Professional Documents

Culture Documents

MC-Q1405 - Automotive Body Repair Technician

MC-Q1405 - Automotive Body Repair Technician

Uploaded by

Ubed Ul HaqueOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MC-Q1405 - Automotive Body Repair Technician

MC-Q1405 - Automotive Body Repair Technician

Uploaded by

Ubed Ul HaqueCopyright:

Available Formats

Model Curriculum

QP Name: Automotive Body Repair Technician

QP Code: ASC/Q1405

QP Version: 2.0

NSQF Level: 4

Model Curriculum Version: 1.0

Automotive Skill Development Council

Leela Building, 153 GF, Okhla Phase III, Okhla Industrial Area, New Delhi, Delhi 110020

1 | Automotive Body Repair Technician

Table of Contents

Table of Contents ................................................................................................................................................................... 2

Training Parameters............................................................................................................................................................... 3

Program Overview ................................................................................................................................................................. 4

Training Outcomes ............................................................................................................................................................. 4

Compulsory Modules ......................................................................................................................................................... 4

Module Details ....................................................................................................................................................................... 6

Module 1- Introduction to the Role of an Automotive Body Repair Technician ............................................................... 6

Bridge Module .................................................................................................................................................................... 6

Module 2 - Work Effectively and Efficiently....................................................................................................................... 7

Mapped to NOS ASC/N9801 v1.0 ................................................................................................................................... 7

Module 3 - Optimize Resource Utilization ......................................................................................................................... 9

Mapped to NOS ASC/N9801 v1.0 ................................................................................................................................... 9

Module 4 - Communicate Effectively and Efficiently ....................................................................................................... 10

Mapped to NOS ASC/N9802 v1.0................................................................................................................................. 10

Module 5 - Repair/Replace Vehicle’s Non-structural Body Components........................................................................ 11

Module 6 - Perform Repairs by Cutting or Welding Sheets on the Vehicle’s Body ......................................................... 13

Annexure .............................................................................................................................................................................. 15

Trainer Requirements ...................................................................................................................................................... 15

Assessor Requirements .................................................................................................................................................... 16

Assessment Strategy ........................................................................................................................................................ 17

References ....................................................................................................................................................................... 18

Glossary............................................................................................................................................................................ 18

Acronyms and Abbreviations ........................................................................................................................................... 19

2 | Automotive Body Repair Technician

Training Parameters

Sector Automotive

Sub-Sector Automotive Vehicle Service

Occupation Technical Service & Repair

Country India

NSQF Level 4

Aligned to NCO/ISCO/ISIC Code NCO-2015/7213.0301

Minimum Educational Qualification & Experience 8th Class + 1 year ITI with 2 years of

experience in Automotive Sector

OR

8th Class + 2 years ITI with 1 year of

experience in Automotive Sector

OR

10th Class with 1 Year of experience

OR

Certificate-NSQF (Automotive Body Repair

Assistant Level 3) with 2 Years of

experience

Pre-Requisite License or Training LMV Driving License

Minimum Job Entry Age 18 Years

Last Reviewed On 29/07/2021

Next Review Date 29/07/2026

NSQC Approval Date 29/07/2021

Version 2.0

Model Curriculum Creation Date 29/07/2021

Model Curriculum Valid Up to Date 29/07/2026

Model Curriculum Version 1.0

Minimum Duration of the Course 400 Hours, 0 Minutes

Maximum Duration of the Course 400 Hours, 0 Minutes

3 | Automotive Body Repair Technician

Program Overview

This section summarizes the end objectives of the program along with its duration.

Training Outcomes

At the end of the program, the learner should have acquired the listed knowledge and skills.

• Work effectively and efficiently as per schedules and timelines.

• Implement safety practices.

• Optimize the use of resources.

• Communicate effectively using interpersonal skills.

• Identify the role, responsibilities and scope of work of an automotive body repair technician.

• Perform repairs and replacement on non-structural body panels/components of vehicles.

• Carry out repairs for the vehicle body by cutting and welding metal sheets under supervision.

Compulsory Modules

The table lists the modules and their duration corresponding to the Compulsory NOS of the QP.

NOS and Module Details Theory Practical On-the-Job On-the-Job Total

Duration Duration Training Training Duration

Duration Duration

(Mandatory) (Recommended)

Bridge Module 08:00 00:00 08:00

Module 1: Introduction to

the role of Automotive Body 08:00 0:00 - - 08:00

Repair Assistant

ASC/N9801: Organize Work

and Resources (Service)

