Professional Documents

Culture Documents

Kat Ohse p02 f04 Aspect Impact

Kat Ohse p02 f04 Aspect Impact

Uploaded by

Vaibhav PadaveOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kat Ohse p02 f04 Aspect Impact

Kat Ohse p02 f04 Aspect Impact

Uploaded by

Vaibhav PadaveCopyright:

Available Formats

RMIL Andheri, East.

EAIA

(Environment Aspect Impact Assessment)

Project Name: RMIL Andheri, East. JB Nagar Mumbai Date:

Inspection by: Vaibhav Padave Attendees:

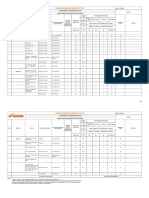

Severity Ranking Probability Ranking

Indicative Frequency

Rating Category Consequence Rating Category

(expected to occur)

1. Incident causing serious environmental

pollution or potential long term ill health to

5 Catastrophic public and other habitat 5 Frequent Daily or twice in a week

2. Legal implication may lead to the closure of

the entity

1. Incident causing major environmental Occurs several times per

4 Major damage. 4 Often year ie., once in a month

2. Potential for legal & regulatory actions or up to three months

1. Incident resulting in moderate

environmental impact.

3 Moderate 3 Likely Once in a year

2. Will cause complaints from neighbouring

industries

Incident resulting minimal environmental harm Possible but

2 Minor 2 Once in every ten years.

which can confine & treat effectively unlikely

1 Insignificant Little or no environmental harm. 1 Rare Once every 30 years.

06-04-2022 Rev. 0.0 Issue No. 1.0 Page 1 of 10 06-04-2022

RMIL Andheri, East.

EAIA

(Environment Aspect Impact Assessment)

Insignificant (1)

Catastrophic (5)

15 to Extreme Activity should not proceed

Moderate (3)

25 Risk in the current form

Minor (2)

Major (4)

Consequence

Activity should be modified to

8 to12 High Risk

Probability include remedial planning

Activity can operate subject

Moderate

Rare (1) 1 2 3 4 5 4 to 6 to management control and

Risk

modification

Possible (2) 2 4 6 8 10 1 to 3 Low Risk No action required

Likely (3) 3 6 9 12 15

Often (4) 4 8 12 16 20

Legend:

LP - Land Pollution, AP - Air Pollution, NP - Noise

Frequent or Pollution, WP - Water Pollution, RD - Resource

Almost certain 5 10 15 20 25 Depletion

(5)

06-04-2022 Rev. 0.0 Issue No. 1.0 Page 2 of 10 06-04-2022

RMIL Andheri, East.

EAIA

(Environment Aspect Impact Assessment)

Aspect & Impact Register

Impact Legal Base Line Risk Residual Risk Level

Sl No Activity Aspect (LP/AP/NP/ Existing Control Measures Additional Control Required Remarks

WP/RD) (Yes / No) PR S V/H/M/L PR S V/H/M/L

ADMINISTRATION

Effective implementation of SAP

system at Dept. level

1.Electronic communication

1. Consumption of paper RD No 5 2 10 Other than essential documents, reuse one 5 1 5

2.Printing two sides of paper.

side papers

Store the data electronically

1 Printing activities 1. Refilling and reusing of cartridges,

Using of electronic communication toners and drums to reduce wastes.

Generation of Waste from

and maintaining the soft copies to 2.Awareness among the employees

cartridges , tonners, Drums LP Yes 4 2 8 3 2 6

avoid printing as practically about low ink consumption methods.

and Fax Rolls

applicable 3.Disposal of cartridges,toners and

drums to authorised agency.

1. Switch off the power of all 1. Ensure that, the office lights, PC's,

electrical equipment's when not in printers are switched off other than the

use. general security lights before leaving

Electricity consumption RD 2. Use low voltage lights for Yes 5 2 10 office 5 1 5

illuminations to conserve power 2. ENERGY STAR rated electrical

equipment's installation will reduce

power consumption

Usage of Electrical

2 Periodic maintenance of all

equipment's and lights

equipment's / electrical

connection.& route the cable on

overhead / on side wall to avoid Usage of short circuit breakers ELCB /

Fire due to Short-circuit AP Yes 3 2 6 2 2 4

cable getting damage RCCB & use corrected rated fuse

Never exceed the capacity of

socket by looping number of

extension boxes.

