Professional Documents

Culture Documents

COOLPLUS-Glc - GLL Oil Cooler Heat Exchanger

COOLPLUS-Glc - GLL Oil Cooler Heat Exchanger

Uploaded by

COOLPLUS OIL COOLERCopyright:

Available Formats

You might also like

- Man 2840 Le Engine Spare Parts CatalogueDocument114 pagesMan 2840 Le Engine Spare Parts Cataloguesantosh tiwari88% (8)

- HPSU RexorthDocument409 pagesHPSU Rexorthf984jykhd6No ratings yet

- 1hu3102 0ad01 Z 9f66312301001imb5 DC Servomotor Siemens ManualDocument62 pages1hu3102 0ad01 Z 9f66312301001imb5 DC Servomotor Siemens ManualJack ReacherNo ratings yet

- Datasheet LV Motor Rev 0Document4 pagesDatasheet LV Motor Rev 0wado11No ratings yet

- TH Series Temperature Controller PDFDocument11 pagesTH Series Temperature Controller PDFjohnNo ratings yet

- MN Comp6e 03Document19 pagesMN Comp6e 03baksof3843No ratings yet

- Aotai MIG250C Operating ManualDocument25 pagesAotai MIG250C Operating Manualmaverick kitaroNo ratings yet

- AS358MDocument15 pagesAS358Mantonio2065100% (1)

- COOLPLUS-YRC Heat Exchanger Oil CoolerDocument4 pagesCOOLPLUS-YRC Heat Exchanger Oil CoolerCOOLPLUS OIL COOLERNo ratings yet

- Daikin V VZ VD M Series Piston Pump PDFDocument51 pagesDaikin V VZ VD M Series Piston Pump PDFAgung MNo ratings yet

- HKD-100D PA ManualDocument5 pagesHKD-100D PA ManualLucas BarriosNo ratings yet

- Eacon Inv Ec500Document74 pagesEacon Inv Ec500michalis zisisNo ratings yet

- D155axi-8 Sen06521-02 Circuit DiagramDocument29 pagesD155axi-8 Sen06521-02 Circuit Diagramhaimay118No ratings yet

- 661 Didb LV To32-33 Lxcos V1.0Document3 pages661 Didb LV To32-33 Lxcos V1.0hariana100% (1)

- Gas Gas Ec300 Parts CatalogDocument7 pagesGas Gas Ec300 Parts CatalogAlejandro EnriqueNo ratings yet

- Form Data Motor FM6Document50 pagesForm Data Motor FM6Fajri HakimNo ratings yet

- Dol Starter With Remote Start and StopDocument1 pageDol Starter With Remote Start and StopAthul ANo ratings yet

- BK130 1Document26 pagesBK130 1huychampiNo ratings yet

- PWM-OCXiv2.PDF PWM HV ModuleDocument11 pagesPWM-OCXiv2.PDF PWM HV ModuleDrazen Dan MijacikaNo ratings yet

- YQK Series Hydraulic Crimping Tools Operation ManualDocument3 pagesYQK Series Hydraulic Crimping Tools Operation ManualgalicruNo ratings yet

- Wiring Diagram: DC GeneratorDocument1 pageWiring Diagram: DC GeneratorAndi Ka100% (1)

- MPR50 User Manual Eng v1.78Document19 pagesMPR50 User Manual Eng v1.78nebiyou100% (2)

- D7150 en PDFDocument4 pagesD7150 en PDFSasko Dimitrov100% (1)

- Conexión Alternadores 4 PolosDocument2 pagesConexión Alternadores 4 PolosDaniel MuratallaNo ratings yet

- DCA-25ESK: DenyoDocument1 pageDCA-25ESK: DenyoAdeelNo ratings yet

- 4-3 Electrical Komponen SpecDocument9 pages4-3 Electrical Komponen Specibnu malkanNo ratings yet

- SML10 SystemDocument33 pagesSML10 SystemgilbertoNo ratings yet

- Mentor Talkback SystemDocument2 pagesMentor Talkback SystemLes OakesNo ratings yet

- Error Codes PDFDocument10 pagesError Codes PDFRosemarie QuitorianoNo ratings yet

- SOS Type Pressure Transmitter NS100A Series: SpecificationsDocument4 pagesSOS Type Pressure Transmitter NS100A Series: SpecificationsTin Chau TrungNo ratings yet

- Centrifugal Pump Split Case PDFDocument8 pagesCentrifugal Pump Split Case PDFApivit MalichaiNo ratings yet

- DynasetDocument64 pagesDynasetAlexis Peña0% (1)

- Trooper 3000 Series Process IndicatorDocument2 pagesTrooper 3000 Series Process Indicatorwramadhani65No ratings yet

- Cast Catalogo ORFS Ing PDFDocument90 pagesCast Catalogo ORFS Ing PDFJOSE ANTONIO MARTINEZ MORALESNo ratings yet

