Professional Documents

Culture Documents

Simazinc Silicate MC: Product Data Sheet

Simazinc Silicate MC: Product Data Sheet

Uploaded by

Muhammad Mulya JatiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Simazinc Silicate MC: Product Data Sheet

Simazinc Silicate MC: Product Data Sheet

Uploaded by

Muhammad Mulya JatiCopyright:

Available Formats

ISO 9001, ISO 14001 & OHSAS 18001

Certified

Product Data Sheet SIMAZINC SILICATE MC

Date of issue : January 2018 1610 - 00

DESCRIPTION

Two component moisture - cured inorganic zinc silicate coating refer to SSPC

paint 20 requirement.

PRINCIPAL CHARACTERISTICS

- Suitable for as a system primer for various paint system

- Has outstanding resistance against weathering and abrasion

- Good anti corrosive, primer for structural steel tanks, outside hull, etc

- Chemical resistance within the Ph 5-9

- Can stand with substrate temperature from -90ºC up to 500ºC, under

normal atmospheric exposure conditions

RECOMMENDED USE

As a general-purpose rust preventing primer for use in new construction and

maintenance in severely corrosive marine and industrial environment.

SPECIFICATION DATA AT 20C

Gloss Flat

Colour Greenish grey

Specific gravity 2.30 + 0.5 kg/litre

Solids by volume 65 + 2 %

Recommended Dry film thickness : 50 - 75 microns

Wet film thickness : 77 - 115 microns

2 2

Coverage theoretical 13 m / litre – 50 microns; 8.7 m / litre – 75 microns

Drying time Temperature Touch dry Hard dry

26C 30 minutes 4 hours

32C 25 minutes 3 hours

36C 20 minutes 2 hours

40C 15 minutes 1 hour

Full cure 7 days

Painting interval Min : 12 hours ; max : unlimited (zinc salt must be removed)

VOC Max. 289 g/litre

Flash point (DIN 53213) O

35 C

Pot life 12 hours for binder (after mixing the components)

o

Service temperature Continuous : 450 C

Periodic : up to 500°C

Shelf life Use within 6 months (for binder ), 12 months (for pigment) of production

SURFACE PREPARATION

- Steel: blast cleaned in situ completely free from rust, scale, shop primer and

other contaminant to at least SSPC-SP 10, blasting profile (RZ) 40 – 70

microns

- Galvanized steel : should be sweep blasted to roughen the surface and to

remove any zinc salts, which might be present.

- Substrate temperatures ranging from –20°C up to +40°C during application

are acceptable

- At high substrate temperatures (above 40°C) SIMAZINC SILICATE MC

must be applied by spray gun and to avoid dry spraying Thinner 46-01 has

to be added.

TRUST, PROTECT AND COMMIT Page 1 of 3

ISO 9001, ISO 14001 & OHSAS 18001

Certified

Product Data Sheet SIMAZINC SILICATE MC

Date of issue : January 2018 1610 - 00

CONDITION OF APPLICATION

o o

Temperature: minimum -20 C ; maximum 30 C

Relative humidity: 50 - 95%

o

Substrate temperature should be at least 3 C above dew point.

SYSTEM SPECIFICATION

Subsequent coat : SIMACOVER EP BUILD COAT, SIMACOVER EP UNICOAT,

SIMATHANE GLOSS

INSTRUCTION FOR USE

Mixing ratio by volume; Binder to Pigment = 4:1

- Add the zinc dust gradually to the container with binder, using a

mechanical mixer.

- Stir the Pigment thoroughly through the binder

- Do not mix in reverse order, in order to avoid lumps in the paints.

- Strain mixture through 30 – 60 microns

- Continue stirring during application by means of a mechanical agitator.

- At an application temperature above 40°C addition of 0 – 10 % volume

of Sima Thinner 46-01 may be necessary.