16:00 24:00 - - 40:00

NOS Version No. 1.0

NSQF Level 4

Module 2: Work effectively 08:00 16:00 - - 24:00

and efficiently

Module 3: Optimize 08:00 08:00 - - 16:00

resource utilization

ASC/N9802: Interact

Effectively with Colleagues,

Customers and Others 16:00 24:00 - - 40:00

NOS Version No. 1.0

NSQF Level 4

Module 4: Communicate

16:00 24:00 - - 40:00

effectively and efficiently

4 | Automotive Body Repair Technician

ASC/N1412: Carry out

repairs and replacement on

non-structural body

52:00 104:00 - - 156:00

panels or components

NOS Version No. 2.0

NSQF Level 4

Module 5 : Repair/Replace

Vehicle’s Non-structural 52:00 104:00 - - 156:00

Body Components

ASC/N1413: Carry out

repair/replacement by

cutting and welding on

structural or non-structural 52:00 104:00 - - 156:00

body panels

NOS Version No. 2.0

NSQF Level 4

Module 6 : Perform repairs

by cutting or welding sheets 52:00 128:00 - - 156:00

on the vehicle’s body

Total Duration 144:00 256:00 - - 400:00

5 | Automotive Body Repair Technician

Module Details

Module 1- Introduction to the Role of an Automotive Body Repair Technician

Bridge Module

Terminal Outcomes:

• Identify the role, responsibilities and scope of work of an automotive body repair technician.

• Identify the importance of following process, policies, and procedures.

Duration: 08:00 Duration: 0:00

Theory – Key Learning Outcomes Practical – Key Learning Outcomes

• Describe the role and responsibilities of an

automotive body repair technician.

• List the schedules and checklists pertaining

to repairs of body panels and components.

• Explain about Automotive Industry in India,

workshop structure and role and

responsibilities of different people in the

workshop.

• Elaborate standard operating procedures

(SOPs) regarding receiving vehicles,

opening job card, allocation of work,

invoicing, vehicle delivery, handling

complaints etc.

• Describe how to work as per organisational

and professional code of ethics and

standards of practice.

• Outline the safety, health and environment

policies to be followed for the automotive

sector.

• Discuss SOPs recommended by OEM w.r.t.

repair and replacement of body panels and

components in the vehicle.

Classroom Aids:

Laptop, white board, marker, projector

Tools, Equipment and Other Requirements

PPE kit, job card, protective covers of vehicle, hand tools, welding & cutting tools and equipment,

vehicle’s body panels and components etc.

6 | Automotive Body Repair Technician

Module 2 - Work Effectively and Efficiently

Mapped to NOS ASC/N9801 v1.0

Terminal Outcomes:

● Employ appropriate ways to maintain a safe and secure working environment.

● Perform work as per the quality standards.

Duration: <08:00> Duration: <16:00>

Theory – Key Learning Outcomes Practical – Key Learning Outcomes

● Outline the organizational structure to be ● Perform routine cleaning of tools, equip-

followed to report about health, safety and ment and machines.

security breaches to the concerned authori-

● Employ various techniques for checking

ties.

malfunctions in the equipment as per

● List the potential workplace related risks Standard Operating Procedure (SOP).

and hazards, their causes and preventions. ● Apply basic housekeeping practices to en-

● State the methods to keep the work area sure that the work area is clean, such as

clean and tidy. mopping spills and leaks, cleaning grease

● Discuss how to complete the given work stains etc.

within the stipulated time period. ● Demonstrate how to evacuate the work-

place in case of an emergency.

● Explain how to maintain a proper balance

between team and individual goals. ● Show how to sanitize and disinfect one's

work area regularly.

● Discuss epidemics and pandemics and their

impact on society at large. ● Demonstrate the correct way of washing

hands using soap and water.

● Discuss the significance of conforming to

basic hygiene practices such as washing ● Demonstrate the correct way of sanitizing

hands, using alcohol-based hand sanitizers. hands using alcohol-based hand rubs.

● Discuss the use of proper PPE for maintain- ● Display the correct way of wearing and re-

ing health and hygiene at workplace and moving PPE such as face masks, hand

the process of wearing/discarding them. gloves, face shields, PPE suits, etc.

● Define self-quarantine or self-isolation. ● Demonstrate appropriate social and behav-

ioural etiquette (greeting and meeting peo-

● Discuss the importance of identifying and ple, spitting/coughing/sneezing, etc.).

reporting symptoms to the concerned au-

thorities. ● Prepare a list of relevant hotline/emer-

gency numbers.

● Explain the significance of following pre-

scribed rules and guidelines during an epi-

demic or a pandemic.

● Discuss organizational hygiene and sanita-

tion guidelines and ways of reporting

breaches/gaps if any.

● Discuss the ways of dealing with stress and

anxiety during an epidemic or a pandemic.

Classroom Aids:

White board/black board marker/chalk, duster, computer or Laptop attached to LCD projector

Tools, Equipment and Other Requirements

7 | Automotive Body Repair Technician

Personal Protection Equipment: safety glasses, head protection, rubber gloves, safety footwear,

warning signs and tapes, fire extinguisher and first aid kit

Sanitization kit, disinfectants, alcohol-based sanitizers, different types of face masks, shields, suits,

etc.

8 | Automotive Body Repair Technician

Module 3 - Optimize Resource Utilization

Mapped to NOS ASC/N9801 v1.0

Terminal Outcomes:

● Use the resources efficiently.

● Apply conservation practices at the workplace.

