Professional Documents

Culture Documents

Nitrogen Gas Generator: 0.1 To 1000 NM /HR

Nitrogen Gas Generator: 0.1 To 1000 NM /HR

Uploaded by

barun1977Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nitrogen Gas Generator: 0.1 To 1000 NM /HR

Nitrogen Gas Generator: 0.1 To 1000 NM /HR

Uploaded by

barun1977Copyright:

Available Formats

Nitrogen Gas Generator

0.1 to 1000 Nm3/hr

Purity range 90 to 99.9997 %

How to work

The major components are a pair of Adsorbers, surge tanks, switching valves, intelligent PLC with touch screen display,

Gas analyzer and other instruments The adsorbers are filled with very high quality Carbon Molecular Sieves (CMS) preferentially

adsorb Oxygen, CO and Co2 whereas Nitrogen is not adsorbed by CMS due to its larger molecular size and lower diffusivity, passes through

the vessel to the surge tank. Based on the pre-fixed time interval the online adsorber switches to desorption mode and all contaminants

in the CMS are purged out to the atmosphere. Gas analyzer monitors the gas concentration and compares with the pre-set value and allows

the product gas to the storags tank. if gas concentration is more than the pre-set value PLC switches the vent valve and purges out the gas

till it reaches the required purity.

Exclusive Features

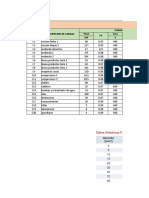

N2 Purity - Output Nm3/hr

Model

Intelligent PLC 99.99 99.95 99.9 99.5 99 98 97 95

NN 002 NA NA 1.3 2.2 3.6 4.6 5.2 6.6

aOn line purity indication NN 004 1.5 2.2 2.9 4.4 5.5 6.8 8 9.3

aUser friendly 4.3” TFT Touch screen NN 007 4 5 6 7.8 9.7 13 14.8 18.8

NN 011 6.8 7.8 8.7 11.7 14.2 17.6 20.8 26.4

aAnimated real time process display NN 014 8 9 10.4 14 16.5 21.5 23.5 30

NN 016 9.6 10.8 12.5 16.8 NA NA NA NA

aAuto cut-in & cut-off based on demand

aRS 485 MODBUS interface for remote monitoring

aInbuilt Data logger stores minimum 50 alarms/trips

aPSA cycle trip for Low Air Inlet Pressure

aAlarm for High Oxygen Content *

aHour meter supports preventive maintenance

aAnnouncement for filter cartridge replacement

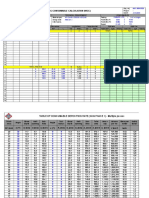

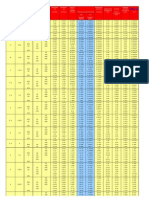

Purity N2 Output Nm3/hr

Model

99.99 99.95 99.9 99.5 99 98 97 95

NN 020 8.8 11.2 13.4 20.0 23.7 28.2 31.8 39.4

NN 035 14.8 19.6 23.3 35.0 41.5 49.2 137.1 69.1

NN 050 21.3 27.9 33.3 50.0 59.4 49.5 79.8 98.8

NN 075 33.0 41.3 48.0 75.0 94.1 113.0 136.0 166.1

NN 100 44.0 55.0 65.0 100.0 125.0 151.0 181.0 222.0

NN 150 66.0 82.0 97.0 150.0 187.1 227.2 272.0 333.0

NN 200 88.0 110.0 130.0 200.0 250.2 303.1 363.0 444.0

NN 300 132.0 165.0 195.0 300.0 375.1 453.9 545.0 666.0

NN 400 176.0 220.0 260.0 400.0 500.3 607.8 727.0 888.0

NN 550 242.0 302.0 357.0 550.0 687.5 834.2 1000.0 1222.0

NN 700 260.0 450.4 525.4 700.0 828.0 991.1 1133.0 1363.2

NN 850 319.8 548.8 640.0 850.0 1004.0 1200.2 1371.0 1651.1

NN 999 478.1 598.1 725.4 1000.0 1216.0 1492.0 1702.0 2090.0

Sub-Micron After

Filter Filter

Air Compressor Air Dryer Dry Air Tank PSA Nitrogen Generator Surge Tank Nitrogen Storage Tank

