Professional Documents

Culture Documents

Solar Distillation of Water: Kanika Mathur, Mathewlal Thomas, Parth Lineswala, Siddharth Nayar

Solar Distillation of Water: Kanika Mathur, Mathewlal Thomas, Parth Lineswala, Siddharth Nayar

Uploaded by

Charan RavulaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solar Distillation of Water: Kanika Mathur, Mathewlal Thomas, Parth Lineswala, Siddharth Nayar

Solar Distillation of Water: Kanika Mathur, Mathewlal Thomas, Parth Lineswala, Siddharth Nayar

Uploaded by

Charan RavulaCopyright:

Available Formats

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 02 Issue: 07 | Oct-2015 www.irjet.net p-ISSN: 2395-0072

Solar Distillation of Water

Kanika Mathur1, Mathewlal Thomas2, Parth Lineswala3, Siddharth Nayar3

1Assistant Professor, Mechanical Department, Fr. C. Rodrigues Institute of Technology, Maharashtra, India

2Associate Professor, Mechanical Department, Fr. C. Rodrigues Institute of Technology, Maharashtra, India

3Undergraduate Students, Mechanical Department, Fr. C. Rodrigues Institute of Technology, Maharashtra, India

---------------------------------------------------------------------***---------------------------------------------------------------------

Abstract - Distillation is a process of separating Acid Battery retailers. Lead – Acid batteries are used in

the component substances from a liquid mixture by vehicles and distilled water is their most essential

requirement. We selected our application on the basis

separate evaporation and condensation. A simple

of the feasibility of the project i.e. the amount of daily

distillation process involves the heating of water water needed for the application and also owing to the

using a flame and immediate condensation of the fact that distilled water is such an essential requirement

vapour in a condenser. The conventional in lead – acid batteries. The project involves designing

distillation process, though simple and effective, and fabricating a solar still which can produce

uses conventional sources of energy such as fossil sufficient amount of distilled water on a daily basis to

fuels. Seeing the rapid depletion of conventional cater to the needs of lead – acid battery retailers. The

sources of energy over the decades, in this project, process involves the evaporation of water using solar

energy from the sun. The evaporated water gets

we have decided to use a non – conventional

condensed on the inner surface of the glass, which is

energy source for the distillation of water. The placed at an angle to the horizontal. Due to an

project involves designing and fabricating a solar inclination of the glass, the condensed vapour droplets

still which can produce sufficient amount of slide down the inner surface of the glass and get

distilled water on a daily basis to cater to the needs collected in the delivery flask through a delivery pipe.

of lead – acid battery retailers and thus, saving on The rate of evaporation depends on the intensity of the

solar radiations incident on the solar still. The aim of

conventional sources of energy and also reducing

the project is to produce around 3 to 5 liters distilled

the cost price of distilled water for the retailers. water using solar energy to cater to the per day

The process involves the evaporation of water requirement of Lead-Acid Battery retailers and thus,

using solar energy from the sun. The evaporated saving on conventional sources of energy and also

water gets condensed on the inner surface of the reducing the cost price of distilled water for the

glass, which is placed at an angle to the horizontal. retailers.

Due to an inclination of the glass, the condensed

vapour droplets slide down the inner surface of the 2.METHODOLOGY

glass and get collected in the delivery flask

The design methodology of the project involves designing

through a delivery pipe. The external reflector is an asymmetrical solar still as per the output requirements.

used to increase the amount of solar radiation An asymmetrical design is chosen as it has higher output

incident on the solar still, leading to an increase in efficiency [1]. The solar still is designed for an estimated

the evaporation process. The rate of evaporation output of around 3 to 5 liters, which is the average

depends on the intensity of the solar radiations requirement for our application. In addition to it, an

incident on the solar still. external reflector has been fabricated to increase the

output efficiency.

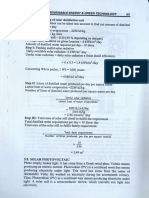

2.1 Design Calculations

Key Words: distillation, evaporation, condensation,

solar energy, etc… a) Base Area

The calculation of the base area of the solar still is the

1. INTRODUCTION most essential part as it is vital to know the area needed

for desired amount of solar radiations to be incident in

The project aims at producing distilled water using order to produce the required output. With a desired

solar energy to cater to the daily requirement of Lead –

© 2015, IRJET ISO 9001:2008 Certified Journal Page 767

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 02 Issue: 07 | Oct-2015 www.irjet.net p-ISSN: 2395-0072

output of 5 liters of water, the amount of solar energy

required can be calculated as follows:

Therefore,

Now,

In order to calculate the amount of incident solar energy

( , it is needed to analyze the data of the average

amount of solar energy incident in Mumbai every month. Fig -1: Basic design of solar still

The average solar energy received in Mumbai throughout

the year is 6.23 . [4] b). External Reflector

Therefore, The external reflector is used to increase the amount of

solar radiation incident on the solar still, leading to an

increase in the evaporation process. The additional

amount of solar energy incident on the solar still, due to

= the external reflector can be calculated as follows.

