Professional Documents

Culture Documents

HSSE Alert-MdB-MV23-003 - 2020 - ENG - Final

HSSE Alert-MdB-MV23-003 - 2020 - ENG - Final

Uploaded by

VALÉRIA PEREIRA ViannaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSSE Alert-MdB-MV23-003 - 2020 - ENG - Final

HSSE Alert-MdB-MV23-003 - 2020 - ENG - Final

Uploaded by

VALÉRIA PEREIRA ViannaCopyright:

Available Formats

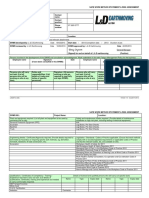

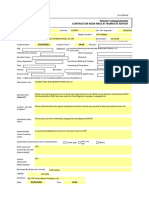

Global Operations HSSE Alert

☐ Inicial | Initial ☒ Final | Final N Alert: HSSE Alert-MdB-MV23-003/2020

Quase Acidente / Near

NOI: IE-2012-0051 Tipo de Formulário | Form Type:

Miss

Queda de Objeto /

Tipo de Incidente | Incident Type: Emitido em | Issued On: 03/31/2022

Dropped Object

Título | Title: Drop of big bag containing oily sludge within COT 2S

Descrição do evento | Description of Event

During sludge removal activities from inside the 2S cargo tank, the steel cable broke and the sludge bag fell from approximately 3,8m

height. At the time of the incident, employees were 4m away from the crash site. No injuries.

Por que isso aconteceu? | Why did it happen?

Steel cable used to lift the big bags of oily sludge from the bottom of the cargo tank was rubbed due to the angle formed in the

manhole bulkheads causing the cable to break.

Lack of risk perception by the supervisor and team - Not observed that there was friction on the cable during the lifting process.

Failure to plan / execute work safely and effectively - A lifting plan for non-routine activities was not prepared as required by

Safe Operations Guide for Cargo Handling (3500-MDB60-CLGD-0008).

Life Saving Rules (If applicable)

☐ ☐ ☐ ☐ ☐ ☐ ☒ ☒ ☐

Fotos - Informações de Apoio | Photographs - Supporting Information

O que podemos fazer para evitar? | What can we do to avoid?

Ensure the risk of hoist cable friction is considered on the Task Risk Assessment for similar works.

Ensure that a lifting plan for non-routine cargo handling is issued as per Safe Operations Guide for Moving Loads (MD60-

CLGD-0008), whenever necessary;

Evaluate the use of two manholes to remove the oily sludge from the bottom of the tank, since most of the FPSO tanks have

large dimensions and several structures which turns hard the lifting of material vertically from just one point, avoiding angling

the cable used by the electric winch;

Ensure that there is no friction point in the cable used to lift material from the bottom of the tank;

Perform daily inspections on the electric winch cable looking for anomalies and signs of damages, before use;

When issuing the TRA/PTW, ensure that the winch operator is familiar with the equipment, area and particularities of the

operation.

Informações adicionais | Additional information

Big Bag weight was 130Kg and the Cargo Handling system capacity was 400Kg, so the operation was inside the limits;

All the equipment had valid certificates.

You might also like

- Critical Lift PlanDocument10 pagesCritical Lift PlanMohammad Anwar Hossain50% (2)

- 7FA Flex Seal Upgrade - LetterDocument2 pages7FA Flex Seal Upgrade - LetterPeter_Phee_341No ratings yet

- Ga HistoryDocument11 pagesGa HistoryjoshcottNo ratings yet

- Observation StatementDocument3 pagesObservation Statementapi-241848470No ratings yet

- Bryant C. Roldan: Project Management Contractor Near-Miss at Worksite ReportDocument15 pagesBryant C. Roldan: Project Management Contractor Near-Miss at Worksite ReportAyaz AhmadNo ratings yet

- Nearmiss Report Bench Vise W #14Document15 pagesNearmiss Report Bench Vise W #14Alok SinghNo ratings yet

- Imcasf 22 19Document5 pagesImcasf 22 19Pippo TopolinoNo ratings yet

- IMCASF - May 20Document6 pagesIMCASF - May 20Shivkumar JadhavNo ratings yet

- Safeguard - January 2022Document15 pagesSafeguard - January 2022ishaqNo ratings yet

- Reynaldo Darcera: Project Management Contractor Near-Miss at Worksite ReportDocument15 pagesReynaldo Darcera: Project Management Contractor Near-Miss at Worksite ReportAyaz AhmadNo ratings yet

- Near Miss 02-02-2022Document15 pagesNear Miss 02-02-2022Zeeshan AbbasiNo ratings yet