- Páginas Extraídas de Manual - MX2Document8 pagesPáginas Extraídas de Manual - MX2Anonymous 97JlpvN4No ratings yet

- Instructions For Pneumatic Operating Mechanism Type AA-10 For Oil Circuit BreakersDocument43 pagesInstructions For Pneumatic Operating Mechanism Type AA-10 For Oil Circuit BreakersJonathan PinillaNo ratings yet

- Generator Automatic Voltage Regulator Operation Ea465 Generator Automatic VoltageDocument6 pagesGenerator Automatic Voltage Regulator Operation Ea465 Generator Automatic Voltagefahad pirzadaNo ratings yet

- 02EN0780 Yd25 PDFDocument2 pages02EN0780 Yd25 PDFKevin TtitoNo ratings yet

- Control Panel: ISO 9001 Certified ISO 14001 / OHSAS18001 CertifiedDocument4 pagesControl Panel: ISO 9001 Certified ISO 14001 / OHSAS18001 CertifiedHaresh vaghelaNo ratings yet

- Ec140b Eng 2Document8 pagesEc140b Eng 2Mohamed Yousif HamadNo ratings yet

- Engine Failures 98Document58 pagesEngine Failures 98Abd ElGhanY AwdNo ratings yet

- PWM With Microcontroller 8051 For SCR or Triac Power ControlDocument3 pagesPWM With Microcontroller 8051 For SCR or Triac Power ControlDirek BoonturmNo ratings yet

- Apleton Receptacles-and-Plugs-ExplosionproofDocument39 pagesApleton Receptacles-and-Plugs-ExplosionproofMuhamad Priyatna100% (1)

- Lincoln Welding Machine ChecklistDocument1 pageLincoln Welding Machine ChecklistEjike Francis ChizobaNo ratings yet

- 841 VCB HVF&HVG Catalogue 2012.1Document56 pages841 VCB HVF&HVG Catalogue 2012.1Sergio Ignacio Zurita VargasNo ratings yet

- Axpert Eazy +LATESTDocument12 pagesAxpert Eazy +LATESTAmtech Aniruddh50% (2)

- ERU Series: Electric Remote ControllerDocument2 pagesERU Series: Electric Remote ControllerUziel CHIMINo ratings yet

- 400HP AC Drilling Motor WL250040 2Document2 pages400HP AC Drilling Motor WL250040 2HayLenLeeNo ratings yet

- Shark GFDocument2 pagesShark GFUlises PiscoyaNo ratings yet

- Instruction Manual: Installation - Operation - MaintenanceDocument13 pagesInstruction Manual: Installation - Operation - MaintenanceNamer HajiNo ratings yet

- RENR4343Document2 pagesRENR4343Cecilia Gomez.contrerasNo ratings yet

- Metal Enclosure IP65 Catalog FINALDocument10 pagesMetal Enclosure IP65 Catalog FINALUsman ZouqueNo ratings yet

- BCH Electric Ltd-Limit Switch-CatalogueDocument6 pagesBCH Electric Ltd-Limit Switch-CataloguesachmayaNo ratings yet

- Premier 300: CT/VT-Operated Energy MeterDocument2 pagesPremier 300: CT/VT-Operated Energy MeterMohammed Nafis N100% (2)

- Siwarex U Quick Guide v3 1Document15 pagesSiwarex U Quick Guide v3 1Chan Kok LamNo ratings yet

- Sid-8bt High Speed Transfer Operation ManualDocument29 pagesSid-8bt High Speed Transfer Operation ManualLEK MAN ꦲꦂꦩꦤ꧀ꦱꦸꦱꦤ꧀ꦠꦺꦴNo ratings yet

- Schematic - How To Make A Current Booster Circuit - 2022-10-18Document1 pageSchematic - How To Make A Current Booster Circuit - 2022-10-18Gilberto VidalNo ratings yet

- DNC160 398sdc005en00Document24 pagesDNC160 398sdc005en00Anonymous Xz3PgZR8No ratings yet

- DNC75 398sdc003en00Document30 pagesDNC75 398sdc003en00Anonymous Xz3PgZR8No ratings yet

- Schematic INDICT 2022-04-15Document1 pageSchematic INDICT 2022-04-15Marko MatićNo ratings yet

- Hayden Oil Cooler Catalogue ORCAERDocument8 pagesHayden Oil Cooler Catalogue ORCAERCOOLPLUS OIL COOLERNo ratings yet

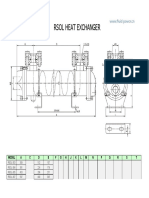

- COOLPLUS-RSOL Heat Exchanger Oil CoolerDocument2 pagesCOOLPLUS-RSOL Heat Exchanger Oil CoolerCOOLPLUS OIL COOLERNo ratings yet