Other Product Ranges

Heatless Air Dryer No loss Split Flow Air Dryer Blower Reactivated Dryer Heat of Compression Dryer Oxygen Generator Modular Dryer Refrigeration Dryer Compressed Air Filter Auto Drain Valve

The data in this brochure are not binding, due to continuous product improvement, SUMMITS reserves the right to make changes without prior notice. For further information, contact factory

Summits Hygronics Private Limited Authorized Business Associate

Compressed Air & Gas Generation - Purification / Industrial Cooling Solutions

S.F.192, Eari Thottam, Kannampalayam, Coimbatore, TN - 641 402, INDIA

P : +91-422-2689020 F : +91-422-2682024 E : imktg@airdryer.in, www.airdryer.in

Summits Provides Customized Solutions

You might also like

- Solution Manual For Materials Selection in Mechanical Design 5th Ed - Michael AshbyDocument15 pagesSolution Manual For Materials Selection in Mechanical Design 5th Ed - Michael AshbyAfshar Arabi24% (17)

- ASME PTC 4.1 Steam GeneratorsDocument81 pagesASME PTC 4.1 Steam Generatorsbarun1977100% (5)

- Retired Model Parts Catalogue PDFDocument434 pagesRetired Model Parts Catalogue PDFbarun197750% (2)

- Daihatsu DC-32 Instruction Manual (Operation)Document105 pagesDaihatsu DC-32 Instruction Manual (Operation)Виктор Медведев100% (3)

- Control Valve Application Technology PreviewDocument20 pagesControl Valve Application Technology PreviewKatherine Fikii100% (2)

- Deutz Catalogue PDFDocument26 pagesDeutz Catalogue PDFNuno Brito Nuno100% (4)

- AC Superdrive (ACS) : DescriptionDocument2 pagesAC Superdrive (ACS) : DescriptionMamadou djibril BaNo ratings yet

- Tube Plug Method PDFDocument63 pagesTube Plug Method PDFbarun1977No ratings yet

- ManDocument154 pagesManbarun1977No ratings yet

- Tbts Parts Catalogue PDFDocument166 pagesTbts Parts Catalogue PDFbarun197767% (3)

- HUBCO Narowal Power Plant Internship ReportDocument12 pagesHUBCO Narowal Power Plant Internship ReportOmar FarooqNo ratings yet

- Psa Nitrogen Generators: Standard Product RangeDocument3 pagesPsa Nitrogen Generators: Standard Product RangeTiar_Rahman_9553No ratings yet

- CT Catalogue - FullDocument9 pagesCT Catalogue - FulldedeNo ratings yet

- Magnetic Coupling Torque Vs Air GapDocument4 pagesMagnetic Coupling Torque Vs Air GapDallie KurniawanNo ratings yet

- Philips TUV T8: Main ApplicationsDocument2 pagesPhilips TUV T8: Main ApplicationsBaskaran NarayanamoorthyNo ratings yet

- Clivet CCWG550EVD 550TR - 2 CompressorDocument7 pagesClivet CCWG550EVD 550TR - 2 CompressorniedhaNo ratings yet

- TS B3 SeriesDocument4 pagesTS B3 SeriesGuadalupe CondoriNo ratings yet

- Ficha Tecnica ZR y ZT Atlas CopcoDocument2 pagesFicha Tecnica ZR y ZT Atlas CopcogustavoorsoNo ratings yet

- extruder fo home plantDocument11 pagesextruder fo home planttiger.patelNo ratings yet

- ABB NFLP IE3-Catalogue PDFDocument12 pagesABB NFLP IE3-Catalogue PDFSabir NasimNo ratings yet

- CAT - PV - AC - 2008 - ProductsDocument79 pagesCAT - PV - AC - 2008 - ProductsHerlofNo ratings yet

- Metering Pumps: Models A and BDocument5 pagesMetering Pumps: Models A and Bbmanojkumar16No ratings yet

- Print Untuk Ujian - Mv. Arawana - Loading ManualDocument11 pagesPrint Untuk Ujian - Mv. Arawana - Loading ManualtperkapalanNo ratings yet

- Tablas de Desgaste PC200-220Document13 pagesTablas de Desgaste PC200-220Frank Felipe Cruz ChavezNo ratings yet