1.Reducing the generation of

Generated waste to be disposed

Handling and Disposal of Generation and disposal of food waste by serving only the

3 LP Yes 4 1 4 through authorized agency 3 1 3

food waste food waste required quantity of food.

Storing of general waste in bins Generated waste to be disposed

4 House keeping activities General waste LP for disposal. Yes 3 2 6 through authorized agency 3 1 3

Pest Control and Usage of hazardous Authorized pest control agency is Disposal of generated waste through

5 fumigation chemicals LP Yes 3 3 9 authorised agency. 2 1 2

carrying out the job

Use the equipment in a recommended

mode

Engineering controls.

Consumption of Electricity RD Switching off when not in use No 5 2 10 4 2 8

Select and Use a good quality

equipment's which consumption less

electricity.

Generation of general and Storage of generated waste and Disposal of generated waste through

LP Yes 5 1 5 5 1 5

plastic waste proper disposal. authorised agency.

06-04-2022 Rev. 0.0 Issue No. 1.0 Page 3 of 10 06-04-2022

RMIL Andheri, East.

EAIA

(Environment aspect impact Assessment)

Impact Legal Base Line Risk Residual Risk Level

Sl No Activity Aspect (LP/AP/NP/ Existing Control Measures Additional Control Required Remarks

WP/RD) (Yes / No) PR S V/H/M/L PR S V/H/M/L

6 Pantry Ensure all the electrical appliances are

switched off when not in use.

Maintaining the electrical

equipments in good condition. Avoid contact of flammable materials

with the electrical cables.

Fire due electrical short circuit AP No 2 3 6 3 1 3

Fire detection system installed. Fire

Conduct training on Safe handling of

extinguisher in close vicinity. electrical equipment's and Fire

Protection systems.

INFORMATION TECHNOLOGY

1. Switch OFF the monitor power

Awareness to all employees on switching

when not in use.

1. Consumption of Power RD No 2 2 4 off the computer power when not in use. 2 1 2

2. Using of LED / LCD monitors to

7 Use of Computer reduce the power consumption.

1.Upgrading and reusing of

1.E-waste disposal through authorized

2. E-Waste LP computers as practically No 2 3 6 2 1 2

applicable. agency

Usage of cables for LP 1. Implemented wireless systems

networking and other (Wi-Fi) to reduce wire connections

8 Cables and Connectors No 2 1 2 Periodic preventive maintenance 2 1 2

connections where ever applicable.

Compressor

1.Pre Start inspection / Periodical 1. Spill kit for handling the spilled oil and

maintenance & maintain service disposal method.

schedule record 2. Always keep tray while carrying out

Compressor used for air maintenance work to avoid spillage of

9 Spillage of oil LP Yes 2 2 4 2 1 2

supply for process oil.

3. Spillage must be cleaned & disposed

immediately.

4. Keep the area very clean & tidy

1. Use of alternative, less noisy

equipment or methods

1. Daily inspection / Periodical

2. Control of noise at source eg acoustic

Compressor used for air maintenance & maintain service

10 Noise NP Yes 5 3 15 hoods / covers. 2 1 2

supply for process schedule record

3. Turn off the compressor when not in

use.

1. Provided separate bins for avoiding

mix-up. Generated waste to be disposed

Maintenance of Oil / grease sacked cotton

11 LP 2. Engaing skilled technicians to Yes 4 3 12 through authorized agency 4 1 4

compressor waste execute maintenance activities &

avoid wastage.

Maintenance Activities

06-04-2022 Rev. 0.0 Issue No. 1.0 Page 4 of 10 06-04-2022

RMIL Andheri, East.

