

- SOP On Transferring Finished Products To Finished Goods StoresDocument3 pagesSOP On Transferring Finished Products To Finished Goods StoresRainMan7567% (3)

- SOP For Finished ProductDocument3 pagesSOP For Finished Productterefe kassaNo ratings yet

- FP Spec.Document3 pagesFP Spec.ShagorShagorNo ratings yet

- SOP For Raw Material ReleaseDocument4 pagesSOP For Raw Material ReleaseSolomonNo ratings yet

- Resource Template 2 Master Formulation RecordDocument2 pagesResource Template 2 Master Formulation RecordIkhtiar InayahdinNo ratings yet

- Sop Gen 18Document3 pagesSop Gen 18cervantessejNo ratings yet

- Aroflam BPRDocument26 pagesAroflam BPRHamidNo ratings yet

- Recall Plan Example PAGE 1 of 12 Plant Name: Issue Date Address: SupersedesDocument12 pagesRecall Plan Example PAGE 1 of 12 Plant Name: Issue Date Address: SupersedesDiana BlueseaNo ratings yet

- SOP 4 Template Standard Operating Procedure For Transfer of Stock Controlled Drugs To or From TDocument3 pagesSOP 4 Template Standard Operating Procedure For Transfer of Stock Controlled Drugs To or From TMillenNo ratings yet

- Bodily Fluids Spillage: Standard Operating ProcedureDocument5 pagesBodily Fluids Spillage: Standard Operating ProcedureLinda Setya Wati100% (1)

- FDA Circular No. 2011 - 003Document12 pagesFDA Circular No. 2011 - 003Lc FernandezNo ratings yet

- Chapter 2 PersonnelDocument6 pagesChapter 2 PersonnelRosie SisonNo ratings yet

- Sorbates Food and Pharma Quality Information PackDocument39 pagesSorbates Food and Pharma Quality Information PackMiguelNo ratings yet

- Pharmaceutical SOP ExampleDocument4 pagesPharmaceutical SOP ExampleFaysal AhmedNo ratings yet

- SOP For Pharmaceutical Products RecallDocument12 pagesSOP For Pharmaceutical Products RecallNayeli MoreiraNo ratings yet

- Doh Revised Guidelines On Current Good ManufacturingDocument25 pagesDoh Revised Guidelines On Current Good Manufacturingcharlimagne100% (3)

- Table For Cleaning SolutionsDocument1 pageTable For Cleaning Solutionsreflectprakash3610No ratings yet

- SOP For Sampling of Finished ProductDocument3 pagesSOP For Sampling of Finished ProductSolomonNo ratings yet

- Guidance For Industry - PQR - 201312 PDFDocument9 pagesGuidance For Industry - PQR - 201312 PDFAshok LenkaNo ratings yet

- Pharmaceutical Quality SystemDocument8 pagesPharmaceutical Quality SystemRainMan75No ratings yet

- Acetaminophen COADocument1 pageAcetaminophen COAHamza HaqueNo ratings yet

- Filling of Hard Gelatin CapsulesDocument30 pagesFilling of Hard Gelatin Capsulesdeep469No ratings yet

- LabSafety PDFDocument18 pagesLabSafety PDFalberto1954100% (1)

- Railway PharmasistDocument2 pagesRailway PharmasistprashantNo ratings yet

- Guidelines For Product RecallDocument18 pagesGuidelines For Product RecallSenthamaraiShanmughamNo ratings yet

- Drug Reg 6757Document32 pagesDrug Reg 6757antonygamalpharma100% (1)

- Kraft Analytical Laboratory ManualDocument13 pagesKraft Analytical Laboratory ManualrodrigofacearNo ratings yet

- Microcrystalline Cellulose USP MonographDocument4 pagesMicrocrystalline Cellulose USP Monographisaac_soto_12No ratings yet

- Basic Questionnaire For Kosher Certificate 2Document1 pageBasic Questionnaire For Kosher Certificate 2C P TiwariNo ratings yet

