Professional Documents

Culture Documents

Elevator Control

Elevator Control

Uploaded by

Beltran Héctor0 ratings0% found this document useful (0 votes)

111 views31 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

111 views31 pagesElevator Control

Elevator Control

Uploaded by

Beltran HéctorCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 31

i ELEVATOR

. CONTROLS

; CORPORATION

+ 3525 LaGrande Blvd, Sacramento, CA 95823

(916) 428-1708 — (916) 428-1728 Fax

; MODEL V800/H800-P3

INTROLLER

sa

MANUAL FOR FIELD RE-PROGRAMMING

AND USE OF ON-BOARD DIAGNOSTICS.

© 1994 Flevator Controls Corporation

Rev 1/97

\

All information contained hercin is confidential and is proprietary to Elevator Controls Corporation and

4 is not to be used or reproduced without prior written consent of Elevator Controls.

Hains.

F + 3097 ttouveado

ane ash Nn

uD E10}

== =a, a

Ee a

So i oe

= HA Ee Olle ee mer tate

te eee : = ee Oe es

[ees [rao [ae oer

090 [Pier [for |Peres| ag sae

eee of a Fier feEeH

ie 3a Hee} Sa

eee te eee Egg tiers ea ae

= a eee aan arma |— S|

ee | Eee tiee East ies

oS, Tf ee ua [ze ye ia EE

2 Ee eS eee

se z bye bie eat ee

ats aca —[-esy— ted | et ee Ere

gees ae oT a ae

Seas Ba ae (san| eee

Csi setae i ee

Si - 2 @' 8 © 0 © B ga

yaa SNISM SVs ANOHSH Meee

AONTUGAY ONINVADOMa 8d—od [

_ STOMLNOD YOLVATTE

Table Of Contents

Introduction .*..... wi ts ss

Section I Re Programming Using the On-Board Dignostics

Selecting the Elevator Status Display

Selecting the User Display

Changing a User Display Menu

Direct Access User Display .

Serial EEPROM

Set Clock Time .

A: FaultLog .

B: Fault Log .

System Timers 2.0... ee

System Variables,

A: System Control...

B

A: Stopping Table ..

B: Stopping Table

Security Coding ......

A: Mem Flags List .

B: Mem Flags List .

A: Elevator Timers ...

stem Control.

B: Elevator Timers .

A: Alt Call Scheme

B; Alt Call Scheme

Password Access ..... .

Appendix A- Working with Hexadecimal Numbers

Converting Hexadecimal Numbers .

Changing Hexadecimal Numbers .

Appendix B- Using Direct Access for Viewing System Flags ..

«Page |

. Page 2

«Page 3

» Page 4

Page 5

. Page 6

«Page 6

«Page 6

Page 7

. Page?

- Pages

- Pages

Page 11

-- Page 12

. Page 13

- Page 14

Page 16

» Page 16

Page 28

++ Page 20

-.Page 22

Page 22,

Page 22,

. Page 22

Page 23

Page 23

Page 24

. Page 25

troduction

‘Throughout this manual certain areas of text will be accentuated with labels as shown below.

‘These labels represent safety wamings, cautions, and interest areas. The labels are explained below:

WARNING This label denotes operating procedures and practices that may

result in personal injury and/or equipment damage if not followed

correctly.

altention

in order to avoid ‘equipment damage. This includes special

adjustments to controller parts that are important for correct

‘operation

Note This label is used to bring attention to areas of special interest

within the text, as well as useful and informative procedures.

Throughout this instruction manual, it is assumed that the field personnel doing the

reprogramming has experience dealing with microprocessor reprogramming. This manual should be

read in its entirety before any actions are taken, in order to familiarize yourself with the operation of the

processor and the controller.

Note The car A/B switch on computer board does not necesarily indicate

machine room cars A/B, unless one computer is used to control two

cars(older systems). Otherwise, car A on computer board refers to

car under "this" computer's control. Ignore all "B: ..." menus keep

car A/B switch in Car A position.

Note Part # MPC-P8._-P7 does not contain a 24 hour time clock. The

information about the "Time Clock" in this manual do not apply to

MPC-P8 -P7. Also, it does not drive the IBM-PC port, and it is not

used with group systems.

Page 1

Section I

RE-PROGRAMMING USING

THE ON-BOARD DIAGNOSTICS

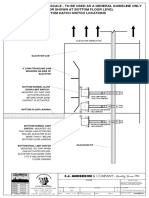

The P8 microprocessor (MPC) board is pictured below. ‘The reprogramming and diagnostic

controls are located on the bottom right-hand side of the P8-MPC. ‘The liquid crystal display (LCD) is

also used by tie on-board diagnostics. The LCD is located at the top center of the P8-MPC board.

rouuiy saanute

DIP Switches Push Buttons

Diagnostic Controls

Elevator Controls P8 Microprocessor Board Layout

WARNING Do not depress the reset buiton (labeled RESET) on the board

{ while elevator is in operation as it will cause the car to come

| to an immediate stop.

‘The four DIP switches and four push buttoas make up the diagnostic controls. The name and function of

cach control is summarized in a table on the next page. The buttons listed in the table from top to bottom

correspond to the buttons on the P8 going from left to right. ‘The name of each button on the left column of the

table corresponds to the labels on the PS board and to the labels on the drawing above. For more information on

the function of each button, please refer to the sections later ia this chapter.

Page 2

Push Button Functions

Button Name Button Function

ON/OFF DIP switch Selects between elevator stains and user display

‘ADB DIP switch Selects between car A and car B for a single computer

duplex system.

MENU/SUB DIP switch Selects menu or sub-menu display in the user display |

VIEW/EDIT DIP switch Selects view parameter or edit (change) parameter in the |

user display, |

UP push but Selects the next menu or |

DOWN push button clects the previous menu or sub-menu in the user display. _ |

‘SHIFT push button Selects the next parameter or digit in the edit (change) |

parameter mode in the user display. |

WR (WRITE) push button Saves the changed parameter permanently on the edit

(change) parameter mode in the user display.