EAIA

(Environment aspect impact Assessment)

Impact Legal Base Line Risk Residual Risk Level

Sl No Activity Aspect (LP/AP/NP/ Existing Control Measures Additional Control Required Remarks

WP/RD) (Yes / No) PR S V/H/M/L PR S V/H/M/L

1. Separate bins for avoiding mix-up.

2.Engaing skilled technicians to execute

1.Generation of grease, Oils maintenance activities to avoid wastage. Generated waste to be disposed

General Maintenance of

12 soaked cotton wastes, waste oil LP 3. Collection in separate barrels No 5 1 5 through authorized agency 3 1 3

Equipment's 4. Effective utilization of grease, rags &

, spare parts

tissues.

Hydraulics Maintenance

Reduce the waste generation Segregation & disposal through

1.Generation of empty oil tins,

General Maintenance of Usage of flow control switch, authorized dealer

13 used oil, oil soaked cotton waste LP Yes 5 1 5 2 1 2

Equipment's Over flow trip switch, Spill kit and proper collection, storage

Continues supervision. and disposal.

Store

1.Generation of waste of 1. Reduce the waste generation. 1. Dispose to authorized waste

Receiving and issuing the packaging material (carton, 2.Segrigation at designated places, recyclers

14 LP No 5 2 10 2 1 2

materials polythene, wooden, metal reuse of collected wastes 2. Practicing 3R's (reduce, reuse &

scraps etc.) recycle)

Spill kit and proper collection, storage

Receiving , storing and Proper handling, Storage of

15 2.Spillage of chemical LP Yes 2 4 8 and to be disposed by authorized 2 1 2

issuing the chemicals chemicals in the store. agency

Receiving the used oil, Proper storage of used oil to avoid

16 3.Spillage of used oil LP Yes 2 3 6 1.Reduce the waste generation. 2 1 2

storage and disposal spillages.

Using electricity for store 1.Switch off the power when not in 1.Spill kit and proper collection, storage

17 4.Power consumption LP Yes 2 2 4 2 1 2

office. use. and disposal.

1.Ensure Flammable material stored

away from source ignition 2.Ensure

Flammable material stored as

instructed in MSDS 3.All Electrical

Equipment's periodically inspected

& maintained

1.Periodical inspection & audit of store

4. Do not over load circuit. Ensure

2.Ensure electrical circuit are equipped

Handling & storage of use of correct rated fuse.

18 5.Fire AP Yes 2 4 8 with RCD(RESIDUAL Current Device) 2 1 2

chemicals 5. Display warning sign &

3. Earth continuity test, leakage test &

emergency contact numbers

insulation resistance test carried out

6.Provision information, instruction

& training to the personnel on

evacuation in case of Emergency /

Fire (evacuation & fire drill by main

Contractor

06-04-2022 Rev. 0.0 Issue No. 1.0 Page 3 of 10 06-04-2022

RMIL Andheri, East.

EAIA

(Environment aspect impact Assessment)

Impact Legal Base Line Risk Residual Risk Level

Sl No Activity Aspect (LP/AP/NP/ Existing Control Measures Additional Control Required Remarks

WP/RD) (Yes / No) PR S V/H/M/L PR S V/H/M/L

Maintaining of high standards of house

keeping always reduce the generation of

waste.

Use various adjustable/available sizes of

Maintaining a good housekeeping.

plastic bags related to the activity which

19 Issuing of materials 6.Plastic and Polythene waste LP Allocated waste disposal and Yes 5 2 10 3 1 3

minimize the weight of usage. Use

collecting points everywhere.

containers instead of polythene parcels.

Reuse the polythene bags to minimize its

usage.

Painting

Schedule and estimate the required

quantity only, to minimize the usage.

During breaks/intervals at work, do not

Using as per required quantity. leave the using paints without covering

1.Mixing of thinners RD Reusing by storing in a separate No 5 2 10 with a lid which avoids the drying of 4 2 8

containers. paint.

Completely utilize the taken amount of

paint and thinners which prevent the

evaporation of materials.

Use proper techniques/tools while

handling of paints and its related

materials to avoid the spillages.

