Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

4 viewsU Chart Tutorials-8: Dr. Abdulmajeed Dabwan

U Chart Tutorials-8: Dr. Abdulmajeed Dabwan

Uploaded by

Hu Oteen (a) For a c chart with average c = 4 nonconformities:

UCL = c + 3√c = 4 + 3√4 = 4 + 3(2) = 4 + 6 = 10

LCL = c - 3√c = 4 - 3√4 = 4 - 6 = -2

(b) For a u chart with c = 4 nonconformities and n = 4 units:

UCL = c/n + 3√(c/n)(1-c/n) = 4/4 + 3√(4/4)(1-4/4) = 1 + 3√0.25 = 1 + 0.75 = 1.75

L

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Gorean Adventures 01 The Tower of ArtDocument36 pagesGorean Adventures 01 The Tower of ArtMahyná Cristina0% (2)

- Roca Gutierrez Deysi Yeraldin 20171482D: P (Kpa) X1 Y1 X2 Y2 Act 1Document6 pagesRoca Gutierrez Deysi Yeraldin 20171482D: P (Kpa) X1 Y1 X2 Y2 Act 1Deysi RocaNo ratings yet

- Concursos Oct Nov22Document7 pagesConcursos Oct Nov22luzelenac949No ratings yet

- JooooDocument3 pagesJooooJosé LuisNo ratings yet

- Chart Title: 4.5 F (X) 0.026931028630826 X + 0.542467116876637 R 0.925289857926806Document7 pagesChart Title: 4.5 F (X) 0.026931028630826 X + 0.542467116876637 R 0.925289857926806Alexander DappNo ratings yet

- Susah BGT Astaghfirullah TP AKU BISADocument4 pagesSusah BGT Astaghfirullah TP AKU BISAMaulid dina AyuNo ratings yet

- Datos Variables AleatoriasDocument322 pagesDatos Variables AleatoriasCristian HernandezNo ratings yet

- Aula 2 Mrp250Document123 pagesAula 2 Mrp250Matheus MacedoNo ratings yet

- Quiz Exercise ClassDocument7 pagesQuiz Exercise ClassSidik AbdullahNo ratings yet

- Roca Gutierrez Deysi Yeraldin 20171482D: P (Kpa) X1 Y1 X2 Y2 Act 1Document6 pagesRoca Gutierrez Deysi Yeraldin 20171482D: P (Kpa) X1 Y1 X2 Y2 Act 1Deysi RocaNo ratings yet

- Life Con 2 AssignmentDocument5 pagesLife Con 2 AssignmentKogi vaaniNo ratings yet

- Loan Principal Amount 50000 Rate 20% Years 5Document22 pagesLoan Principal Amount 50000 Rate 20% Years 5M.Sreeram SanjayNo ratings yet

- 2020 Ind 155 Formulas Colas 21Document11 pages2020 Ind 155 Formulas Colas 21bismar jaramillo orellanaNo ratings yet

- Libro1FISICA 4Document4 pagesLibro1FISICA 4Tania Gutiérrez AlanyaNo ratings yet

- 1901me17 - Exp2 - Calculations - Sheet1Document1 page1901me17 - Exp2 - Calculations - Sheet1Ramanamma PosaNo ratings yet

- Pre-Dimensionamento de SapatasDocument9 pagesPre-Dimensionamento de SapatasThiagoNo ratings yet

- Afica de Control NPDocument4 pagesAfica de Control NPGaby CamachoNo ratings yet

- Zomato 2021 - RawdataDocument7 pagesZomato 2021 - RawdataASHWIN KumarNo ratings yet

- Taller Distribucion Normal 2Document6 pagesTaller Distribucion Normal 2Juan JimenezNo ratings yet

- LANTIN BSEE 2C Electronics Lab2Document11 pagesLANTIN BSEE 2C Electronics Lab2Alwin LantinNo ratings yet

- Organizacion de DatosDocument5 pagesOrganizacion de DatosIsai CubasNo ratings yet

