Professional Documents

Culture Documents

T Echnical Data J-B Weld: PR Oduct Descri Pti On: R E Commended F or

T Echnical Data J-B Weld: PR Oduct Descri Pti On: R E Commended F or

Uploaded by

Sylvester WafulaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T Echnical Data J-B Weld: PR Oduct Descri Pti On: R E Commended F or

T Echnical Data J-B Weld: PR Oduct Descri Pti On: R E Commended F or

Uploaded by

Sylvester WafulaCopyright:

Available Formats

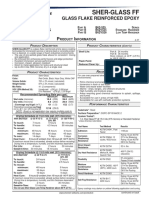

J - B WELD COMPANY Revision Date: 10/2013

P.O. BOX 483, SULPHUR SPRINGS,TEXAS 75483 Supersedes: All Previous dates

903-885-7696 • Fax: 903-885-5911 Literature Reference #: JBWTT0001

www.jbweld.com • e-mail: in Fo@ JBWELD.COM

T ECHNICAL DATA J-B Weld

PRODUCT DESCRI PTI ON: R ECOMMENDED F OR:

Bonding and filling various metals such as steel, aluminum, iron,

J-B Weld is the original “Cold Weld” copper, brass and bronze. Can also be used on non-metal surfaces

steel reinforced two part epoxy adhesive that such as concrete, most plastics, wood, tile, ceramic, fiberglass and

many others.

provides strong and lasting repairs to metal,

aluminum and multiple surfaces found in T YPICAL APPL ICATI ONS:

the automotive, household, mechanical and Can be used to repair many items including, machinery, automo-

industrial applications. tive components, tools, pipes, housings, outdoor equipment, off

road equipment, appliances, fuel tanks, furniture, fixtures and

household items.

DIR ECTI ONS:

1. Clean and Prepare surface area of all dirt, grease, oil, paint,

rust or debris.

2. Mix equal parts of the Part A Hardener and the Part B steel resin.

Be sure to mix equal parts thoroughly until color is uniform.

3. Apply with appropriate tool or spatula in an even coat,

weld bead, or extruded shape as needed.

4. Let Product Set. Product will set for 20-25 minutes and cure in

15-24 hours (depending on the environment and termperature

conditions present. Allow 4-6 hours minimum before putting

object back into use or service.

PRODUCT F EATUR ES AN D B E NE FITS:

• Superior Product Strength able to withstand significant

ITEM # 8265S ITEM # 8280 sheer loads, shock loads, and impact resistance.

PACKAGE: Carded Tubes PACKAGE: Boxed Tubes • Can be used on differing substrates and multiple surfaces

SIZE: 2 x1oz. SIZE: 2 x 5 oz. • High Heat Resistant up to 600 F intermittent temperatures

• Gasoline and Petroleum resistant

• Water Resistant when fully cured

PROPERTIES TEST METHOD RESULT • Won’t shrink or crack

• Can be tapped, filed, sanded and drilled when fully cured

Color (cured) Dark Grey

Working time (70° F) 45 min. max NOT R ECOMMENDED F OR:

Set time 4-6 hours

Polyethylene Plastic (PE), polypropylene Plastic (PPE), Nylon,

Cure time 16-24 hours and other highly flexible materials and non-porous surfaces.

Max temp (intermittent) 600° F Not recommended for under water immersion.

Max temp (continuous) 500° F

Tensile strength ASTM Cl,638 3960 psi SAF ET Y AN D PR ECAUTI ONS:

Adhesion strength ASTM D297 3960 psi

Avoid product contact with eye, skin ord clothing. Use rubber

Flexural strength ASTM D790 3960 psi gloves and eye protection. Use in an adequately ventilated area.

Compressive strength ASTM 0695 3960 psi Do not ingest. If contact with eyes occurs flush with water for

Shore D hardness ASTM 02240 85 (1wk) 10-15 minutes and seek medical attention immediately.