- COOLPLUS-FCY Heat Exchanger Oil CoolerDocument3 pagesCOOLPLUS-FCY Heat Exchanger Oil CoolerCOOLPLUS OIL COOLERNo ratings yet

- COOLPLUS-YRC Heat Exchanger Oil CoolerDocument4 pagesCOOLPLUS-YRC Heat Exchanger Oil CoolerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Loc-007-80l - Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Loc-007-80l - Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- COOLPLUS-YFC, YFCY Heat Exchanger Oil CoolerDocument2 pagesCOOLPLUS-YFC, YFCY Heat Exchanger Oil CoolerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus Ah2431t Ca Air Oil Cooler Heat ExchangerDocument1 pageCoolplus Ah2431t Ca Air Oil Cooler Heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Ah1680t-Ca - Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Ah1680t-Ca - Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Aw0607t-Ca-20l - Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Aw0607t-Ca-20l - Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Ah3818t-Ca-600l-Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Ah3818t-Ca-600l-Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Ah1490t-Dc - Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Ah1490t-Dc - Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Ah1490t-Ca-250l - Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Ah1490t-Ca-250l - Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Ah1470t-Dc - Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Ah1470t-Dc - Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLER0% (1)

- Coolplus-Ah1470t-Ca - Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Ah1470t-Ca - Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Ah1012t-Dc-100l-Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Ah1012t-Dc-100l-Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Ah1012t-Ca-100l-Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Ah1012t-Ca-100l-Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Af0510t Ca 10L CoolplusDocument1 pageAf0510t Ca 10L CoolplusCOOLPLUS OIL COOLERNo ratings yet

- Steel Pipes Dimensions - ANSI Schedule 40Document4 pagesSteel Pipes Dimensions - ANSI Schedule 40ciblixNo ratings yet

- Ar Quite Ctur A 2010Document485 pagesAr Quite Ctur A 2010Cordova Gutierrez OmarNo ratings yet

- Aus Cable Laying Standard1Document34 pagesAus Cable Laying Standard1Anonymous MDkp0hnb3lNo ratings yet

- Irjet V4i7516 PDFDocument7 pagesIrjet V4i7516 PDFRajat MohanNo ratings yet

- PR600 PLDocument38 pagesPR600 PLSantiago Marmolejo CifuentesNo ratings yet

- P304 - Wood Acoustic FenceDocument1 pageP304 - Wood Acoustic FencesarthibhavsarNo ratings yet

- DetailsDocument11 pagesDetailsAzllina AnuarNo ratings yet

- Daily Exam 2B OpenDocument4 pagesDaily Exam 2B OpenLatif RadwanNo ratings yet

- AHUs 2020Document36 pagesAHUs 2020Technical OfficeNo ratings yet

- Module No.1 Prepare Architectural Job RequirementsDrafting Tools Materials and InstrumentsDocument23 pagesModule No.1 Prepare Architectural Job RequirementsDrafting Tools Materials and InstrumentsJay S. On100% (1)

- Fire Therm IntucompoundDocument1 pageFire Therm Intucompoundopenid_WdYgOQj7No ratings yet

- Bracing Manual FluorDocument28 pagesBracing Manual FluornpwalNo ratings yet

- InvarDocument5 pagesInvardusan.papez9216No ratings yet

- RCC LAB-316 Design of A Single Reinforced Beam Both in WSD and USD and ComparisonDocument7 pagesRCC LAB-316 Design of A Single Reinforced Beam Both in WSD and USD and ComparisonRakash MondalNo ratings yet

- Jis B-1186Document21 pagesJis B-1186nate anantathatNo ratings yet

- Autoclave - Tools, Installation, Operation and MaintenanceDocument20 pagesAutoclave - Tools, Installation, Operation and Maintenancejbjb2000100% (1)

- Ammonia Relief Valves SystemDocument10 pagesAmmonia Relief Valves SystemXixxixaNo ratings yet

- NEW Atlanta Blue in House 2019Document2 pagesNEW Atlanta Blue in House 2019Sick FreakNo ratings yet

- 00 - Recommended Practices - ListDocument4 pages00 - Recommended Practices - ListJames CraikNo ratings yet

- Basis of DesignDocument7 pagesBasis of DesignAnonymous GlTpXopWNo ratings yet

- B - Namrata Karuna - Mit Chandya U21172 - Kalyan Mudris U21064Document8 pagesB - Namrata Karuna - Mit Chandya U21172 - Kalyan Mudris U21064Mit ChandyaNo ratings yet

- List of V.OsDocument43 pagesList of V.OsAilyn O. DungogNo ratings yet

- 03SD0B02Document4 pages03SD0B02Jhonny RinconesNo ratings yet

- BIM ThesisDocument102 pagesBIM ThesisSahil KaushikNo ratings yet

- CFA Coatings and ProtectionDocument24 pagesCFA Coatings and ProtectionangthiankongNo ratings yet