- Catálogo - NeoTek - High TorqueDocument4 pagesCatálogo - NeoTek - High TorqueElson BgNo ratings yet

- Siemens Motor PDFDocument1 pageSiemens Motor PDFsumitsharma2010No ratings yet

- Alloy 825Document5 pagesAlloy 825Richart ChaiyakmaneeNo ratings yet

- Nitrogen Generators Nitrogen On Wall: Series: NOW CP-211Document2 pagesNitrogen Generators Nitrogen On Wall: Series: NOW CP-211Rajendra LabadeNo ratings yet

- WCC.11031MM (Rolled Pipe)Document7 pagesWCC.11031MM (Rolled Pipe)keymal9195No ratings yet

- Informemindraydigieye 280Document10 pagesInformemindraydigieye 280noguri25No ratings yet

- Cable Selection (Multi-Core)Document1 pageCable Selection (Multi-Core)Hùng Trần XuânNo ratings yet

- Transformer Design FormulasDocument8 pagesTransformer Design Formulasvishwas raneNo ratings yet

- Calculo de Conductores E Interruptores Termomagneticos 380V, 60HzDocument7 pagesCalculo de Conductores E Interruptores Termomagneticos 380V, 60HzGUTARRA QUISPE OSCAR ALEXANDERNo ratings yet

- Siemens EexdDocument10 pagesSiemens EexdmithuntcvNo ratings yet

- Senx Technology Firstlook Pulse SensorDocument31 pagesSenx Technology Firstlook Pulse SensorAlexia GrammatikopoulouNo ratings yet

- Shively Labs: Model 6814 Super-High-Power FM Antenna Full-Wave-SpacedDocument2 pagesShively Labs: Model 6814 Super-High-Power FM Antenna Full-Wave-SpacedAditya KulkarniNo ratings yet

- Psa Nitrogen GeneratorDocument7 pagesPsa Nitrogen GeneratorFarjallahNo ratings yet

- EC 40 40 MM, Brushless, 120 Watt: Part NumbersDocument1 pageEC 40 40 MM, Brushless, 120 Watt: Part NumbersLeonardo LeoNo ratings yet

- Nied 2005 en RemovedDocument2 pagesNied 2005 en RemovednarminaNo ratings yet

- Analog Lab ReportDocument9 pagesAnalog Lab ReportGayank NegiNo ratings yet

- Data Sheet - DHDA Test PumpDocument2 pagesData Sheet - DHDA Test PumpDeepak DeepuNo ratings yet

- Bca Standards - LMZDocument15 pagesBca Standards - LMZlorenzo_zarateNo ratings yet

- Product Table JindalDocument2 pagesProduct Table JindalBRIGHT TECH INDUSTRIALS INDIA PVT LTD50% (2)

- Open Blackoil Export Table CalcDocument5 pagesOpen Blackoil Export Table Calcedwin altamiranoNo ratings yet

- Main Engine 3516C 1920 BKW 1600 RPM SpecDocument6 pagesMain Engine 3516C 1920 BKW 1600 RPM SpecCarlos Luis Esquerdo Marcano100% (1)

- Cat 6A S FTP Installation Cable 600MHZ V1901Document2 pagesCat 6A S FTP Installation Cable 600MHZ V1901Trunghieu LeNo ratings yet

- W F y Z T 2 4 4 4: Le 07/26/2020 Profilés Profiles Du 485065812.xlsx Page 1 Sur 17Document17 pagesW F y Z T 2 4 4 4: Le 07/26/2020 Profilés Profiles Du 485065812.xlsx Page 1 Sur 17Maheshwari TradersNo ratings yet

- 4723LNX - Bul-North American Evenglow LNX BulletinDocument5 pages4723LNX - Bul-North American Evenglow LNX BulletinsaravalipourNo ratings yet

- A600 SonnenscheinDocument1 pageA600 SonnenscheinDaniel SepulvedaNo ratings yet

- Full Line Brochure 7-2021Document32 pagesFull Line Brochure 7-2021PrudzNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument7 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Parker (M4 - M4S, M4D, M4SD) Hydraulic Motors, Vane Motors M4 - M4S SeriesDocument12 pagesParker (M4 - M4S, M4D, M4SD) Hydraulic Motors, Vane Motors M4 - M4S SeriesJose FonsecaNo ratings yet

