Professional Documents

Culture Documents

Test Certificate No.: 0000524872: Chemical Analysis Mechanical Properties

Test Certificate No.: 0000524872: Chemical Analysis Mechanical Properties

Uploaded by

Suman JanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Certificate No.: 0000524872: Chemical Analysis Mechanical Properties

Test Certificate No.: 0000524872: Chemical Analysis Mechanical Properties

Uploaded by

Suman JanaCopyright:

Available Formats

JINDAL STEEL & POWER LIMITED

Post Box No. 16, Kharsia Road, Raigarh(Chhattisgarh)-PIN 496001 INDIA

Registered Office : Post Box No. 6, O.P. Jindal Marg , Hisar (Haryana)

Corporate Office : Jindal Centre, 12 Bhikaji Cama Place, New Delhi- 110066 INDIA

Phone: (07762) 227001-227010; Fax : 07762-227021-227022;Gram : PIG IRON

Email : qcrailmill@jspl.com

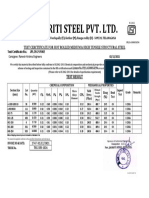

TEST CERTIFICATE FOR HOT ROLLED MEDIUM & HIGH TENSILE STRUCTURAL STEEL

Test Method : Tensile : IS 1608 ; Bend : IS 1599 ; Impact : IS 1757 ; Chemical : ASTM E 415 / IS 8811

Test Certificate No. : 0000524872 Date : 05.04.2022 Time : 06:50:03

Customer: M/s SWAMINA INTERNATIONAL PRIVATE LIMIT

C/o- HPCL-MITTAL ENERGY LIMITED,DELIVERY AT:-HMEL,BATHINDABATHINDA,PIN-151301 Punjab Page 1 of 1

We certify that the material described below fully conforms to IS 2062:2011. Chemical composition and mechanical properties of the product as tested in accordance with the scheme of testing and inspection

contained in the BIS certification marks licence No. CM/L-8558192 are as indicated below against each Heat Number.

Process of Manufacture : EAF/NOF-LRF-CCM-Hot Rolling ( PLEASE REFER TO IS:2062:2011 FOR DETAILS OF SPECIFICATION REQUIREMENT) Supply Condition : As Rolled

TEST RESULTS Deoxidation : Killed

Heat No. Pcs/ Weight Chemical Analysis Mechanical Properties

Bndl in MT LA/PA %C %S %P %Si %Mn %AL %Cu %V %Nb %Ti %Mo %Ni %B %Cr N2 CE P YS UTS %EL Bend Test

**

% MPa MPa Mand Dia

Min - - - - - - - - - - - - - 250 410 23

Max 0.22 .045 .045 0.40 1.50 - - - - - - - 0.41 - - -

(Section Depth(mm) X Fl.Width(mm) X Fl.Thk(mm) X WEB Thk(mm) X Sectional Weight/Mtr) & Grade WPB 254.1X254.6X14.2X8.6X73.1 & IS2062 E250BR

2125249 13 11.546 LA 0.16 0.006 0.017 0.16 0.80 0.022 0.009 0.001 0.000 0.001 0.002 0.007 0.01 0.0058 0.30 P 304 456 28 Satisfactory(2.0T)

2125249 PA 0.18 0.006 0.015 0.15 0.79 0.023 0.008 0.001 0.000 0.001 0.002 0.007 0.01 0.0068 0.31 P 303 454 28 Satisfactory(2.0T)

3125978 10 8.881 LA 0.17 0.006 0.016 0.16 0.76 0.022 0.005 0.002 0.001 0.002 0.002 0.008 0.02 0.0068 0.30 P 344 489 27 Satisfactory(2.0T)

3125978 PA 0.17 0.004 0.013 0.17 0.79 0.023 0.007 0.001 0.001 0.002 0.009 0.01 0.0079 0.30 P 345 491 27 Satisfactory(2.0T)