Duration: <08:00> Duration: <08:00>

Theory – Key Learning Outcomes Practical – Key Learning Outcomes

● Explain the ways to optimize usage of re- ● Perform basic checks to identify any spills

sources. and leaks and that need to be plugged

● Discuss various methods of waste manage- /stopped.

ment and its disposal. ● Demonstrate different disposal techniques

● List the different categories of waste for depending upon different types of waste.

the purpose of segregation ● Employ different ways to check if equip-

● Differentiate between recyclable and non- ment/machines are functioning as per re-

recyclable waste quirements and report malfunctioning, if

observed.

● State the importance of using appropriate

colour dustbins for different types of ● Employ ways for efficient utilization of ma-

waste. terial and water

● Discuss the common sources of pollution ● Use energy efficient electrical appliances

and ways to minimize it. and devices to ensure energy conservation

Classroom Aids:

White board/black board marker/chalk, duster, computer or Laptop attached to LCD projector

Tools, Equipment and Other Requirements

Different type of waste bins to collect and segregate waste for disposal

9 | Automotive Body Repair Technician

Module 4 - Communicate Effectively and Efficiently

Mapped to NOS ASC/N9802 v1.0

Terminal Outcomes:

● Use effective communication and interpersonal skills.

● Apply sensitivity while interacting with different genders and people with disabilities.

Duration: <16:00> Duration: <24:00>

Theory – Key Learning Outcomes Practical – Key Learning Outcomes

● Explain the organizational structure for • Employ different means of communication

communicating with colleagues, seniors depending upon the requirement while in-

and others. teracting with others.

● Discuss the ways to adjust the communica- • Demonstrate using new ways to maintain

tion styles to reflect sensitivity towards good relationships with colleagues and su-

gender and persons with disability (PwD). pervisor.

● Explain the importance of respecting per- • Prepare a sample report to send the work

sonal space of colleagues and customers. status to the supervisor.

● State the procedure to receive work in- • Demonstrate how to communicate with dif-

structions and report problems to the su- ferent genders and persons with disability

pervisor. (PwD) in a sensitive manner.

● List the various organizational policies and

procedures to be followed at the work-

place.

● Describe different ways to rectify com-

monly occurring errors.

● Explain the importance of complying with

the instructions/guidelines and procedures

while performing tasks related to the job

specifications.

● Discuss the importance of PwD and gender

sensitization.

Classroom Aids:

White board/black board marker/chalk, duster, computer or Laptop attached to LCD projector

Tools, Equipment and Other Requirements

Sample of escalation matrix, organisation structure.

10 | Automotive Body Repair Technician

Module 5 - Repair/Replace Vehicle’s Non-structural Body Components

Mapped to NOS ASC/N1412, v2.0

Terminal Outcomes:

• Demonstrate the process of assessing damages and repair estimation under supervision.

• Perform repairing or replacement activities on non-structural panels or components

Duration: 52:00 Duration: 104:00

Theory – Key Learning Outcomes Practical – Key Learning Outcomes

• Identify different types of vehicle body and • Employ various techniques to assess the

chassis damage/defects their cause, extent of damages in the vehicle’s body and

prevention and rectification, features of report malfunctions/repairs that are

body construction and structural/non- beyond own scope to the

structural panels, characteristics of supervisor/service advisor.

common metals. • Demonstrate how to park/place the vehicle

• Discuss the job card received from the on a suitable platform as per the job

supervisor to understand repair requirements.

requirements. • Demonstrate how to collect, check and use

• Assess the extent of damage to determine the tools, equipment,

direction of impact and whether all the components/aggregates, fittings, new

damages are due to the same time and panel, spare parts, consumables or

situation. materials as required for the repair.

• Explain how to assist the supervisor/service • Perform appropriate steps using proper

advisor for visual inspection of the vehicle techniques to remove detachable parts of

and identification of the type of damages the vehicle and tag removed items for

on various parts of the body. repair, reuse and replacement.

• Describe how to prepare initial estimate by • Implement different ways to perform

listing down repair requirements, time and various OEM specific tasks during repair

replacement of consumables and other such as riveting, bonding, screwing, bolting

OEM components along with the etc.

supervisor/service advisor. • Demonstrate how to apply suitable sealers,

• Identify the nomenclature, manufacturer's foams, anti-corrosion coatings and sound

specifications of different dampening pads on the vehicle’s body parts

consumable/material and hand tools, during repair.

manual and electric dent pullers, welding • Employ suitable techniques for reinstalling

equipment etc. and vehicle parts and body non-structural removed/repaired/new

panels. panels/parts ensuring correct alignment of

• Discuss the overall functioning of various the panels and components.

types of collision repair equipment, • Implement ways for inspecting grooves,

workshop tools /materials, their usage, angles, or gap allowances of body

storage and maintenance. panels/components after repair and

• Recall the processes and procedures for reinstallation by using testing devices as per

preparing replacement panel work and manufacturer's specifications.

panel fixing positions. • Perform steps to test for water leaks in the

• Summarise the removal, replacement, body panels and ensure that the sealing or

repair, and testing procedures related to adhesion of replaced rubber seal/weather

vehicle body and frame strip or glass work activity is correct and as

per OEM recommended guidelines.