Usage of spill kits at painting Use dip trays and bundings which avoid

activities. the land pollution and water pollution in

Using metal/tarpaulin sheets to case of spillage.

2.Paint spills during painting

LP prevent the soil contamination. Yes 5 2 10 Ensure the required amount of spill kits 3 1 3

activity

Segregation of hazardous waste are available while carrying the activity.

from other general waste. Carry out all the paint activities at

dedusting system which avoid the air

contaminations.

Conduct periodic inspections and

trainings which build an environmental

awareness in the organization.

Periodical inspections of stored

20 Painting container.

Place a hygro meter and maintain a

Storing paint materials as per

register for the temperature

MSDS instructions and

3. Storage of Paints and measurements.

LP requirements. No 4 2 8 3 1 3

Thinner Do not stock excess amount if not

Paint containers are tightly closing

necessary.

every time after its use

Storing in a cool and ventilated area

away from combustible materials.

06-04-2022 Rev. 0.0 Issue No. 1.0 Page 4 of 10 06-04-2022

RMIL Andheri, East.

EAIA

(Environment aspect impact analysis)

Impact Legal Base Line Risk Residual Risk Level

Sl No Activity Aspect (LP/AP/NP/ Existing Control Measures Additional Control Required Remarks

WP/RD) (Yes / No) PR S V/H/M/L PR S V/H/M/L

Storage area is restricted for Hot

Work activities.

Strictly implementing Non

Display the stored materials area with

Smoking Zone.

"Flammable materials Storage Area".

Safety awareness training on Fire

Prevention and Fire Protection

Install/Arrange designated smoking

Systems.

zones with fire points.

4.Fire/Explosion AP Provision of Fire Points with Fire Yes 5 3 15 4 2 8

Conduct trainings for flammable

Extinguishers.

materials.

All electrical cables and connection

Maintain a log book for electrical

are good in condition and properly

inspections.

inspected

Cranes and Mobile Cranes

Proper handling of spillages , storage

Proper maintenance of machine

Oil leakage / spillage LP Yes 2 2 4 and disposal through authorized 2 1 2

parts.

agency

Switch off the power when not in Use the equipment in recommended

Crane activity and Power Consumption AP No 5 1 5 3 1 3

use. mode.

21 Movement of vehicle

(Mobile Crane) Proper maintenance of the vehicle to Regular emission test as per regulatory

Emission AP Yes 5 2 10 4 1 4

control the emission. requirement

Ensure periodical servicing is

Air Conditioner use RD being done as per the scheduled No 3 2 6 Use of non/ less ozone depleting AC 2 1 2

time. gas for Air coolers

06-04-2022 Rev. 0.0 Issue No. 1.0 Page 5 of 10 06-04-2022

You might also like

- BTME HSE PlanDocument122 pagesBTME HSE PlanNibu P ShajiNo ratings yet

- Flash On English For Construction PDFDocument13 pagesFlash On English For Construction PDFЖаныбек Б.No ratings yet

- Aspect Impact PressingDocument2 pagesAspect Impact Pressinglalit GuptaNo ratings yet

- Emergency Response Plan Sri City Project Rev 00Document23 pagesEmergency Response Plan Sri City Project Rev 00HSE OFFICENo ratings yet

- Aspect Impact Assessment For Environment - Raimoha ProjectDocument2 pagesAspect Impact Assessment For Environment - Raimoha ProjectAradhya SinghNo ratings yet

- HIRA Injection MouldingDocument17 pagesHIRA Injection MouldingAnish Kumar PandeyNo ratings yet

- BEMS-MP-06 OHS Monitoring and Measurement PlanDocument13 pagesBEMS-MP-06 OHS Monitoring and Measurement PlanrememberNo ratings yet

- UntitledDocument6 pagesUntitledAnkit SinghNo ratings yet

- EHS ManualDocument78 pagesEHS ManualSagar BahirjeNo ratings yet

- 1.ooreedoo - RA For Maintenance of Chillers. RevisedDocument6 pages1.ooreedoo - RA For Maintenance of Chillers. RevisedstarwingsNo ratings yet