- Technical Spec 3516C - 2575 BHP at 1600 RPM PDFDocument4 pagesTechnical Spec 3516C - 2575 BHP at 1600 RPM PDFiw100% (1)

- Mbr1060Ctl Schottky Rectifier: Sangdest Microelectronics Green ProductsDocument6 pagesMbr1060Ctl Schottky Rectifier: Sangdest Microelectronics Green ProductsManos MagicasNo ratings yet

- Time, Fuel and Distance To Climb: Figure 5-15Document1 pageTime, Fuel and Distance To Climb: Figure 5-15Brizzi PaulNo ratings yet

- ROUND DIFFUSER Single PageDocument9 pagesROUND DIFFUSER Single PageRaed AlmhimdNo ratings yet

- Walker Filtration Alpha Medical Vacuum Filter DatasheetDocument2 pagesWalker Filtration Alpha Medical Vacuum Filter DatasheetDHINAKARAN KumarNo ratings yet

- Technical Specifications - Three Phase MotorsDocument1 pageTechnical Specifications - Three Phase MotorsNirmal mehtaNo ratings yet

- SR20 POH Speed An FuelDocument3 pagesSR20 POH Speed An FuelBrizzi PaulNo ratings yet

- MtE325-Assignment 3Document3 pagesMtE325-Assignment 3Hacker YousafzaiNo ratings yet

- Brelata, Raffy Pastidio, Julie Ann Rabadon, John ClydeDocument32 pagesBrelata, Raffy Pastidio, Julie Ann Rabadon, John Clyderaffy brelata100% (1)

- ACS - Danaher MotionDocument2 pagesACS - Danaher MotionMamadou Djibril BaNo ratings yet

- Maxon RE16 Graphite Brushes 4.5wattDocument2 pagesMaxon RE16 Graphite Brushes 4.5wattElectromateNo ratings yet

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextFrom EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextNo ratings yet

- Service Manual Service Manual: Rb1FsDocument141 pagesService Manual Service Manual: Rb1Fsbarun1977No ratings yet

- BooksDocument2 pagesBooksbarun1977No ratings yet

- Pdi-2 (Water Hammer Arrestors) PDFDocument27 pagesPdi-2 (Water Hammer Arrestors) PDFbarun1977No ratings yet

- Nitrogen PSA Brochure US - tcm136-454333Document12 pagesNitrogen PSA Brochure US - tcm136-454333barun1977No ratings yet

- En - Ineos Bichlor ElectrolyserDocument8 pagesEn - Ineos Bichlor Electrolyserbarun1977No ratings yet

- Comparison of Hydrogen Specification in National Standards For ChinaDocument5 pagesComparison of Hydrogen Specification in National Standards For Chinabarun1977No ratings yet

- Resin TableDocument1 pageResin Tablebarun1977No ratings yet

- Hlep / Vsax: High Performance Cryogenic Reciprocating PumpsDocument4 pagesHlep / Vsax: High Performance Cryogenic Reciprocating Pumpsbarun1977No ratings yet

- Pdi-2 (Water Hammer Arrestors) PDFDocument27 pagesPdi-2 (Water Hammer Arrestors) PDFbarun1977No ratings yet

- Centrifugal - Pump - Hand Book PDFDocument150 pagesCentrifugal - Pump - Hand Book PDFbarun1977100% (1)

- User Manual PDFDocument41 pagesUser Manual PDFbarun1977No ratings yet

- Flow and Level Measurement HandbookDocument100 pagesFlow and Level Measurement Handbookmtayyab_786No ratings yet

- Royal Enfield Price ListDocument126 pagesRoyal Enfield Price Listmaniamson50% (20)

- Royal Enfield Price ListDocument126 pagesRoyal Enfield Price Listmaniamson50% (20)

- Centrifugal Pump Hand BookDocument150 pagesCentrifugal Pump Hand Bookbarun1977100% (2)

- JBL Club Speaker SpecSheet EnglishDocument3 pagesJBL Club Speaker SpecSheet Englishbarun1977No ratings yet

- Kick Start Pawl Replacement - A4Document3 pagesKick Start Pawl Replacement - A4barun1977No ratings yet