3126001 3 2.632 LA 0.17 0.011 0.019 0.17 0.75 0.024 0.005 0.002 0.001 0.001 0.002 0.006 0.02 0.0066 0.30 P 301 451 26 Satisfactory(2.0T)

3126001 PA 0.17 0.007 0.009 0.16 0.76 0.033 0.008 0.001 0.002 0.010 0.01 0.0086 0.30 P 300 449 26 Satisfactory(2.0T)

Section Total : 26 23.059

(Section Depth(mm) X Fl.Width(mm) X Fl.Thk(mm) X WEB Thk(mm) X Sectional Weight/Mtr) & Grade WPB 620X305X40X21X285.5 & IS2062 E250BR

2125122 1 3.121 LA 0.16 0.007 0.019 0.19 1.18 0.030 0.006 0.001 0.000 0.002 0.003 0.006 0.02 0.0069 0.36 P 292 459 24 Satisfactory(3.0T)

2125122 PA 0.18 0.007 0.019 0.22 1.18 0.033 0.006 0.001 0.002 0.002 0.009 0.01 0.0078 0.38 P 293 461 24 Satisfactory(3.0T)

Section Total : 1 3.121

Total : 27 26.180

The material conforms to the standard rolling tolerances as IS 12779

The above section(s) is / are equivalent to the following section(s) respectively : ,UC 254X254X73,WPB 600X300X285.5

** Gauge Length = 5.65sqrt(So) ,LA:LadleAnalysis,PA:ProductAnalysis,P:Product

Purchase Oder No. & Date : SIPL/KOL/HMEL_VGO_STR/STEEL/PO/0091/22.03.2022

Despatch Advice No : 27377453

Truck/Wagon No.: PB65AZ7417

Created by :DEEPAK_RUBM Printing Date 05.04.2022 & Time 10:53:55

FORMAT No. F13 (8.6.0-05) /02.08.2017 (SK Ojha) (Rakesh Yadav)

Authorised signatory (Mechanical Lab) Authorised signatory (Chemical Lab)

You might also like

- Page 1 of 6: Test Certificate No. 0000052877Document6 pagesPage 1 of 6: Test Certificate No. 0000052877panduranganraghurama78% (9)

- Test Certificate 16mmDocument1 pageTest Certificate 16mmSabyasachi Bangal50% (4)

- Apl Apollo Tubes LTD.: Manufacture Test Certificate For Steel Tubes For Structural PurposesDocument1 pageApl Apollo Tubes LTD.: Manufacture Test Certificate For Steel Tubes For Structural Purposestarun kaushal43% (7)

- Material TCDocument1 pageMaterial TCgmbakshiNo ratings yet

- 2452169253-6x1500mm E250Document1 page2452169253-6x1500mm E250Mohd YaskeenNo ratings yet

- Essar MTCDocument1 pageEssar MTCGowtham Vishvakarma33% (3)

- MTC Inv 053 PDFDocument1 pageMTC Inv 053 PDFBeshnu Garanaik100% (2)

- Test CertificateDocument7 pagesTest CertificateTARUNKUMAR100% (3)

- Test Certificate: Ferro Steel SolutionDocument1 pageTest Certificate: Ferro Steel SolutionNeeraj Singh80% (5)

- Nippon Sumitomo Seamless One Page-7Document1 pageNippon Sumitomo Seamless One Page-7rutuja rogeNo ratings yet

- 304 1.5MM PCDocument1 page304 1.5MM PCsabir hussain100% (1)

- TV 100x100x5#S235JRDocument5 pagesTV 100x100x5#S235JRRazvan CristeaNo ratings yet

- MTC-2 - Service STRCDocument1 pageMTC-2 - Service STRCHema NandhNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOMANIMARAN QC100% (1)

- Sumaja MTC 40 RNDDocument1 pageSumaja MTC 40 RNDRINL GZB0% (1)

- Mill Test Certificate: Jindal Stainless (Hisar) LimitedDocument1 pageMill Test Certificate: Jindal Stainless (Hisar) Limitedhemantmech0992000% (1)