- A Product Which Has Completed All Stages of Manufacture, Including Final PackagingDocument4 pagesA Product Which Has Completed All Stages of Manufacture, Including Final Packagingom shankar JhaNo ratings yet

- Haccp PlanDocument1 pageHaccp Planjlordmercader100% (1)

- Clean RoomDocument19 pagesClean Roomhouas menasriaNo ratings yet

- Procedure For Preparation of Disinfectant and Sanitization SolutionDocument2 pagesProcedure For Preparation of Disinfectant and Sanitization SolutionPrince Moni100% (1)

- Specifications of Finished ProductDocument5 pagesSpecifications of Finished ProductMajd KittanehNo ratings yet

- ASEAN TMHS GMP Training Chapter 9Document4 pagesASEAN TMHS GMP Training Chapter 9nsk79in@gmail.comNo ratings yet

- Sop NarcoticDocument2 pagesSop Narcoticibrahim0% (1)

- Storage and Transport of Sensitive Pharmaceutical ProductsDocument28 pagesStorage and Transport of Sensitive Pharmaceutical ProductscarupiaNo ratings yet

- SOP For Operation of Bottle LabelingDocument4 pagesSOP For Operation of Bottle LabelingSolomonNo ratings yet

- Finished ProductDocument4 pagesFinished ProductDilip Chaudhary100% (1)

- Care Intensive Drug Pharmaceutical CompanyDocument1 pageCare Intensive Drug Pharmaceutical CompanyMajd Kittaneh100% (1)

- Standard Operating Procedure of Automatic Coating System Used For Coating On TabletDocument5 pagesStandard Operating Procedure of Automatic Coating System Used For Coating On TabletSolomonNo ratings yet

- Work Experience Sample2Document7 pagesWork Experience Sample2ziadddNo ratings yet

- Food Safety PolicyDocument39 pagesFood Safety Policymohd shariqueNo ratings yet

- Quality Management Systems A Complete Guide - 2021 EditionFrom EverandQuality Management Systems A Complete Guide - 2021 EditionNo ratings yet

- Data Integrity and Compliance: A Primer for Medical Product ManufacturersFrom EverandData Integrity and Compliance: A Primer for Medical Product ManufacturersNo ratings yet

- Biocontamination Control for Pharmaceuticals and HealthcareFrom EverandBiocontamination Control for Pharmaceuticals and HealthcareRating: 5 out of 5 stars5/5 (1)

- Corrective And Preventative Action A Complete Guide - 2020 EditionFrom EverandCorrective And Preventative Action A Complete Guide - 2020 EditionNo ratings yet

- Pharmacognosy Unit 4 5th Short Important Questions Shahruddin KhanDocument16 pagesPharmacognosy Unit 4 5th Short Important Questions Shahruddin KhanZeyad A AbdullahNo ratings yet

- Unit 1 Topic ICHDocument10 pagesUnit 1 Topic ICHZeyad A AbdullahNo ratings yet

- Vol. 3, Issue 3, March 2015, PharmaTutor, Paper-4Document7 pagesVol. 3, Issue 3, March 2015, PharmaTutor, Paper-4Zeyad A AbdullahNo ratings yet

- Project 1 7/5/2021Document1 pageProject 1 7/5/2021Zeyad A AbdullahNo ratings yet

- QMS 035 Deviation Report System SampleDocument6 pagesQMS 035 Deviation Report System SampleZeyad A AbdullahNo ratings yet

- Form 400 Employee Signature RegisterDocument1 pageForm 400 Employee Signature RegisterZeyad A AbdullahNo ratings yet

- QA - Market Complaint Unit 4Document2 pagesQA - Market Complaint Unit 4Zeyad A AbdullahNo ratings yet

- Form 085 Released StickersDocument1 pageForm 085 Released StickersZeyad A AbdullahNo ratings yet

- U 1 PP 2 4th Sem B Pharm Pharmacy Wala Shahruddin Khan 18811494Document7 pagesU 1 PP 2 4th Sem B Pharm Pharmacy Wala Shahruddin Khan 18811494Zeyad A AbdullahNo ratings yet