- Environmental Aspects and Impacts Evaluation REV-003Document12 pagesEnvironmental Aspects and Impacts Evaluation REV-003sunthu100% (1)

- Incident Accident Emergency Response Plan Rev. 01Document57 pagesIncident Accident Emergency Response Plan Rev. 01rajaNo ratings yet

- RMR HSMS P 002 Aspect Impact AssessmentDocument5 pagesRMR HSMS P 002 Aspect Impact AssessmentkamranNo ratings yet

- 2.emergency Preparedness Response PlanDocument5 pages2.emergency Preparedness Response PlantatNo ratings yet

- Higg List of Legal DocumentsDocument6 pagesHigg List of Legal Documentsvarman RaviNo ratings yet

- 200-74195 Aspect & Impacts Register RevDocument484 pages200-74195 Aspect & Impacts Register RevCandice100% (2)

- Arc Welder Risk MG T FormDocument9 pagesArc Welder Risk MG T FormMohd FikryNo ratings yet

- Environment Improvement PlanDocument2 pagesEnvironment Improvement PlanmuhinNo ratings yet

- Aspect & Impact TrainingDocument37 pagesAspect & Impact Trainingmahmoud mody100% (1)

- FM-EHS-02 Non-Conformance Report Log Sheet Rev.1Document1 pageFM-EHS-02 Non-Conformance Report Log Sheet Rev.1joanNo ratings yet

- 19-F02 Lifting Machinery RegisterDocument1 page19-F02 Lifting Machinery RegisterSn AhsanNo ratings yet

- D, Environmental Aspects and Impacts RegisterDocument7 pagesD, Environmental Aspects and Impacts RegisterAnand SinghNo ratings yet

- IBSPL-HSE-F17 HSE Violation ReportDocument1 pageIBSPL-HSE-F17 HSE Violation ReportAbdul RaheemNo ratings yet

- RA Arc, Welding 150310Document4 pagesRA Arc, Welding 150310Mohd FikryNo ratings yet

- 03-F02 HIRA-Hazard ID and Risk Assessment Form and RegisterDocument8 pages03-F02 HIRA-Hazard ID and Risk Assessment Form and RegisterSn AhsanNo ratings yet

- Procedure Manual - IMS: Locomotive Workshop, Northern Railway, LucknowDocument2 pagesProcedure Manual - IMS: Locomotive Workshop, Northern Railway, LucknowMarjorie Dulay DumolNo ratings yet

- Cs f11 Non Conformity ReportDocument1 pageCs f11 Non Conformity ReportIdrus IsmailNo ratings yet

- Agro - ChemicalsDocument20 pagesAgro - ChemicalsMandisa NgaloNo ratings yet

- ENV18 Aspects Register Procedure 2014 - UpdatedDocument5 pagesENV18 Aspects Register Procedure 2014 - UpdatedsametggtNo ratings yet

- Cebe JSS Audit 2 Report 08.12.2017Document14 pagesCebe JSS Audit 2 Report 08.12.2017mthokozisishangase6No ratings yet

- 12 Month HSE RoadmapDocument2 pages12 Month HSE RoadmapolaogunNo ratings yet

- Planned Job Observation: ChecklistDocument2 pagesPlanned Job Observation: ChecklistMOHAMMED RIYAN TNo ratings yet

- SA8000 Measures Social Performance in Eight Areas Important To Social Accountability in WorkplacesDocument21 pagesSA8000 Measures Social Performance in Eight Areas Important To Social Accountability in WorkplacesSkr SkrNo ratings yet

- HSE KPI's Dashboard RevDocument15 pagesHSE KPI's Dashboard RevBangaly Haidara100% (1)

- Rev - Safety DocumentsDocument9 pagesRev - Safety DocumentsCar ThickNo ratings yet

- Working During (Ramadhan) and Hot Atmosphere - RA-R9-01-007-01Document2 pagesWorking During (Ramadhan) and Hot Atmosphere - RA-R9-01-007-01cmrig74No ratings yet