Shrinkage ASTM 01779 0.0% If contact with skin, wash with soap and water.

Flash Power (uncured) 7400

TECHNICAL DATA SHEET

J-B WELD

TEST ASTM RESULTS

Adhesion Strength D297 1800 psi/126.6 kg/cm2

Flexural Strength D790 7320 psi/514.7 kg/cm2

Tensile Lap Shear D1002 1040 psi/73.1 kg/cm 2 (Room Temp 25 oC Steel)

1840 psi/129.4 kg/cm 2 (3 hrs 400 oF/204oC Steel)

671 psi/42.2 kg/cm 2 (3 hrs 550 oF/288oC Steel)

1367 psi/96.1 kg/cm 2 (3 hrs 400 oF/204oC Alum)

580 psi/40.8 kg./ cm 2 (3 hrs 550 oF/288oC Alum)

Shrinkage Volumetric Change D1779 0

Deflection Temperature D648 102.5oF/39.2oC

Tensile Strength D638 3960 psi/278.4 kg/cm2

% elongation 1.7

Volume Resistivity 3.16 x 10 15 ohm cm

Surface Resistivity 9.78 x 10 15 ohm cm

Water Soak Absorption Test D470 24 hr Wgt Gain 0.07%

Mix ratio by Weight 1 to 1

Mix ratio by Volume 1 to 1

Viscosity mixed (cps) Approx. 250,000 cps

Specific Volume 1.78

Coverage per lb in sq. in 1/4” thick 65

Cured Hardness (Shore D) D224 85

TEST METHOD CHEMICAL SOLN EFFECT

Sulfuric Acid Spot Test (7 days) 20% Sulfuric Acid None

30% Sulfuric Acid None

40% Sulfuric Acid None

40-Day Immersion Test (D543-67) 20% Sulfuric Acid 5.3% Wgt Gain

30% Sulfuric Acid 5.2% Wgt Gain

40% Sulfuric Acid 4.1% Wgt Gain

You might also like

- Cooling Tower 3DTrasar ManualDocument90 pagesCooling Tower 3DTrasar ManualArevaLemaNo ratings yet

- Hi Solid PolyurethaneDocument4 pagesHi Solid PolyurethaneafvasquezNo ratings yet

- Nytro® Gemini X: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument20 pagesNytro® Gemini X: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingMambak Udin100% (1)

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahNo ratings yet

- Ceramic Repair Putty: Technical Data SheetDocument2 pagesCeramic Repair Putty: Technical Data SheetNiku SamarthNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- Titanium Putty HPDocument2 pagesTitanium Putty HPDivyanshu GuptaNo ratings yet

- WWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinDocument2 pagesWWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinVinodKandukuriNo ratings yet

- Dfense Blok™: Technical Data SheetDocument1 pageDfense Blok™: Technical Data SheetjohnNo ratings yet

- DEVCON® Fasmetal 10 HVAC Repair (Special F)Document2 pagesDEVCON® Fasmetal 10 HVAC Repair (Special F)mohamed hamedNo ratings yet

- Technical Data: Plastic Steel 5-Minute Putty (SF)Document4 pagesTechnical Data: Plastic Steel 5-Minute Putty (SF)Hoàng DũngNo ratings yet

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- Dfense Blok™: Technical Data SheetDocument1 pageDfense Blok™: Technical Data SheetjohnNo ratings yet

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthNo ratings yet

- Brushable CeramicDocument2 pagesBrushable CeramicDivyanshu GuptaNo ratings yet

- Sherglass FFDocument4 pagesSherglass FFJhose BonillaNo ratings yet

- Sikafloor - 264 EngDocument5 pagesSikafloor - 264 Engbassem kooliNo ratings yet

- Red Devil Technical SheetDocument2 pagesRed Devil Technical SheetJonathan MouzoneNo ratings yet