APPLICATION DETAILS

Method of application Airless spray Air spray Roller/brush

Thinner No. Not recomended 46-01 46-01

Volume of thinner Not recomended 5 – 15% Max.5%

Nozzle orifice Not recomended 2 mm -

Nozzle pressure Not recomended 4 Bar /57 psi -

Cleaning Solvent Sima Thinner 46-01

ADDITIONAL DATA

Over coating table :

Substrate temperature -5°C 0°C 10°C 20°C

Min. interval 24 hours 24 hours 18 hours 12 hours

Max. interval Several months when free from zinc salts and

contaminant

- Zinc rich primer can form zinc salts on the surface, they should not be weathered for long periods before

over coating.

- An interval of several months can be allowed, however, under clean interior exposure conditions.

- In clean exterior conditions maximum interval of 14 days can be tolerated, but in industrial or marine

conditions this interval should be reduced to the practical minimum.

- At all time visible surface contamination must be removed before over coating by high pressure water

cleaning, sweep blasting or mechanical cleaning

TRUST, PROTECT AND COMMIT Page 2 of 3

ISO 9001, ISO 14001 & OHSAS 18001

Certified

Product Data Sheet SIMAZINC SILICATE MC

Date of issue : January 2018 1610 - 00

SAFETY PRECAUTION

- Avoid contact with the skin and eyes.

- Wear suitable protective clothing such as overalls, goggles, dust mask and

gloves.

- Ensure that there is adequate ventilation in the area where the product is being

applied.

- Do not breathe the vapour or spray.

- This product is flammable.

- Keep away from sources of ignition. Do not smoke.

HEALTH AND SAFETY: For detailed information on the health and safety hazards and precaution for use

of this product, please see the MATERIAL SAFETY DATA SHEET (MSDS).

PACKING SIZE AND STORAGE

Packing size (two packs product) : 5 and 20 litres

Storage

The product must be storage in accordance with national regulation. Preferred

storage conditions are to keep the containers in the dry space provided with

adequate ventilation. The containers should be sealed tightly

The 9th Edition

The information in this data sheet is to the best our knowledge connects at date printing. The company reserves the right to the modify data without notice. Any change in data will normally be

followed by issued of new data sheet. The user should check the data of printing and if more than 12 months have elapsed, then the data should on only be used after checking with our nearest

self-office to establish that they are still valid. Since condition of application and services may be beyond our control, no liability can accept on basis of this data.

TRUST, PROTECT AND COMMIT Page 3 of 3

You might also like

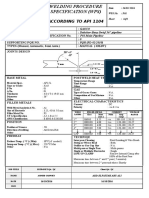

- Welding Procedure Specification (WPS) : According To Api 1104Document1 pageWelding Procedure Specification (WPS) : According To Api 1104Maged Lotfy Abdel-aal100% (1)

- Teddybear in PajamasDocument27 pagesTeddybear in PajamasMarilyne Blt100% (3)

- Tds Paratherm 600Document2 pagesTds Paratherm 600yarth880% (1)

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- AASHTODocument39 pagesAASHTOResearcher50% (2)

- Simazinc Silicate MC: Product Data SheetDocument3 pagesSimazinc Silicate MC: Product Data SheetAkmalNo ratings yet

- 1402-00 Simazinc EP PrimerDocument2 pages1402-00 Simazinc EP PrimerMuhammad Mulya JatiNo ratings yet

- 3500-00 Simathane GlossDocument3 pages3500-00 Simathane GlossSAEFUDDIN SAEFUDDINNo ratings yet

- 2401-00 Simacover EP UnicoatDocument3 pages2401-00 Simacover EP UnicoatSAEFUDDIN SAEFUDDINNo ratings yet

- 3302-00 Simacrylic FinishDocument2 pages3302-00 Simacrylic FinishSAEFUDDIN SAEFUDDINNo ratings yet

- 3500-00 Simathane Gloss (Finish Coat)Document3 pages3500-00 Simathane Gloss (Finish Coat)Hendri Dwi cahyonoNo ratings yet