= 259.58

Amount of incident solar energy, Qinc

Commercial glass transmits a minimum of 80% of light

rays incident on it.

Therefore, = 5980.72

The effective area of the external reflector is 4’ x 3’ which

= 207.66 is equivalent to 1.15 .

Assuming a period of 8 hours per day of incident solar Thus,

energy, = 5980.72 x 1.15

= 6877.82 KJ

= 5980.72 Now,

Thus, Let us assume that, at any given time and angle of

inclination of the external reflector, at least 50% of the

For

= , total incident solar radiations will be reflected directly

onto the inclined glass of the solar still.

Thus,

Area of base required = The minimum amount of additional solar energy incident

on the solar still due to the external reflector is

= = 0.5 x 6877.82 KJ

= 1.89 = 3438.91 KJ

Therefore, the minimum total incident solar energy on the

Thus, considering area of base as 2 , solar still is

= 11961.44 = Total solar energy incident on base + Total solar

Fig 1 shows the basic design of the solar still. energy incident on reflector

= 11961.44 + 3438.91

= 15400.35 KJ

Thus, amount of distilled water that can be obtained by

using an external reflector attachment can be calculated by

© 2015, IRJET ISO 9001:2008 Certified Journal Page 768

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 02 Issue: 07 | Oct-2015 www.irjet.net p-ISSN: 2395-0072

= 6.8 kg placed at an inclination which enables the collected water

= 6.8 litres of water to flow downwards to the final collection tank.

Thus, using an external reflector, theoretically, about 35%

increase can be obtained in the daily output of the solar

still. 4. EXTERNAL REFLECTOR MECHANISM

3. FABRICATION An external reflector is a mirror attached externally to

the solar still, which reflects a portion of the incoming

The body of the solar still consists of a triangular structure solar radiations onto the inclined glass. The external

mounted over a cuboidal base. Commercial plywood is reflector is thus able to reflect some amount of solar

used to fabricate the entire setup. radiations that are incident outside the solar still, onto

the glass, thereby increasing the total incident solar

As per calculations, the dimensions of the base are taken energy[2].

as 1640 mm x 1220 mm for a 2 m2 base area, considering

the standard sizes of plywood available. The entire set up It is understood that the position of the sun constantly

is a wooden frame of thickness 50 mm to ensure changes with time. Thus, to ensure maximum efficiency of

sturdiness. the system, the reflector is hinged to the edge of the still

The triangular section is designed using trigonometric and cantilevers are connected to the sides to enable free

calculations. The total height of the frame is considered movement of the mirror. Thus, the position of the mirror

1000 mm. can be changed as per the position of the sun. This

incorporation will certainly allow a greater amount of

As base of the frame is taken as 1220 mm and angle of solar radiations incident on the solar still, thus increasing

inclination of glass as 30° [5], the height of the triangular the overall efficiency. Fig 3 shows the solar still with the

frame is calculated as 705 mm. external reflector mechanism.

The triangular side walls of the frame are accordingly

given dimensions of 1220 mm x 705 mm x 1420 mm.

The total height of the frame is taken as 1000 mm and the

height of the triangular section is calculated as 705 mm.

Therefore, the height of the base frame is calculated as

295 mm. Considering 50 mm thickness of the frame on

either side, the effective height of the base frame

becomes 195 mm. Fig 2 shows the fabricated setup of the

solar still.

Fig -3: Solar still with external reflector

5.RESULTS AND DISCUSSIONS

Testing was done on solar still in the month of March. The

volume of water filled initially was varied and output for

Fig -2: Fabricated solar still each volume was measured. The volumes of water filled

were 10 liters, 15 liters and 20 liters.