- Nearmiss Report Uncoupling Trailer W #13Document15 pagesNearmiss Report Uncoupling Trailer W #13Alok SinghNo ratings yet

- Bryant C. Roldan: Project Management Contractor Near-Miss at Worksite ReportDocument15 pagesBryant C. Roldan: Project Management Contractor Near-Miss at Worksite ReportAyaz AhmadNo ratings yet

- Imcasf 14 20 PDFDocument6 pagesImcasf 14 20 PDFsameer hiiNo ratings yet

- Reynaldo Darcera: Project Management Contractor Near-Miss at Worksite ReportDocument15 pagesReynaldo Darcera: Project Management Contractor Near-Miss at Worksite ReportAyaz AhmadNo ratings yet

- SF 23 22Document6 pagesSF 23 22Shivkumar JadhavNo ratings yet

- Reynaldo Darcera: Project Management Contractor Near-Miss at Worksite ReportDocument15 pagesReynaldo Darcera: Project Management Contractor Near-Miss at Worksite ReportAyaz AhmadNo ratings yet

- Near Miss Report NM SIN 025Document15 pagesNear Miss Report NM SIN 025za8319712No ratings yet

- IMCASF - Dec 18Document5 pagesIMCASF - Dec 18Shivkumar JadhavNo ratings yet

- Imcasf20 18Document6 pagesImcasf20 18Era ErmerraNo ratings yet

- Chapt. 02 Risk AssessmentDocument6 pagesChapt. 02 Risk Assessmentramjmaristela17No ratings yet

- IMCASF - Jun 17Document5 pagesIMCASF - Jun 17Shivkumar JadhavNo ratings yet

- HSSE Alert-MdB-MV24-001 - 2022 - ENGDocument2 pagesHSSE Alert-MdB-MV24-001 - 2022 - ENGJane CastroNo ratings yet

- IRP 22 Hazard and Risk Assessment Register: Column Headings Column LetterDocument29 pagesIRP 22 Hazard and Risk Assessment Register: Column Headings Column LetterKhuda Buksh100% (2)

- Ship Risk Review AkoaDocument29 pagesShip Risk Review Akoatheodore akNo ratings yet

- Near Miss ReportDocument15 pagesNear Miss ReportAyaz AhmadNo ratings yet

- IMCA Safety Flash 09/19Document4 pagesIMCA Safety Flash 09/19Harman SandhuNo ratings yet

- IMCASF - Sept 16Document7 pagesIMCASF - Sept 16Shivkumar JadhavNo ratings yet

- IMCASF - Jan 18Document5 pagesIMCASF - Jan 18Shivkumar JadhavNo ratings yet

- IMCASF - Dec 17Document6 pagesIMCASF - Dec 17Shivkumar JadhavNo ratings yet

- IMCASF - Oct 17Document6 pagesIMCASF - Oct 17Shivkumar JadhavNo ratings yet

- OISDCS202223EP03Document3 pagesOISDCS202223EP03Krishna KumarNo ratings yet

- Near Miss Reporting ProcessDocument4 pagesNear Miss Reporting ProcessLoveNo ratings yet

- IMCASF - Sept 17Document4 pagesIMCASF - Sept 17Shivkumar JadhavNo ratings yet

- HSE Alert - Equipment Damage - Forklift Truck - JDE # 74807Document1 pageHSE Alert - Equipment Damage - Forklift Truck - JDE # 74807Edwin M. MolinaNo ratings yet

- Jorge Tariga: Project Management Contractor Near-Miss at Worksite ReportDocument15 pagesJorge Tariga: Project Management Contractor Near-Miss at Worksite ReportEever Paul De LeonNo ratings yet

- IMCASF - July 19Document5 pagesIMCASF - July 19Shivkumar JadhavNo ratings yet

- G-005C 016 Near Miss and Unsafe Act - Health of Life 27 Jun 2022 at SingaporeDocument2 pagesG-005C 016 Near Miss and Unsafe Act - Health of Life 27 Jun 2022 at Singaporemasterdalia48No ratings yet

- IMCASF - Jun 18Document5 pagesIMCASF - Jun 18Shivkumar JadhavNo ratings yet

- IMCASF - Jun 18Document4 pagesIMCASF - Jun 18Shivkumar JadhavNo ratings yet

- Doug Ingram: General ManagerDocument14 pagesDoug Ingram: General ManagerArshad Rashid ShahNo ratings yet

