Professional Documents

Culture Documents

Course Outcome CL: CIE-25 Marks SEE-100 Marks

Course Outcome CL: CIE-25 Marks SEE-100 Marks

Uploaded by

Sreedhar MCopyright:

Available Formats

You might also like

- Heui Fuel System c9 EngineDocument25 pagesHeui Fuel System c9 Enginebabaisandip91% (53)

- Isa-Tr75 25 02-2000Document40 pagesIsa-Tr75 25 02-2000Daniel Leonardo Barrera EspartaNo ratings yet

- P&ID AbbreviationDocument4 pagesP&ID AbbreviationDjil Rezoug100% (5)

- 3.fluid Power EngineeringDocument13 pages3.fluid Power Engineeringsnemo30No ratings yet

- Hyd& PneumaticsDocument18 pagesHyd& PneumaticssathishNo ratings yet

- FM - FP - CompressedDocument215 pagesFM - FP - CompressedKumar SubramanianNo ratings yet

- Hyd & Pneumatics LabDocument6 pagesHyd & Pneumatics LabPepe AkashNo ratings yet

- 2171912Document3 pages2171912Krupal VithlaniNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19Chandler BingNo ratings yet

- Hydraulics and Pneumatics SyllabusDocument2 pagesHydraulics and Pneumatics SyllabusMulu Girmay67% (3)

- Amt 1201 Midterm Lab Module 1Document11 pagesAmt 1201 Midterm Lab Module 1stzy405No ratings yet

- 2 Basic Thermal Engg.Document19 pages2 Basic Thermal Engg.Pepe AkashNo ratings yet

- Course Title Advanced Fluid Mechanics Course Level: UG Credit Units: 04 Course Code: MAE304Document4 pagesCourse Title Advanced Fluid Mechanics Course Level: UG Credit Units: 04 Course Code: MAE304Surjit DuttaNo ratings yet

- 3.automobile Engineering-IDocument14 pages3.automobile Engineering-IAmrithNo ratings yet

- Advanced Automotive SystemsDocument14 pagesAdvanced Automotive SystemsVikram Athreya VNo ratings yet

- AICTE Model Curriculum Scheme2020-2021 - 06.02.2021Document55 pagesAICTE Model Curriculum Scheme2020-2021 - 06.02.2021Deedad SaleemNo ratings yet

- Sona College of Technology: Department of Mechatronics EngineeringDocument41 pagesSona College of Technology: Department of Mechatronics EngineeringKanishk KannaNo ratings yet

- New SyllabusDocument4 pagesNew Syllabuspriyankaraut0014No ratings yet

- Ihp PDFDocument9 pagesIhp PDFKalpesh MadhaviNo ratings yet

- 1.elements of Mechanical Engineering Science-1Document17 pages1.elements of Mechanical Engineering Science-1Ashrit sarurNo ratings yet

- Lab Manual Hydraulics and Pneumatics .Document56 pagesLab Manual Hydraulics and Pneumatics .Aniket ChavanNo ratings yet

- Gujarat Technological University: Semester - IV Subject Name: Oil Hydraulics and PneumaticsDocument4 pagesGujarat Technological University: Semester - IV Subject Name: Oil Hydraulics and PneumaticsNisarg ShahNo ratings yet

- 2.industrial ElectronicsDocument12 pages2.industrial ElectronicsNIKHIL ASNo ratings yet

- Nowledge of Science,: Course Outcome CLDocument15 pagesNowledge of Science,: Course Outcome CLAbhishek DadhichNo ratings yet

- Hydraulic & Pneumatic ControlsDocument9 pagesHydraulic & Pneumatic ControlsVikram Rao100% (1)

- 4th Sem NEP SyllabusDocument11 pages4th Sem NEP SyllabusVikram C KNo ratings yet

- BE MechanicalDocument162 pagesBE Mechanicalsatish kurraNo ratings yet

- Instruction: 4 Lectures & 1 Tutorial / Week Sessional Marks: 40 End Exam: 3 Hours End Exam Marks: 60Document3 pagesInstruction: 4 Lectures & 1 Tutorial / Week Sessional Marks: 40 End Exam: 3 Hours End Exam Marks: 60Palaka RahulNo ratings yet

- Course CurriculumDocument4 pagesCourse CurriculumPRASENJIT MUKHERJEENo ratings yet

- HVACR 10 Module 1 (FINAL)Document56 pagesHVACR 10 Module 1 (FINAL)Homer R. MagistradoNo ratings yet