A blackened tray is placed at the base of the solar still The observations and readings recorded are as follows:

which acts as a black body to absorb the incident heat. Testing time: 8 hours

The condensed water from the glass is collected in a pipe

Max temperature achieved: 65°C

© 2015, IRJET ISO 9001:2008 Certified Journal Page 769

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 02 Issue: 07 | Oct-2015 www.irjet.net p-ISSN: 2395-0072

Volume of water obtained with and without the use The total cost involved in the fabrication of the solar still is

of reflector is shown in table 1. Rs. 12000, with a recovery period of around 10-12 months

Table -1: Volume of water obtained with and without for the lead-acid battery retailers.

reflector

REFERENCES

Vol of water poured 10 15 20 [1] Imad A1-Hayek and Omar O. Badran, “The effect

(Liters) of using different designs of solar stills on water

Volume of water obtained 3.3 3.5 3.2 distillation”, Al-Balqh Applied University, FET,

without reflector (Liters) Basic Science Department, Mechanical

Engineering Department, Amman, Jordan.

Volume of water obtained 3.7 4 3.5 [2] Hiroshi Tanaka, “Experimental study of a basin

with reflector (Liters) type solar still with internal and external

reflectors in Winter”, Mechanical Engineering

Department, Kurume National College of

Technology, Komorino, Kurume, Fukuoka 830-

From the recorded data, it is observed that the 8555, Japan.

maximum output of distilled water in a single day is

obtained with an input of 15 liters of water. [3] Khaled M. S. Eldalil, “New concept for improving

Thus volumetric efficiency of the system is, solar still performance by using vibratory

ηv , without reflector = 23.33 % harmonical effect experimental prediction, Part –

1”, Mech. Eng. Dept, Tanta University, Tanta,

ηv, with reflector = 26.67 % Egypt.

[4] http://www.eai.in/club/users/krupali/blogs/627

[5] http://www.solarpoweristhefuture.com/how-to-

figurecorrect-angle-for-solar panels.shtml

Fig -4: Supplied water versus collected water with and

without reflector

5. CONCLUSION

It was observed that the volumetric efficiency of the

system is 23.33% for an input of 15 liters of water per

day.

The incorporation of an external reflector mechanism

resulted in a 14.2% increase in the volumetric efficiency of

the system.

The distilled water was successfully tested for pH value

and EDTA test was also conducted. The pH value of water

obtained was 6.

© 2015, IRJET ISO 9001:2008 Certified Journal Page 770

You might also like

- KPL MSDS - CPP-films-Lamination-MetalizedDocument3 pagesKPL MSDS - CPP-films-Lamination-MetalizedZaheer AbbasNo ratings yet

- Floating Solar PhotovoltaicDocument12 pagesFloating Solar PhotovoltaiciaksiamNo ratings yet

- Concentrated Solar Powered Distillation - Google SearchDocument4 pagesConcentrated Solar Powered Distillation - Google SearchRudolph ScheepersNo ratings yet

- Solar Still Research PapersDocument8 pagesSolar Still Research Papersgmannevnd100% (1)

- ctt048Document8 pagesctt048suresh isravelNo ratings yet

- Development and Evaluation of Solar Agro SprayerDocument10 pagesDevelopment and Evaluation of Solar Agro SprayerIJRASETPublicationsNo ratings yet

- Conical Solar StillDocument27 pagesConical Solar StillAbhijeet EkhandeNo ratings yet

- Wastewater Treatment Technology: Auo Sunpower SDN BHD Visit ReportDocument8 pagesWastewater Treatment Technology: Auo Sunpower SDN BHD Visit Reportfatin naziraNo ratings yet

- Research Article: Computer-Aided Design, Modeling and Simulation of A New Solar Still DesignDocument6 pagesResearch Article: Computer-Aided Design, Modeling and Simulation of A New Solar Still DesignDrEmadEl-SaidNo ratings yet

- Ctae 004Document12 pagesCtae 004Kannadas PuthuvalNo ratings yet

- Bubble Wrap The Key To A New Floating Solar Thermal SystemDocument2 pagesBubble Wrap The Key To A New Floating Solar Thermal SystemEditor IJTSRDNo ratings yet

- Experimental Verification and Analysis of Solar Parabolic Collector For Water DistillationDocument6 pagesExperimental Verification and Analysis of Solar Parabolic Collector For Water DistillationInnovative Research PublicationsNo ratings yet

- 1 - Published ArticleDocument7 pages1 - Published Articleالسيد ابراهيم عبدالعزيز عبداللهNo ratings yet

- Solar Distillation 7534 EIywQXODocument16 pagesSolar Distillation 7534 EIywQXOMUHAMMED FAISALNo ratings yet

- Solar Still PyramidDocument26 pagesSolar Still PyramidNikhil SinglaNo ratings yet