- IMCA Safety Flash 19/20: 1 Fall From A Height Into A Ballast TankDocument6 pagesIMCA Safety Flash 19/20: 1 Fall From A Height Into A Ballast TankGianluca PiccinettiNo ratings yet

- Unsafe Act Unsafe Condition (UAUC)Document4 pagesUnsafe Act Unsafe Condition (UAUC)Noryati Abdullah100% (5)

- Maibsafetydigest 12011 PDFDocument70 pagesMaibsafetydigest 12011 PDFkahl983No ratings yet

- Chennai Radha Engineering Works (P) LTD.: Near Miss / Incident Report & Investigation FormDocument2 pagesChennai Radha Engineering Works (P) LTD.: Near Miss / Incident Report & Investigation FormsamNo ratings yet

- Mohammed Mustafa: Project Management Contractor Near-Miss at Worksite ReportDocument15 pagesMohammed Mustafa: Project Management Contractor Near-Miss at Worksite ReportUsman RajputNo ratings yet

- IMCASF - Nov 16Document7 pagesIMCASF - Nov 16Shivkumar JadhavNo ratings yet

- Safety Digest 3-07 PDFDocument70 pagesSafety Digest 3-07 PDFkahl983No ratings yet

- SF-10-24Document7 pagesSF-10-24Shivkumar JadhavNo ratings yet

- Third Party Equipment ChecklistDocument5 pagesThird Party Equipment ChecklistMARIO LEALNo ratings yet

- H-Line - Pre-Departure Orientation SeminarDocument39 pagesH-Line - Pre-Departure Orientation SeminarFrankrisna Kusuma HendraNo ratings yet

- IMCASF - Sept 20Document6 pagesIMCASF - Sept 20Shivkumar JadhavNo ratings yet

- IMCASF - Jan 18Document5 pagesIMCASF - Jan 18Shivkumar JadhavNo ratings yet

- Ittc 75-02-07-023Document13 pagesIttc 75-02-07-023Muhammad MohsinNo ratings yet

- Mumbai High North Disaster Summary - 27 July 2005 - UnlockedDocument1 pageMumbai High North Disaster Summary - 27 July 2005 - UnlockedSimon TounsiNo ratings yet

- S200 Acifm MNT 30 RPT XXXXXXX 04123Document3 pagesS200 Acifm MNT 30 RPT XXXXXXX 04123fayasibrahimkuttyNo ratings yet

- HiLo Campaign Q3-2021Document6 pagesHiLo Campaign Q3-2021Spider SpiderNo ratings yet

- Sandline Flagging Operation Results in FatalityDocument2 pagesSandline Flagging Operation Results in FatalityReda AL-mesbahNo ratings yet

- IMCASF - Feb 19Document6 pagesIMCASF - Feb 19Shivkumar JadhavNo ratings yet

- Rahul Ap: Project Management Contractor Near-Miss at Worksite ReportDocument15 pagesRahul Ap: Project Management Contractor Near-Miss at Worksite ReportEever Paul De LeonNo ratings yet

- IMCASF - Aug 19Document6 pagesIMCASF - Aug 19Shivkumar JadhavNo ratings yet

- Critical Risks of Different Economic Sectors: Based on the Analysis of More Than 500 Incidents, Accidents and DisastersFrom EverandCritical Risks of Different Economic Sectors: Based on the Analysis of More Than 500 Incidents, Accidents and DisastersNo ratings yet

- Shaping Safety Culture Through Safety Leadership: OGP Report No. 452Document38 pagesShaping Safety Culture Through Safety Leadership: OGP Report No. 452VALÉRIA PEREIRA ViannaNo ratings yet

- Diorgenes M Rocha: Aes Union Do Brasil S.A. Fit Test Result ReportDocument2 pagesDiorgenes M Rocha: Aes Union Do Brasil S.A. Fit Test Result ReportVALÉRIA PEREIRA ViannaNo ratings yet

- PL SDB HR HLT 001 P Política de Álcool e Drogas (1 55)Document7 pagesPL SDB HR HLT 001 P Política de Álcool e Drogas (1 55)VALÉRIA PEREIRA ViannaNo ratings yet

- Leonardo N Balbino: Aes Union Do Brasil S.A. Fit Test Result ReportDocument2 pagesLeonardo N Balbino: Aes Union Do Brasil S.A. Fit Test Result ReportVALÉRIA PEREIRA ViannaNo ratings yet

- Alexsander S Brauna: Aes Union Do Brasil S.A. Fit Test Result ReportDocument2 pagesAlexsander S Brauna: Aes Union Do Brasil S.A. Fit Test Result ReportVALÉRIA PEREIRA ViannaNo ratings yet