- BS-88R 2018 Literature On Corrosion Protection in Concrete StructuresDocument48 pagesBS-88R 2018 Literature On Corrosion Protection in Concrete StructuresM PMNo ratings yet

- NATA Sample Paper 1Document8 pagesNATA Sample Paper 1natahelper88% (8)

- 43 Opc Test Certificate (W-01 2019 )Document1 page43 Opc Test Certificate (W-01 2019 )alanNo ratings yet

COOLPLUS-Glc - GLL Oil Cooler Heat Exchanger

COOLPLUS-Glc - GLL Oil Cooler Heat Exchanger

Uploaded by

COOLPLUS OIL COOLEROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

COOLPLUS-Glc - GLL Oil Cooler Heat Exchanger

COOLPLUS-Glc - GLL Oil Cooler Heat Exchanger

Uploaded by

COOLPLUS OIL COOLERCopyright:

Available Formats

www.fluid-power.

cn

GL

GL TUBE TYPE OIL COOLER SERIES

INTRODUCTION

This product is manufactured by our company that combining with the inter-

nal and external base of advanced technology and craft. The material of heat-e-

xchange pipe, adopted low-rib finned red copper pipe, used the structure of tr-

ansverse current breaker board, turbulence board and the advanced manufac-

ture craft of mechanism expanding, has the features of novel structure, small

dimension, light weight and well heat-exchanging effect and soon. This produ-

ct is a new type and high efficiency cooler, mainly used in low-viscosity hydrau-

lic and oil system to cool the work oil to the specified temperature. So it is an I-

deal cooling facility that can be widely used in cooling the hydraulic equipment

in the trade such as chemical industry, electric power, metallurgical industry,

mine and light industry and soon.

Each cooler series has many specification and type to suit for each user's requirement. Except the main products introduced in the operation manual, the c-

ompany also can make all kinds large or special cooler for the customers according to their requirements.

MODEL CODE

GL

Tube type oil cooler

C finned tube

L bare pipe L

Install method:L-vertical; non-horizontal type

Series No .

A=1.6MPa( )

Nominal cooling area:m2 Nominal pressure:A=1.6MPa(omit)

GLC

1 TECHICAL DATA

(MPa)

Pressure lose W/M2

Medium Inlet-oil Inlet-water Oil Flow-ratio of

Heat-exchange

viscosity temperature temperature cooling oil to water

Oil side Water side factor

N68 55 1 30 8 0.1 0.05 1:1 350

www.fluid-power.cn

2 MOUNTING SIZE

2-d1 A View

L1 C

b

I

H1

2-d2

D2

C1

D1

H2

t

L2 A C2 n-b 1

L B

L C L1 H1 H2 D1 D2 C1 C2 B L2 t n-b I d1 d2 Weight

Model L/min (Kg)

GLC1-0.4 390 240 145 20 7

GLC1-0.6 555 405 310 30 9

GLC1-0.8 685 532 80 64 75 80 120 50 65 105 435 2 4-10 20 G1 G3/4 40 10

GLC1-1 815 665 570 45 12

GLC1-1.2 955 805 715 50 14

GLC2-1.3 555 375 225 52 17

GLC2-1.7 680 500 350 57 20

GLC2-2.1 815 635 485 62 24

94 85 100 121 160 70 110 150 2 4-10 20 G1 G1

GLC2-2.6 955 775 630 70 28

GLC2-3 1105 925 780 80 33

GLC2-3.5 1265 1085 935 85 37

GLC3-4 820 570 380 75 45

GLC3-5 970 720 530 100 51

G11/2 G11/4

GLC3-6 1120 870 680 125 57

GLC3-7 1290 1040 850 150 64

132 115 151 162 220 100 160 205 3 4-15 25

GLC3-8 1450 1200 1010 175 70

GLC3-9 1610 1360 1170 200 76

G2 G11/2

GLC3-10 1780 1530 1340 225 83

GLC3-11 1960 1710 1520 250 90

GLC4-13 1355 985 745 230 132

GLC4-15 1515 1145 905 260 142

GLC4-17 1675 1305 1065 300 153

GLC4-19 1845 1475 1235 330 165

197 160 180 219 310 120 200 280 8.5 4-22 30 G2 G2

GLC4-21 2025 1655 1415 360 177

GLC4-23 2195 1825 1585 400 188

GLC4-25 2375 2005 1765 430 200

GLC4-27 2545 2175 1935 470 212

www.fluid-power.cn

( ) GLL

1 TECHICAL DATA

(MPa)