- Solar Distiller - An Overview - ScienceDirect TopicsDocument7 pagesSolar Distiller - An Overview - ScienceDirect TopicsRudolph ScheepersNo ratings yet

- CFD Analysis of Single Basin Double Slope Solar StillDocument5 pagesCFD Analysis of Single Basin Double Slope Solar StilljournalNo ratings yet

- Solar Water Distillation SystemDocument44 pagesSolar Water Distillation SystemMahesh VishwakarmaNo ratings yet

- Deslination Using Solar EnergyDocument13 pagesDeslination Using Solar Energyomarrgb97No ratings yet

- Design and Fabrication of Solar Desalination System: P. VijayakumarDocument5 pagesDesign and Fabrication of Solar Desalination System: P. Vijayakumarmichelangelo lemonNo ratings yet

- Irjet V2i3350Document7 pagesIrjet V2i3350Akash SolankiNo ratings yet

- 1 s2.0 S0038092X22008088 MainDocument15 pages1 s2.0 S0038092X22008088 MainSudesh PowarNo ratings yet

- Renewable EnergyDocument24 pagesRenewable EnergyAnnu BinoyNo ratings yet

- Presentation On Case StudyDocument19 pagesPresentation On Case StudyNehar ShubheschaNo ratings yet

- FINAL REVIEW. Final (Autosaved) - 1Document26 pagesFINAL REVIEW. Final (Autosaved) - 1SKYWINDURAI RNo ratings yet

- Minor Project PPT SolarDocument21 pagesMinor Project PPT Solarganesh ambiyaNo ratings yet

- Post Data SampleDocument12 pagesPost Data SampleTechnob StudioNo ratings yet

- Crossmark: Renewable and Sustainable Energy ReviewsDocument12 pagesCrossmark: Renewable and Sustainable Energy ReviewsJay ThakarNo ratings yet

- 02 03 2013 Design and Fabrication of Solar Seed SprayerDocument25 pages02 03 2013 Design and Fabrication of Solar Seed SprayerNaveen KumarNo ratings yet

- Sun Tracking System For Productivity Enhancement o PDFDocument9 pagesSun Tracking System For Productivity Enhancement o PDFRameswaran BalasubramaniamNo ratings yet

- ECG ReportDocument14 pagesECG ReportShrikant RathodNo ratings yet

- ISS Lab Assignment 5 2019247Document2 pagesISS Lab Assignment 5 2019247Savio MoviesNo ratings yet

- Cost Analysis of Different Solar Still ConfigurationsDocument8 pagesCost Analysis of Different Solar Still ConfigurationshashimhasnainhadiNo ratings yet

- Concentrated Solar CollectorsDocument4 pagesConcentrated Solar CollectorsAbduillh AlshahriNo ratings yet

- Optimization The Performance of Single Basin Solar Still With Corrugated Wick Surface at High PlacesDocument6 pagesOptimization The Performance of Single Basin Solar Still With Corrugated Wick Surface at High Placesashna latheefNo ratings yet

- Solar-Assisted Dual-Effect Adsorption Cycle For THDocument8 pagesSolar-Assisted Dual-Effect Adsorption Cycle For THGonzalo BenavidesNo ratings yet

- Ss With ReflectorsDocument12 pagesSs With ReflectorsEsskindirNo ratings yet

- Solar Parabolic Dish Stirling Engine System Design, Simulation, and Thermal AnalysisDocument17 pagesSolar Parabolic Dish Stirling Engine System Design, Simulation, and Thermal AnalysisStephen TabiarNo ratings yet

- Res AssignmentDocument7 pagesRes AssignmentEshwar KNo ratings yet

- Seawater DesalinationDocument15 pagesSeawater DesalinationmkkNo ratings yet

- A Brief Study of An Installation of A Rooftop Solar PV System in IndiaDocument6 pagesA Brief Study of An Installation of A Rooftop Solar PV System in IndiaKarthik SivaNo ratings yet

- Solarcollector 150223120848 Conversion Gate01Document12 pagesSolarcollector 150223120848 Conversion Gate01Jaya RajNo ratings yet

- Solar StillDocument44 pagesSolar Stillابو علي الحيدريNo ratings yet

- Solar DistillationDocument10 pagesSolar DistillationJohn Johnson VNo ratings yet

- Materials Today: Proceedings: Pavushetti Abhilash, Raghavan Nanda Kumar, Raparthi Praveen KumarDocument5 pagesMaterials Today: Proceedings: Pavushetti Abhilash, Raghavan Nanda Kumar, Raparthi Praveen Kumarmuntasir antuNo ratings yet