- 3rd Year Copy 2Document43 pages3rd Year Copy 2sai jaswanth putturuNo ratings yet

- H & P SyllabusDocument3 pagesH & P SyllabusDrPrashant NeheNo ratings yet

- Automotive Electrical and Elctronics SystemsDocument15 pagesAutomotive Electrical and Elctronics SystemsAmrithNo ratings yet

- MechatronicsDocument3 pagesMechatronicsAshutosh KumarNo ratings yet

- Fluid Power Engineering FPE 18ME55 Syllabus 2018 19Document3 pagesFluid Power Engineering FPE 18ME55 Syllabus 2018 19ChinthanNo ratings yet

- Course plan-MFE303Document6 pagesCourse plan-MFE303sureshNo ratings yet

- ME8694 Hydraulics and Pneumatics SyllabusDocument2 pagesME8694 Hydraulics and Pneumatics SyllabusThangamKumarNo ratings yet

- Birla Institute of Technology and Science-Pilani - Hyderabad CampusDocument3 pagesBirla Institute of Technology and Science-Pilani - Hyderabad CampusAgtNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19Pratik VishwakarmaNo ratings yet

- Anna University Semester II Syllabus (Regulation 2017)Document10 pagesAnna University Semester II Syllabus (Regulation 2017)BENHAR ARVINDNo ratings yet

- Production Handbook - Facilities & MaintenanceDocument454 pagesProduction Handbook - Facilities & MaintenancePerfect Trend Energy100% (1)

- Transmision Distribution and UtilisationDocument24 pagesTransmision Distribution and UtilisationVijaya BhaskerNo ratings yet

- P1icic03 Ic Engines SyllabusDocument8 pagesP1icic03 Ic Engines SyllabusSriramulu JaichandarNo ratings yet

- ME453 - 1 IntroDocument55 pagesME453 - 1 IntroElormeNo ratings yet

- Syllabus Hydraulics and Pneumatics (Me8694) (III Year Vi Sem Mech) (r2017)Document2 pagesSyllabus Hydraulics and Pneumatics (Me8694) (III Year Vi Sem Mech) (r2017)ganeshNo ratings yet

- SY BTech Mech Syllabus AutonomousDocument30 pagesSY BTech Mech Syllabus Autonomousjeetupatilp7No ratings yet

- Fluid Power SystemDocument2 pagesFluid Power SystemVijay Shakar0% (1)

- Aeronautical Engineering 4th YearDocument19 pagesAeronautical Engineering 4th YearMuskan RawatNo ratings yet

- Vel Tech High Tech DR - Ranagarajan DR - Sakunthala Engineering College - Department of ECEDocument27 pagesVel Tech High Tech DR - Ranagarajan DR - Sakunthala Engineering College - Department of ECEkarthikapecNo ratings yet

- 5th Sem Course SyllabusDocument9 pages5th Sem Course SyllabusSahiti DarikaNo ratings yet

- Automobile Sem 5 PDFDocument49 pagesAutomobile Sem 5 PDFFiroz AminNo ratings yet

- Basic Hydraulic Systems and ComponentsDocument67 pagesBasic Hydraulic Systems and Componentsnareshkumaran100% (8)

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

- Distillation Design and Control Using Aspen SimulationFrom EverandDistillation Design and Control Using Aspen SimulationRating: 5 out of 5 stars5/5 (2)

- Decoding Reliability-Centered Maintenance Process for Manufacturing Industries 10th Discipline of World Class Maintenance Management: 1, #7From EverandDecoding Reliability-Centered Maintenance Process for Manufacturing Industries 10th Discipline of World Class Maintenance Management: 1, #7No ratings yet

- Process System Value and Exergoeconomic Performance of Captive Power PlantsFrom EverandProcess System Value and Exergoeconomic Performance of Captive Power PlantsNo ratings yet

- Small Unmanned Fixed-wing Aircraft Design: A Practical ApproachFrom EverandSmall Unmanned Fixed-wing Aircraft Design: A Practical ApproachNo ratings yet

- Multivariable Predictive Control: Applications in IndustryFrom EverandMultivariable Predictive Control: Applications in IndustryNo ratings yet

- WWW - Manaresults.Co - In: (Common To Ae, Me, MSNT)Document3 pagesWWW - Manaresults.Co - In: (Common To Ae, Me, MSNT)Sreedhar MNo ratings yet