- Mill'S Test Certificate ACC. TO EN 10204 / 3.1Document2 pagesMill'S Test Certificate ACC. TO EN 10204 / 3.1Durulsan MakinaNo ratings yet

- 1.20mm T.C - Mehta SteelsDocument1 page1.20mm T.C - Mehta SteelsRonak FireNo ratings yet

- 16 MM MS Plate 355 JR - India-MTCDocument1 page16 MM MS Plate 355 JR - India-MTCQc QatarNo ratings yet

- Cert ACERO INOX 316L PDFDocument1 pageCert ACERO INOX 316L PDFCarlos RomeroNo ratings yet

- Jindal Steel & Power LTD: Test CertificateDocument2 pagesJindal Steel & Power LTD: Test CertificateAmandeep Singh50% (2)

- R.K Steel Udyog PVT - LTD: Test Certificate For High Strength Deformed Steel Bars and Wires For Concrete ReinforcementDocument2 pagesR.K Steel Udyog PVT - LTD: Test Certificate For High Strength Deformed Steel Bars and Wires For Concrete Reinforcementnanda kishopre100% (4)

- Test Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811Document1 pageTest Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811akash_smhs0% (1)

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh Mehta100% (1)

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOBilal Luhar100% (2)

- Page 2 of 6: Test Certificate No. 0000052877Document1 pagePage 2 of 6: Test Certificate No. 0000052877pranesh kadam100% (2)

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Jindal Steel & Power Limited: Page 1 of 6Document1 pageJindal Steel & Power Limited: Page 1 of 6pranesh kadam100% (3)

- 300 C SailDocument2 pages300 C Sailchandrabhushan kushwahaNo ratings yet

- PSP TCDocument7 pagesPSP TCPSP kanpurdehatNo ratings yet

- 10MM - 60.960 TonDocument4 pages10MM - 60.960 TonRAJKUMAR CHATTERJEE. (RAJA.)100% (1)

- 6X1830 HR CoilDocument1 page6X1830 HR CoilBhavik PanchalNo ratings yet

- MTC PipeDocument1 pageMTC PipeMathavan ABMNo ratings yet

- TC 1419 McnallyDocument2 pagesTC 1419 McnallymtlhwhNo ratings yet

- Sample Test Certificate (24.12.2022)Document1 pageSample Test Certificate (24.12.2022)PalaniyandiNo ratings yet

- Test Certificate: CM/L-NO:5200036277Document10 pagesTest Certificate: CM/L-NO:5200036277TARUNKUMARNo ratings yet

- Bishweshwar Lal Steels: Hot Rolled Steel Strip For Welded Tubes and Pipes As Per Is: 10748 - 2004Document1 pageBishweshwar Lal Steels: Hot Rolled Steel Strip For Welded Tubes and Pipes As Per Is: 10748 - 2004ravigurajapuNo ratings yet

- Global Aluminium Private Limited: M/S. Wonjin Autoparts India PVT LTD, ChennaiDocument1 pageGlobal Aluminium Private Limited: M/S. Wonjin Autoparts India PVT LTD, ChennaiSonu Singh100% (1)

- Test Certificate: CM/L-NO:5530357Document10 pagesTest Certificate: CM/L-NO:5530357TARUNKUMARNo ratings yet

- Mgoha : ' "Xsjjl8Document1 pageMgoha : ' "Xsjjl8PetroPower OilandgasNo ratings yet

- 65X M L - 211224 - 180120 - Converted - by - AbcdpdfDocument1 page65X M L - 211224 - 180120 - Converted - by - AbcdpdfVidhyarthi Photocopy KhargoneNo ratings yet

- BF20112602 English MTC PDFDocument2 pagesBF20112602 English MTC PDFSvetlana VujovićNo ratings yet

- S355J2 Plate MTCDocument2 pagesS355J2 Plate MTCHarminder Kumar100% (1)