- List of Glassware Used in Pharmaceuticals - PharmaguidelineDocument4 pagesList of Glassware Used in Pharmaceuticals - PharmaguidelineZeyad A AbdullahNo ratings yet

- Melatonin Oral DropDocument3 pagesMelatonin Oral DropZeyad A AbdullahNo ratings yet

- Form 160 Example - Line - Clearance Opening and Cleaning Form For Tablet PackingDocument8 pagesForm 160 Example - Line - Clearance Opening and Cleaning Form For Tablet PackingZeyad A AbdullahNo ratings yet

- Form 125 Example Batch Reconciliation Sheet For Tablet PackingDocument4 pagesForm 125 Example Batch Reconciliation Sheet For Tablet PackingZeyad A AbdullahNo ratings yet

- Tube Filling and Sealing Machine Lab ModelDocument5 pagesTube Filling and Sealing Machine Lab ModelZeyad A AbdullahNo ratings yet

- Catalogue Tablet-Press 2019 V3Document16 pagesCatalogue Tablet-Press 2019 V3Zeyad A AbdullahNo ratings yet

- Form 140 Visitor Entry Into The FactoryDocument1 pageForm 140 Visitor Entry Into The FactoryZeyad A AbdullahNo ratings yet

- Us Cleanroom Standards CompliancewireDocument1 pageUs Cleanroom Standards CompliancewireZeyad A AbdullahNo ratings yet

- Product MonographDocument31 pagesProduct MonographZeyad A AbdullahNo ratings yet

- PortaFab Mezzanine BrochureDocument2 pagesPortaFab Mezzanine BrochureZeyad A AbdullahNo ratings yet

- RRT - DB - Mat WND enDocument2 pagesRRT - DB - Mat WND enZeyad A AbdullahNo ratings yet

- Ludipress Technical InformationDocument8 pagesLudipress Technical InformationZeyad A AbdullahNo ratings yet

- S 065 LBLDocument10 pagesS 065 LBLZeyad A AbdullahNo ratings yet

- IndJPhaEdRes 54 3s s473Document12 pagesIndJPhaEdRes 54 3s s473Zeyad A AbdullahNo ratings yet

- Sodium Stearyl Fumarate Excipient Pubchem 1559559385Document2 pagesSodium Stearyl Fumarate Excipient Pubchem 1559559385Zeyad A AbdullahNo ratings yet

- GMP Clearance GuidanceDocument84 pagesGMP Clearance GuidanceZeyad A AbdullahNo ratings yet

- Tech Bulletin - Suglets - More Than MonographDocument2 pagesTech Bulletin - Suglets - More Than MonographZeyad A AbdullahNo ratings yet

- Crosslinked Povidone Pubchem 1482747992Document4 pagesCrosslinked Povidone Pubchem 1482747992Zeyad A AbdullahNo ratings yet

- 09 Nov 2016 180959770P8GWIJNEANNEXUREDocument2 pages09 Nov 2016 180959770P8GWIJNEANNEXUREZeyad A AbdullahNo ratings yet

- Good Practice Manufacturing Operation SampleDocument21 pagesGood Practice Manufacturing Operation SampleZeyad A AbdullahNo ratings yet

- What Is Environmental Monitoring in Pharmaceutical IndustryDocument12 pagesWhat Is Environmental Monitoring in Pharmaceutical IndustryZeyad A AbdullahNo ratings yet

- Grow As We GoDocument68 pagesGrow As We GoEg MemoriaNo ratings yet

- ExerciseDocument51 pagesExerciseyay100% (1)

- Chromosome Mapping by Conjugation ExperimentsDocument26 pagesChromosome Mapping by Conjugation ExperimentskittyngameNo ratings yet

- Ans of State Level MCQ Practice Test On Emerging Trends in Civil Engineering (22603) Organize by GPJDocument27 pagesAns of State Level MCQ Practice Test On Emerging Trends in Civil Engineering (22603) Organize by GPJ39 Najima PatelNo ratings yet

