Professional Documents

Culture Documents

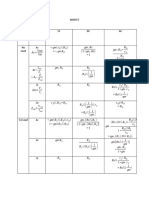

RAP RAP Totalmix % AC RAS RAS Total Mix% AC

RAP RAP Totalmix % AC RAS RAS Total Mix% AC

Uploaded by

cursostangOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RAP RAP Totalmix % AC RAS RAS Total Mix% AC

RAP RAP Totalmix % AC RAS RAS Total Mix% AC

Uploaded by

cursostangCopyright:

Available Formats

Advantages of WMA:

o Lower mix temperatures, Lower emissions

o Reduced fuel costs

o Can be placed during cooler temperatures

o The amount of RAP could be increased

Techniques for producing WMA:

o Adding a especial filler to the asphalt mixture (WAX, Zeolites, thiopave)

o Adding water to the asphalt binder (foamed)

o Adding way like material

o Adding asphalt emulsion as the binder (chemical, Waves)

Dynamic load: there is no resting always applying load

Repeated load: apply load and stop, apply and stop…

Indirect tensile test (IDT): measures the critical low temperatures cracking properties of a

mixture

Higher layer (stress control, strain is variable) thin layer (strain control, stress is variable).

The more RAP used, the stiffer the design becomes

Consensus properties:

o Coarse agg. o Sand equivalent.

o Fine agg. o Flat and elongated.

Lttpbind: selecting the climate data, and select you PG

RAP binder

RAP BR=

Total mix % AC

RAS binder

RAS BR =

Total mix % AC

T blend −(%RAP x T RAP )

T Virgin =

1−% RAP

T blend −T virgin

RAP BR=

T RAP−T Virgin

100−Pb ( RAP )

Gse (RAP)=

100 Pb ( RAP )

−

GmmRAP Gb ( RAP )

Gse( RAP)

Gsb (RAP)=

Pba ( RAP ) x Gse(RAP)

+1

100 x Gb(RAP)

You might also like

- 3 1 Seminar DR - Kasahara RAP-4 PDFDocument18 pages3 1 Seminar DR - Kasahara RAP-4 PDFAnggun PratamiNo ratings yet

- Analysis and Design of Analog Integrated Circuits Differential AmplifiersDocument17 pagesAnalysis and Design of Analog Integrated Circuits Differential AmplifiersAndrea FasatoNo ratings yet

- Ricci TensorDocument4 pagesRicci TensorJuan David MesaNo ratings yet

- FORMULA 3 - Farm Structures, Post-Processing, and ElectrificationDocument11 pagesFORMULA 3 - Farm Structures, Post-Processing, and ElectrificationBilly AgustinNo ratings yet

- Ae 201 10Document28 pagesAe 201 10Antony BalabanNo ratings yet

- Assessment Feedback (Updated 09 May 2022)Document30 pagesAssessment Feedback (Updated 09 May 2022)Kay DevchandNo ratings yet

- Michael H. Perrott (C) 2002: Open Circuit Time Constant Calculations 6.301 - Spring 2002Document2 pagesMichael H. Perrott (C) 2002: Open Circuit Time Constant Calculations 6.301 - Spring 2002Andrea FasatoNo ratings yet

- 005 - Zvijezda - TrokutDocument2 pages005 - Zvijezda - TrokutBozo BasicNo ratings yet

- Formulario Compresor Axial 2Document4 pagesFormulario Compresor Axial 2Julio Eme-ErreNo ratings yet

- MOSFETDocument3 pagesMOSFETCúc CauNo ratings yet

- JMF Density Void Analysis PDFDocument231 pagesJMF Density Void Analysis PDFujjawaldaharwalNo ratings yet

- 36buhsdpa DCRDocument1 page36buhsdpa DCRFebri RawlinsNo ratings yet

- 58Document18 pages58Rajat Verma X D 39No ratings yet

- L7-Properties of Dry GasesDocument35 pagesL7-Properties of Dry GasesRakesh SinghNo ratings yet