11 | Automotive Body Repair Technician

• Explain how to report any malfunctions • Implement proper waste disposal

observed in the tools/equipment/material techniques for disposing scrap of damaged

or any additional repair requirement in the parts/panels.

vehicle to the concerned person. • Employ proper procedure for returning

• Describe the importance of using proper leftover consumable/parts and

PPE and ensuring order and cleanliness in tools/equipment to the store/person

the work area to avoid any hazard or incharge and informing them about any

damage to the vehicle and its components. malfunctions.

• List the methods for removing and • Perform steps to reinstate suitable

replacing exterior and interior body parts of corrosion protection to replaced parts of

the vehicle. the vehicle’s body.

• Identify the characteristics of commonly • Demonstrate how to inspect the repaired

used glass parts such as body panel/components of the vehicle for

Tempered/Toughened glass & Laminated proper functioning and test drive vehicles

glass and plastic parts in the vehicle such as to verify proper alignment and handling.

Polypropylene (PP), Poly Carbonate (PC) in

the vehicle’s body.

• Emphasize on the importance of proper

tagging and placement of vehicle’s

removed parts securely as per

manufacturers' guidelines.

• Describe the importance for maintaining

complete documentation on the

repair/replacement job/task of the vehicle.

• Discuss how to check whether all repair

activities/tasks have been completed as per

requirements and specifications before

releasing the vehicle for the next

procedure.

Classroom Aids:

Laptop, white board, marker, projector

Tools, Equipment and Other Requirements

PPE kit, job card, protective covers of vehicle, hand tools, welding & cutting tools and equipment,

vehicle’s body panels and components etc.

12 | Automotive Body Repair Technician

Module 6 - Perform Repairs by Cutting or Welding Sheets on the Vehicle’s Body

Mapped to NOS ASC/N1413, v2.0

Terminal Outcomes:

• Perform cutting and welding activities on vehicle body panels.

• Carry out post cutting and welding activities.

Duration: 52:00 Duration: 104:00

Theory – Key Learning Outcomes Practical – Key Learning Outcomes

• Discuss the job card received from the • Demonstrate how to park/place the vehicle

supervisor to understand repair on a suitable platform for performing

requirements. cutting and welding activities on the vehicle

• Explain the principles of pulling systems, body.

operation and adjustment of welding • Employ various techniques to assess the

systems used for panel repair or extent of damages in the vehicle’s body and

replacement. report malfunctions/repairs that are

• Describe the overall functioning of different beyond own scope to the concerned

types of collision repair tools/equipment person.

and materials. • Demonstrate how to collect, check and use

• Identify the workshop tools/equipment and the tools and equipment, for cutting and

materials along with their usage, storage welding job.

and maintenance procedures. • Employ suitable techniques to use

• Explain the importance of using proper PPE workshop tools/equipment (manual and

for cutting and welding activities and automated) as per OEM SOPs.

ensure order/cleanliness in the work area • Perform appropriate steps using proper

to avoid any hazard or damage to the techniques to remove detachable parts of

vehicle and its components. the vehicle and tag removed items for

• Describe how to take assistance from repair, reuse and replacement before

supervisor to perform rough pulling for commencing cutting/welding activities.

body alignment process. • Demonstrate how to cut and remove

• Discuss how to assist supervisor in damaged/dented/welded structural panels

measuring the vehicle body dimensions to with minimal disturbance to surrounding

ensure correct alignment or final panels in order to prepare the body for new

correction. panel installation.

• Emphasize on the importance of • Implement different ways to properly

maintaining complete documentation on install/replace the new panel ensuring its

the cutting/welding job/task performed on correct alignment with the vehicle body.

the vehicle’s body. • Employ appropriate welding techniques to

• Discuss how to check whether all weld new panels or panel assemblies as per

cutting/welding have been completed as OEM specifications.

per requirements and specifications before • Demonstrate how to dress weld seams

releasing the vehicle for the next using sanding/grinding operations and

procedure. apply body seam sealers for rust prevention

treatment.

• Employ suitable techniques for reinstalling

non-structural removed/repaired/new

panels/parts (internal and external)

ensuring correct alignment of the panels

and components.

• Implement proper waste disposal

techniques for disposing scrap of damage

13 | Automotive Body Repair Technician

parts/panels used during cutting/welding

activities.

• Employ proper procedure for returning

leftover consumable/parts and

tools/equipment to the store/person

incharge and informing them about any

malfunctions, if observed.

• Demonstrate how to inspect the repaired

body panel/part of the vehicle for proper

functioning to verify proper alignment and

handling.

Classroom Aids:

Laptop, white board, marker, projector

Tools, Equipment and Other Requirements

PPE kit, job card, protective covers of vehicle, hand tools, welding & cutting tools and equipment,

vehicle’s body panels and components etc.