Selecting the Elevator Status Display

Move the ON/OFF DIP owitch to the OFF position. The Elevator Status display is now selected and the

LCD will display up to four of the following messages. The LED's display the highest priority code below:

2000 BGO ee saci

8888 2888 '& {kee to see us iin sont ae soe mae ON A MENU VIEW

8650 coe os: beeeusirED Fs. or aorTow OF ms

36800800 ot | RenmuanaD Fi oven Sa FuoaRs

8380 SRee oS | RELAY eves ison barcsrms At ennon A gy g y

8888 $080 a. Exrmguane woraa. coNorHON OFF B SUB EDIT.

0630 8080 oo | EARTHQUAKE AsnemuAi Conotton

‘Sop0 soo oe sont sea a apn on at Sit Dior TOE

800 8800 So | Saya sre cnt a ova w tam

bene amen os | amRTEORNT SERVICE

0000 #880" or | Sur oF sunvicr Tar ELAPSED

86599000 9 : teivr ros oi cat

Geos couw ix | Lose OF HAL Cal. coMDWON (x0 40 BUS)

0080 S868 aF : Tor SLWEOM! LNUTS VIRED BACEWORDS.

Inno seem cr | sorreat StowOCWN LAUES WIRED BxckVARDS.

Sc08 Ooe8 17: tenants DoW

0 Geee 2 : Leveune oP

Gove eee a7 inreuNG ZONE w/uo OFF

Gcoe coco is | ke ueveue sone 4

Beso Oeco+as | UerOR INET THER LOY elk Glvaeo)

Mores St Traction)

ewe cagc 9s | MING To RE LEVEE w/G OFF £

8688 088% fa | Excaim stuck iN TY! em BLOWN MER RELAY DANER \

begeoeoe ia | ExecuTINe mann GroeneN Bue ro biseareNex cos

Bese eseo 13 | soo omvmn noun

= Bienie cece Gs | meabaun bo MetmcTiow (GAD PROGRIM CH)

Benggoce 49 | Serumry srenrs

88008980 12 | hoseeromer & SECURITY.

Bec Geee is | PasGvorD tay exes

9038 $008 ie | ene a cur or ore

feeococd 0 | cxx s on wesmiral DeRsENcr

Seo coos 21: cats oo Hesprrar evensecr

Segoeeeo & = RENIRICr rove

ceo ans= at | doone wnuacia Ge-pE VALUE. tor to ssTK 29c8) {

_ cee sere be | bonne UNockeD (XaPL VALUE. Lend To 22D DOS) 1

P8009 nex Gt some 97 We above but DLA elppea-epen et alzn spree |

S869 rece | Sune ar EX above, but SLE eppea open ct nigh spect

= Page 3

The left hand column of the table above gives the LED codes for each error display. These codes

are generally only useful if there is no LCD installed on your system; the LCD messages provide the

same information.

‘The Elevator Status display will also display the car position (floor number) and date and time

for the current job.

Selecting the User Display

To select the User Display, move the ON/OFF switch to the ON position. Move the

MENU/SUB DIP switch to the MENU position. Finally, move the VIEW/EDIT switch to the VIEW

position.

‘The User Display has twenty options that you can select from, given below. ‘The exact function

of each of the menu items is explained on the following pages. Each menu works in the same way,

however. Use the UP and DN (DOWN) push buttons to select the menu item from the list below. When

the menu item you want is displayed, move the MENU/SUB DIP switch to the SUB position. The LCD

will then show the sub-menu for that User Display menu.

User Display Menus

Direct Access System Control | A:Mem Flag List

Serial EEPROM System Control B:Mem Flag List

Set Time Clock* “Elevator Timers | A:Alt Call Scheme

‘AFault Log B:Elevator Timers B:Alt Call Scheme

B:Fault Log _ Stopping Table __| Password Access

System Timers _ Table

System Variables Security Coding

ON A MENU VIEW UP DN

sees) CO

OFF B SUB EDIT

Set the DIP switches as shown and use the UP and DN push buttons to select

the User Display menu you want.

ON A MENU VIEW

waa Si]

OFF B SUB EDIT

2. Then move the MENU/SUB DIP switch to the SUB position. The LCD

will then show the sub-menu for that User Display menu.

Page 4

Changing a User Display Menu Parameter

Once you have selected a user display item, you have the option of changing its value. You

might do this, for example, to increase or decrease the door limit time; or to change the recall floor for

fire operation. For any User Display menu, follow this procedure.

First, select the User Display item to change, as described on the previous page. Then move the

VIEW/EDIT DIP switch to the EDIT position. The bottom linc of the LCD will change; 'New-XX' will

appear where XX is the current value of the User Display parameter.

Next, use the UP and DN (DOWN) push buitons to change the value. Use the SHIFT push

button to switch to the next digit, When you have the value you want press the WR (WRITE) push

button to record the new value permanently. Move the VIEW/EDIT DIP switch back to the VIEW

position.

Caution Write down the value of the parameter before you begin changing

it. If you make a mistake, you can always testore the old value

If you realize you made a mistake, DON'T PRESS THE WR

BUTTON. Instead, skip that step and move the VIEW/EDIT DIP

switch to the VIEW position. The old value will automatically be

restored,

ON A MENU VIEW DN SHIFT

ssza) O00

B SUB EDIT

Set the DIP switches as shown to change a User Display parameter. Use the UP, DN

and SHIFT push buttons to change the value of the prameter.

WR

L

2, Press the WR (WRITE) push button to record your changes permanently. Or

skip this step if you decided that you don’t want to record your changes permanently.

ON A MENU VIEW

WA SI

OFF =B SUB EDIT

3. Move the DIP switches back to the positon shown. Or to select another User

Display sub-menu, start over again as described on the previous page.

Page S

Direct Access User Display

The Direct Access User Display menu bypasses many of the other menus. Use this menu when

directed by Elevator Controls' technical support. For those familiar with EC's MPC-P7 computer boards,

you can reprogram the MPC-PS in a similar “address/data” fashion as done with the -P7 switehgear. The

reprogramming address conversions are: (P7) £400's = FCO0s (P8), and (P7) E700's = FFO0's (P8). To

view "Memory Flags, inputs/outputs" using direct access, refer to "Memory Flag Listing" table

Normally, you will use one of the other User Display menus:

‘To change system programming, use the SYSTEM VARIABLES User Display menu

‘To change system /O programming, use A: SYSTEM CONTROL User Display menu.

To change car and door timers, use A: ELEVATOR TIMERS User Display menu.

To view computer inputs, use A: MEM FLAGS LIST User Display menu.