- Kurva Hubungan Nilai Konduktivitas Terhadap WaktuDocument8 pagesKurva Hubungan Nilai Konduktivitas Terhadap Waktudela cahyaNo ratings yet

- Grafico COP VS PotenciaDocument5 pagesGrafico COP VS PotenciaJULIANA BARRERA HINCAPIENo ratings yet

- UntitledDocument366 pagesUntitledDiana Sofia Serna PeñaNo ratings yet

- 27 Mei 21Document1 page27 Mei 21yani sumiyaniNo ratings yet

- GraficasDocument5 pagesGraficasKaren TavaresNo ratings yet

- MaDocument5 pagesMaLino HuaracalloNo ratings yet

- Matriz de DatosDocument2 pagesMatriz de Datoskatherin PCNo ratings yet

- Data GeoquimicaDocument18 pagesData GeoquimicaIbis TorresNo ratings yet

- StatDocument3 pagesStatZOREN LORENZANANo ratings yet

- Pva97nk FinalDocument648 pagesPva97nk FinalDishank SharmaNo ratings yet

- Tugasweek11telat 5003231106Document10 pagesTugasweek11telat 5003231106umarbackupsatuNo ratings yet

- Loan Repayment Schedule - Mar25 - 145402Document2 pagesLoan Repayment Schedule - Mar25 - 145402solaciNo ratings yet

- Trabajo Poritoc2 Nivels + 2 VigasDocument57 pagesTrabajo Poritoc2 Nivels + 2 VigasFERMIN CONDORI QUISPENo ratings yet

- Bab Iv Data Dan Pembahasan 1. Sudut 11 DerajatDocument7 pagesBab Iv Data Dan Pembahasan 1. Sudut 11 DerajatAini FadilahNo ratings yet

- Name Roll: Answer in The Designated Areas Only. Show All Calculations Save File As Rollno - Name - QDCDocument10 pagesName Roll: Answer in The Designated Areas Only. Show All Calculations Save File As Rollno - Name - QDCAman NagraleNo ratings yet

- Ceotimes: Numpy NP Pandas PD Pandas Matplotlib - Pyplot PLTDocument3 pagesCeotimes: Numpy NP Pandas PD Pandas Matplotlib - Pyplot PLTmohed ahmedNo ratings yet

- Secant MethodDocument3 pagesSecant MethodPatrick FernandezNo ratings yet

- LBDocument5 pagesLBAdnan AdrikaNo ratings yet

- 01 June 21Document1 page01 June 21yani sumiyaniNo ratings yet

- Zomato 2021 - RawdataDocument45 pagesZomato 2021 - RawdataASHWIN KumarNo ratings yet

- M20 CDPMDocument4 pagesM20 CDPMArunkumar CHNo ratings yet

- TopografiDocument9 pagesTopografiAnonymous sSFtjbNo ratings yet

- Flores Rojas Limbert JunniorDocument55 pagesFlores Rojas Limbert JunniorJhonatan Martín Bernabé NuntónNo ratings yet

- Alcoholometric TableDocument3 pagesAlcoholometric Tablebrendadsouza235No ratings yet

- Sol27 1Document1 pageSol27 1Joy PaulNo ratings yet

- Zomato 2021 - RawdataDocument31 pagesZomato 2021 - RawdatathinkestanNo ratings yet

- IEEE33 BusDocument17 pagesIEEE33 BusBách Tạ DuyNo ratings yet

- Husnain Iqbal Example 9.6Document12 pagesHusnain Iqbal Example 9.6Husnain iqbalNo ratings yet

- Ejercicio SimulacionDocument19 pagesEjercicio SimulacionJoseNo ratings yet

- Powder Usage and Waste 2020Document24 pagesPowder Usage and Waste 2020NURUL HIDAYAH BT IBRAHIM / UPMNo ratings yet

- 1.walmart and Macy's Case StudyDocument4 pages1.walmart and Macy's Case StudyJyothi VenuNo ratings yet

- N (X, Average, Stdev)Document8 pagesN (X, Average, Stdev)AdNo ratings yet

- Cálculo de Parámetros CinéticosDocument9 pagesCálculo de Parámetros CinéticosGirard GarciaNo ratings yet