- WWW - Manaresults.Co - In: (Common To Me, Ae, MSNT)Document2 pagesWWW - Manaresults.Co - In: (Common To Me, Ae, MSNT)Sreedhar MNo ratings yet

- WWW - Manaresults.Co - In: (Common To AE, MSNT, ME)Document3 pagesWWW - Manaresults.Co - In: (Common To AE, MSNT, ME)Sreedhar MNo ratings yet

- Sme 3033 Finite Element Method Steady STDocument37 pagesSme 3033 Finite Element Method Steady STSreedhar MNo ratings yet

- Chap 5 Finite Elements For Heat Transfer Problems: Finite Element Analysis and Design Nam-Ho Kim Audio by Raphael HaftkaDocument16 pagesChap 5 Finite Elements For Heat Transfer Problems: Finite Element Analysis and Design Nam-Ho Kim Audio by Raphael HaftkaSreedhar MNo ratings yet

- JNTUH - B Tech - 2019 - 3 2 - May - R18 - MECH - 136BW FEM Finite Element MethodsDocument2 pagesJNTUH - B Tech - 2019 - 3 2 - May - R18 - MECH - 136BW FEM Finite Element MethodsSreedhar MNo ratings yet

- F Inite Element MethodDocument66 pagesF Inite Element MethodSreedhar MNo ratings yet

- Micro Level Lesson Planning: Department of Mechanical EngineeringDocument2 pagesMicro Level Lesson Planning: Department of Mechanical EngineeringSreedhar MNo ratings yet

- 5.syllabus Copy and Brief On PrerequisitesDocument3 pages5.syllabus Copy and Brief On PrerequisitesSreedhar MNo ratings yet

- R16 Nano Technology-SyllabusDocument2 pagesR16 Nano Technology-SyllabusSreedhar MNo ratings yet

- Fluid Power Systems Theory, Worked Examples and Problems by A. B. Goodwin (Auth.)Document221 pagesFluid Power Systems Theory, Worked Examples and Problems by A. B. Goodwin (Auth.)Sreedhar MNo ratings yet

- Pressure Control Equipment PDFDocument5 pagesPressure Control Equipment PDFben mohamed SofianeNo ratings yet

- 3 Element ControllerDocument3 pages3 Element ControllermgkvprNo ratings yet

- Roc On Water Control ValveDocument4 pagesRoc On Water Control ValveSBeardNo ratings yet

- A A10VSO140 DFR1 31R-VPB12N00 - R910945253 - en - 202311333Document23 pagesA A10VSO140 DFR1 31R-VPB12N00 - R910945253 - en - 202311333motasem alqaisiNo ratings yet

- C4 - Components in Hydraulic SystemDocument64 pagesC4 - Components in Hydraulic SystemKubheran SelvathuraiNo ratings yet

- 357 Series Control Valves (Obsolete Product)Document17 pages357 Series Control Valves (Obsolete Product)Yogurtu NngeNo ratings yet

- Electronic Controlled Fuel SystemDocument34 pagesElectronic Controlled Fuel SystemMohamed ZakiNo ratings yet

- 5-1. Machatronics SystemDocument50 pages5-1. Machatronics Systemmarcelo rojas100% (1)

- Techno News: Introduction of Safety Screen Filter For Control Valve With FIVA / ELFI / ELVADocument6 pagesTechno News: Introduction of Safety Screen Filter For Control Valve With FIVA / ELFI / ELVASrivatsanNo ratings yet

- c4 - Components in Hydraulic SystemDocument65 pagesc4 - Components in Hydraulic SystemBazil Suhaimi100% (1)

- Liu Gong Hydraulic System PDFDocument86 pagesLiu Gong Hydraulic System PDFYadi100% (3)

- April 15, 1969: R. G., McintyreDocument9 pagesApril 15, 1969: R. G., McintyregorgiNo ratings yet

- GP 15-09-01 Control ValvesDocument23 pagesGP 15-09-01 Control ValvesAllia-Europe100% (1)

- Industrial Automation Engineers Interview QuestionsDocument5 pagesIndustrial Automation Engineers Interview QuestionsJêmš NavikNo ratings yet

- Proces ValveDocument98 pagesProces Valvehimansh871100% (1)

- Mokveld-Product Sheet Axial Control ValveDocument2 pagesMokveld-Product Sheet Axial Control Valveจตุพล กมลเลิศNo ratings yet