14 | Automotive Body Repair Technician

Annexure

Trainer Requirements

Trainer Prerequisites

Minimum Specialization Relevant Industry Training Remarks

Educational Experience Experience

Qualification Years Specialization Years Specialization

ITI (Mechanic Automotive 2 Two/Four Wheeler 1 Two/Four NA

Motor Repair Service Wheeler

Vehicle) Service

ITI (Mechanic Automotive 3 Two/Four Wheeler NA NA NA

Motor Repair Service

Vehicle)

Diploma Automotive 1 Two/Four Wheeler 1 Two/Four NA

(Automobile Repair Service Wheeler

Engineering/ Service

Mechanical

Engineering)

Diploma Automotive 2 Two/Four Wheeler NA NA NA

(Automobile Repair Service

Engineering/

Mechanical

Engineering)

Certificate- Automotive 2 Two/Four Wheeler 1 Two/Four NA

NSQF(Two/Fo Repair Service Wheeler

ur Wheeler Service

Master

Technician)

Level-6

Trainer Certification

Domain Certification Platform Certification

Certified for Job Role: “Automotive Body Repair Recommended that the Trainer is certified for the

Technician”, QP: “ASC/Q1405”, v2.0”. Minimum Job Role: “Trainer”, “MEP/Q2601, v1.0”, Minimum

accepted score is 80% accepted score is 80%

15 | Automotive Body Repair Technician

Assessor Requirements

Assessor Prerequisites

Minimum Specialization Relevant Industry Training Remarks

Educational Experience Experience

Qualification

Years Specialization Years Specialization

ITI (Mechanic Automotive 3 Two/Four Wheeler 1 Two/Four NA

Motor Repair Service Wheeler

Vehicle) Service

ITI (Mechanic Automotive 4 Two/Four Wheeler NA NA NA

Motor Repair Service

Vehicle)

Diploma Automotive 2 Two/Four Wheeler 1 Two/Four NA

(Automobile Repair Service Wheeler

Engineering/ Service

Mechanical

Engineering)

Diploma Automotive 3 Two/Four Wheeler NA NA NA

(Automobile Repair Service

Engineering/

Mechanical

Engineering)

Certificate- Automotive 3 Two/Four Wheeler 1 Two/Four NA

NSQF(Two/Fo Repair Service Wheeler

ur Wheeler Service

Master

Technician)

Level-6

Assessor Certification

Domain Certification Platform Certification

Certified for Job Role: “Automotive Body Repair Recommended that the Assessor is certified for

Technician”, QP: “ASC/Q1405”, v2.0”. Minimum the Job Role: “Assessor” “MEP/Q2701, v1.0”

accepted score is 80%

16 | Automotive Body Repair Technician

Assessment Strategy

1. Assessment System Overview:

● Batches assigned to the assessment agencies for conducting the assessment on SIP or email

● Assessment agencies send the assessment confirmation to VTP/TC looping SSC

● Assessment agency deploys the ToA certified Assessor for executing the assessment

● SSC monitors the assessment process & records

2. Testing Environment – The assessor should:

● Confirm that the centre is available at the same address as mentioned on SDMS or SIP

● Check the duration of the training.

● Check the Assessment Start and End time to be as 10 a.m. and 5 p.m.

● If the batch size is more than 30, then there should be 2 Assessors.

● Check that the allotted time to the candidates to complete Theory & Practical Assessment is

correct.

● Check the mode of assessment—Online (TAB/Computer) or Offline (OMR/PP).

● Confirm the number of TABs on the ground are correct to execute the Assessment smoothly.

● Check the availability of the Lab Equipment for the particular Job Role.

3. Assessment Quality Assurance levels/Framework:

● Question papers are created by the Subject Matter Experts (SME)

● Question papers created by the SME are verified by the other subject Matter Experts

● Questions are mapped with NOS and PC

● Question papers are prepared considering that level 1 to 3 are for the unskilled & semi-skilled

individuals, and level 4 and above are for the skilled, supervisor & higher management

● Assessor must be ToA certified & trainer must be ToT Certified

● Assessment agency must follow the assessment guidelines to conduct the assessment

4. Types of evidence or evidence-gathering protocol:

● Time-stamped & geotagged reporting of the assessor from assessment location

● Centre photographs with signboards and scheme specific branding

● Biometric or manual attendance sheet (stamped by TP) of the trainees during the training pe-

riod

● Time-stamped & geotagged assessment (Theory + Viva + Practical) photographs & videos

5. Method of verification or validation:

● Surprise visit to the assessment location

● Random audit of the batch

● Random audit of any candidate

6. Method for assessment documentation, archiving, and access

● Hard copies of the documents are stored

● Soft copies of the documents & photographs of the assessment are uploaded/accessed from

Cloud Storage

● Soft copies of the documents & photographs of the assessment are stored in the Hard Drives

17 | Automotive Body Repair Technician

References

Glossary

Term Description

Declarative Declarative knowledge refers to facts, concepts and principles that need to

Knowledge be known and/or understood in order to accomplish a task or to solve a

problem.

Key Learning Key learning outcome is the statement of what a learner needs to know,

Outcome understand and be able to do in order to achieve the terminal outcomes. A

set of key learning outcomes will make up the training outcomes. Training

outcome is specified in terms of knowledge, understanding (theory) and

skills (practical application).

OJT (M) On-the-job training (Mandatory); trainees are mandated to complete

specified hours of training on site

OJT (R) On-the-job training (Recommended); trainees are recommended the

specified hours of training on site

Procedural Procedural knowledge addresses how to do something, or how to perform a

Knowledge task. It is the ability to work, or produce a tangible work output by applying

cognitive, affective or psychomotor skills.