‘To change car stopping table, use A: STOPPING TABLE User Displey menu,

Serial EEPROM

‘The Serial EEPROM User Display bypasses many of the other menus. Use this menu when

directed by Elevator Controls! technical support.

Normally, you will use one of the other User Display mem

‘To change system programming, use the SYSTEM VARIABLES User Display menu.

To change system I/O programming, use A: SYSTEM CONTROL User Display menu. *

‘To change car and door timers, usc A: ELEVATOR TIMERS User Display menu.

To view computer inputs, use A: MEM FLAGS LIST User Display menu.

‘To change car stopping table, use A: STOPPING TABLE User Display menu.

Set Clock Time (not available on part # MPC-P8 -P7)

Use the Set Clock Time User Display to change your date and time display. The table on the

next page lists all of the options available with the Set Clock Time menu. Use the UP and DN (DOWN)

push buttons to select which of the date and time options to view.

If you need to change the system date or time, select the parameter as described above, then

follow the instructions on page 5.

Page 6

Set Time Clock Parameters

Parameter Function _— _ _

Seconds Sets the current second for the system clock.

Minutes ~[ Sets the current minute for the system clock.

Hours ‘Sets the current hour for the system clock, The clock uses military

he _time. 00 hour is midnight to TAM, 13 hour is 1PM.

Day “Sets the current day of the week. Days are set numerically as

follows. 0! = Sunday, 02=Monday, 03=Tuesday, 04=Wednessday,

7 = 05~Thursday, 06=Friday and 07 ~Saturday

Date “Sets the current day of the month,

Month | Seis the current month of the year

Year Sets the current year since 1900. Only two digits are allowed; 05

equals 1995 7 -

[ Control Fault log control. Should be0.* gf _—

| Halfdone Fault log control. Should be 00 or 80." 7 -

“Fault-Ptr Fault log control. Should be between 00 and 06. *

* ifany of the fault

og, ata proetas arenot Within he Taanes Giver above, allof |

these parameters must be reset to 00,

A: Fault Log List

‘The Fault Log List is

B: Fault Log List

‘The Fault Log List is

B: Fault Logs are intended for compatibility with older systems. Do not use this display unless

you are instructed to do so ay Elevator Controls technical support.

‘ault Log

1 M/S UPDN

aot available on this model

L=01 W/S UP DN

not available on this model.

Page 7

System Timers

Use System Timer to access the Security Code Sequence. See Security Coding later in this

manual for a complete description of the security system.

To access other timers, use the A: ELEVATOR TIMERS User Display sub-menu. If you need to

change the Security Code Sequence Timer, follow the directions on page 5.

System Variables |

1-33 M/S UP DN

The System Variables represent a variety of options. ‘The chart below summaries the function

and programming options of each. To select an option, select the System Variables User Display as

described on page 4. ‘Then use the UP and DN (DOWN) push buttons to sclect one of the options below.

To change an option, follow the procedure above. ‘Then use the procedurs on page 5 to change

the value of the option. Some of the options should not ever be changed unless directed to by

technical support staff. These option will change the configuration of your /O and will require some

rewiring. These options are marked with a}.

System Variables

F SYSTEM VARIABLES a

| Variable Option Name _| Deseription a_i

LCD Display Raie Controls system LCD seroll rate. Normally set 10 5.

| RL/EQS/ PL Factory set . Normally 0 for none. Do not change.

BIA Stop’ No longer used. - —

BTA Threshold No longer used. ——

ETA Run Time [Nolongerused.

Swap PI Option 2 + Factory set. Normally FF for none. D

Misc. Options + Use 43 for tractions and CA hydros; 4B for other hydros.

63 for INT-10-5 boards. Factory set. Do not change. +

| Misc. Opontions 2 + Factory set. Normally 08. Do not change.*

Park Pref Option * Normally 00 for off. 80 if car A is preferred free. CO if car

Bis profiered free. *

Alt Parking floort Factory set. Normally FF. This is not same as upper

a parking

PASSI Password data. Use the PASSWORD ACCESS User

PASS2 Display

NPO Factory set timer. Do not change.

Page 8

Serial Duplex

SD1 Option (PVF)

Reserved.

Reserved

Reserved

Lobby floor number. ¢ @

Sid. Fire RinExh 77 0

"Lower Parking Floor Ff

Upper Parking Floor_F #

Excess Call Can,

(Old) Simpl/Dup.*

Car Stop SW Bypass

Rot MG Start Opt

Door Lock Gong

tt

Factory set. Normally 0.

Factory set. Normally 0.

00 = Simplex. 03 = Master car. 01 = "slave" car.

00 = Off. 01

Set to the floor number, minus one, of the lobby.

Set to EX, where X is the floor number, minus one, of the

in fire recall floor.

e: to floor number, minus one, of the main parking floor.

Set to the floor number, minus one, of 2nd parking floor.

Set to 82 to cancel car calls after 2 floors of no activity on

| the photo-eye. Set to 04 to cancel calls after 4 if the light

[oad weight switch is active. .

Set to 00 for simplexes and serial duplex systems. Set to

01 for old single computcr duplex system. *

Normally 00 for ANSI fire service. Sct to 40 to ‘bypass ca car

| stop switch immediately during door close on fire phase 1.

Normally 00, Set to 01 to start MG sets one at a time on

duplexes and groups.

Normally 00. Set to 80 to delay gongs until the door lock

breaks (for jobs w/o hall gongs),

Set to EX, where X is the floor number, minus one, of the

secondary | fire recall floor.

Safety Edge Qual Normaliy 01 for ANSI, this ignores the safety edge input

i on fire phase 2, Set to 00 to enable safety edge.

Rear Door Option t+ Set 10 00 for front only or staggered rear doors. Set to 41

for selective rear doors. + 7

Bth Door Lob Rtn Normally 00. Set to 02 to open both front and rear doors at

the lobby. : ee _

Car Call Disconn Normally 00. Set to 01 if car call buttons do NOT shorten

FY oo

door limit time, Set to 02 if hall call, SE or PHE shorten

door time. Set to 20 to use lobby door limit time at the

designated lobby.

Normally 00. Sct to O1 if the system has emergeney power

generators and appropriate system operation.