- Chart Title: X (T) 0.0644t + 0.4595t + 1.442 40 45 50Document6 pagesChart Title: X (T) 0.0644t + 0.4595t + 1.442 40 45 50Jessica Marisol Arhuire MamaniNo ratings yet

- Comp - Pont - IvanDocument7 pagesComp - Pont - Ivanluis diego otero peñaNo ratings yet

- Datos: ProbabilidadDocument12 pagesDatos: ProbabilidadSergio Zabala DavilaNo ratings yet

- Trafo Step Down Trafo Step Up: VP Ip Vs Is VP Ip Vs IsDocument2 pagesTrafo Step Down Trafo Step Up: VP Ip Vs Is VP Ip Vs IsIhza CahyaNo ratings yet

- Analisis TransformatorDocument2 pagesAnalisis TransformatorIhza CahyaNo ratings yet

- Budget Analysis: by Department Period: Desember 2019 002-Asia Sumedang/FDocument10 pagesBudget Analysis: by Department Period: Desember 2019 002-Asia Sumedang/Flank4 pissNo ratings yet

- Oracle Exambible 1z0-083 Sample Question 2020-Oct-08 by Hayden 71q VceDocument11 pagesOracle Exambible 1z0-083 Sample Question 2020-Oct-08 by Hayden 71q VcejowbrowNo ratings yet

- Halal ListDocument5 pagesHalal ListNavruz XodjayevNo ratings yet

- P-T-T Paths: (Type Text) (Type Text) (Type Text)Document8 pagesP-T-T Paths: (Type Text) (Type Text) (Type Text)Thirukumaran VenugopalNo ratings yet

- Solution Manual For Introduction To Electrodynamics 4 e 4thDocument17 pagesSolution Manual For Introduction To Electrodynamics 4 e 4thglaivefang2a8v67100% (22)

- 10961C Automating Administration With Windows PowerShellDocument12 pages10961C Automating Administration With Windows PowerShellChris BuenaventuraNo ratings yet

- Portfolio: Enrique B. Montecalvo, PH.DDocument15 pagesPortfolio: Enrique B. Montecalvo, PH.DAlvin Rey ReyesNo ratings yet

- Human Resource Management 14th Edition Mondy Solutions Manual 1Document17 pagesHuman Resource Management 14th Edition Mondy Solutions Manual 1freida100% (44)

- Week4.Individual AssignmentDocument6 pagesWeek4.Individual AssignmentFrederickPaigeIIINo ratings yet

- Vadodara Stock Exchange Ltd.Document97 pagesVadodara Stock Exchange Ltd.Ashwin KevatNo ratings yet

- Astm f2164 PDFDocument5 pagesAstm f2164 PDFLuis J Villa Roel Bullon100% (1)

- Module 1Document140 pagesModule 1naitik S TNo ratings yet

- CPU MagDocument112 pagesCPU MagErnesto de la TorreNo ratings yet

- Base WorksheetDocument4 pagesBase WorksheetNicola StephensNo ratings yet

- C3h - 14 MERALCO v. QuisumbingDocument2 pagesC3h - 14 MERALCO v. QuisumbingAaron AristonNo ratings yet

- Propeller ShaftDocument8 pagesPropeller ShaftlomejorNo ratings yet

- Curriculum Vitae: Hem KumarDocument6 pagesCurriculum Vitae: Hem KumarHem KumarNo ratings yet

- Commodore 64 Fun and Games (1984)Document196 pagesCommodore 64 Fun and Games (1984)Delfin ButlonosyNo ratings yet

- 9-Pipes and Cisterns-06-01-2023Document18 pages9-Pipes and Cisterns-06-01-2023Srikar Prasad D 21BEC2075No ratings yet

- ArticleDocument9 pagesArticleHenry TraoréNo ratings yet

- Calculation Chek - CorrectionDocument37 pagesCalculation Chek - Correctiondebashish sarkarNo ratings yet