- Sigmazinc 158: Description Principal CharacteristicsDocument7 pagesSigmazinc 158: Description Principal CharacteristicsRobert FrankyNo ratings yet

- 7570 SigmaZinc 170 Sigmazinc 9 (January 2014)Document6 pages7570 SigmaZinc 170 Sigmazinc 9 (January 2014)Akhtar AnsariNo ratings yet

- Product Data Sheet: Simathane GlossDocument3 pagesProduct Data Sheet: Simathane GlossAdnan FrrNo ratings yet

- Apcosil 605Document1 pageApcosil 605rihtak123No ratings yet

- Zn03-Pv. Epoxy Zinc Primer Qd-EngDocument2 pagesZn03-Pv. Epoxy Zinc Primer Qd-EngANIBALLOPEZVEGANo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsDinesh ChouguleNo ratings yet

- Inorganic Zinc-Rich Silicate: IS 14946: Protective Coating World Wide ProductsDocument4 pagesInorganic Zinc-Rich Silicate: IS 14946: Protective Coating World Wide ProductsSubham SahuNo ratings yet

- TDS Simacover EP Buildcoat (Intermediate)Document2 pagesTDS Simacover EP Buildcoat (Intermediate)rrahardiandiasNo ratings yet

- Product Data Sheet: Transocean Cold Zinc Primer 10.16Document3 pagesProduct Data Sheet: Transocean Cold Zinc Primer 10.16rimshadtpNo ratings yet

- Simarine Deck Paint: Product Data SheetDocument2 pagesSimarine Deck Paint: Product Data SheetPerseroan MustikaNo ratings yet

- b1) Zincanode330 6548Document2 pagesb1) Zincanode330 6548chepurthiNo ratings yet

- 2305-00 Simacrylic CoatingDocument2 pages2305-00 Simacrylic CoatingSAEFUDDIN SAEFUDDINNo ratings yet

- Simarine Acrylic Coating: Product Data SheetDocument2 pagesSimarine Acrylic Coating: Product Data SheetPerseroan MustikaNo ratings yet

- Simazinc EP Primer 1402-01Document2 pagesSimazinc EP Primer 1402-01Agung RiyantoNo ratings yet

- 1604-01 Simatherm HR Primer ATP 600CDocument2 pages1604-01 Simatherm HR Primer ATP 600CBagusRekaNo ratings yet

- Epoxy Anticorrosive Paint - Mar 445 - EvasDocument2 pagesEpoxy Anticorrosive Paint - Mar 445 - EvasEngr. Imran Hasan PathanNo ratings yet

- SigmaZinc 100Document4 pagesSigmaZinc 100Johnson Chng Hou KiatNo ratings yet

- Simathane Gloss: Product Data SheetDocument3 pagesSimathane Gloss: Product Data SheetAkmal100% (1)

- PC 7078 Apcosil 605 Primer - Apcosil 601Document3 pagesPC 7078 Apcosil 605 Primer - Apcosil 601onshore purchaseNo ratings yet

- Sigmazinc 158 New PDFDocument7 pagesSigmazinc 158 New PDFgst ajahNo ratings yet

- Pds Zincanode 620 VocDocument2 pagesPds Zincanode 620 VocmuthukumarNo ratings yet

- TO 1.58 Transozinc Silicate 158 ENDocument5 pagesTO 1.58 Transozinc Silicate 158 ENTirumala PrasadNo ratings yet

- BR Epoxy High Bulid Finish NewDocument2 pagesBR Epoxy High Bulid Finish NewAhmed AtefNo ratings yet

- Zincanode 620 Voc v1 Jan 2018Document2 pagesZincanode 620 Voc v1 Jan 2018Moin AltafNo ratings yet

- Zinc Silicate (Inorganic) : Product CodeDocument5 pagesZinc Silicate (Inorganic) : Product CodeGeorgianaNo ratings yet