- Ejercicio: Enlace en Banda C: G ? G ? F ? HZ F ? HZDocument1 pageEjercicio: Enlace en Banda C: G ? G ? F ? HZ F ? HZCRISTIAN MARTINESNo ratings yet

- 36buhsdpa DCRDocument1 page36buhsdpa DCRFebri RawlinsNo ratings yet

- Standard CostingDocument3 pagesStandard CostingSatish MahatoNo ratings yet

- Log Eval. EtrlDocument36 pagesLog Eval. Etrlfaisal arifinNo ratings yet

- Two Stage AmplifierDocument23 pagesTwo Stage AmplifierDennis Michael De GuzmanNo ratings yet

- Company Name of The Component S & P Heat Exchanger Drawing No. Prepared: Design According To The ASME Code Section VIII, Div.1, Edition 2015, AddendaDocument1 pageCompany Name of The Component S & P Heat Exchanger Drawing No. Prepared: Design According To The ASME Code Section VIII, Div.1, Edition 2015, AddendaYassine SayehNo ratings yet

- Presnremeaement: AtmosphericDocument8 pagesPresnremeaement: AtmosphericShreyas PrabhuNo ratings yet

- H01 - Mole Balances - BKDocument3 pagesH01 - Mole Balances - BKhsieglerNo ratings yet

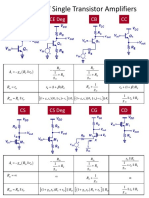

- Transistor Amplifier SummaryDocument1 pageTransistor Amplifier SummaryJhonNo ratings yet

- Simultaneous Inversion of Pre-Stack Seismic DataDocument29 pagesSimultaneous Inversion of Pre-Stack Seismic DataLeonela AguadaNo ratings yet

- 8 TxdotDocument42 pages8 TxdotOmar CarlosNo ratings yet

- Formulas 2Document1 pageFormulas 2udumariomNo ratings yet

- Lecture21-Multistage Amplifiers PDFDocument10 pagesLecture21-Multistage Amplifiers PDFkanushkaNo ratings yet

- Series-Parallel Impedance ParametersDocument14 pagesSeries-Parallel Impedance ParameterspolyykingNo ratings yet

- Emailing Chemical Kinetics (Class 12)Document12 pagesEmailing Chemical Kinetics (Class 12)Bakul ShrivastavaNo ratings yet

- Free Flash CardsDocument6 pagesFree Flash Cardsannarickard11No ratings yet

- Emailing Chemical Kinetics (Class 12)Document12 pagesEmailing Chemical Kinetics (Class 12)roceniNo ratings yet

- BJT Conf Notes 13 2Document3 pagesBJT Conf Notes 13 2rk433No ratings yet

- Algoritm of Solution Chem. Reaction Eng. (Intepretation of Batch Data) BatchDocument3 pagesAlgoritm of Solution Chem. Reaction Eng. (Intepretation of Batch Data) BatchAnonymous pm9ApyB9MpNo ratings yet

- Algoritm of Solution Chem. Reaction Eng. (Intepretation of Batch Data) BatchDocument2 pagesAlgoritm of Solution Chem. Reaction Eng. (Intepretation of Batch Data) BatchXxxNo ratings yet

- Amen Compression CheatsheetDocument2 pagesAmen Compression CheatsheetfkcuntfaceNo ratings yet

- FE 445 - Investment Analysis and Portfolio Management: Fall 2020Document20 pagesFE 445 - Investment Analysis and Portfolio Management: Fall 2020kate ngNo ratings yet

- AD8009 Part10 PDFDocument1 pageAD8009 Part10 PDFmhasansharifiNo ratings yet

- AD8009 Part10Document1 pageAD8009 Part10mhasansharifiNo ratings yet

- Report On RAP and HRRR Verification IncludingDocument5 pagesReport On RAP and HRRR Verification Includinggerntrash2No ratings yet