- Lion Air Eticket Itinerary / ReceiptDocument2 pagesLion Air Eticket Itinerary / ReceiptKokoh RayNo ratings yet

- CC 110 Syllabus in Financial Management For Agri-Based Enterprises (F)Document11 pagesCC 110 Syllabus in Financial Management For Agri-Based Enterprises (F)Cesar Della33% (3)

- Formal Classroom Observation FormDocument4 pagesFormal Classroom Observation FormHANS LUIGI SAYNO100% (1)

- Wartsila Brochure - Marine Solutions 2016Document228 pagesWartsila Brochure - Marine Solutions 2016OnceoffpleaseNo ratings yet

- ESG Media ListDocument4 pagesESG Media ListPoojaa ShirsatNo ratings yet

- 05 - Roaring 20sDocument37 pages05 - Roaring 20sBob JohnsonNo ratings yet

- CurriculaDocument6 pagesCurriculaAngel ValentinNo ratings yet

- Pent4343 XS-96 Uk L PDFDocument84 pagesPent4343 XS-96 Uk L PDFLOUKILkarimNo ratings yet

- E-Tivity 4 Research Question Proposed in E-Tivity-1Document2 pagesE-Tivity 4 Research Question Proposed in E-Tivity-1shanNo ratings yet

U Chart Tutorials-8: Dr. Abdulmajeed Dabwan

U Chart Tutorials-8: Dr. Abdulmajeed Dabwan

Uploaded by

Hu Oteen0 ratings0% found this document useful (0 votes)

4 views9 pages (a) For a c chart with average c = 4 nonconformities:

UCL = c + 3√c = 4 + 3√4 = 4 + 3(2) = 4 + 6 = 10

LCL = c - 3√c = 4 - 3√4 = 4 - 6 = -2

(b) For a u chart with c = 4 nonconformities and n = 4 units:

UCL = c/n + 3√(c/n)(1-c/n) = 4/4 + 3√(4/4)(1-4/4) = 1 + 3√0.25 = 1 + 0.75 = 1.75

L

Original Description:

Original Title

Tutorials 8

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document (a) For a c chart with average c = 4 nonconformities:

UCL = c + 3√c = 4 + 3√4 = 4 + 3(2) = 4 + 6 = 10

LCL = c - 3√c = 4 - 3√4 = 4 - 6 = -2

(b) For a u chart with c = 4 nonconformities and n = 4 units:

UCL = c/n + 3√(c/n)(1-c/n) = 4/4 + 3√(4/4)(1-4/4) = 1 + 3√0.25 = 1 + 0.75 = 1.75

L

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

4 views9 pagesU Chart Tutorials-8: Dr. Abdulmajeed Dabwan

U Chart Tutorials-8: Dr. Abdulmajeed Dabwan

Uploaded by

Hu Oteen (a) For a c chart with average c = 4 nonconformities:

UCL = c + 3√c = 4 + 3√4 = 4 + 3(2) = 4 + 6 = 10

LCL = c - 3√c = 4 - 3√4 = 4 - 6 = -2

(b) For a u chart with c = 4 nonconformities and n = 4 units:

UCL = c/n + 3√(c/n)(1-c/n) = 4/4 + 3√(4/4)(1-4/4) = 1 + 3√0.25 = 1 + 0.75 = 1.75

L

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 9

CHAPTER FIVE :Drilling Operation

IE 3391 Quality Engineering

u chart

Tutorials-8

Dr. Abdulmajeed Dabwan

Formulation

Control charts based on the average sample size

Problem 1

A paper mill uses a control chart to monitor

the imperfection in finished rolls of paper.

Production output is inspected for 20 days,

and the resulting data are shown in the

Table. Use these data to set up a control

chart for nonconformities per roll of paper.

Does the process appear to be in statistical

control? What center line and control limits

would you recommend for controlling

current production?