- HojaTecnica Heat Flex Hi Temp 1200Document4 pagesHojaTecnica Heat Flex Hi Temp 1200NANCY JASMIN MORENONo ratings yet

- Nukote Har: DescriptionDocument4 pagesNukote Har: DescriptionMarco Dos Santos NevesNo ratings yet

- Custom Fiberglass Products - Pas-Gon - Israel ExporterDocument2 pagesCustom Fiberglass Products - Pas-Gon - Israel ExporterIsrael ExporterNo ratings yet

- Plastic Steel Putty (A) : Technical Data SheetDocument3 pagesPlastic Steel Putty (A) : Technical Data SheetsanjayNo ratings yet

- Steel PuttyDocument1 pageSteel PuttySiva SubramaniNo ratings yet

- Armorseal 650 SL/RC: Armorseal Heavy Duty Floor CoatingsDocument4 pagesArmorseal 650 SL/RC: Armorseal Heavy Duty Floor CoatingsOswaldo SantoyoNo ratings yet

- PU COMPOSITE WRAP EN December 2012Document2 pagesPU COMPOSITE WRAP EN December 2012Iwan AgusNo ratings yet

- Shalipoxy Cte 303: DescriptionDocument3 pagesShalipoxy Cte 303: DescriptionV L HariNo ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- Carboguard 1207 PDSDocument4 pagesCarboguard 1207 PDSmartinbeyerNo ratings yet

- Smarter Building Systems SBS-R30 Insulating Paint InstructionsDocument5 pagesSmarter Building Systems SBS-R30 Insulating Paint InstructionsJJ Sherem MoraNo ratings yet

- Reactamine 760: Selection & Specification DataDocument4 pagesReactamine 760: Selection & Specification DataPrakashNo ratings yet

- Sealtite Sealant Butyl Tape: DescriptionDocument2 pagesSealtite Sealant Butyl Tape: DescriptionSantoshNo ratings yet

- ShaliPoxy CTE 503Document3 pagesShaliPoxy CTE 503raviteja036No ratings yet

- PO Lapox EpogroutDocument4 pagesPO Lapox Epogroutjohn paulNo ratings yet

- Sherwin Williams - Heatflex Hi-Temp 1200 DatasheetDocument4 pagesSherwin Williams - Heatflex Hi-Temp 1200 DatasheetAce AceNo ratings yet

- PO - Lapox Metalam BDocument2 pagesPO - Lapox Metalam Bcherukuri.sriramNo ratings yet

- Plastic Steel 5 Minute PuttyDocument3 pagesPlastic Steel 5 Minute PuttyDivyanshu GuptaNo ratings yet

- Nukote XT Plus TdsDocument4 pagesNukote XT Plus TdsAnsar AliNo ratings yet

- 201 Ceramic Paste Tds rv1 PDFDocument3 pages201 Ceramic Paste Tds rv1 PDFAzril DahariNo ratings yet

- ShaliPoxy CTE 103Document4 pagesShaliPoxy CTE 103Prashant BaruaNo ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- TDS - Pioneer Non Sag Epoxy - 022019Document3 pagesTDS - Pioneer Non Sag Epoxy - 022019Nancy AndriannaNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- DATA SHEET Industrial Enamel BlancoDocument4 pagesDATA SHEET Industrial Enamel BlancoAlfredo OrellanaNo ratings yet

- SC Precision Grout Product Data 2193944Document2 pagesSC Precision Grout Product Data 2193944Vajbayee elangovanNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- American Polywater Pad N PoleDocument4 pagesAmerican Polywater Pad N Polevivek jayswalNo ratings yet

- Sikadur 52Document2 pagesSikadur 52JessiNo ratings yet

- ShaliProtek PuR 100Document3 pagesShaliProtek PuR 100Rana MahatoNo ratings yet

- Urethane Coating 165 PWDocument3 pagesUrethane Coating 165 PWANIBALLOPEZVEGANo ratings yet