- Beam Design-Lrfd: Mu From StaadDocument4 pagesBeam Design-Lrfd: Mu From StaadAndrea MagtutoNo ratings yet

- Cosmo FormDocument3 pagesCosmo FormMarta BGNo ratings yet

- David Knezevic PDFDocument89 pagesDavid Knezevic PDFYuxiang WangNo ratings yet

- Hw3 SolutionsDocument3 pagesHw3 SolutionsColin ZhangNo ratings yet

- 5.60 Thermodynamics & Kinetics: Mit OpencoursewareDocument5 pages5.60 Thermodynamics & Kinetics: Mit OpencoursewarecaptainhassNo ratings yet

- Adprn4 1Document14 pagesAdprn4 1NapoletanoDokNo ratings yet

- Asphalt MQC2Document30 pagesAsphalt MQC2Wosemy SoyNo ratings yet

- EquationsDocument7 pagesEquationsJuhaina HeibaNo ratings yet

- Anisotropy Interpretation: How Rocks Get To Be Anisotropic Measurement Issues AIT-HRLA CombinationDocument25 pagesAnisotropy Interpretation: How Rocks Get To Be Anisotropic Measurement Issues AIT-HRLA CombinationIgnacio JuarezNo ratings yet

- N ( ÷eceiver) : GroundDocument6 pagesN ( ÷eceiver) : GroundMatthew ListroNo ratings yet

- AVO & InversionDocument44 pagesAVO & InversionRizkaNo ratings yet

- Analyzing Amplifier Circuits: ReadingDocument13 pagesAnalyzing Amplifier Circuits: ReadingRahul VaddepallyNo ratings yet

- Lecture17-Cascode Amplifiers PDFDocument7 pagesLecture17-Cascode Amplifiers PDFVarunKaradesaiNo ratings yet

- Lec17 Cascade AmplifiersDocument7 pagesLec17 Cascade AmplifiersJai KumarNo ratings yet

- Fully Differential Amplifiers Applications: Line Termination, Driving High-Speed Adcs, and Differential Transmission LinesDocument7 pagesFully Differential Amplifiers Applications: Line Termination, Driving High-Speed Adcs, and Differential Transmission LinespippoNo ratings yet

- Solutions - Class Notes - Lakshya NEET 2025Document24 pagesSolutions - Class Notes - Lakshya NEET 2025Dipanshu MundNo ratings yet

- Figure: Station Incremental RateDocument4 pagesFigure: Station Incremental RateArafat Hossain AkashNo ratings yet

- Compressors Efficiency Calculations5Document2 pagesCompressors Efficiency Calculations5Ahmed HassanNo ratings yet

- Lecture8a RegularizationDocument30 pagesLecture8a Regularizationmayb3todayNo ratings yet

- The Effect of Applied Pressure On Vapor Pressure:) (M, Equilibriu atDocument20 pagesThe Effect of Applied Pressure On Vapor Pressure:) (M, Equilibriu atVeliyana Londong AlloNo ratings yet

- Assignment #4Document2 pagesAssignment #4cursostangNo ratings yet

- Environmental Group ProjectDocument19 pagesEnvironmental Group ProjectcursostangNo ratings yet

- Constant Head Permeability TestDocument8 pagesConstant Head Permeability TestcursostangNo ratings yet

- Title: Average Velocity ExperimentDocument2 pagesTitle: Average Velocity ExperimentcursostangNo ratings yet

- Capitulo 2 de FisicaDocument14 pagesCapitulo 2 de FisicacursostangNo ratings yet

- Stopping Sight Distance: CE 331 Transportation EngineeringDocument6 pagesStopping Sight Distance: CE 331 Transportation EngineeringcursostangNo ratings yet

- Unidad Numero 1 de Ingles TecnicoDocument5 pagesUnidad Numero 1 de Ingles TecnicocursostangNo ratings yet