Training Outcome Training outcome is a statement of what a learner will know, understand

and be able to do upon the completion of the training.

Terminal Outcome Terminal outcome is a statement of what a learner will know, understand

and be able to do upon the completion of a module. A set of terminal

outcomes help to achieve the training outcome.

18 | Automotive Body Repair Technician

Acronyms and Abbreviations

NOS National Occupational Standard(s)

NSQF National Skills Qualifications Framework

QP Qualifications Pack

TVET Technical and Vocational Education and Training

PwD Persons with Disability

OEM Original Equipment Manufacturer

19 |Automotive Body Repair Technician

You might also like

- PDO Thread Lift ManualDocument65 pagesPDO Thread Lift ManualsanlaypossoliaestheticNo ratings yet

- PH - English - ASC - Q1429 - Electric Vehicle Service Technician - V4.0Document325 pagesPH - English - ASC - Q1429 - Electric Vehicle Service Technician - V4.0संजीव कुमार झाNo ratings yet

- Diagnostic Communication with Road-Vehicles and Non-Road Mobile MachineryFrom EverandDiagnostic Communication with Road-Vehicles and Non-Road Mobile MachineryRating: 1 out of 5 stars1/5 (1)

- Competency Based Learning Material-AutomotiveDocument7 pagesCompetency Based Learning Material-AutomotiveMarx Engel Monreal Juntado100% (1)

- Agriculture SSWPDocument2 pagesAgriculture SSWPAriel Dela Cruz100% (2)

- Step /1/: The Seven Steps That Save LivesDocument2 pagesStep /1/: The Seven Steps That Save LivesShung Tak Chan100% (1)

- MC - Q1426 - Automotive Service AdvisorDocument18 pagesMC - Q1426 - Automotive Service AdvisorPraveenNo ratings yet

- Syallabus Model For Tap ProgramDocument20 pagesSyallabus Model For Tap ProgramABHINAV BHATNo ratings yet

- MC Automotive Additive Manufacturing EngineerDocument20 pagesMC Automotive Additive Manufacturing Engineerankitsharma00171No ratings yet

- ASC - Q1424 - v1.0 - Electric Vehicle Service Lead TechnicianDocument44 pagesASC - Q1424 - v1.0 - Electric Vehicle Service Lead Techniciananilkdas4590No ratings yet

- MC - ASCQ3502 - v1.0 - Automotive Machining AssistantDocument17 pagesMC - ASCQ3502 - v1.0 - Automotive Machining AssistantARUNKUMAR PMCNo ratings yet

- MC - ELE - Q3115 - Multi Skill Technician (Electrical) - V2.0 - 19022021Document21 pagesMC - ELE - Q3115 - Multi Skill Technician (Electrical) - V2.0 - 19022021AshfaqUmarNo ratings yet

- MC - ASCQ3503 - v1.0 - CNC Machining TechnicianDocument19 pagesMC - ASCQ3503 - v1.0 - CNC Machining TechnicianARUNKUMAR PMCNo ratings yet

- CNC ProgrammerDocument35 pagesCNC ProgrammerArun ManoharNo ratings yet

- MC - Assistant Installation Technician Computing and Peripherals - q4609Document18 pagesMC - Assistant Installation Technician Computing and Peripherals - q4609ardigital226No ratings yet

- Trainer Guide: Automotive Service TechnicianDocument30 pagesTrainer Guide: Automotive Service Technicianjameel babooramNo ratings yet

- ASC Q6809 v1.0 Electric Vehicle Maintenance TechnicianDocument30 pagesASC Q6809 v1.0 Electric Vehicle Maintenance TechniciansamuelNo ratings yet

- Mechanic Motor Vehicle - CTS2.0 - NSQF-4 - 0Document76 pagesMechanic Motor Vehicle - CTS2.0 - NSQF-4 - 0Pta NahiNo ratings yet

- Tool and Die MakerDocument24 pagesTool and Die MakerArun ManoharNo ratings yet

- Automotive Engine ED Technician (Petrol) - STC - NSQF-5Document21 pagesAutomotive Engine ED Technician (Petrol) - STC - NSQF-5Richu RajNo ratings yet

- MC - LED Light Repair TechnicianDocument19 pagesMC - LED Light Repair Techniciancomputerssai4No ratings yet

- Pump Operator Cum Mech - CTS2.0 - NSQF-3Document48 pagesPump Operator Cum Mech - CTS2.0 - NSQF-3Thameemul AnsariNo ratings yet

- MC SSCQ4201 Product Design Engineer-Mechanical v2.0Document23 pagesMC SSCQ4201 Product Design Engineer-Mechanical v2.0ebookddugkyNo ratings yet

- SSCQ0508 Junior Software DeveloperDocument23 pagesSSCQ0508 Junior Software DeveloperTechmake ProjectNo ratings yet

- CTS MMV-NSQFDocument76 pagesCTS MMV-NSQFSreejith MenonNo ratings yet

- TESDA Circular No. 132-2020Document9 pagesTESDA Circular No. 132-2020ChamsonNo ratings yet