Dbl Ding - 10=DN

Pass Fir Ding Opt

Normally 10 which generates two gong pulses for down

travel. Set to 00 to gencrated one pulse for gongs which

generated two on their own.

Normally 00; PGO is used for a floor passing chime. Set to

01 for a single pulse on car gongs as car passes each floor.

Page 9

Wild Op ifn 50 F Normally 00. Set to 10 to use Wild Operation if 50 bus,

(hall riser supply) looses power. t

CCD on Reversal Normally 00. Set to 80 for group systems.

_CCD, Siwdn & Ind Normally 00. Set to 80 for group systems.

Fire: Chicago Opt Normally 00. Set to FF to select fire operation for the city

Set to 4 to select HCRO on the /O. Set to 00 to remove

| HCRO on the HO. +

‘Door Enab: Nudging Normally set to 20 which allows the door open button to

re-open doors in nudging mode. Set to 00 to disable DOB

in nudging mode.

Pee

Door Lk Dir Pref [Normally 00. Set to 80 to cancel disection preference

| (UPD and DPD) with DLK instead of DCF. (Do this if

support staff) eee

+”, | Normally 00, Set to FF to bypass the car stop switch on

fire phase 2 mode.

"Hall Call Rej Op +

“[ Normally 00. Set to FF for old New York fire e phase 2,

Normally 00. Set to FF to ignore safety edge during

= nudging. a = _

‘SE Qualif: Phase 2 Normally 00. Set to FF for photo-eletric SEs, these must

be bypassed in phase 2. 7

N.Y. Const Pressure Normally 00. Set to FF for New York style momentary

| pressure to close doors on fire phase 2.

Stat Bit Mask These two options are described under SECURITY

CODING later in this manual,

Set to C8 for ANSI fire with E.C. fire module; use E8 for

ANSI fire without a fire module. Set to C8 for N.Y. fire

service. Set to 08 for California and Chicago fire service.

Set to D8 for Canada fire service.

* These options are for single computer duplex systems only. This type of system is

obsolete and the options should be left in their normal or default state unless you are

refitting an existing job.

+ These options will cause your wiring hookup terminals to change. Elevator Controls

Corporation support staff will need to assist you in rewiring your system if you change one

of these options.

Page 10

‘System Control

Use A: System Control to view or change system parameters for a simplex, serial duplex or

group system. Follow the instructions on page 4 to access A: System Control. ‘Then use the UP and the

DN (DOWN) push buttons to select the parameter you want {rom the table below. If you want to change

the parameter, continue to follow the instructions on page 5.

Like some other the parameters above, many of these parameters will change the /O

configuration of the controller, These parameters are marked with a. Do not change these parameters

without contacting B.C. support staff for assistance.

fem Control

Bottom Fleer No. Nommally 00. Increase this value to star. the PI

outputs for duplex or group jobs with different bottom

floor levels.

No. Floor escoacss|

Hi Speed Step Op Nonmally 00, Set to 20 on jobs that require slowdown

distances greater than the floor height.

Set to number of floors on job, minus one.

Hydro? 0O-NFF=Y [Normally 00 for tmction jobs. Set to FF for

hydro-electric systems.

Fr Ctr GF _|Setto the number of front car call inputs.

Car Call Rr Ctr Set to the number of rear car call inputs in a selective

fiontrear door system.

“Number of PI's GA _|Setto the number of PI outputs on the system,

Total No. Outputs _| Normally set to FF.

‘Tot Up Calls Et_0°?_ | Setto the number of front up hall ca

‘Tot Dn Calls Fr_Q°)_ | Setto the number of front down hall calls.

Tot Up Calls Rr sal

Set to the number of rear up hall calls inputs in a

O° | selective frontirear door system.

TotDn Calls Rr ¢ | Set to the number of rear down hall calls inputs in a

selective frontrear door system.

No of Hosp Inputs | Normally 00. Actually the number of 400 series

‘hospital outputs in a systert with hospital operation.

Page 11 1

INAOP|+ 7% | A hex number with seven options. See appendix A

1 O}} | for complete information on hex numbers. The hex

| number is:

2 i M: X ATT UCR DCR; Li: CCR UCF DCF CCF

8 Descriptions:

3 CCE- Set to I to enable Car Call input ¢

+ ( DCF- Set to 1 to enable Down Call input +

| UCE: Set to 1 to enable Up Call input +

| CCR- Set to I to enable Rear Car Call input +

DCR- Set to 1 to enable Rear Down Call input 7

UCR- Setto 1 to enable Rear Up Call input

ATT- Set to 1 to enable Attendant inputs & outputs +

X- Unused. Set to 0.

INAOP2 + | Factory set. Do not change. +

TNAOP3 + Eactory set. Do not change.

INAOP4 + et ee

Nudging? 10= Yes} | Normally 00. Set to 10 on when the door operator has

nudging. +

Do not cha

Reserved

jekeseryete ee a2 ae

+ These options will cause your wiring hookup terminals to change. E.C.

support staff will need to assist you in rewiring your system if you change one of

these options. Record current values before changing.

B: System Control

00 M/S UPDN

B: System Contvol is intended for compatibility with older systems. Do not use this User

Display unless you are instructed to do so by E.C. support staff.

Use B: System Control to view or change system parameters for a simplex, serial duplex or

group system. Follow the instructions on page 4 to access B: System Control. Then use the UP and the

DN (DOWN) push buttons to sclect the parameter you want. If you want to change the parameter,

continue to follow tke instructions on page $. The parameter list for car B is the same as that for car A

(again, this if for older single computer duplex systems only),refer to table "A:System Control” for

detail

Like some other the parameters above, many of these parameters will change the VO

configuration of the controller. ‘These parameters are marked with a f. Do not change these parameters

without contacting E.C. support staff.

Page 12

A: Stopping Table

The A: Stopping Table User Display is used to program which floors-and how many-the elevator

car will stop at. This is the User Display to. change if you need to increase or decrease the number of

floors in the system, This user display also programs which calls (up, down and car calls) are accepted

at each floor, so this User Display can be used to set up systems like down collective.

If you do change car stopping information in this User Display, you will also need to change

parameters in A: SYSTEM CONTROL. If you change the number of car, up or down calls, the Car Call

Fr Ctr, Tot Up Call Fr and Tot Dn Call Fr parameters will need to be changed to match the new system

configuration. The same applies to any rear car call parameters that you change.