- .No. Base Form Meaning Past Form Past Participle Form S / Es/ Ies Ing' FormDocument47 pages.No. Base Form Meaning Past Form Past Participle Form S / Es/ Ies Ing' Formbarun1977No ratings yet

- Noise Measurement Procedures Manual: Second Edition July 2008Document85 pagesNoise Measurement Procedures Manual: Second Edition July 2008barun1977No ratings yet

- NGK Spark PlugDocument1 pageNGK Spark Plugbarun1977No ratings yet

- Asme PTC 1Document25 pagesAsme PTC 1barun1977No ratings yet

- 3508 SS 8769325 18377766 017 470kW 1200rpm PDFDocument6 pages3508 SS 8769325 18377766 017 470kW 1200rpm PDFayman akrabNo ratings yet

- C FIX Report0Document11 pagesC FIX Report0Ihab MohamedNo ratings yet

- Grade 7 Handouts Vector and ScalarDocument3 pagesGrade 7 Handouts Vector and ScalarLovieAlfonsoNo ratings yet

- Technical Data: Rotary Gear Limit SwitchDocument3 pagesTechnical Data: Rotary Gear Limit SwitchAntônio PimentaNo ratings yet

- Hard Shut inDocument6 pagesHard Shut inWCGNo ratings yet

- HCDP Danalyzerdan An 42 NGC An HDCP 700xaDocument4 pagesHCDP Danalyzerdan An 42 NGC An HDCP 700xakenangrok2009No ratings yet

- Vdisp - 3Document4 pagesVdisp - 3Nrl SyafiniNo ratings yet

- 10 Viscoelasticity 01 Intro PDFDocument4 pages10 Viscoelasticity 01 Intro PDFSourav SutradharNo ratings yet

- General Catalogue: Sample Preparation MachinesDocument16 pagesGeneral Catalogue: Sample Preparation Machinesfatih_hideNo ratings yet

- Dynamics of Machines and Vibrations Assignment-1: InstructionsDocument4 pagesDynamics of Machines and Vibrations Assignment-1: InstructionsParmar KevalNo ratings yet

- Article N° (KG) Article N° (KG) : Doka Wall System Large-Area Formwork Top 50Document1 pageArticle N° (KG) Article N° (KG) : Doka Wall System Large-Area Formwork Top 50Pedro Vieira PedrobecoNo ratings yet

- Static Equipment EngineerDocument5 pagesStatic Equipment EngineerSakthikumar ChandrasekaranNo ratings yet

- NP 51863Document9 pagesNP 51863Teresa CarterNo ratings yet

- Simple Machine-Draw A Circle Around The Fulcrum Class of LeverDocument4 pagesSimple Machine-Draw A Circle Around The Fulcrum Class of Levertashema rhoden100% (1)

- Shounter Volume III, Section - 4Document99 pagesShounter Volume III, Section - 4Jawad UsmaniNo ratings yet

- Activity 6 ME LABORATORYDocument7 pagesActivity 6 ME LABORATORYAlan Jade de LeonNo ratings yet

- Ineo 161 PartsDocument66 pagesIneo 161 PartslaitangNo ratings yet

- Renkmaag Synchronousclutchcouplings HsDocument4 pagesRenkmaag Synchronousclutchcouplings Hshumayun121No ratings yet

- Power Plant Instrumentation Unit 1 PDFDocument31 pagesPower Plant Instrumentation Unit 1 PDFRahul KumarNo ratings yet

- Ecoair HVLS Fans PresentationDocument10 pagesEcoair HVLS Fans PresentationSales ecoairNo ratings yet

- Review MODULE: - HYDRAULICS (Fluid Properties)Document2 pagesReview MODULE: - HYDRAULICS (Fluid Properties)I'm an EngineerNo ratings yet

- SSP 211 New BeetleDocument48 pagesSSP 211 New BeetleAlexandru CraiovanNo ratings yet

- Standard Pipe DimensionDocument3 pagesStandard Pipe DimensionprokjongNo ratings yet

- Friction Class 8 Notes - Chapter 12 Friction Class 8 Notes - Chapter 12Document11 pagesFriction Class 8 Notes - Chapter 12 Friction Class 8 Notes - Chapter 12GjzhsssNo ratings yet

- Spiral Duct Engineering - DataDocument11 pagesSpiral Duct Engineering - DatamahondeNo ratings yet