Problem 1 (answer)

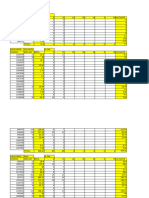

Day Rol Imp u UCL LCL

A u chart of average number of nonconformities per 1 18 12 0.666667 1.291608 0.108392

unit is appropriate with control limits based on each 2 18 14 0.777778 1.291608 0.108392

sample size: 3 24 20 0.833333 1.212348 0.187652

4 22 18 0.818182 1.23513 0.16487

5 22 15 0.681818 1.23513 0.16487

6 22 12 0.545455 1.23513 0.16487

7 20 11 0.55 1.261249 0.138751

8 20 15 0.75 1.261249 0.138751

9 20 12 0.6 1.261249 0.138751

10 20 10 0.5 1.261249 0.138751

11 18 18 1 1.291608 0.108392

12 18 14 0.777778 1.291608 0.108392

13 18 9 0.5 1.291608 0.108392

14 20 10 0.5 1.261249 0.138751

15 20 14 0.7 1.261249 0.138751

16 20 13 0.65 1.261249 0.138751

17 24 16 0.666667 1.212348 0.187652

18 24 18 0.75 1.212348 0.187652

19 22 20 0.909091 1.23513 0.16487

20 21 17 0.809524 1.247723 0.152277

13.98629

The process is in statistical control.

Problem 2

Continuation of Problem 1. Consider the

paper-making process in Problem 1. Set up

a standardized u chart for this process.

Problem 2 (answer)

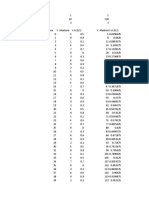

Day Rol (ni) Imp u Zi

1 18 12 0.666667 -0.16903

2 18 14 0.777778 0.394405

3 24 20 0.833333 0.78072

4 22 18 0.818182 0.662541

5 22 15 0.681818 -0.10193

6 22 12 0.545455 -0.8664

7 20 11 0.55 -0.80178

8 20 15 0.75 0.267261

9 20 12 0.6 -0.53452

10 20 10 0.5 -1.06904

11 18 18 1 1.521278

12 18 14 0.777778 0.394405

13 18 9 0.5 -1.01419

14 20 10 0.5 -1.06904

15 20 14 0.7 0

16 20 13 0.65 -0.26726

17 24 16 0.666667 -0.19518

18 24 18 0.75 0.29277

19 22 20 0.909091 1.172189

20 21 17 0.809524 0.599887

The process is in statistical control, with no patterns or out-of-control points.

Problem 3

An electronics manufacturer wishes to

control the number of nonconformities in a

subassembly area producing mother

boards. The inspection unit is defined as

nine mother boards, and data from 16

samples (each of size 9) are shown in the

Table. Set up a control chart for

nonconformities per unit.

Problem 3 (answer)

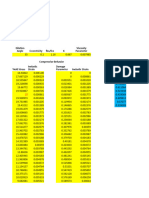

Samp Num u

A u chart of average number of nonconformities per unit is

1 1 0.111111

appropriate, with n = 9 mother boards in each inspection.

2 3 0.333333

3 2 0.222222

4 1 0.111111

5 0 0

6 2 0.222222

7 1 0.111111

8 5 0.555556

9 2 0.222222

10 1 0.111111

11 0 0

12 2 0.222222

13 1 0.111111

14 1 0.111111

15 2 0.222222

16 3 0.333333

27

The process is in statistical control, with no obvious patterns or out-of-control points.

Problem 4

Find the three-sigma control limits for

(a) a c chart with process average equal to four nonconformities.

(b) a u chart with c = 4 and n = 4.