- Protective & Marine Coatings: Pro-Cryl Universal PrimerDocument4 pagesProtective & Marine Coatings: Pro-Cryl Universal PrimerAna CabreraNo ratings yet

- P-413 Technical Data SheetDocument5 pagesP-413 Technical Data SheetdennisjuntakNo ratings yet

- CRC Galvanizado en FrioDocument2 pagesCRC Galvanizado en Friojedd021873No ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- WBEpoxyCoating Data SheetDocument2 pagesWBEpoxyCoating Data SheetkaleshNo ratings yet

- Sikafloor®-263 SLDocument6 pagesSikafloor®-263 SLHalit Baris SertbakanNo ratings yet

- Metalset A4 TBDocument2 pagesMetalset A4 TBedgar.sanchez.urreaNo ratings yet

- Devcon Flexane-High-Performance-Putty - 15330Document2 pagesDevcon Flexane-High-Performance-Putty - 15330Yajaira ValdezNo ratings yet

- Sikadur 52: Advanced, Very-Low-Viscosity, Moisture-Tolerant Epoxy Injection AdhesiveDocument2 pagesSikadur 52: Advanced, Very-Low-Viscosity, Moisture-Tolerant Epoxy Injection Adhesivehendri sukrisnoNo ratings yet

- 1040 Stangard (ST) Epoxy MasticDocument5 pages1040 Stangard (ST) Epoxy MasticMayank Gupta50% (2)

- DS BR ACRYLIC PU CoatingDocument3 pagesDS BR ACRYLIC PU CoatingSomak DuariNo ratings yet

- Attachment 1Document3 pagesAttachment 1Sylvester WafulaNo ratings yet

- Econ Revision QuestionsDocument1 pageEcon Revision QuestionsSylvester WafulaNo ratings yet

- Economic Revision Questions1Document3 pagesEconomic Revision Questions1Sylvester WafulaNo ratings yet

- Attachment 1Document5 pagesAttachment 1Sylvester WafulaNo ratings yet

- Attachment 1Document8 pagesAttachment 1Sylvester WafulaNo ratings yet

- Attachment 1Document5 pagesAttachment 1Sylvester WafulaNo ratings yet

- Attachment 2Document5 pagesAttachment 2Sylvester WafulaNo ratings yet

- Student Design Lab Report Comparison of Different Types of WeldsDocument26 pagesStudent Design Lab Report Comparison of Different Types of WeldsSylvester WafulaNo ratings yet

- Movin LD 54Document26 pagesMovin LD 54Sylvester WafulaNo ratings yet

- AnswersDocument4 pagesAnswersSylvester WafulaNo ratings yet

- Examples On Hydraulic Jump PDFDocument3 pagesExamples On Hydraulic Jump PDFSylvester WafulaNo ratings yet

- Chapter 7 Flow Measuring Hydraulic Structures Weirs Lecture Notes and Examples PDFDocument7 pagesChapter 7 Flow Measuring Hydraulic Structures Weirs Lecture Notes and Examples PDFSylvester WafulaNo ratings yet

- Chapter 5 Hydraulic Jump Lecture Notes Original PDFDocument7 pagesChapter 5 Hydraulic Jump Lecture Notes Original PDFSylvester WafulaNo ratings yet

- Agreement and Conditions 0F C0ntracts - JBC PDFDocument74 pagesAgreement and Conditions 0F C0ntracts - JBC PDFSylvester WafulaNo ratings yet

- Dimensional Analysis PDFDocument15 pagesDimensional Analysis PDFJavier ECNo ratings yet

- Cahpter 8 Lecture 2 Dimensional Analysis PDFDocument5 pagesCahpter 8 Lecture 2 Dimensional Analysis PDFSylvester WafulaNo ratings yet

- Product Nasivion SprayDocument5 pagesProduct Nasivion SprayMueen mohsinNo ratings yet