- Outokumpu: Si MN P S CR NiDocument3 pagesOutokumpu: Si MN P S CR NiDarkedgeNo ratings yet

- Test Certificate: Zhejiang Huaxia Flow Technology Co.,LtdDocument1 pageTest Certificate: Zhejiang Huaxia Flow Technology Co.,LtdjohnjaricocNo ratings yet

- 20MM - 63.150 TonDocument1 page20MM - 63.150 TonRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- JSW Steel MTCDocument5 pagesJSW Steel MTCNelson 2428No ratings yet

- 1jsl Ltd. TPI 3 (31803) MMDocument2 pages1jsl Ltd. TPI 3 (31803) MMPratik KarekarNo ratings yet

- DB-En 19 R-2-829 PDFDocument4 pagesDB-En 19 R-2-829 PDFashokNo ratings yet

- No. A-14-401751 Rev 00Document3 pagesNo. A-14-401751 Rev 00Adrian CeplinschiNo ratings yet

- 622888Document1 page622888DeepakNo ratings yet

- Flange 24 InchDocument2 pagesFlange 24 InchreniNo ratings yet

- MTC FITTINGSDocument5 pagesMTC FITTINGSAzee TitouNo ratings yet

- Test Certificates Stainless SteelDocument4 pagesTest Certificates Stainless SteelSurajPandey50% (4)

- 2.5 MM 1250....Document1 page2.5 MM 1250....Balaji Defence100% (1)

- Quality Mill Certificate 3:1: 1 9550 290 71050 AISI4140 290 6000 3Document1 pageQuality Mill Certificate 3:1: 1 9550 290 71050 AISI4140 290 6000 3Mohamed NabeilNo ratings yet

- Mittal Corp Limited Test Certificate FinalDocument1 pageMittal Corp Limited Test Certificate FinalMehmet SoysalNo ratings yet

- DMR-223 0001Document2 pagesDMR-223 0001Avishek GuptaNo ratings yet

- HMM Infra TCDocument1 pageHMM Infra TCraisingh085No ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOshekarNo ratings yet

- Yellowing Mechanisms of Epoxy and Vinyl Ester Resins Under Thermal, UV and Natural Aging Conditions and Protection MethodsDocument14 pagesYellowing Mechanisms of Epoxy and Vinyl Ester Resins Under Thermal, UV and Natural Aging Conditions and Protection MethodszrpyhjtzztNo ratings yet

- A Review of Seasonal Hydrogen Storage Multi-EnergyDocument20 pagesA Review of Seasonal Hydrogen Storage Multi-EnergyClara SanchezNo ratings yet

- Jurnal+AL KHIDMAH+Vol+1+No+2+April+2023+Hal+14 21Document8 pagesJurnal+AL KHIDMAH+Vol+1+No+2+April+2023+Hal+14 21Rismha AnthyNo ratings yet

- Selina Concise Chemistry Class 9 ICSE Solutions Chemical Changes and Reactions - A Plus TopperDocument27 pagesSelina Concise Chemistry Class 9 ICSE Solutions Chemical Changes and Reactions - A Plus TopperleenaapNo ratings yet

- Corrosion Behavior of Carbon Steel in The Monoethanolamine-H2O-CO2-O2Document11 pagesCorrosion Behavior of Carbon Steel in The Monoethanolamine-H2O-CO2-O2gabriel norbertNo ratings yet

- Certificate of Analysis: 17α-Hydroxy Progesterone AcetateDocument2 pagesCertificate of Analysis: 17α-Hydroxy Progesterone Acetatewindli2012No ratings yet

- Bopp-Films Technical Data SheetsDocument76 pagesBopp-Films Technical Data SheetsAhmad SalahNo ratings yet

- RVWN' M Vi-01912-886558: GŠ Ji Ch©Vqe Ë Ag© I Ivmvqwbk EübDocument17 pagesRVWN' M Vi-01912-886558: GŠ Ji Ch©Vqe Ë Ag© I Ivmvqwbk EübLiam Saul DuncanNo ratings yet