Pressure lose W/M2

Medium Inlet-oil Inlet-water Oil Flow-ratio of

Heat-exchange

viscosity temperature temperature cooling oil to water

Oil side Water side factor

N68 50 1 30 8 0.1 0.05 1:1.5 230

2 MOUNTING SIZE

A View

L

L1 C

d

2-DN1 2-D3 I n-d1

n-d2

2-D4

H1

2-DN2

D1

D2

C1

H2

L2 L3 A

C2 n-b 1

L C L1 H1 H2 D1 D2 C1 C2 B L2 L3 D3 D4 n-d1 n-d2 n-b I DN1 DN2 Flow of oil Weight

Model

(L/min) (Kg)

GLL3-4 1150 682 485 75 108

100 32

GLL3-5 1450 982 785 100 123

265 190 180 219 310 140 200 280 367 100 4- 17.5 4- 17.5 4-22 30 32

GLL3-6 1750 1282 1085 125 138

110 40

GLL3-7 1980 1512 1385 150 150

GLL4-12 1555 960 660 250 238

GLL4-16 1960 1365 1065 145 4- 17.5 65 350 300

GLL4-20 2370 1775 345 262 232 325 435 200 300 370 497 1475 145 4- 17.5 4-22 30 65 450 360

GLL4-24 2770 2175 1885 550 455

160 8- 17.5 80

GLL4-28 3180 2585 2295 650 536

GLL5-35 2480 1692 1232 625 570

GLL5-40 2750 1962 1502 180 100 750 640

GLL5-45 2990 2202 500 315 293 426 535 235 400 500 730 1772 180 8- 17.5 8- 17.5 4-22 30 100 875 745

GLL5-50 3260 2472 2042 1000 825

210 125

GLL5-60 3800 3012 2582 1250 955

GLL6-80 3160 2015 1555 1500 1617

GLL6-100 3760 2615 700 500 408 616 780 360 550 700 935 2155 295 295 8- 22 8- 22 4-25 32 200 200 2000 1890

GLL6-120 4360 3215 2755 2500 2163

www.fluid-power.cn

3 GLL-L MOUNTING SIZE

DN1

D3

D n-d2

C

L

L1

DN2

D4

C1

n-d3

D1

D2 n-d1

H H

L C L1 C1 H D D1 D2 D3 D4 DN1 DN2 n-d1 n-d2 n-d3

Model (L/min) (kg)

GLL3-4L 1220 682 75 125

100 32

GLL3-5L 1520 982 100 32 4- 17.5 4- 17.5 100 140

320 100 190 219 320 360 8- 24

GLL3-6L 1820 1282 125 155

110 40

GLL3-7L 2050 1512 150 165

GLL4-12L 1630 960 250 268

GLL4-16L 2035 1365 145 65 4- 17.5 350 330

GLL4-20L 2445 1775 400 130 262 325 440 480 145 65 8- 24 4- 17.5 450 390

GLL4-24L 2845 2175 550 485

160 80 8- 17.5

GLL4-28L 3255 2585 650 566

GLL5-35L 2545 1692 625 605

180 100

GLL5-40L 2815 1962 750 660

GLL5-45L 3065 2202 530 180 315 426 570 620 180 100 8- 28 8- 17.5 8- 17.5 875 781

GLL5-50L 3335 2472 210 125 1000 860

GLL5-60L 3875 3012 1250 960

GLL6-80L 3170 2015 1500 1630

GLL6-100L 3770 2615 690 215 500 616 800 870 295 295 200 200 8- 35 8- 22 8- 22 2000 1900

GLL6-120L 4370 3215 2500 2175

1

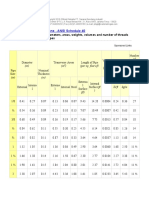

(4) K(kca l/m2h )

(1) A(m2) (2) Q(Kca l/h)

, , (3) m( )

Q=(T1-T2)CW=(t2-t1)C W a)

T1-T2= 1 t 2 -t 1 = 2

Q T1=

A= 1 (T1+T2)-(t1+t2) k=200

T2= 2 m

m K T1= 2 2 b) K=250

t2=

Q= (kca l/h) C= (kca l/kg )

, c)

k= (kca l/m h ) C= (kca l/kg ) 1 (T1-T2)-(t1-t2)

W= , (kg/h) 2 m K=350~400

m= ( ) 2 2

W= (kg/h)

2 7.5-10 10-15 15-20 20-30 30-40 40-75 75-100 100-120 120-150 150-200

kw

0.4 0.6 0.8 1.0 1.2 1.3 1.7 2.1 2.6 3 3.5 4 5 6 7 8 8 9 10 11

(m2 )

You might also like

- Man 2840 Le Engine Spare Parts CatalogueDocument114 pagesMan 2840 Le Engine Spare Parts Cataloguesantosh tiwari88% (8)