- Demonstration On Endothermic or Exothermic Reaction (Latest) PDFDocument5 pagesDemonstration On Endothermic or Exothermic Reaction (Latest) PDFLester PioquintoNo ratings yet

- Topic SentenceDocument1 pageTopic Sentenceketian15No ratings yet

- Cebex Cable Grout PlusDocument13 pagesCebex Cable Grout PlustalatzahoorNo ratings yet

- Tbutyl Report PDFDocument20 pagesTbutyl Report PDFEhsan RahmanNo ratings yet

- Chemistry 1 Jefado March 2020-1Document7 pagesChemistry 1 Jefado March 2020-1nassorussi9No ratings yet

- Kcet PortionsDocument15 pagesKcet PortionsShashank RamakrishnanNo ratings yet

- DegassingDocument11 pagesDegassingrobin hasanNo ratings yet

- 1 - A Study Concerning Intercritical HAZ Microstructure and Toughness in ...Document10 pages1 - A Study Concerning Intercritical HAZ Microstructure and Toughness in ...Filipe RenanNo ratings yet

- ME Sci 11 - 12 Q3 0402 SGDocument13 pagesME Sci 11 - 12 Q3 0402 SGRonnaDhel RaraNo ratings yet

- Specific Gravity and Weight Per Cum of Construction MaterialsDocument2 pagesSpecific Gravity and Weight Per Cum of Construction MaterialsZERONo ratings yet

- Pro Elite Analyzer Operation Manual 4001051 Rev A PDFDocument36 pagesPro Elite Analyzer Operation Manual 4001051 Rev A PDFintermountainwaterNo ratings yet

- E 1644 Â " 98 RTE2NDQ - PDFDocument4 pagesE 1644 Â " 98 RTE2NDQ - PDFDiego MorenoNo ratings yet

- P&ID Symbol Desk Reference - Assured AutomationDocument3 pagesP&ID Symbol Desk Reference - Assured AutomationJesus N Rodriguez100% (3)

- Oligotherapy RemediesDocument9 pagesOligotherapy RemediesLuiz AlmeidaNo ratings yet

- Fluconazole - Customer - Notification - Recall Communication - LetterDocument1 pageFluconazole - Customer - Notification - Recall Communication - Lettermohammed shaffi abdul rahmanNo ratings yet

- List of SymbolsDocument11 pagesList of SymbolsKaarthic EmayNo ratings yet

- Air Microbiology 2018 - IswDocument26 pagesAir Microbiology 2018 - IswOktalia Suci AnggraeniNo ratings yet

- Y8 RespirationDocument26 pagesY8 RespirationJohan Sukweenadhi100% (3)

- QC of SuppositoriesDocument36 pagesQC of Suppositoriesroma imtiazNo ratings yet

- IR Spectra of Paracetamol and Phenacetin. 1. Theoretical and Experimental Studies 2004 Journal of Structural ChemistryDocument11 pagesIR Spectra of Paracetamol and Phenacetin. 1. Theoretical and Experimental Studies 2004 Journal of Structural ChemistryGanesh MNo ratings yet

- Fire System - Maaz AhmedDocument11 pagesFire System - Maaz AhmedMiniYumNo ratings yet

- Giant African Land SnailsDocument2 pagesGiant African Land Snailsconquester rhanmiaNo ratings yet

- 16527Document22 pages16527Jaikrishna SukumarNo ratings yet

- Module 1Document15 pagesModule 1venugopal_aeroNo ratings yet

- Energy Calculation Very Good OneDocument22 pagesEnergy Calculation Very Good Onerum43100% (1)

- Cable HMWPE - Proteccion CatodicaDocument2 pagesCable HMWPE - Proteccion CatodicaEdwin Alfaro GNo ratings yet

- RFEvaluation LPGPool Fire Heat FluxDocument44 pagesRFEvaluation LPGPool Fire Heat FluxKanchan KhetanNo ratings yet