- VP 29 21140Document6 pagesVP 29 21140Jeanne Kim BaladadNo ratings yet

- Solar Stills FinalDocument65 pagesSolar Stills FinalSiva RajNo ratings yet

- Floating Solar Power PlantDocument25 pagesFloating Solar Power PlantiaksiamNo ratings yet

- Research Paper Solar Still PDFDocument10 pagesResearch Paper Solar Still PDFMd IrfanNo ratings yet

- Fabrication of Floating Solar Power PlantDocument6 pagesFabrication of Floating Solar Power PlantIJRASETPublicationsNo ratings yet

- Concentrated Solar CollectorsDocument4 pagesConcentrated Solar CollectorsLima CostaNo ratings yet

- Performance Analysis of Solar Based Water Purification System Using ReflectorDocument3 pagesPerformance Analysis of Solar Based Water Purification System Using ReflectorDhruvin GotiNo ratings yet

- باسل 2Document16 pagesباسل 2atheer hassoonNo ratings yet

- Experimental Study On Modified Solar Still Using Convex Lenses On The Glass Cover and Radiating Surfaces InsideDocument14 pagesExperimental Study On Modified Solar Still Using Convex Lenses On The Glass Cover and Radiating Surfaces InsideAhmed Mohamed AhmedNo ratings yet

- Deslination Using Solar Energy 12345Document13 pagesDeslination Using Solar Energy 12345omarrgb97No ratings yet

- Integration of A Solar Pond in A Salt Work in Sabzevar in Northeast IranDocument11 pagesIntegration of A Solar Pond in A Salt Work in Sabzevar in Northeast Iranmohammad reza JaefarzadehNo ratings yet

- A Stand Alone Solar Energy Plant by Using PV ModulesDocument5 pagesA Stand Alone Solar Energy Plant by Using PV ModulesKing khanNo ratings yet

- Sunflower Solar RooftopDocument12 pagesSunflower Solar RooftopTejas ValaNo ratings yet

- A Review On Various Solar Still DesignsDocument10 pagesA Review On Various Solar Still DesignsajaymNo ratings yet

- Basic Off-grid & On-grid Design Solar Systems from Scratch: Bonus: Guide to Project Design in Autodesk© Autocad©.From EverandBasic Off-grid & On-grid Design Solar Systems from Scratch: Bonus: Guide to Project Design in Autodesk© Autocad©.Rating: 5 out of 5 stars5/5 (1)

- Rolling FrictionDocument19 pagesRolling FrictionCharan RavulaNo ratings yet

- Rao 2012Document5 pagesRao 2012Charan RavulaNo ratings yet

- Finite-Size Effects of Diffusion Coefficients Computed From Molecular Dynamics A Review of What We Have Learned So FarDocument16 pagesFinite-Size Effects of Diffusion Coefficients Computed From Molecular Dynamics A Review of What We Have Learned So FarCharan RavulaNo ratings yet

- 2day Thermal-Fluid Workshop - BrochureDocument3 pages2day Thermal-Fluid Workshop - BrochureCharan RavulaNo ratings yet

- Advanced - Composite - Materials - 2024 2 1 9 47 23Document2 pagesAdvanced - Composite - Materials - 2024 2 1 9 47 23Charan RavulaNo ratings yet

- Performance Characteristics of Axial CompressorDocument4 pagesPerformance Characteristics of Axial CompressorCharan RavulaNo ratings yet

- CFD Analysis of Flow Through Venturi Tube and Its Discharge CoefficientDocument9 pagesCFD Analysis of Flow Through Venturi Tube and Its Discharge CoefficientCharan RavulaNo ratings yet

- CFD Analysis of Rectangular FinDocument12 pagesCFD Analysis of Rectangular FinCharan RavulaNo ratings yet

- CFD Analysis of Naca 2421 Aerofoil at Several Angles of AttackDocument4 pagesCFD Analysis of Naca 2421 Aerofoil at Several Angles of AttackCharan RavulaNo ratings yet

- 9696 Learner Guide (For Examination From 2018) PDFDocument54 pages9696 Learner Guide (For Examination From 2018) PDFstanford marindaNo ratings yet

- 1200 26 PV 13 API CML Markup and TableDocument6 pages1200 26 PV 13 API CML Markup and TableTomasPavlovicNo ratings yet

- CCWO Sanitary PlumbingDocument36 pagesCCWO Sanitary PlumbingHiyao AngelicaNo ratings yet