- MC CON Q0603 Construction Electrician LV V2.0 03022021Document22 pagesMC CON Q0603 Construction Electrician LV V2.0 03022021KeviNo ratings yet

- ASC Q6802 v2.0 Automotive Maintenance Technician Mechanical 4 5 2021Document23 pagesASC Q6802 v2.0 Automotive Maintenance Technician Mechanical 4 5 2021Vikram Athreya VNo ratings yet

- SYL Mechanic Motor Vehicle 08 06 14 PDFDocument43 pagesSYL Mechanic Motor Vehicle 08 06 14 PDFபாலவிக்னேஷ்No ratings yet

- Mech Two - Three Wheeler - CTS2.0 - NSQF-3Document47 pagesMech Two - Three Wheeler - CTS2.0 - NSQF-3Sunil SudhirNo ratings yet

- IMM Operator - ATS - NSQF-5Document44 pagesIMM Operator - ATS - NSQF-5CA-VIJAY MORE3344No ratings yet

- Mechanic Tractor - CTS2.0 - NSQF-3Document53 pagesMechanic Tractor - CTS2.0 - NSQF-3Babytai Ghorpade100% (1)

- Ats MMTM NSQF 5Document52 pagesAts MMTM NSQF 5Jess YbanezNo ratings yet

- Solar LED Technician - ELE - Q5903 - v3.0Document37 pagesSolar LED Technician - ELE - Q5903 - v3.0computerssai4No ratings yet

- Mechanic Diesel: Syllabus of Semester SystemDocument28 pagesMechanic Diesel: Syllabus of Semester Systempradeep100% (1)

- MC - Project Soft - Landing ExecutiveDocument19 pagesMC - Project Soft - Landing ExecutiveAbdur Rauf RahmaniNo ratings yet

- Automotive Servicing Repairing Technician FLX NSQF-5Document61 pagesAutomotive Servicing Repairing Technician FLX NSQF-5Shubham KumarNo ratings yet

- Mechanic Diesel PDFDocument38 pagesMechanic Diesel PDFpradeepNo ratings yet

- Mech. Auto Electrical Electronics - CTS2.0 - NSQFDocument48 pagesMech. Auto Electrical Electronics - CTS2.0 - NSQFMr. ZishanNo ratings yet

- Perform Periodic Maintenance of Automotive Engine v.2Document70 pagesPerform Periodic Maintenance of Automotive Engine v.2Francine DatorNo ratings yet

- Auto Service Technician Level3 PDFDocument29 pagesAuto Service Technician Level3 PDFArun PrasathNo ratings yet

- TESDA Circular No. 129-2020Document10 pagesTESDA Circular No. 129-2020Jay Mar VillegasNo ratings yet

- Automotive Paint Technician FLX1.0 NSQF-4Document61 pagesAutomotive Paint Technician FLX1.0 NSQF-4Bionick CharlesNo ratings yet

- Automotive Engine Repair Technician PDFDocument33 pagesAutomotive Engine Repair Technician PDFArun PrasathNo ratings yet

- Mechanic Auto Electrical & ElectronicsDocument38 pagesMechanic Auto Electrical & ElectronicsIlie BorșNo ratings yet

- Wiring Harness Assembly Operator - ELE - Q6306 - v2.0Document33 pagesWiring Harness Assembly Operator - ELE - Q6306 - v2.0arun.nagarkarNo ratings yet

- ATS-Mech Advance Machine Tool Maint-NSQF-5Document52 pagesATS-Mech Advance Machine Tool Maint-NSQF-5Jess YbanezNo ratings yet

- Offshore Crane Operator Stage 2 Training: Standard Title CodeDocument63 pagesOffshore Crane Operator Stage 2 Training: Standard Title Codereda mesbahNo ratings yet

- CNC Programmer Cum OperatorDocument34 pagesCNC Programmer Cum OperatorUma SivajiNo ratings yet

- ELE Q4609 v3.0Document32 pagesELE Q4609 v3.0ardigital226No ratings yet

- QP - ASC Q1411 - Automotive Service Technician (Two and Three Wheelers)Document31 pagesQP - ASC Q1411 - Automotive Service Technician (Two and Three Wheelers)Sunil SudhirNo ratings yet

- Ats CNC Progr Cum Optr NSQF 4Document37 pagesAts CNC Progr Cum Optr NSQF 4Krishnav BarmanNo ratings yet

- External Assessment SpecificationsDocument8 pagesExternal Assessment SpecificationsElisette RahantamalalaNo ratings yet

- Elements and Performance Criteria - NVH TEST ENGINEERDocument73 pagesElements and Performance Criteria - NVH TEST ENGINEERJitendra ItankarNo ratings yet

- MC - Solar LED TechnicianDocument16 pagesMC - Solar LED Techniciancomputerssai4No ratings yet

- STC-Operation Maint of PSA Oxygen Plant NSQF-4Document17 pagesSTC-Operation Maint of PSA Oxygen Plant NSQF-4Vishal KotiaNo ratings yet

- Mechanic Diesel: Craftsmen Training Scheme (CTS)Document51 pagesMechanic Diesel: Craftsmen Training Scheme (CTS)Mfanasibili SitsebeNo ratings yet