- HPSU RexorthDocument409 pagesHPSU Rexorthf984jykhd6No ratings yet

- 1hu3102 0ad01 Z 9f66312301001imb5 DC Servomotor Siemens ManualDocument62 pages1hu3102 0ad01 Z 9f66312301001imb5 DC Servomotor Siemens ManualJack ReacherNo ratings yet

- Datasheet LV Motor Rev 0Document4 pagesDatasheet LV Motor Rev 0wado11No ratings yet

- TH Series Temperature Controller PDFDocument11 pagesTH Series Temperature Controller PDFjohnNo ratings yet

- MN Comp6e 03Document19 pagesMN Comp6e 03baksof3843No ratings yet

- Aotai MIG250C Operating ManualDocument25 pagesAotai MIG250C Operating Manualmaverick kitaroNo ratings yet

- AS358MDocument15 pagesAS358Mantonio2065100% (1)

- COOLPLUS-YRC Heat Exchanger Oil CoolerDocument4 pagesCOOLPLUS-YRC Heat Exchanger Oil CoolerCOOLPLUS OIL COOLERNo ratings yet

- Daikin V VZ VD M Series Piston Pump PDFDocument51 pagesDaikin V VZ VD M Series Piston Pump PDFAgung MNo ratings yet

- HKD-100D PA ManualDocument5 pagesHKD-100D PA ManualLucas BarriosNo ratings yet

- Eacon Inv Ec500Document74 pagesEacon Inv Ec500michalis zisisNo ratings yet

- D155axi-8 Sen06521-02 Circuit DiagramDocument29 pagesD155axi-8 Sen06521-02 Circuit Diagramhaimay118No ratings yet

- 661 Didb LV To32-33 Lxcos V1.0Document3 pages661 Didb LV To32-33 Lxcos V1.0hariana100% (1)

- Gas Gas Ec300 Parts CatalogDocument7 pagesGas Gas Ec300 Parts CatalogAlejandro EnriqueNo ratings yet

- Form Data Motor FM6Document50 pagesForm Data Motor FM6Fajri HakimNo ratings yet

- Dol Starter With Remote Start and StopDocument1 pageDol Starter With Remote Start and StopAthul ANo ratings yet

- BK130 1Document26 pagesBK130 1huychampiNo ratings yet

- PWM-OCXiv2.PDF PWM HV ModuleDocument11 pagesPWM-OCXiv2.PDF PWM HV ModuleDrazen Dan MijacikaNo ratings yet

- YQK Series Hydraulic Crimping Tools Operation ManualDocument3 pagesYQK Series Hydraulic Crimping Tools Operation ManualgalicruNo ratings yet

- Wiring Diagram: DC GeneratorDocument1 pageWiring Diagram: DC GeneratorAndi Ka100% (1)

- MPR50 User Manual Eng v1.78Document19 pagesMPR50 User Manual Eng v1.78nebiyou100% (2)

- D7150 en PDFDocument4 pagesD7150 en PDFSasko Dimitrov100% (1)

- Conexión Alternadores 4 PolosDocument2 pagesConexión Alternadores 4 PolosDaniel MuratallaNo ratings yet

- DCA-25ESK: DenyoDocument1 pageDCA-25ESK: DenyoAdeelNo ratings yet

- 4-3 Electrical Komponen SpecDocument9 pages4-3 Electrical Komponen Specibnu malkanNo ratings yet

- SML10 SystemDocument33 pagesSML10 SystemgilbertoNo ratings yet

- Mentor Talkback SystemDocument2 pagesMentor Talkback SystemLes OakesNo ratings yet

- Error Codes PDFDocument10 pagesError Codes PDFRosemarie QuitorianoNo ratings yet

- SOS Type Pressure Transmitter NS100A Series: SpecificationsDocument4 pagesSOS Type Pressure Transmitter NS100A Series: SpecificationsTin Chau TrungNo ratings yet

- Centrifugal Pump Split Case PDFDocument8 pagesCentrifugal Pump Split Case PDFApivit MalichaiNo ratings yet

- DynasetDocument64 pagesDynasetAlexis Peña0% (1)

- Trooper 3000 Series Process IndicatorDocument2 pagesTrooper 3000 Series Process Indicatorwramadhani65No ratings yet

- Cast Catalogo ORFS Ing PDFDocument90 pagesCast Catalogo ORFS Ing PDFJOSE ANTONIO MARTINEZ MORALESNo ratings yet

- Páginas Extraídas de Manual - MX2Document8 pagesPáginas Extraídas de Manual - MX2Anonymous 97JlpvN4No ratings yet

- Instructions For Pneumatic Operating Mechanism Type AA-10 For Oil Circuit BreakersDocument43 pagesInstructions For Pneumatic Operating Mechanism Type AA-10 For Oil Circuit BreakersJonathan PinillaNo ratings yet