- Pioneer Deh-2200ub 2250ub KeyboardDocument6 pagesPioneer Deh-2200ub 2250ub KeyboardYEMC YEMC0% (1)

- Deep Learning: Huawei AI Academy Training MaterialsDocument47 pagesDeep Learning: Huawei AI Academy Training Materialsfadhil muhammad hanafiNo ratings yet

- 8816 User Manual Iss6 5Document40 pages8816 User Manual Iss6 5Richard Ritchie MettensNo ratings yet

- Wa0000.Document16 pagesWa0000.Gurunath MetriNo ratings yet

- Science 7 Q4 SLM11Document15 pagesScience 7 Q4 SLM11Seen Tuna-doughNo ratings yet

- Swahili LanguageDocument14 pagesSwahili LanguagenedNo ratings yet

- Chapter - 10: Respiration in OrganismsDocument13 pagesChapter - 10: Respiration in OrganismsCHINMAYA RANJAN SAHOONo ratings yet

- Exposure: The PhotoreactionDocument16 pagesExposure: The PhotoreactionGeetha ThiruvengadamNo ratings yet

- 1 Chapter 6 SPE 116633 PA An Integrated Geomechanical and Passive Sand Control ApproachDocument13 pages1 Chapter 6 SPE 116633 PA An Integrated Geomechanical and Passive Sand Control ApproachViệt Toàn ĐỗNo ratings yet

- Stopping and Positioning Modules For Automation Technology: Product Overview - 2018 /19Document19 pagesStopping and Positioning Modules For Automation Technology: Product Overview - 2018 /19Siddiqui SarfarazNo ratings yet

- Airbus FBW Flight Control Laws: Abbreviated SummaryDocument5 pagesAirbus FBW Flight Control Laws: Abbreviated SummaryPiyushNo ratings yet

- Camouflage Matt EnamelsDocument3 pagesCamouflage Matt EnamelsIqra AngelsNo ratings yet

- Signals and Systems: BITS PilaniDocument21 pagesSignals and Systems: BITS Pilanirajeevdutt_1215No ratings yet

- Modal Verbs Must or MustntDocument3 pagesModal Verbs Must or MustntCamila VasquezNo ratings yet

- TIS REV5 BRAINFARMA Brasile 1-055-12-12-22-1Document14 pagesTIS REV5 BRAINFARMA Brasile 1-055-12-12-22-1AndreaNo ratings yet

- Mvc2 ManualDocument49 pagesMvc2 ManualMICHELLE ALEXANDRA SOTOMAYOR MONTECINOSNo ratings yet

- LG 26lc51-c 26lc7r Chassis Lp78a SMDocument30 pagesLG 26lc51-c 26lc7r Chassis Lp78a SMВМалиновNo ratings yet

- Control Panel ETV 0551Document40 pagesControl Panel ETV 0551Thillainathan So ThanabhalanNo ratings yet

- Eerc 07 01Document73 pagesEerc 07 01Hugo BobadillaNo ratings yet

- Offshore Wind FarmDocument32 pagesOffshore Wind FarmKonstantinos Papadopoulos100% (1)

- Class 10 National Genius Search Examination: Advanced: Check The Correctness of The Roll No. With The Answer SheetDocument4 pagesClass 10 National Genius Search Examination: Advanced: Check The Correctness of The Roll No. With The Answer SheetPPNo ratings yet

- AS3696747610644481465148739173 Content 11Document15 pagesAS3696747610644481465148739173 Content 11Shivraj ChouguleNo ratings yet

- 6 Food Borne Pathogens Staphylococcus AureusDocument50 pages6 Food Borne Pathogens Staphylococcus Aureusdr Alex stanNo ratings yet

- SLG Chem2 LG 4.9 BuffersDocument6 pagesSLG Chem2 LG 4.9 BuffersIman SontousidadNo ratings yet