- Simatherm HR Primer 600°C: Product Data SheetDocument2 pagesSimatherm HR Primer 600°C: Product Data SheetAkmalNo ratings yet

- b1) Zincanode330 6548Document2 pagesb1) Zincanode330 6548Syed FaridNo ratings yet

- b3) Zincanode685 4586Document2 pagesb3) Zincanode685 4586Syed FaridNo ratings yet

- PDS - 7863 - Sigmacap Zinc Silicate IIDocument5 pagesPDS - 7863 - Sigmacap Zinc Silicate IIIbrahim MahranNo ratings yet

- Pds Zincanode 690 VocDocument2 pagesPds Zincanode 690 VocmuthukumarNo ratings yet

- 113.007 - Zinc Clad Xi WB BR PDFDocument2 pages113.007 - Zinc Clad Xi WB BR PDFFernando VittoNo ratings yet

- 7678 Sigmacap Zinc Primer EPDocument3 pages7678 Sigmacap Zinc Primer EPEyoh EffiongNo ratings yet

- 38 Makeguard 614Document3 pages38 Makeguard 614taztika putriNo ratings yet

- Versapox Novoline 98 PDSDocument2 pagesVersapox Novoline 98 PDSjfairbairn69No ratings yet

- Product Data Sheet: Transpoxy Primer 1.16Document3 pagesProduct Data Sheet: Transpoxy Primer 1.16Sachin NambiarNo ratings yet

- Simaguard MB Ep Coating: Product Data SheetDocument3 pagesSimaguard MB Ep Coating: Product Data Sheetantonsugiarto20_7049No ratings yet

- Acothane Spray Grade 0117Document2 pagesAcothane Spray Grade 0117gregNo ratings yet

- Hempadur Zinc 17360Document2 pagesHempadur Zinc 17360Bang OchimNo ratings yet

- Simarine Bitumen: Product Data SheetDocument2 pagesSimarine Bitumen: Product Data SheetPerseroan MustikaNo ratings yet

- Phap - Anh Feloxane HB Ac PDFDocument1 pagePhap - Anh Feloxane HB Ac PDFvinh thieuNo ratings yet

- Apcosil 605 IzssDocument3 pagesApcosil 605 IzssPavul RajNo ratings yet

- Apcosil - PC 2119Document3 pagesApcosil - PC 2119Naren SudarsanNo ratings yet

- 8340A SILVA SPAR (2301)Document2 pages8340A SILVA SPAR (2301)4canNo ratings yet

- TDS - 00 - 7702 SigmaZinc 102HSDocument4 pagesTDS - 00 - 7702 SigmaZinc 102HSMina RemonNo ratings yet

- THMT SCDocument2 pagesTHMT SCZaheer Ahmad RazaNo ratings yet

- 112.025 - SUMAZINC S-659 PRIMER RICO EM ZINCO - Inglês PDFDocument2 pages112.025 - SUMAZINC S-659 PRIMER RICO EM ZINCO - Inglês PDFFernando VittoNo ratings yet

- Transpoxy Primer 1.16Document2 pagesTranspoxy Primer 1.16thinesNo ratings yet

- Asian Epoxy HB CoatingDocument1 pageAsian Epoxy HB CoatingNS2 Engineering and ConstructionNo ratings yet

- Thermoplastic Road Marking Paint: Product Code: TTP 1 & TTP 2Document3 pagesThermoplastic Road Marking Paint: Product Code: TTP 1 & TTP 2Veera PandiNo ratings yet

- TDS Aquazinga en v4Document4 pagesTDS Aquazinga en v4mahmoud tahaNo ratings yet

- Ken Kyd 200 SPDocument2 pagesKen Kyd 200 SPDany Muhammad FNo ratings yet

- Bathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofFrom EverandBathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofNo ratings yet