- Generator Automatic Voltage Regulator Operation Ea465 Generator Automatic VoltageDocument6 pagesGenerator Automatic Voltage Regulator Operation Ea465 Generator Automatic Voltagefahad pirzadaNo ratings yet

- 02EN0780 Yd25 PDFDocument2 pages02EN0780 Yd25 PDFKevin TtitoNo ratings yet

- Control Panel: ISO 9001 Certified ISO 14001 / OHSAS18001 CertifiedDocument4 pagesControl Panel: ISO 9001 Certified ISO 14001 / OHSAS18001 CertifiedHaresh vaghelaNo ratings yet

- Ec140b Eng 2Document8 pagesEc140b Eng 2Mohamed Yousif HamadNo ratings yet

- Engine Failures 98Document58 pagesEngine Failures 98Abd ElGhanY AwdNo ratings yet

- PWM With Microcontroller 8051 For SCR or Triac Power ControlDocument3 pagesPWM With Microcontroller 8051 For SCR or Triac Power ControlDirek BoonturmNo ratings yet

- Apleton Receptacles-and-Plugs-ExplosionproofDocument39 pagesApleton Receptacles-and-Plugs-ExplosionproofMuhamad Priyatna100% (1)

- Lincoln Welding Machine ChecklistDocument1 pageLincoln Welding Machine ChecklistEjike Francis ChizobaNo ratings yet

- 841 VCB HVF&HVG Catalogue 2012.1Document56 pages841 VCB HVF&HVG Catalogue 2012.1Sergio Ignacio Zurita VargasNo ratings yet

- Axpert Eazy +LATESTDocument12 pagesAxpert Eazy +LATESTAmtech Aniruddh50% (2)

- ERU Series: Electric Remote ControllerDocument2 pagesERU Series: Electric Remote ControllerUziel CHIMINo ratings yet

- 400HP AC Drilling Motor WL250040 2Document2 pages400HP AC Drilling Motor WL250040 2HayLenLeeNo ratings yet

- Shark GFDocument2 pagesShark GFUlises PiscoyaNo ratings yet

- Instruction Manual: Installation - Operation - MaintenanceDocument13 pagesInstruction Manual: Installation - Operation - MaintenanceNamer HajiNo ratings yet

- RENR4343Document2 pagesRENR4343Cecilia Gomez.contrerasNo ratings yet

- Metal Enclosure IP65 Catalog FINALDocument10 pagesMetal Enclosure IP65 Catalog FINALUsman ZouqueNo ratings yet

- BCH Electric Ltd-Limit Switch-CatalogueDocument6 pagesBCH Electric Ltd-Limit Switch-CataloguesachmayaNo ratings yet

- Premier 300: CT/VT-Operated Energy MeterDocument2 pagesPremier 300: CT/VT-Operated Energy MeterMohammed Nafis N100% (2)

- Siwarex U Quick Guide v3 1Document15 pagesSiwarex U Quick Guide v3 1Chan Kok LamNo ratings yet

- Sid-8bt High Speed Transfer Operation ManualDocument29 pagesSid-8bt High Speed Transfer Operation ManualLEK MAN ꦲꦂꦩꦤ꧀ꦱꦸꦱꦤ꧀ꦠꦺꦴNo ratings yet

- Schematic - How To Make A Current Booster Circuit - 2022-10-18Document1 pageSchematic - How To Make A Current Booster Circuit - 2022-10-18Gilberto VidalNo ratings yet

- DNC160 398sdc005en00Document24 pagesDNC160 398sdc005en00Anonymous Xz3PgZR8No ratings yet

- DNC75 398sdc003en00Document30 pagesDNC75 398sdc003en00Anonymous Xz3PgZR8No ratings yet

- Schematic INDICT 2022-04-15Document1 pageSchematic INDICT 2022-04-15Marko MatićNo ratings yet

- Hayden Oil Cooler Catalogue ORCAERDocument8 pagesHayden Oil Cooler Catalogue ORCAERCOOLPLUS OIL COOLERNo ratings yet

- COOLPLUS-RSOL Heat Exchanger Oil CoolerDocument2 pagesCOOLPLUS-RSOL Heat Exchanger Oil CoolerCOOLPLUS OIL COOLERNo ratings yet

- COOLPLUS-FCY Heat Exchanger Oil CoolerDocument3 pagesCOOLPLUS-FCY Heat Exchanger Oil CoolerCOOLPLUS OIL COOLERNo ratings yet