- Development of 360 Degree Rotating VehicleDocument4 pagesDevelopment of 360 Degree Rotating VehicleIJIRST57% (7)

- Control Narratives - Drum Level ControlDocument6 pagesControl Narratives - Drum Level ControlRahul AnandNo ratings yet

- Servo Valve OperationDocument16 pagesServo Valve OperationBhagat ShardanandNo ratings yet

- Mohamad Safuan Sheafi (CD 5000)Document24 pagesMohamad Safuan Sheafi (CD 5000)givepleaseNo ratings yet

- Fundamentals of Final Control ElementsDocument57 pagesFundamentals of Final Control ElementshazemNo ratings yet

- Series: CC CCT CCVS/CCVLDocument15 pagesSeries: CC CCT CCVS/CCVLxmen norNo ratings yet

- Man B&W: GeneralDocument18 pagesMan B&W: GeneralFelipe RibasNo ratings yet

- H CONTROLAIR Valves PDFDocument18 pagesH CONTROLAIR Valves PDFebrahem khderNo ratings yet

- What Is Pneumatic SystemDocument2 pagesWhat Is Pneumatic SystemAiman ShukriNo ratings yet

- Westlock IOM TECHUK-20 ATEX ICoT 5000Document38 pagesWestlock IOM TECHUK-20 ATEX ICoT 5000Smith IncheonNo ratings yet

- High Plains Engineering: HPE-TR-1999-05-01aDocument20 pagesHigh Plains Engineering: HPE-TR-1999-05-01azanazan110% (1)

Course Outcome CL: CIE-25 Marks SEE-100 Marks

Course Outcome CL: CIE-25 Marks SEE-100 Marks

Uploaded by

Sreedhar MOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Course Outcome CL: CIE-25 Marks SEE-100 Marks

Course Outcome CL: CIE-25 Marks SEE-100 Marks

Uploaded by

Sreedhar MCopyright:

Available Formats

Course Title: Fluid Power Transmission And Control

Course Code: 15AT41T

Systems

Credits (L:T:P) : 4:0:0 Core/ Elective: Core

Type of course: Lectures Total Contact Hours: 52

CIE-25 Marks SEE- 100 Marks

Prerequisites:

Basic knowledge of subjects studied in the previous semesters.

Course Objectives:

To know the concepts of hydraulics & pneumatics, components of hydraulic and pneumatic

circuits and applications of hydraulics and pneumatics in automobiles.

On successful completion of the course, the students will be able to attain CO'S:

CL Linked Teaching

Course Outcome PO Hrs

Understand the purpose and applications of

CO1 R/U/A 1,2,3,10 04

fluid power systems in Automobiles.

Explain functions, types, construction and

working of different types of valves and R/U 1,2,10 12

CO2 actuators.

Understand purpose, types construction and

working of different components of different R/U 1,2,10 12

CO3 hydraulic circuits.

Explain purpose, applications, types,

construction and working of different R/U/A 1,2,3,10 9

CO4 components of pneumatic system.

Explain purpose, types, construction and

working and maintenance of different R/U/A 1,2,3,10 9

C05 components of different pneumatic system.

Explain the merits of combination circuits by

understanding the construction and working of R/U/A 1,2,3,10 06

CO6 these systems.

Total sessions 52

Directorate Of Technical Education Karnataka State 15AT41T Page 1

COURSE-PO ATTAINMENT MATRIX

Course Programme Outcomes

1 2 3 4 5 6 7 8 9 10

Fluid power

transmission and 3 3 3 - - - - - - 3

control

Level 3- Highly Addressed, Level 2-Moderately Addressed, Level 1-Low Addressed.

Method is to relate the level of PO with the number of hours devoted to the COs which address the given PO.

If >40% of classroom sessions addressing a particular PO, it is considered that PO is addressed at Level 3

If 25 to 40% of classroom sessions addressing a particular PO, it is considered that PO is addressed at Level 2

If 5 to 25% of classroom sessions addressing a particular PO, it is considered that PO is addressed at Level 1

If < 5% of classroom sessions addressing a particular PO, it is considered that PO is considered not-addressed.