- MC Electric Vehicle Service TechnicianDocument31 pagesMC Electric Vehicle Service Technicianrajkashyapofficial6No ratings yet

- MC - New QP - Refinery Process OperatorDocument16 pagesMC - New QP - Refinery Process OperatorgreendaycheNo ratings yet

- 6 CBLM - UC1 Carry Out Minor Vehicle MaintenanceDocument127 pages6 CBLM - UC1 Carry Out Minor Vehicle MaintenanceTESDA Lazi Technical Institute100% (2)

- Qualfile Accmm 27Document14 pagesQualfile Accmm 27PPDC NAGAURNo ratings yet

- QF CTS MMTM 0Document44 pagesQF CTS MMTM 0Jess YbanezNo ratings yet

- Mechanic Diesel CTS2.0 NSQF-3Document51 pagesMechanic Diesel CTS2.0 NSQF-3Kushal kumar singhNo ratings yet

- TR Scaffold Erection NC IiDocument64 pagesTR Scaffold Erection NC IiAtoniya Skills Education INC100% (1)

- Steel Structure WorkDocument9 pagesSteel Structure Workmohd firdaus100% (1)

- RA 02 - Earth WorkDocument38 pagesRA 02 - Earth WorkAnonymous kWfNFb100% (2)

- Ieee 1106-2015-Recommended-Practice-For-Installation-Maintenance-Testing-ADocument49 pagesIeee 1106-2015-Recommended-Practice-For-Installation-Maintenance-Testing-Aenjiniring sbklNo ratings yet

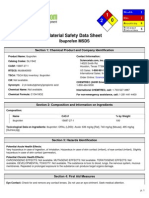

- Ibuprofen MSDS: Section 1: Chemical Product and Company IdentificationDocument5 pagesIbuprofen MSDS: Section 1: Chemical Product and Company IdentificationadeandiniNo ratings yet

- OM201311Conext Core XC-NA Operating Manual (990-5145 - Rev-)Document96 pagesOM201311Conext Core XC-NA Operating Manual (990-5145 - Rev-)bianca7sallesNo ratings yet

- PHILL AssignmentDocument7 pagesPHILL AssignmentAFANJI PHILLNo ratings yet

- Health and Safety in WeldingDocument46 pagesHealth and Safety in Weldingegn2007No ratings yet

- Emergency Contact Information: Your Name Address City, State, Zip Telephone Special DirectionsDocument2 pagesEmergency Contact Information: Your Name Address City, State, Zip Telephone Special DirectionsVictor Hugo Calvanapón SalasNo ratings yet

- Enviroline 405HT+ds+eng PDFDocument4 pagesEnviroline 405HT+ds+eng PDFMohamed NouzerNo ratings yet

- Chemical Spill ManagementDocument35 pagesChemical Spill ManagementArielen Magno Bismar100% (1)

- Safety Data Sheet: Section 1 - Product and Company IdentificationDocument10 pagesSafety Data Sheet: Section 1 - Product and Company IdentificationAndhie OsloNo ratings yet

- Villamor College of Business and Arts.: Balimbing St. General Santos CityDocument4 pagesVillamor College of Business and Arts.: Balimbing St. General Santos CityOne Piece AdikNo ratings yet

- Risk Assessment For Existing Asphalt Cutting For Laying Utilities Reinstatement Rev1 0Document30 pagesRisk Assessment For Existing Asphalt Cutting For Laying Utilities Reinstatement Rev1 0nagaaNo ratings yet

- Fehling Solution A MSDSDocument5 pagesFehling Solution A MSDSindra suryanaNo ratings yet

- IMI Level 3 Assessment CriteriaDocument87 pagesIMI Level 3 Assessment CriteriaTrevor100% (1)

- SDS (Ups) Silicone Mould Release Paintable - enDocument4 pagesSDS (Ups) Silicone Mould Release Paintable - enhugocupuNo ratings yet

- Heat Stress at WorkplaceDocument4 pagesHeat Stress at Workplacemirali74No ratings yet

- PQ PT. POMI NewDocument3 pagesPQ PT. POMI Newbragga suwargiNo ratings yet

- Method StatementDocument3 pagesMethod StatementHossain amjad HossainNo ratings yet

- Risk Assessment Recrystallization 1.1Document3 pagesRisk Assessment Recrystallization 1.1h9g886qdnpNo ratings yet

- PR-1148 - Entry Into A Confined Space ProcedureDocument25 pagesPR-1148 - Entry Into A Confined Space ProcedureajayNo ratings yet

- Rammer R18P Omr18pxeng.418Document104 pagesRammer R18P Omr18pxeng.418Антон ЛазаровNo ratings yet

- 20220225 醫療用品類的名單Document104 pages20220225 醫療用品類的名單batsy4evNo ratings yet

- Swot Analysis Strengths 1. Quick ServiceDocument2 pagesSwot Analysis Strengths 1. Quick ServiceMigs MigsyNo ratings yet

- Section 3 - Assembly SafetyDocument35 pagesSection 3 - Assembly SafetyLuis TorresNo ratings yet