- A 2021 Vision IAS Test 8Document34 pagesA 2021 Vision IAS Test 8Archer MonarchNo ratings yet

- Bulk Water Suppliers in The City of Harare - An Endogenous Form of Privatisation of Urban Domestic Water Services in Zimbabwe?Document25 pagesBulk Water Suppliers in The City of Harare - An Endogenous Form of Privatisation of Urban Domestic Water Services in Zimbabwe?Colbert JohnesNo ratings yet

- Wedeco Wel Seri Ozon SistemleriDocument4 pagesWedeco Wel Seri Ozon SistemleriAndrey GyrychNo ratings yet

- Cean Hermal Nergy Onversion: Renin ShubhamDocument12 pagesCean Hermal Nergy Onversion: Renin ShubhamgaviNo ratings yet

- 8 Bit Adventures Welcome To The Fungal KingdomDocument86 pages8 Bit Adventures Welcome To The Fungal KingdomJoshuaNo ratings yet

- Met Wet FGD PaperDocument19 pagesMet Wet FGD Paperopenid_ZrfbXb06No ratings yet

- Farmers: For Infrastructure Projects, Show The Estimated Ongoing Operating Costs To Be Included in Forward EstimatesDocument6 pagesFarmers: For Infrastructure Projects, Show The Estimated Ongoing Operating Costs To Be Included in Forward EstimatesMarnie M. DavidNo ratings yet

- Bilge Water Management & PollutionDocument12 pagesBilge Water Management & PollutionGeorgios PapakostasNo ratings yet

- G5 Science Exercise - Living Together & The Environment 2Document2 pagesG5 Science Exercise - Living Together & The Environment 2Lay Rikky Citra sdibcNo ratings yet

- Calculation Sheet Document No. Page No. Revision No. Date Prepared by Approved by Plant PlaceDocument22 pagesCalculation Sheet Document No. Page No. Revision No. Date Prepared by Approved by Plant PlaceSwapnil Pratap Singh100% (1)

- النظام القانوني لتسيير النفايات الصناعية في الجزائرDocument21 pagesالنظام القانوني لتسيير النفايات الصناعية في الجزائرmohcherif1993No ratings yet

- THB C4 ENG 07 Training ManualDocument156 pagesTHB C4 ENG 07 Training Manuallevuthien2902No ratings yet

- Safety Data Sheet: TetrahydrofuranDocument13 pagesSafety Data Sheet: TetrahydrofuranMuh. Thaufik UmarNo ratings yet

- Material Safety Data Sheet: 1. Product and Company IdentificationDocument11 pagesMaterial Safety Data Sheet: 1. Product and Company IdentificationRenalyn TorioNo ratings yet

- Btech Ce 7 Sem Water Resources Engineering Nce 702 2017Document4 pagesBtech Ce 7 Sem Water Resources Engineering Nce 702 2017Saket RusiaNo ratings yet

- CW-5000 - 5200 Manual - 20220308135247Document15 pagesCW-5000 - 5200 Manual - 20220308135247AlbertoCabrera100% (1)

- Architectural LandscapeDocument14 pagesArchitectural LandscapeDiya MakanurNo ratings yet

- SourcesDocument6 pagesSourcesPearl Angelie MahusayNo ratings yet

- Water Is LifeDocument39 pagesWater Is LifeKundan ChaudharyNo ratings yet

- E30070 V 20 EA0 P10 Hawassa 0 ESIA0 P129174Document120 pagesE30070 V 20 EA0 P10 Hawassa 0 ESIA0 P129174Biniyam BekeleNo ratings yet

- Geography P2 Memo June 2024Document13 pagesGeography P2 Memo June 2024rukieymNo ratings yet

- Briefing Note: The Benefits of Wetland RestorationDocument20 pagesBriefing Note: The Benefits of Wetland RestorationAnjay AyNo ratings yet

- WWW Biologycorner Com Worksheets Articles Hydra HTMLDocument3 pagesWWW Biologycorner Com Worksheets Articles Hydra HTMLHugvhNo ratings yet

- Septic Tank ThesisDocument4 pagesSeptic Tank Thesisleanneuhlsterlingheights100% (2)

- Introduction To Environmental Studies: Unit 1Document15 pagesIntroduction To Environmental Studies: Unit 1Faisal jamanNo ratings yet

- Project MGMT Semester ProjectDocument27 pagesProject MGMT Semester ProjectAbdul QadeerNo ratings yet