COURSE CONTENT AND BLUE PRINT OF MARKS FOR SEE

Unit Hour Questions to be set Marks weightage

No Unit Name (%)

R U A

I Introduction 04 5 5 6.9

II Valves and Actuators 12 30 5 24.1

III Design of Hydraulic Circuits 12 5 30 24.1

IV Pneumatic systems 9 5 15 5 17.2

Design of Pneumatic 5 15 5 17.2

V 9

Circuits

VI Combination Circuits 06 15 10.4

Total 52 145 100

Legend: R; Remember, U: Understand A: Application

Course Delivery:

The course will be delivered through lectures, presentations and classroom discussions.

Course Content:

UNIT I

INTRODUCTION 04 hr

Fluid power engineering – definition - importance - areas of application, application in

automobiles, fluid-definition- properties, Pascal Law with illustrations, transmission of power

- methods, fluid system – types –hydraulics – pneumatics - block diagrams.

UNIT II

VALVES AND ACTUATORS 12 hr

valves – functions – types – lifting type – sliding/rotary type – poppet – ball – flap – disc –

spool valves, requirements - pressure control valve - pressure relief valve – pressure (counter)

Directorate Of Technical Education Karnataka State 15AT41T Page 2

balance valve - pressure reducing valves, directional control valves - 2/2 - 3/2 - 4/2 - 5/2 - 5/3,

control of valves – manual – mechanical - hydraulic – pneumatic - electro pneumatic,

combination valves - hydro pneumatic – electro hydraulic - electro pneumatic, flow control

valve, non return/check valves, pilot operated sequence valve.

Actuators –functions, types, cylinder type-ram type, and piston type- single acting cylinder-

double acting cylinder- Rotary actuators- Gear- vane- piston- Unidirectional – Bidirectional

actuators.

UNIT III

DESIGN OF HYDRAULIC CIRCUITS 12 hr

Hydraulics - definition, properties of hydraulic fluids, pumps - necessity - classification,

construction and working of - external gear, lobe, Vane pumps, Piston-radial pumps,

Reservoir, Accumulators-weight loaded- spring loaded- gas loaded, Intensifier, pressure

switches, pressure regulators.

Hydraulic Circuits-Hydraulic symbols, Port markings- ports and positions, Basic hydraulic

circuits- Meter in circuits- Meter out circuits- Bleed off circuits - Accumulator circuits -

Regenerative circuits-pressure reducing circuits, Maintenance of hydraulic system- common

faults - visual checks of oil- causes of contamination- preventive measures - maintenance

schedule.

Hydraulic circuits of systems used in automotive-hydraulic brake-clutch- shock absorber -

hydraulic power steering.

UNIT IV

PNEUMATIC SYSTEMS 09hr

Pneumatics – definition - importance - areas of Applications, automotive applications.

properties of air, humidity, Pneumatic Components - Air compressors-necessity-types-

reciprocating-diaphragm-vane compressor, requirement of multi stage compressors,

reservoirs- functions of reservoirs, air filter - screen type - bowl type, pressure regulators –

diaphragm type, lubricator, FRL unit.

Air motors- piston motor, gear motor, sliding vane motor

UNIT V

DESIGN OF PNEUMATIC CIRCUITS 09hr

Pneumatic Symbols, Basic pneumatic circuit -control of double acting cylinder using 4/2

DCV-pilot controlled double acting cylinder 4/2 DCV - speed control circuit for a double

acting cylinder - semi-automatic material handling circuit - time delay circuit, pneumatic tool

circuit. Maintenance of pneumatic systems - common faults - preventive measures -

maintenance schedule.

UNIT VI

COMBINATION CIRCUITS 06hr

Combination circuit - advantages - hydro pneumatic circuits - air over oil circuit- air over oil

intensifier circuit - mechanical hydraulic servo system- electro hydraulic servo system,

comparison of hydraulic - pneumatic and hydro pneumatic systems - power steering circuit -

power brake circuit - hoist circuit.