‘You can increase or decrease the number of stops in the system by adding or removing entire

floors from the top of the stopping table. When you do this, you will need to change No. Floors-1 and

‘Number of PI's parameters in the A: SYSTEM CONTROL User Display.

Changing parameters in this User Display will cause you terminal wiring configuration to

change. You should contact Elevator Controls Corporation support staff for help if you need to change

any of these parameters.

A: Stopping Table _

Parameter Function

AFIT £0) Each parameter contains the hex coding for one floor of

the elevator system

M: X CCR X CCF; L: UPR DNR UPF DNF

Description:

DNE- Set fo 0 to enable a down call at this floor. + 4

UPE- Set to 0 to enable an up call at this floor. +

DNR- Set to 0 to enable a rear down call at this floor. +

UPR- Set to 0 to enable a rear up calls at this floor. +

CCF- Set to 0 to enable a car call at this floor. $

X- Unused. Set to 1. ss 7

AH2t £¢ same as above t oon

AF3f £C same as above t _

etc. Tok | etc. oe

+ Changing these parameters will change your terminal 1/0 config

Elevator Controls Corporation support staff for assistance. :

You can use appendix A to get the correct hex number codes for each floor. However there are

some common codes that you will use listed on the next page. (

Page 13

Common Codes for A: Stopping Table

Function

IFT Car doesn't stop here. All your floors above the top one

must have this code. +

EET (One car call and one down call. This is the normal code for

_ the top floor. + 7 .

Ct (One car call, up call and down call. This is the normal code

: | for an intermediate floor. +

EDt | One ear call and one up call. This is the normal code for the

bottom floor, Fl 1

AQT All calls-front and rear car calls, up calls and down calls.

This is the code for levels with two openings. t =

BBT “One rear car call and down call. A top floor with a only a

rear opening, +

B3t One rear car call, up call and down call. An intermediate

| floor with a rear opening, +

[One rear car call and up call. A bottom floor with rear

openings. t

+ Changmg these parameters will change your terminal 1/0 configuration,

Contact Elevator Controls Corporation support staff for assistance.

B: Stopping Table

The B: Stopping Table User Display is intended for compatibility with older systems. Do not

use this display unless you are instructed to do so by Elevator Controls support staff.

‘The B: Stopping Table User Display is used to program which floors-and how many-the elevator

car will stop at. This is the User Display to change if you need to increase or decrease the number of

floors in the system. This user display also programs which calls (up, down and car calls) are accepted

at each floor, so this User Display can be used to set up systems like down collective,

If you do change car stopping information in this User,Display, you will also need to change

parameters in B: SYSTEM CONTROL. If you change the number of car, up. or down calls, the Car Call

Fr Ctx, Tot Up Call Fr and Tot Dn Call Fr parameters will need to be changed to match the ew system

configuration. The same applies to any rear car call parameters that you change.

‘You can increase or decrease the number of stops in the system by adding or removing entire

floors fiom the top of the stopping table. When you do this, you will need to change No. Floors-1 and

Number of P's parameters in the B: SYSTEM CONTROL User Display.

Page 14

Changing parameters in this User Display will cause you terminal wiring configuration to

change. You should contact Elevator Controls Corporation support staff for help if you need to change

any of these parameters.

B: Stopping Table _

Parameter | Funetion

BRIT "Each parameter contains the hex coding for one floor of

the elevator system_

M: COR X CCF XL: UPR DNR UPF DNF +

Description:

DNF- Set to 0 to enable a down call at this floor. +

UPF- Set to 0 to enable af up call at this floor. +

DNR- Set to 0 to enable a rear down call at this floor. +

UPR Set to 0 to cnable a rear up calls at this floor. f

CCF. Set to 0/10 enable a car call at this floor. +

|X Unused. Set. tol.

"| same as above |

same as above f

etc. —

+ Changing these parameters will change your terminal /O configuration. Contact

Elevator Controls Corporation support staff for assistance.

‘You can use appendix A to get the correct hex number codes for each floor. However there are

some common codes that you will use listed below.

"Common Codes for B: Stopping Table

Function

Car doesnt stop here. All your floors above the top one

must have this code. 7

‘One car call and one down call. ‘This is the normal code for

the top floor. ee

(One car call, up call and down call. This is the normal code

for an intermediate floor. +

‘One car call and one up call. ‘This is the normal code for the |

bottom floor, FIL. t _

All calls-front and rear car calls, up calls and down calls.

This is the code for levels with tworopenings. +

‘One rear car call and down call. A top floor with a only a

rear opening. +

One rear car eall, up call and down call, An intermediate

floor with only a tear opening. | 7

(One rear car call and up call. A bottom floor with only a

rear opening. ¢

Page 15

Changing these parameters will change your terminal 1/O configuration.

ntact Elevator Controls Corporation support staff for assistance.

Stcurity Coding

ecurity Coding

L=02_ M/S UP DN

‘The Security Coding User Display is not currently implemented

A: Mem Flags List (See Memory Flags Listing Table at end of this section for viewing these

flags using "Direct Access” feature)

‘A: Mem Flag List

-08_ M/S UP DN

!

‘Use the A: Mem Flag List User Display to view the system inputs. This User Display can be an

important debugging aid. If you suspect that the system is not responding to a signal, you should check

here to see if the system is receiving the signal. If not, verify the input voltage at the bookup terminal

with a voltmeter. If the signal is present there, you may have a defective board. Please contact Elevator

Controls Corporation support staff for help.

To use A: Mem Flag List, follow the instructions on page 4. Then use the UP and DN (DOWN)

push-button one of the sub-menu displays below. NOTE: even though you may enter the EDIT mode

as described on page 5, trying to change system inputs has no effect.

A: Mem Flags List

Parameter | Function

430 | This is a hex number with eight inputs. See appendix A for

Aq_ | complete information on hex numbers. The description is

M: DOLF DBC SAF LLI; L: FRA STU STD IND

DOLF - Term. 36, Door Open Limit

DBC - Door Button Close terminal, from COP

SAK - Safety String input; this does not include door interlocks

LLE- Term 76, Light Load input; also used for Car Call Cancel

input and Bypass (fire phase 1) input.

FRA- Term 444, Alternate Fire Return

STU- Term. 71, Step Up (increments PI when going up)

STD- Ten. 72, Step Down (decrements PI when going down)

IND- Term 49, Independent; also used in test mode.