- COOLPLUS-YRC Heat Exchanger Oil CoolerDocument4 pagesCOOLPLUS-YRC Heat Exchanger Oil CoolerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Loc-007-80l - Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Loc-007-80l - Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- COOLPLUS-YFC, YFCY Heat Exchanger Oil CoolerDocument2 pagesCOOLPLUS-YFC, YFCY Heat Exchanger Oil CoolerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus Ah2431t Ca Air Oil Cooler Heat ExchangerDocument1 pageCoolplus Ah2431t Ca Air Oil Cooler Heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Ah1680t-Ca - Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Ah1680t-Ca - Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Aw0607t-Ca-20l - Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Aw0607t-Ca-20l - Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Ah3818t-Ca-600l-Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Ah3818t-Ca-600l-Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Ah1490t-Dc - Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Ah1490t-Dc - Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Ah1490t-Ca-250l - Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Ah1490t-Ca-250l - Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Ah1470t-Dc - Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Ah1470t-Dc - Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLER0% (1)

- Coolplus-Ah1470t-Ca - Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Ah1470t-Ca - Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Ah1012t-Dc-100l-Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Ah1012t-Dc-100l-Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Coolplus-Ah1012t-Ca-100l-Air Oil Cooler/heat ExchangerDocument1 pageCoolplus-Ah1012t-Ca-100l-Air Oil Cooler/heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Af0510t Ca 10L CoolplusDocument1 pageAf0510t Ca 10L CoolplusCOOLPLUS OIL COOLERNo ratings yet

- Steel Pipes Dimensions - ANSI Schedule 40Document4 pagesSteel Pipes Dimensions - ANSI Schedule 40ciblixNo ratings yet

- Ar Quite Ctur A 2010Document485 pagesAr Quite Ctur A 2010Cordova Gutierrez OmarNo ratings yet

- Aus Cable Laying Standard1Document34 pagesAus Cable Laying Standard1Anonymous MDkp0hnb3lNo ratings yet

- Irjet V4i7516 PDFDocument7 pagesIrjet V4i7516 PDFRajat MohanNo ratings yet

- PR600 PLDocument38 pagesPR600 PLSantiago Marmolejo CifuentesNo ratings yet

- P304 - Wood Acoustic FenceDocument1 pageP304 - Wood Acoustic FencesarthibhavsarNo ratings yet

- DetailsDocument11 pagesDetailsAzllina AnuarNo ratings yet

- Daily Exam 2B OpenDocument4 pagesDaily Exam 2B OpenLatif RadwanNo ratings yet

- AHUs 2020Document36 pagesAHUs 2020Technical OfficeNo ratings yet

- Module No.1 Prepare Architectural Job RequirementsDrafting Tools Materials and InstrumentsDocument23 pagesModule No.1 Prepare Architectural Job RequirementsDrafting Tools Materials and InstrumentsJay S. On100% (1)

- Fire Therm IntucompoundDocument1 pageFire Therm Intucompoundopenid_WdYgOQj7No ratings yet

- Bracing Manual FluorDocument28 pagesBracing Manual FluornpwalNo ratings yet

- InvarDocument5 pagesInvardusan.papez9216No ratings yet

- RCC LAB-316 Design of A Single Reinforced Beam Both in WSD and USD and ComparisonDocument7 pagesRCC LAB-316 Design of A Single Reinforced Beam Both in WSD and USD and ComparisonRakash MondalNo ratings yet

- Jis B-1186Document21 pagesJis B-1186nate anantathatNo ratings yet

- Autoclave - Tools, Installation, Operation and MaintenanceDocument20 pagesAutoclave - Tools, Installation, Operation and Maintenancejbjb2000100% (1)

- Ammonia Relief Valves SystemDocument10 pagesAmmonia Relief Valves SystemXixxixaNo ratings yet

- NEW Atlanta Blue in House 2019Document2 pagesNEW Atlanta Blue in House 2019Sick FreakNo ratings yet

- 00 - Recommended Practices - ListDocument4 pages00 - Recommended Practices - ListJames CraikNo ratings yet

- Basis of DesignDocument7 pagesBasis of DesignAnonymous GlTpXopWNo ratings yet

- B - Namrata Karuna - Mit Chandya U21172 - Kalyan Mudris U21064Document8 pagesB - Namrata Karuna - Mit Chandya U21172 - Kalyan Mudris U21064Mit ChandyaNo ratings yet

- List of V.OsDocument43 pagesList of V.OsAilyn O. DungogNo ratings yet

- 03SD0B02Document4 pages03SD0B02Jhonny RinconesNo ratings yet

- BIM ThesisDocument102 pagesBIM ThesisSahil KaushikNo ratings yet

- CFA Coatings and ProtectionDocument24 pagesCFA Coatings and ProtectionangthiankongNo ratings yet

- BS-88R 2018 Literature On Corrosion Protection in Concrete StructuresDocument48 pagesBS-88R 2018 Literature On Corrosion Protection in Concrete StructuresM PMNo ratings yet

- NATA Sample Paper 1Document8 pagesNATA Sample Paper 1natahelper88% (8)

- 43 Opc Test Certificate (W-01 2019 )Document1 page43 Opc Test Certificate (W-01 2019 )alanNo ratings yet