- QA - Aspect & ImpactDocument5 pagesQA - Aspect & Impacttravi95100% (1)

- RAID Register - SapphireDocument11 pagesRAID Register - SapphireMuhammadMuzammalJamilNo ratings yet

- 03 IMS Needs and Expectations of Interested PartiesDocument6 pages03 IMS Needs and Expectations of Interested PartiesShardul ManjrekarNo ratings yet

- TRA FOR FRT - Rev.S2-2 (Recovered)Document31 pagesTRA FOR FRT - Rev.S2-2 (Recovered)rodman823No ratings yet

- Hearing Conservation: Adani Group Ohs Procedure ForDocument29 pagesHearing Conservation: Adani Group Ohs Procedure ForAshok PatelNo ratings yet

- Risk Assessment GardenDocument2 pagesRisk Assessment GardenMatthew BaguleyNo ratings yet

- Quantitative Summary of Impacts: Construction PhaseDocument6 pagesQuantitative Summary of Impacts: Construction PhaseNîsệệñ ElñậqầNo ratings yet

- QMS Risk & Opportunity RegisterDocument4 pagesQMS Risk & Opportunity Registernaveen yadavNo ratings yet

- Management Review MOM ODS-QHSE-SF-044 V01: Participants Distribution Name Position Attendance TypeDocument2 pagesManagement Review MOM ODS-QHSE-SF-044 V01: Participants Distribution Name Position Attendance TypeFahmi AbdullahNo ratings yet

- Ra RegisterDocument2 pagesRa Registerzarni77No ratings yet

- CD04 Aspects Impacts RegisterDocument15 pagesCD04 Aspects Impacts RegisterQuality HosurNo ratings yet

- EP06Document5 pagesEP06Chrome PicassoNo ratings yet

- HSE-FRM-40 Daily HSE Report (04-05-2020)Document2 pagesHSE-FRM-40 Daily HSE Report (04-05-2020)SHAH NAWAZ SAEEDNo ratings yet

- Procedure For Hazard Identification, Risk Assessment and Risk ManagementDocument12 pagesProcedure For Hazard Identification, Risk Assessment and Risk ManagementkamranNo ratings yet

- HSE Corrective Action Plan: S/N Observation Corrective Action Required Action by Target Date Remarks StatusDocument3 pagesHSE Corrective Action Plan: S/N Observation Corrective Action Required Action by Target Date Remarks StatusMANIINo ratings yet

- F0610-01 Risk & Opportunity RegisterDocument5 pagesF0610-01 Risk & Opportunity RegisterRito BaloyiNo ratings yet

- F 05 KDI QHSE 17a Environmental Inspection ChecklistDocument4 pagesF 05 KDI QHSE 17a Environmental Inspection ChecklistArsh AlamNo ratings yet

- MEC HO-HIRAC Update As of May 10, 2023Document27 pagesMEC HO-HIRAC Update As of May 10, 2023Judes BayleNo ratings yet

- EKR-HSE Inspection & Audit Program - 2020Document1 pageEKR-HSE Inspection & Audit Program - 2020syamimi balkhisNo ratings yet

- Tyre Technocrats India Pvt. LTD.: Employees Feedback On Ppe Zawar MinesDocument2 pagesTyre Technocrats India Pvt. LTD.: Employees Feedback On Ppe Zawar MinesDeepanshu SewakNo ratings yet

- BOCW and SafetyDocument31 pagesBOCW and Safetydreamboy87No ratings yet

- EOHS Management System Procedure Procedure For Context of The OrganizationDocument4 pagesEOHS Management System Procedure Procedure For Context of The OrganizationSuresh MuruganNo ratings yet

- Environmental Aspects ProcedureDocument4 pagesEnvironmental Aspects ProcedureEneyo VictorNo ratings yet

- Central Recordable Incident ReportDocument2 pagesCentral Recordable Incident ReportRonaldo MontemayorNo ratings yet

- Risk Assessment Form: Work/Activity Detail: Date: Officer in Charge: Team Member/sDocument2 pagesRisk Assessment Form: Work/Activity Detail: Date: Officer in Charge: Team Member/sNitai MittalNo ratings yet