Page 16

This is a hex number with eight inputs. See appendix A for

complete information on hex numbers. The description is:

M: INDOB DLK DEL; L: UPS DNS LVL EPI

IN- Term 59, Inspection; also controller inspection switch input

DOB- Door Open Button input, from COP

DLK- Term. 11, Door Interlock input; this input is reversed.

DEL- Delta Starter input; set by Y-A timer contact

UPS- Up Sense; activated by U NO-I contact on HLS board

DNS- Down Sense activated by D NO-4 contact on HLS board

LVL- Leveling; active if LU (term. 26) or LD (term. 27) active

EPI- Emergency Power mode input

This is a hex number with eight inputs. See appendix

complete information oa hex numbers. The description is:

M: SE PHE DZ.FRS; L: FCS USD1 DSD1 DELD.

SE- Safety Edge

PHE- Photoeye

DZ- Term. 27, Door Zone

FRS- Term. 443, Main Fire Recall

FCS- Term. 435, Fire Phase 2

USD1- Term. 32, Up Terminal Slowdown

DSDI- Term. 35, Down Terminal Slowdown

/DHLD- Term 82, Door Hold input; also fire phase 2 bold

for

This is a hex number with eight inputs. See appendix A for

complete information on hex numbers. The description is:

M: USD2 DSD2 ISTU ISTD; L: ATT UP DN HLL

USD2- Term 31, Up Terminal Slowdown

DSD2- Term 34, Down Terminal Slowdown

ISTU- Tem. 74, Intermediate Step Up

ISTD- Term. 73, Intermediate Step Down

| ATT- Attendant mode

| UP- Attendant Up switeh

| DN- Attendant Down switch

HLL Heavy Load Input

[This is a hex number with eight inputs. See appendix A for

| complete information on hex mumiers. The description is |

| M: PTR PTS NSB X; L: BSI ACS HSI WILDSW |

| PTR. Permission to Run (Group Control Only)

| PTS- Permission to Start (Group Control Only)

NSB- 50 Bus power input

X- unused ®

| BSI- Building Security

ACS- Alternate Call Scheme |

H(SI- Hospital Mode Select

WILDSW- Wild Operation Switch |

Page 17

This is « hex number with eight inputs. See appendix A for

complete information on hex numbers. ‘The description

M: DOLR DBCR DOBR DHLDR; L: PITF SER PHER DZR

DOLR. Rear Door Open Limit

DBCR- Rear Door Close Button

DOBR- Rear Door Open Button

DHLDR- Rear Door Hold Input

PITE- Position Indicator Test input (obsolete)

SER- Rear Door Safety Edge

PHER- Rear Door Photocye

DZR- Rear Door Zone Input

complete information on hex numbers. ‘The description is:

M: EQI CWLEDS APF; L: PON XXX

EQI- Earthquake Seismic Switch input

CWE Earthquake Counterweight Derailment input

EDS- Earthquake Direction Switch input

APE- Altemate Parking Floor input

PGN- Passing Gong Activation input

X- unused,

B: Mem Flags List

The B: Mom Flag List User Display is intended for compatibility with older systems. Do not use

this display uniess you are instructed to do so by Elevator Controls support staff.

Use the B: Mem Flag List User Display to view the system inputs. This User Display can be an

important debugging aid. If you suspect that the system is not responding to a signal, you should check

here to see if the system is receiving the signal. If not, verify the input voltage at the hookup terminal

with a voltmeter. Ifthe signal is present there, you may have a defective board. Please contact Elevator

Controls Corporation support staff for help.

To use B: Mem Flag List, follow the instructions on page 4. Then use the UP and DN (DOWN)

push-button to select one the sub-menu displays on the next page. NOTE: even though you may enter

the EDIT mode as deseribed on page 5, trying to change system inputs has no effect.

The B: Mem Flags List table is identical as that for A: Mem Flags List above. Please refer to

the A: Mem Flags List table above for detail.

Page 18

Sears

(FESO Sere oa 420 51 =]

NO oat =O

S999 Beae

sagoa

NoIaNoD NoHtS

4CIND SONTGAT ONINVEDONg 8d—OaNn “—

STOMLNOD YOLVARTE

Page 19

‘A: Elevator Timers

levator Timers

UP DN

Use the A: Elevator Timers to review and adjust most of the timers used by the controller

Follow the instructions on page 4 to access the-A: Elevator Timers User Display. ‘Then use the UP and

DN (DOWN) push buttons to select one of the timers on the next page.

"To change a timer value, select the timer parameter as described above. Then follow the

instructions on page 5

Note ‘the A: Elevator Timers can only be used to change timer

values fiom 0 to 60 seconds. Please refer to "Direct Access” feature

in this manual to change timer values larger than 60 seconds, or

contact Elevator Controls.

Page 20

‘A: Elevator Timers

‘Timer Parameter

Function

A: Door Protection

Set for the maximum time that the doors are allowed to

close. Default is 30 seconds.

hort Door Timer

Set for the time the doors will wait at the open limit

_after re-opening. Default is 2 seconds.

‘A: Car Door Timer

A: Hall Door Time

A: MG Timer

7

‘A: TOS Timer |

"Set for the time the doors will. wait at the open limit

| Set for the time the doors will wait at the open limit

| after opening for a hall call. Default is 7 seconds.

Set for the delay after the seismic switch retums to a

normal condition before returning the car to automatic

operation. Default is 30 seconds.

Sct for the delay before opening the doors at a floor after

making an emergency stop due to earthquake operation.

| Default is 5 seconds.

{Used for two purposes. The frst isthe time a generator

is allowed to run before shutting down if there is no

activity. Default is 90 seconds.

‘The second purpose is the soft stop timer on a hydro.

Default is | second.

Set for the time the car can be held normally at a floor

before the system attempts to use nudging to close the

doors. Default is 45 seconds.

‘A: Lobby Door Time

‘A: Gong Timer-DD

Set for the time the doors will wait at the open limit at

the lobby, if lobby timing is programmed. See Car Call

Disconn parameter in the System Variables section,

| page 8. Default is 10 seconds.

Set for the time between pulses for a double ding.

Default is 0 seconds.