- BY Tabish Ul Rehman Khan Operations Coordinator Rutledge, PakistanDocument49 pagesBY Tabish Ul Rehman Khan Operations Coordinator Rutledge, Pakistantabish_khattakNo ratings yet

- Stray Gassing of Mineral OilDocument6 pagesStray Gassing of Mineral OilangelNo ratings yet

- China Nylon Industry Operation Report: Crude Oil & Benzene 2-Aug 13-Aug ChangeDocument4 pagesChina Nylon Industry Operation Report: Crude Oil & Benzene 2-Aug 13-Aug ChangeNISHSHANKANo ratings yet

- BD Ps12eDocument1 pageBD Ps12eLiran AnabyNo ratings yet

- Alligation & MixtureDocument4 pagesAlligation & MixtureSwethaNo ratings yet

- EN Series Material, EN Steel Grades Chart PDF - Manan Steels & MetalsDocument5 pagesEN Series Material, EN Steel Grades Chart PDF - Manan Steels & MetalsAbhay PanchbhaveNo ratings yet

- C FSRTC Elec Works1619Document84 pagesC FSRTC Elec Works1619VincentNo ratings yet

- Mechanical Properties of Al-14Si-2.5Cu-0.5Mg Aluminum-Silicon P/M AlloyDocument5 pagesMechanical Properties of Al-14Si-2.5Cu-0.5Mg Aluminum-Silicon P/M AlloySathwikRaoNo ratings yet

- PS 3580 Pak 151Document17 pagesPS 3580 Pak 151Thuanne Braúlio HennigNo ratings yet

- Coating FultsDocument4 pagesCoating FultsAhmed BoraeyNo ratings yet

- 3 of 3 Worksheet Class Viii Science L-6combustion and FlameDocument4 pages3 of 3 Worksheet Class Viii Science L-6combustion and FlameRekha kumariNo ratings yet

- Zinc Grades Used For Hot Dip GalvanizingDocument2 pagesZinc Grades Used For Hot Dip GalvanizingmaksimceljeNo ratings yet

- Riser Clamp InsulatorDocument1 pageRiser Clamp InsulatorFrancisNo ratings yet

- Final - PPT On Aqua SilncerDocument35 pagesFinal - PPT On Aqua SilncerPravin PatilNo ratings yet

- Plan of U.C HadokeyDocument61 pagesPlan of U.C Hadokeymuhammad iqbalNo ratings yet

- Project ReportDocument8 pagesProject ReportRitesh BoraseNo ratings yet

- C Topic 3 OxidesDocument10 pagesC Topic 3 Oxidesapi-546066323No ratings yet

- Cumene From PropyleneDocument9 pagesCumene From PropyleneIbrahim ElsayahNo ratings yet

- Prisma - Fisa Tehnica EngDocument1 pagePrisma - Fisa Tehnica EngOana PaisvanteNo ratings yet

- Worksheet in DB ScheduleDocument14 pagesWorksheet in DB Scheduleamrsah61083No ratings yet

- Organic Functional Group Tests - Practicals Chemistry Class 12Document4 pagesOrganic Functional Group Tests - Practicals Chemistry Class 12Rudraksh mittalNo ratings yet

- Building Construction Costs Handbook 2019-2020Document89 pagesBuilding Construction Costs Handbook 2019-2020Rotich philipNo ratings yet

- 05 Aramco Approved Coating SystemDocument3 pages05 Aramco Approved Coating SystemRyanNo ratings yet

- Exhibit F Chapt F5 PDFDocument91 pagesExhibit F Chapt F5 PDFfaisal jasimNo ratings yet

- Design and Analysis of Low-Cost CFRP Wheel Rims For A Formula Student Race CarDocument29 pagesDesign and Analysis of Low-Cost CFRP Wheel Rims For A Formula Student Race CarPABLO APARICIO ALONSONo ratings yet

- YukDocument158 pagesYukrezaNo ratings yet

- Comple JosDocument25 pagesComple JosMarco Antonio FloresNo ratings yet