- On Brochure Carbon-CaptureDocument8 pagesOn Brochure Carbon-Capturerob.careyNo ratings yet

- Stack Height CalculationDocument2 pagesStack Height CalculationWong SengNo ratings yet

- Msds Jonbuoy RMDocument2 pagesMsds Jonbuoy RMRio WitcandraNo ratings yet

- Turbodrain EnglDocument8 pagesTurbodrain EnglIonut BuzescuNo ratings yet

- Reflection PaperDocument5 pagesReflection Paperapi-316657763No ratings yet

- Regional Standard For Water ServicesDocument130 pagesRegional Standard For Water ServicesJames Everett AbdulNo ratings yet

- LNG Shipping & Bunkering Nikhil MogheDocument8 pagesLNG Shipping & Bunkering Nikhil MoghepkkothariNo ratings yet

- Paragraph WritingDocument3 pagesParagraph WritingDivyaNo ratings yet

- Environmental Pollution and Control - A Case Study of Delhi Mega City PDFDocument14 pagesEnvironmental Pollution and Control - A Case Study of Delhi Mega City PDFpankajNo ratings yet

- Environmental Crisis and Sustainable DevelopmentDocument62 pagesEnvironmental Crisis and Sustainable DevelopmentAnti Happy100% (1)

- BLOOM ENERGY Final PresentationDocument6 pagesBLOOM ENERGY Final Presentationrakesh makkapatiNo ratings yet

- Berde NC v220 PDFDocument137 pagesBerde NC v220 PDFdesignfrrNo ratings yet

- Treatment of Grey Water Using Technique of PhytoremediationDocument8 pagesTreatment of Grey Water Using Technique of PhytoremediationAnonymous kw8Yrp0R5rNo ratings yet

- Coral Triangle DayDocument10 pagesCoral Triangle DayVincent AlcaydeNo ratings yet

- Planta de Tratamiento de Aguas Residuales: Determinacion de Los Caudales de Diseño DatosDocument36 pagesPlanta de Tratamiento de Aguas Residuales: Determinacion de Los Caudales de Diseño DatosMiguel Lulo100% (2)

- Biology at Ease: Community Post 120: Biodiversity & Conservation+ Environmental IssuesDocument19 pagesBiology at Ease: Community Post 120: Biodiversity & Conservation+ Environmental IssuesNeha SharmaNo ratings yet

- Illinois Environmental Protection AgencyDocument62 pagesIllinois Environmental Protection AgencyMijail David Felix NarvaezNo ratings yet

- Msds Carbon BlackDocument15 pagesMsds Carbon Blackexodus_legendaryNo ratings yet

- Misc Equipment ItemsDocument18 pagesMisc Equipment Itemshk168No ratings yet

- PropaneDocument6 pagesPropaneFERNANDO JOSE NOVAESNo ratings yet

- Tyre Waste Recycle PlantDocument2 pagesTyre Waste Recycle PlantSusheel JalaliNo ratings yet

- NotesDocument27 pagesNotesaaaNo ratings yet

- Soe AirDocument205 pagesSoe AirDebiGoenkaCATNo ratings yet

- Deepwater Horizon Oil SpillDocument5 pagesDeepwater Horizon Oil SpillKartik GuptaNo ratings yet

- Treatment of Distillery Spent WashDocument63 pagesTreatment of Distillery Spent WashYash BansodNo ratings yet

- Solvent SDS Version 8 2021Document7 pagesSolvent SDS Version 8 2021johanbesarNo ratings yet

- Solid Waste Management WordDocument8 pagesSolid Waste Management WordjhaykNo ratings yet

- Drafting Sanitary and Plumbing Layout and DetailsDocument53 pagesDrafting Sanitary and Plumbing Layout and DetailsSinduja Kanagaraj50% (2)

- 21850, Issue 17 Flotation DAF, IAF, SAFDocument3 pages21850, Issue 17 Flotation DAF, IAF, SAFSyariful Maliki NejstaršíNo ratings yet