A: Gong Hold Time

“A: Trip Failure zy

A: MG Rotational

‘A: Door Hold Time

‘Set for the time a gong pulse will be held. Default is 3

Set for the maximum time the car is allowed to run in

the hoistway. Default is 180 seconds for an open loop, 0

seconds for a closed loop.

Set for the maximum time the starter is allowed to spend

in wye (Y-starting) configuration. Default is 15

seconds. .

Set for the time doors will wait at the door open limi

when the Door Hold input is used. Default is 10

seconds.

Page 21

B: Elevator Timers

The B: Elevator Timers User Display is intended for compatibility with older systems, Do not

use this display unless you are instructed to do so by Elevator Controls Corporation support staff.

Use the B: Elevator Timers to review and adjust most of the timers used by the controller.

Follow the instructions on page 4 to access the B: Elevator Timers User Display. Then use the UP and

DN (DOWN) push- buttons to select one of the timers below.

To change a timer value, select the timer parameter as described above. Then follow the

instructions on page 5.

The B: Elevator Timers table is identical to the Az Elevator Timers table above.

Please refer to A: Elevator Timers above for detail.

A: Alt Call Scheme

B: Elevator Timers

MS UP DN

‘A: Alt Call Scheme is not currently implemented.

(lt Call Scheme

B: Alt Call Scheme is not currently implemented.

Password Access

B: Elevator Timers

L=0E_ M/S UP DN

Password Access is not currently implemented.

Page 22

Appendix A

Working with

Hexadecimal Numbers

Elevator Controls uses hexadecimal (hex) numbers in several of the User Displays. Hex

numbers are a compact way of representing information.

Converting Hexadecimal Numbers

Hex numbers are always displayed as two digits. The first (left hand side) di

or most significant information; the (second right hand side) digit contains the L or lest significant

information. The digits themselves use the number 0 through 9 and letters A through F.

Hex Numbers

<—— Typical LCD display

Hex numbers

In the example above, AO and FE are the hex numbers. A and E are the M digits and 0 and E are

the L digits. The M and L digits are indicated in the description in the text by bold letters.

To use hex mumbers, you must convert each digit separately into a series of four ones and zeros.

Use the table on the next page to do the conversion. Then compare the ones and zeros with the

description given in the User Display.

Converting Hex Numbers

Example convertion A:F12 VAL=AQhex (see page15)

Hex Number A 0

¥ v

Converted 1010 0000

vvV\ ¥¥ VN

Description M: X CCR X CCF 31: UPR DNR UPF DNF

Result This shows that car will respond to front and rear car calls

(CCR/CCF =0), and to all ball calls front and rear (UPR~.

DNR=UPF=UPR=0) . Since a0 here means "elegible”

(see text).

Page 23

Hexadecimal Number Convertions

Convertion Hex Number Convertion

- 0000 _ 1000

oor | 9 | 1001

oo10| AL 1010

ooil B toi |

oi0o- | “1100

ole1 | 1101

o1lo0 7 [ou tti0 |

o1il 4 Titi

Changing Hex Numbers

Changing a hex number is a four step process, whether its an option, an intemal flag or anything

else. Follow the outline below:

1. Convert the hex number as described on the previous page. Tiis will show you what options

are set now.

2. Decide what options you what to set or reset. If necessary, write the new series of ones and

zeros down on paper. This will help you verify that the new scries is correct. Do not try to proceed until

you've checked this new series at least once. It is very easy to make a mistake at this point,

3. Use the table above to look up the new hex number from the new series of ones and zeros.

‘The ones and zeros are in no particular order so you'll have to search the table carefully. Double cheek

that you have the correct new hex number, maybe by converting the new number as described in thc

previous page.

4, Now change the hex number in the User

splay as described on page 5 of this manual.

Changing a Hexadecmal Number .

1. First convert the existing number to see A 0

what options are already set. See the Lolo 0000

instructions on the previous page, x=1, CCRéO, X“1, CCE=0: UPR=0 DNR=D, UPE=O, DNE=O

2. Then decide what options need tobe X=1, CC

changed. For exemple, assume that

wwe only want car to respond to front Lito 1100

calls car and hall up and down. .

X=1,CCF=0; UPR=1 DNR=I, UPF=0, DNF=0

3. Lookup the new series of ones and E c

zeros in the table above.

Finally, follow the instructions on page 5 of this manual to change the number.