You might also like

- Gorean Adventures 01 The Tower of ArtDocument36 pagesGorean Adventures 01 The Tower of ArtMahyná Cristina0% (2)

- Roca Gutierrez Deysi Yeraldin 20171482D: P (Kpa) X1 Y1 X2 Y2 Act 1Document6 pagesRoca Gutierrez Deysi Yeraldin 20171482D: P (Kpa) X1 Y1 X2 Y2 Act 1Deysi RocaNo ratings yet

- Concursos Oct Nov22Document7 pagesConcursos Oct Nov22luzelenac949No ratings yet

- JooooDocument3 pagesJooooJosé LuisNo ratings yet

- Chart Title: 4.5 F (X) 0.026931028630826 X + 0.542467116876637 R 0.925289857926806Document7 pagesChart Title: 4.5 F (X) 0.026931028630826 X + 0.542467116876637 R 0.925289857926806Alexander DappNo ratings yet

- Susah BGT Astaghfirullah TP AKU BISADocument4 pagesSusah BGT Astaghfirullah TP AKU BISAMaulid dina AyuNo ratings yet

- Datos Variables AleatoriasDocument322 pagesDatos Variables AleatoriasCristian HernandezNo ratings yet

- Aula 2 Mrp250Document123 pagesAula 2 Mrp250Matheus MacedoNo ratings yet

- Quiz Exercise ClassDocument7 pagesQuiz Exercise ClassSidik AbdullahNo ratings yet

- Roca Gutierrez Deysi Yeraldin 20171482D: P (Kpa) X1 Y1 X2 Y2 Act 1Document6 pagesRoca Gutierrez Deysi Yeraldin 20171482D: P (Kpa) X1 Y1 X2 Y2 Act 1Deysi RocaNo ratings yet

- Life Con 2 AssignmentDocument5 pagesLife Con 2 AssignmentKogi vaaniNo ratings yet

- Loan Principal Amount 50000 Rate 20% Years 5Document22 pagesLoan Principal Amount 50000 Rate 20% Years 5M.Sreeram SanjayNo ratings yet

- 2020 Ind 155 Formulas Colas 21Document11 pages2020 Ind 155 Formulas Colas 21bismar jaramillo orellanaNo ratings yet

- Libro1FISICA 4Document4 pagesLibro1FISICA 4Tania Gutiérrez AlanyaNo ratings yet

- 1901me17 - Exp2 - Calculations - Sheet1Document1 page1901me17 - Exp2 - Calculations - Sheet1Ramanamma PosaNo ratings yet

- Pre-Dimensionamento de SapatasDocument9 pagesPre-Dimensionamento de SapatasThiagoNo ratings yet

- Afica de Control NPDocument4 pagesAfica de Control NPGaby CamachoNo ratings yet

- Zomato 2021 - RawdataDocument7 pagesZomato 2021 - RawdataASHWIN KumarNo ratings yet

- Taller Distribucion Normal 2Document6 pagesTaller Distribucion Normal 2Juan JimenezNo ratings yet

- LANTIN BSEE 2C Electronics Lab2Document11 pagesLANTIN BSEE 2C Electronics Lab2Alwin LantinNo ratings yet

- Organizacion de DatosDocument5 pagesOrganizacion de DatosIsai CubasNo ratings yet

- Kurva Hubungan Nilai Konduktivitas Terhadap WaktuDocument8 pagesKurva Hubungan Nilai Konduktivitas Terhadap Waktudela cahyaNo ratings yet

- Grafico COP VS PotenciaDocument5 pagesGrafico COP VS PotenciaJULIANA BARRERA HINCAPIENo ratings yet

- UntitledDocument366 pagesUntitledDiana Sofia Serna PeñaNo ratings yet

- 27 Mei 21Document1 page27 Mei 21yani sumiyaniNo ratings yet

- GraficasDocument5 pagesGraficasKaren TavaresNo ratings yet

- MaDocument5 pagesMaLino HuaracalloNo ratings yet

- Matriz de DatosDocument2 pagesMatriz de Datoskatherin PCNo ratings yet

- Data GeoquimicaDocument18 pagesData GeoquimicaIbis TorresNo ratings yet

- StatDocument3 pagesStatZOREN LORENZANANo ratings yet

- Pva97nk FinalDocument648 pagesPva97nk FinalDishank SharmaNo ratings yet

- Tugasweek11telat 5003231106Document10 pagesTugasweek11telat 5003231106umarbackupsatuNo ratings yet

- Loan Repayment Schedule - Mar25 - 145402Document2 pagesLoan Repayment Schedule - Mar25 - 145402solaciNo ratings yet