- Chemistry - Free High School Science Texts - A Textbook For High Schools Students Studying Chemistry - FHSST 2005 PDFDocument140 pagesChemistry - Free High School Science Texts - A Textbook For High Schools Students Studying Chemistry - FHSST 2005 PDFYoussef ArbaNo ratings yet

- Weed Suppression by Release of Isothiocyanates From Turnip-Rape MulchDocument7 pagesWeed Suppression by Release of Isothiocyanates From Turnip-Rape Mulchsaman rasulNo ratings yet

- Nitoflor TF10000Document3 pagesNitoflor TF10000mrameshceNo ratings yet

- Acid Base Titration Post LabDocument3 pagesAcid Base Titration Post Labapi-532693623No ratings yet

- R410a IceloongDocument6 pagesR410a IceloongMarco Ruales100% (2)

- Chemical Engineering Journal: A B C D e e CDocument10 pagesChemical Engineering Journal: A B C D e e CHemanth Peddavenkatappa GariNo ratings yet

- Cambridge IGCSE: Chemistry 0620/22Document16 pagesCambridge IGCSE: Chemistry 0620/22SasukeNo ratings yet

- J LASTIC 101 DATA SheetDocument2 pagesJ LASTIC 101 DATA SheetAdnanCassimNo ratings yet

- A Novel Sample Preparation For Shotgun Proteomics Characterization of HCPs in AntibodiesDocument9 pagesA Novel Sample Preparation For Shotgun Proteomics Characterization of HCPs in AntibodiesTaylor SimmonnsNo ratings yet

- Epimeya: Ribulose S-Phosprade Isomer YaseDocument1 pageEpimeya: Ribulose S-Phosprade Isomer YaseOmpriya SNo ratings yet

- Advanced Material Application in Civil Engineering-Reactive Powder Concrete - Atri Agrawal, Nirav ThakkarDocument8 pagesAdvanced Material Application in Civil Engineering-Reactive Powder Concrete - Atri Agrawal, Nirav Thakkarbemd_ali6990100% (2)

- Optimization of Ultrasonic Treatment of Apple (Malus Domestica) Mash in The Extraction of Juice With High Antioxidant ContentDocument4 pagesOptimization of Ultrasonic Treatment of Apple (Malus Domestica) Mash in The Extraction of Juice With High Antioxidant ContentIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Class 11 Chemistry Support MaterialDocument182 pagesClass 11 Chemistry Support Materialmauryadc.15No ratings yet

- Swiss Target PredictionDocument5 pagesSwiss Target PredictionramdaniNo ratings yet

- 4410 - Section E - Technical PDFDocument45 pages4410 - Section E - Technical PDFArnaldo BenitezNo ratings yet

- Sodium Chloride: Standard Specification ForDocument4 pagesSodium Chloride: Standard Specification Forsebastian novoaNo ratings yet

- A Review of Biogas Utilisation, Purification and Upgrading TechnologiesDocument17 pagesA Review of Biogas Utilisation, Purification and Upgrading TechnologiesXavier OrtizNo ratings yet

- Human Resource Management Version 2 0 2nd Portolese Solution ManualDocument36 pagesHuman Resource Management Version 2 0 2nd Portolese Solution Manualvill.jay.2tjq100% (39)

- Index: Desktop GuideDocument6 pagesIndex: Desktop GuideLungu RoxanaNo ratings yet

- HND Polymer Note Part OneDocument46 pagesHND Polymer Note Part OnemuhammadmaihadisiNo ratings yet

- Microbial Technique Iii HndiiDocument11 pagesMicrobial Technique Iii Hndiisanusi bello bakuraNo ratings yet

- Method To Recover A Lipophilic Drug From Hydroxypropyl Methylcellulose Matrix TabletsDocument9 pagesMethod To Recover A Lipophilic Drug From Hydroxypropyl Methylcellulose Matrix TabletscurtisvaleroNo ratings yet