Page 24

Appendix B

Using Direct Access

for Viewing System Flags

Led Bank

Name | Address Type | Description 7

‘ACS F084 S1_| Altemate Call Scheme =

BFD FOSF ~ [|_| [82] Bottom Floor Demand -

BSI FOs4 Si_| Building Security Input

cAc F096 {|} s2__| Car Above Counterweight |

CBC F096 [| $2 | Car Below Counterweight

“cca | F090 a $2 | CarCall Above Car

F090 _| Tu $2_| Car Call Below Car Til

cccl FOB $2_| Car Call Cancel Input Flag

ccD FSF E $2_| CarCall Disconnect

CCF FOL Ea $2__| CarCall Cancel Flag- Front

ccu__| F097 s2_|CarCalHod

ccr_|_ Fosc S2_| Car Call Cancel Flag- Rear

CCT F096 $2_| Car Call Door Time - Front

ccme_| Fosp _$2_| Car Call Door Time - Rear

CSB F087 0 | Car Stop Bypass Output

CSB(ivl) | F093 2_| Car Safety Stop Switch Bypass _|

CSB(Gire) | F092 |_| 82__| Car Safety Stop Switch Bypass,

cw F086 S1_| Counterweight Earthquake Input

DBC F080 S1_| Door Close Pushbutton

DBcR | _F08s fehl S1_ | Door Close Pushbutton - Rear

DG FOOL : $2 | Down Call Cancel Flag

“pea | F090 al $2_| Down Call Above the Car

pces_| F090 $2 | Down Call Below the Car

DCF Foss © _| Door Close Function

porr_| rosa | a [[ 0 | Door Close Funetion-Rear |

|_Dep. F088 | _0 _| Door Close Power {

Derr | F08c © _| Door Close Power - Rear

per | Fosc_| | Down Call Cancel Flag - Rear

DEL F081 Delta Enabled

DELD | F082 |_| s1_ | Door fold Input

Led Bank

Name | Address Type Description

DHLDR | F085 S1_| Door Hold Input - Rear

DIK | FOS | S1_| Door Lock Input

DNS F081 [| | si_| Down Sense

a) Fos1 | S1_| Door Open Push-button - Front

DOBR | F085 _[_|_[_[-1 st | Door Open Push-button - Rear

DOL F097 _ | 82__| Door Open Intent oi

DOR | FOSE | $2_| Door Open Intent - Rear

DOLF F030 ule S1_| Door Open Limit- Front

DOLR FOSS | x “Door Open Limit - Rear

DOF F087 | | | | || Door Open Function |

DOER FosB | “| | 0 _ | Door Open Function - Rear

DPD rose | | | _[ [82 _| Down Previous Direction

|

[_S1_| Down Slowdown Switeh 1 Input

Down Slowdown Switch 2 Input

Door Zone - Front

Door Zone - Rear

Emergency Power Input

“LT Earthquake Input

i ‘Front Gong Enable Down

| I O_| Front Gong Enable Up

S1__| Fire Return Altemate Input

S2_| Fire Service Phas r

S2_| Fire Service Phase _

S1_| Lobby Fire Service Input

| Fire Waming Indicator

$2_ | High Speea

$2__| Hall Call Disconnect

P| $2 | Hall Call Reject

© _| Hall Call Reject Output

# _| | -[- [82 [Halt Call Door Time - Front

| || $2 | Hall Call Door Time - Rear

“| 82. | High SpeedDelry |

$2. | High Intermediate Speed

Led Bank

Name | Address Type | "Description

Page 26

HR F087 © _| High Intermediate Speed Output

HLT F083 SI_| Heavy Loadweigher Input

HLW F099 S2__| Heavy Load ~

HR F087 z © _| High Speed Output

IN FO81 ae S1_| Inspection or Access Input

INC FOSE S2__| Independent Service Aux. Flag

IND O80 S1_| Independent Service Input

“stp [Foss || ~ | S1_ | inteomediate Step Down Input

istu_ | ross | | | S1_| Intermediate Step Up Input

ISR Fos | | $2__| InService & Ready

Isv__ | FO8E iE _[in Service

LBE F098 7 _[ sz | CaratLobby

LEP FOI S2_| Lower Floor Parking Intent

LL F080 | Si_| Light Loadweigher Input

Luw | F099 | | [82] Light Load

LRC F098 | “| S2_ | Lobby Return Call

LRE F098 $2__| Lobby Retum Fmetion |

LT FO | | | 2 | Lobby Door Time -

LIR FO8D PEELE] [82 Lobby Door Time - Rear /

LVL FO81 Si |NotLevelinginpt ‘|

MGRVAA | _F087 PT TT TP] 6 | WG set Run Output

MLT F093 S2__| Motor Limit Timer a

“MPR | Foss © | Microprocessor Running

NuDG | Foss “| 0 _| Nudging =

NSB F084 $1_| No 50 Buss (Hall Call C omamon)

pon | Foss | | | S1_| Passing Gong Input

PG-P F092 | | | © | Passing Gong Out _|

PK Foor | | [| s2 |e i

PHE F082 SL Photo-Eye luput 7

PHER | F085 Sl_| Photo-Eye Input- Rear

PRT FO9C sz_|

PIR F034 Si_| Permission to Run -

PIS O84 St_| Permission to Start

RGED | F08B |] 0 | RearGongEnableDown

RGEU_ | FOsB Q _| Rear Gong Enable Up 7

Led Bank _

Name | Address ‘Type ~_ Deseription

RL F087 © | Lever/Relevel Output

Page 27

S2_| Blevator Run Flag

S1_| Primary Safety String Input

O__| Down Direction Output

RUN F097

O_| Down Direction Arrow

$2__| Short Door Time

S82 Short Door Time Rear

S1_| Safety Bdge Input

S1_| Safety Edge Input - Rear

S2_| Stepping Complete

Down Input

Si_| Step Up Input _

© | UpDirection Output

| Up Direction Arow

=| Up Descton Anon

S2_ | Top Floor Demand

S2_ | Transfer Function

| Tongue Hanging

$2__| Timed Out Of Service

82 | UpCallCancel Flag

| ove the Car

Below the Car

82_ | Up Call Cancel Flag-Rear

S2_| Up Direction Preference

Upper Floor Patking

Up Previous Direction

SL_| Up Direction Sense

Si_| Up Slowdown Switch E

Si_| Up Slowdown Switch 2 Input

“St | Wild Switch Inpat 7

S2_| Request to Start WIG

O_| Fire Service Output__

Page 28

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 0572-SATE-EN-V0 ARCA III IssuesDocument2 pages0572-SATE-EN-V0 ARCA III IssuesBeltran HéctorNo ratings yet

- Schema EPB2 V3F10 PropreDocument36 pagesSchema EPB2 V3F10 PropreBeltran Héctor100% (1)

- Controller Fault LogDocument9 pagesController Fault LogBeltran HéctorNo ratings yet

- EPB2.4 + V3f20 Installation - Start-Up ProcDocument30 pagesEPB2.4 + V3f20 Installation - Start-Up ProcBeltran Héctor75% (4)

- General-Controller-Manual-VVVFDocument47 pagesGeneral-Controller-Manual-VVVFBeltran HéctorNo ratings yet

- CJA General Operating InformationDocument4 pagesCJA General Operating InformationBeltran HéctorNo ratings yet

- 2010-Slow Down Location SwitchDocument4 pages2010-Slow Down Location SwitchBeltran HéctorNo ratings yet

- Canny Serial Control Manual InglesDocument117 pagesCanny Serial Control Manual InglesBeltran Héctor100% (3)

- Elvoron Stella 77932 D DPDocument24 pagesElvoron Stella 77932 D DPBeltran HéctorNo ratings yet

- Canny Instalacion Mecanica Manual InglesDocument57 pagesCanny Instalacion Mecanica Manual InglesBeltran Héctor100% (1)

- Elenessa (VFGL) AscensorDocument96 pagesElenessa (VFGL) AscensorBeltran Héctor93% (14)

- Arca III Esquemas PDFDocument24 pagesArca III Esquemas PDFBeltran HéctorNo ratings yet

- Electra Victoria Control CHLH DiagramasDocument1 pageElectra Victoria Control CHLH DiagramasBeltran HéctorNo ratings yet