- Trabajo Poritoc2 Nivels + 2 VigasDocument57 pagesTrabajo Poritoc2 Nivels + 2 VigasFERMIN CONDORI QUISPENo ratings yet

- Bab Iv Data Dan Pembahasan 1. Sudut 11 DerajatDocument7 pagesBab Iv Data Dan Pembahasan 1. Sudut 11 DerajatAini FadilahNo ratings yet

- Name Roll: Answer in The Designated Areas Only. Show All Calculations Save File As Rollno - Name - QDCDocument10 pagesName Roll: Answer in The Designated Areas Only. Show All Calculations Save File As Rollno - Name - QDCAman NagraleNo ratings yet

- Ceotimes: Numpy NP Pandas PD Pandas Matplotlib - Pyplot PLTDocument3 pagesCeotimes: Numpy NP Pandas PD Pandas Matplotlib - Pyplot PLTmohed ahmedNo ratings yet

- Secant MethodDocument3 pagesSecant MethodPatrick FernandezNo ratings yet

- LBDocument5 pagesLBAdnan AdrikaNo ratings yet

- 01 June 21Document1 page01 June 21yani sumiyaniNo ratings yet

- Zomato 2021 - RawdataDocument45 pagesZomato 2021 - RawdataASHWIN KumarNo ratings yet

- M20 CDPMDocument4 pagesM20 CDPMArunkumar CHNo ratings yet

- TopografiDocument9 pagesTopografiAnonymous sSFtjbNo ratings yet

- Flores Rojas Limbert JunniorDocument55 pagesFlores Rojas Limbert JunniorJhonatan Martín Bernabé NuntónNo ratings yet

- Alcoholometric TableDocument3 pagesAlcoholometric Tablebrendadsouza235No ratings yet

- Sol27 1Document1 pageSol27 1Joy PaulNo ratings yet

- Zomato 2021 - RawdataDocument31 pagesZomato 2021 - RawdatathinkestanNo ratings yet

- IEEE33 BusDocument17 pagesIEEE33 BusBách Tạ DuyNo ratings yet

- Husnain Iqbal Example 9.6Document12 pagesHusnain Iqbal Example 9.6Husnain iqbalNo ratings yet

- Ejercicio SimulacionDocument19 pagesEjercicio SimulacionJoseNo ratings yet

- Powder Usage and Waste 2020Document24 pagesPowder Usage and Waste 2020NURUL HIDAYAH BT IBRAHIM / UPMNo ratings yet

- 1.walmart and Macy's Case StudyDocument4 pages1.walmart and Macy's Case StudyJyothi VenuNo ratings yet

- N (X, Average, Stdev)Document8 pagesN (X, Average, Stdev)AdNo ratings yet

- Cálculo de Parámetros CinéticosDocument9 pagesCálculo de Parámetros CinéticosGirard GarciaNo ratings yet

- Chart Title: X (T) 0.0644t + 0.4595t + 1.442 40 45 50Document6 pagesChart Title: X (T) 0.0644t + 0.4595t + 1.442 40 45 50Jessica Marisol Arhuire MamaniNo ratings yet

- Comp - Pont - IvanDocument7 pagesComp - Pont - Ivanluis diego otero peñaNo ratings yet

- Datos: ProbabilidadDocument12 pagesDatos: ProbabilidadSergio Zabala DavilaNo ratings yet

- Trafo Step Down Trafo Step Up: VP Ip Vs Is VP Ip Vs IsDocument2 pagesTrafo Step Down Trafo Step Up: VP Ip Vs Is VP Ip Vs IsIhza CahyaNo ratings yet

- Analisis TransformatorDocument2 pagesAnalisis TransformatorIhza CahyaNo ratings yet

- Budget Analysis: by Department Period: Desember 2019 002-Asia Sumedang/FDocument10 pagesBudget Analysis: by Department Period: Desember 2019 002-Asia Sumedang/Flank4 pissNo ratings yet