- Lorran S Silva: Aes Union Do Brasil S.A. Fit Test Result ReportDocument2 pagesLorran S Silva: Aes Union Do Brasil S.A. Fit Test Result ReportVALÉRIA PEREIRA ViannaNo ratings yet

- PPR - Programa de Proteção Respiratória (1-80)Document7 pagesPPR - Programa de Proteção Respiratória (1-80)VALÉRIA PEREIRA ViannaNo ratings yet

- Robson R Souza: Aes Union Do Brasil S.A. Fit Test Result ReportDocument2 pagesRobson R Souza: Aes Union Do Brasil S.A. Fit Test Result ReportVALÉRIA PEREIRA ViannaNo ratings yet

- Test - Environmental Eng. - DRAFTDocument7 pagesTest - Environmental Eng. - DRAFTDesire IsaiahNo ratings yet

- Describing The Impact of Massive Open Online Course: Darielle Apilas-Bacayan Developer LessonDocument5 pagesDescribing The Impact of Massive Open Online Course: Darielle Apilas-Bacayan Developer LessonJhunel FernandezNo ratings yet

- Twelve Principles SMC2017 2Document65 pagesTwelve Principles SMC2017 2Fadel PratamaNo ratings yet

- Introduction To Proof in AnalysisDocument113 pagesIntroduction To Proof in AnalysisAndreas DewantoNo ratings yet

- Fariha (MGT 212)Document11 pagesFariha (MGT 212)Rabib AhmedNo ratings yet

- Operator'S Manual: FANUC FAST Ethernet FANUC FAST Data ServerDocument240 pagesOperator'S Manual: FANUC FAST Ethernet FANUC FAST Data ServerSergio Trujillo CerroNo ratings yet

- Presentation Geotextile (November 2010)Document22 pagesPresentation Geotextile (November 2010)Gizachew ZelekeNo ratings yet

- Week7Advanced Materials Electronic MaterialsDocument16 pagesWeek7Advanced Materials Electronic Materialsmarlon corpuzNo ratings yet

- Comm 10Document2 pagesComm 10boopNo ratings yet

- Writing A Narrative EssayDocument6 pagesWriting A Narrative EssayBob BolNo ratings yet

- Chapter 6 - ImplementationDocument8 pagesChapter 6 - ImplementationtadiwaNo ratings yet

- National Career Assessment ExaminationDocument1 pageNational Career Assessment ExaminationHomo Ma. PaulaNo ratings yet

- Sep2 Meterview: Energy Measurement and ManagementDocument2 pagesSep2 Meterview: Energy Measurement and ManagementAdil HameedNo ratings yet

- Git TaskDocument2 pagesGit TaskLissa JacksonNo ratings yet

- An Overview of Function Point AnalysisDocument6 pagesAn Overview of Function Point AnalysisavinashnNo ratings yet

- Physics 2018 Prelims NYJC Paper 2Document19 pagesPhysics 2018 Prelims NYJC Paper 2NG KAI EE EMMANUELLE NG KAI EE EMMANUELLENo ratings yet

- IJCRT2006540Document4 pagesIJCRT2006540Bhushan BhoyeNo ratings yet

- Audit Non Conformance ReportDocument4 pagesAudit Non Conformance Reportbudi_alamsyah100% (2)

- Types of TournamentDocument22 pagesTypes of TournamentROSALYNN MATANo ratings yet

- Study of Investment Planing Among Working Womens PDFDocument113 pagesStudy of Investment Planing Among Working Womens PDFAjay S PatilNo ratings yet

- 5013Document3 pages5013glennfreyolaNo ratings yet

- Nippon SteelDocument7 pagesNippon SteelAnonymous 9PIxHy13No ratings yet

- Information Systems For Healthcare Management Eighth Edition 8Th Edition Full ChapterDocument41 pagesInformation Systems For Healthcare Management Eighth Edition 8Th Edition Full Chapterarnold.kluge705100% (24)

- Exercise 6 Make An Incident Report and Conduct An InvestigationDocument5 pagesExercise 6 Make An Incident Report and Conduct An InvestigationRoxana BaltatescuNo ratings yet

- Cma Part 1 Mock 2Document44 pagesCma Part 1 Mock 2armaghan175% (8)

- Welc OME..Document26 pagesWelc OME..Priya RamNo ratings yet

- Kautilya Arthashastra and Its Relevance To Urban Planning StudiesDocument9 pagesKautilya Arthashastra and Its Relevance To Urban Planning Studies4gouthamNo ratings yet