- Oracle Exambible 1z0-083 Sample Question 2020-Oct-08 by Hayden 71q VceDocument11 pagesOracle Exambible 1z0-083 Sample Question 2020-Oct-08 by Hayden 71q VcejowbrowNo ratings yet

- Halal ListDocument5 pagesHalal ListNavruz XodjayevNo ratings yet

- P-T-T Paths: (Type Text) (Type Text) (Type Text)Document8 pagesP-T-T Paths: (Type Text) (Type Text) (Type Text)Thirukumaran VenugopalNo ratings yet

- Solution Manual For Introduction To Electrodynamics 4 e 4thDocument17 pagesSolution Manual For Introduction To Electrodynamics 4 e 4thglaivefang2a8v67100% (22)

- 10961C Automating Administration With Windows PowerShellDocument12 pages10961C Automating Administration With Windows PowerShellChris BuenaventuraNo ratings yet

- Portfolio: Enrique B. Montecalvo, PH.DDocument15 pagesPortfolio: Enrique B. Montecalvo, PH.DAlvin Rey ReyesNo ratings yet

- Human Resource Management 14th Edition Mondy Solutions Manual 1Document17 pagesHuman Resource Management 14th Edition Mondy Solutions Manual 1freida100% (44)

- Week4.Individual AssignmentDocument6 pagesWeek4.Individual AssignmentFrederickPaigeIIINo ratings yet

- Vadodara Stock Exchange Ltd.Document97 pagesVadodara Stock Exchange Ltd.Ashwin KevatNo ratings yet

- Astm f2164 PDFDocument5 pagesAstm f2164 PDFLuis J Villa Roel Bullon100% (1)

- Module 1Document140 pagesModule 1naitik S TNo ratings yet

- CPU MagDocument112 pagesCPU MagErnesto de la TorreNo ratings yet

- Base WorksheetDocument4 pagesBase WorksheetNicola StephensNo ratings yet

- C3h - 14 MERALCO v. QuisumbingDocument2 pagesC3h - 14 MERALCO v. QuisumbingAaron AristonNo ratings yet

- Propeller ShaftDocument8 pagesPropeller ShaftlomejorNo ratings yet

- Curriculum Vitae: Hem KumarDocument6 pagesCurriculum Vitae: Hem KumarHem KumarNo ratings yet

- Commodore 64 Fun and Games (1984)Document196 pagesCommodore 64 Fun and Games (1984)Delfin ButlonosyNo ratings yet

- 9-Pipes and Cisterns-06-01-2023Document18 pages9-Pipes and Cisterns-06-01-2023Srikar Prasad D 21BEC2075No ratings yet

- ArticleDocument9 pagesArticleHenry TraoréNo ratings yet

- Calculation Chek - CorrectionDocument37 pagesCalculation Chek - Correctiondebashish sarkarNo ratings yet

- Lion Air Eticket Itinerary / ReceiptDocument2 pagesLion Air Eticket Itinerary / ReceiptKokoh RayNo ratings yet

- CC 110 Syllabus in Financial Management For Agri-Based Enterprises (F)Document11 pagesCC 110 Syllabus in Financial Management For Agri-Based Enterprises (F)Cesar Della33% (3)

- Formal Classroom Observation FormDocument4 pagesFormal Classroom Observation FormHANS LUIGI SAYNO100% (1)

- Wartsila Brochure - Marine Solutions 2016Document228 pagesWartsila Brochure - Marine Solutions 2016OnceoffpleaseNo ratings yet

- ESG Media ListDocument4 pagesESG Media ListPoojaa ShirsatNo ratings yet

- 05 - Roaring 20sDocument37 pages05 - Roaring 20sBob JohnsonNo ratings yet

- CurriculaDocument6 pagesCurriculaAngel ValentinNo ratings yet

- Pent4343 XS-96 Uk L PDFDocument84 pagesPent4343 XS-96 Uk L PDFLOUKILkarimNo ratings yet

- E-Tivity 4 Research Question Proposed in E-Tivity-1Document2 pagesE-Tivity 4 Research Question Proposed in E-Tivity-1shanNo ratings yet