Directorate Of Technical Education Karnataka State 15AT41T Page 3

Resources

Reference books

Sl no Title of book author publisher

1 Hydraulic and Pneumatic Controls K.Shanmuga.Sundaram S.Chand & Co

2 Pneumatic Systems S.R.Majumdar Tata McGrawhill

3 Pneumatic Controls Joji P Wiley India Pvt Ltd

4 Fluid Power with Applications Anthony Esposito Pearson india

Jaico publishing

5 Hydraulics & Pneumatics Andrew Parr

house

A Alavudeen

Fluid Power Transmission & Charotor Publisher

6 Khalid Hussain Syed

Control Anand-388001

N Shanmugum

Web links:-

Pascal’s Law Demo

https://www.youtube.com/watch?v=VxLTDtaRCZk

Basic Hydraulic System

https://www.youtube.com/watch?v=KgphO-u7MlQ

Valves

https://www.youtube.com/watch?v=3RAxRed7QuE

Spool Valve

https://www.youtube.com/watch?v=dnVjKV74sAQ

Hydraulic Lifters

https://www.youtube.com/watch?v=lorANZ1Tptw

4/2 Directional Control Valves

https://www.youtube.com/watch?v=XOYqnLWCYEc

Pressure Regulating Valve

https://www.youtube.com/watch?v=sFAYW_D3G_g

Pilot Operated Pressure Relief Valve

https://www.youtube.com/watch?v=q5NV2gBsryk

Pressure Relief Valve Working

https://www.youtube.com/watch?v=DAqnpaHf2Qs

Pressure Reducing Valve

https://www.youtube.com/watch?v=YgnwuTJB-wc&list=PL9DA65D90A4561300

Mechanicl Control Valve

https://www.youtube.com/watch?v=HJRE5EfTPcU

Non Return/Check Valve

Directorate Of Technical Education Karnataka State 15AT41T Page 4

https://www.youtube.com/watch?v=C-8FKgxSg68

https://www.youtube.com/watch?v=StHAmZpDHi0

https://www.youtube.com/watch?v=XAItnsUcES0&list=PLDaXKeQT8i0-

ojLE8MMzWQXp1HfeJMqc1

Pumps

https://www.youtube.com/watch?v=KM3ivQL6W6w

https://www.youtube.com/watch?v=bdib6XwxNuc

Gear Pump

https://www.youtube.com/watch?v=c6gwU7IHtlo

Vane Pump

https://www.youtube.com/watch?v=BnvzPoNSXCg

Lobe Pump

https://www.youtube.com/watch?v=vE7y0ElIrgk

Actuators

https://www.youtube.com/watch?v=cScz67tWqCY

Radial Piston Pump

https://www.youtube.com/watch?v=a58zzqfF5N0

Air Compressors

https://www.youtube.com/watch?v=Ue7BkzBARXw

FRL Unit

https://www.youtube.com/watch?v=zPT0YDERfy4

Student Activities to be performed to award five marks in continuous internal

evaluation:

Visit any service centres /workshop/ construction company / earth moving vehicle showroom

and

1. Prepare a report with materials and manufacturing process of different types of

hydraulic valves, pumps and actuators used in earth moving/ construction vehicles.

2. Prepare a report on different types of pneumatic compressors, motors, filters,

regulators and lubricators in earth moving and construction vehicles.

3. Draw hydraulic circuits used in Automobile's, construction vehicles and garage

equipment/machines.

4. Draw pneumatic circuits used in Automobile's, construction vehicles and garage

equipment/machines.

Note:

1. Student should prepare a report on any one of the above/similar activity, which

helps in achieving above course outcomes.

Directorate Of Technical Education Karnataka State 15AT41T Page 5

2. The report prepared should be approved by the concerned staff and HOD.

3. The activity group should consist of maximum of three students.

Directorate Of Technical Education Karnataka State 15AT41T Page 6

MODEL OF RUBRICS FOR ASSESSING STUDENT ACTIVITY

Note: The dimensions given in below table are representatives; lecturer has to design/decide the dimensions based on the activity given.

Dimension Scale Students Score

Unsatisfactory Developing Satisfactory Good Exemplary 5marks 1 2 3 4 5

1marks 2marks 3marks 4marks

1. Research and gather Does not collect Collects very Collects basic Collects more Collects a great 1

information information relate limited information, most information, most deals of

to topic information, some refer to the topic refer to the topic information, all

relate to topic refer to the topic

2.Full fills teams roles Does not perform Performs very Performs nearly all Performs almost Performs all duties 2

and duties any duties little duties duties all duties of assigned team

assigned to the roles

team role

3.Shares work equally Always relies on Rarely does the Usually does the Always does the Always does the 3

others to do the assigned work, assigned work, assigned work, assigned work,

work often needs rarely needs rarely needs without needing

reminding reminding reminding. reminding

4. listen to other team Is always talking, Usually does most Listens, but Listens and talks a Listens and talks a 4

mates never allows of the talking, sometimes talk too little more than fare amount

anyone to else to rarely allows much, needed.

speak others to speak

Grand Average/Total=1+2+3+4/4=10/4=2.5=3 3

Directorate Of Technical Education Karnataka State 15AT32T Page 7

Course Assessment and Evaluation Scheme:

When/Where

Method

Max Evidence Course

What To whom (Frequency in

Marks collected outcomes

the course)

Three IA Tests;

Direct Assessment

CIE(Continuous (Average of 20 Blue books 1,2,3,4,5,6

IA

Internal three Tests)

Evaluation)

Students

Activity

Activity 05 1,2,3,4,5,6

reports

SEE ( Semester

End End of the Answer

End 100 1,2,3,4,5,6

Exam course scripts at BTE

Examination)

1,2 &3

Middle of the Feedback

Student Feedback on course Delivery of

course forms

course

Indirect Assessment

Students

1,2,3,4,5&6

Questionnaires

Effectiveness of

End of the Delivery of

End of Course Survey

course instructions &

Assessment

Methods

*CIE – Continuous Internal Evaluation *SEE – Semester End Examination

Note: I.A. test shall be conducted for 20 marks. Average marks of three tests shall be rounded off

to the next higher digit.

Directorate Of Technical Education Karnataka State 15AT41T Page 8

FORMAT OF I A TEST QUESTION PAPER (CIE)

Test/Date and Time Semester/year Course/Course Code Max Marks

Ex: I test/6 th weak of I/II SEM

20

sem 10-11 Am

Year:

Name of Course coordinator : Units:__

CO’s:____

Question

Question MARKS CL CO PO

no

1

2

3

4

Note: Internal choice may be given in each CO at the same cognitive level (CL).

MODEL QUESTION PAPER (CIE)

Note: The lecturer has to fallow the question paper blue print given in above table to

prepare CIE question paper also.

Test/Date and

Semester/year Course/Course Code Max Marks

Time

Fluid power transmission and

Ex: I test/6 th week IV semester

control 20

of sem 10-11 Am

Year: 2015-16 Course code:15AT41T

Name of Course coordinator :

Units:1,2 Co: 1,2

Note: Answer all questions

Question

Question CL CO PO

no

1 Classify the valves based on their function. 5marks A 1 1,2,3,10

2 List the applications of fluid power engineering in U 1 1,2,10

industries. 5marks

Or

Explain Pascal’s law with example. 5marks

3 Explain the construction and working of poppet valve with U 2 1,2,10

a neat sketch. 10marks

Or

Explain working of bidirectional actuator with a neat

sketch. 10marks

LEGEND: R; REMEMBER, U: UNDERSTAND A: APPLICATION

Directorate Of Technical Education Karnataka State 15AT41T Page 9

MODEL QUESTION BANK

CO1:Understand the purpose and applications of fluid power systems in Automobiles.

FIVE MARK QUESTIONS

1. Explain fluid power engineering. (U)

2. Mention the importance of fluid power engineering in industries. (A)

3. List the applications of fluid power engineering in industries. (A)

4. List the applications of fluid power engineering in automobiles. (A)

5. Explain Pascal’s law with example. (U)

6. Explain power transmission methods. (U)

7. Sketch block diagram of hydraulic system and label the parts. (U)

8. Sketch block diagram of pneumatic system and label the parts (U).

TEN MARK QUESTIONS

1. Explain the properties of fluids. (U)

2. List and mention the functions of hydraulic system components with block

diagram. (R)

3. List and mention the functions of pneumatic system components with block

diagram. (R)

CO2: Explain functions, types, construction and working of different types of valves and

actuators.

FIVE MARK QUESTIONS

1. Write the functions of valves. (A)

2. Classify the valves by construction. (A)

3. Classify the valves by function. (A)

4. Draw a neat sketch of poppet valve and label the parts. (U)

5. Draw a neat sketch of ball valve and label the parts. (U)

6. Draw a neat sketch of flap valve and label the parts. (U)

7. Draw a neat sketch of rotary disc valve and label the parts. (U)

8. Draw a neat sketch of rotary spool valve and label the parts.(U)

9. Draw a neat sketch of sliding spool valve and label the parts. (U)

10. Draw a neat sketch of pressure control valve and label the parts. (U)

11. Draw a neat sketch of pressure relief valve and label the parts. (U).

12. Draw a neat sketch of pressure reducing valve and label the parts. (U).

13. Draw a neat sketch of pressure balance valve and label the parts. (U)

14. List the different methods used to control the valve .(R)

15. Define the actuator and write the classification of actuators. (R/A)

Directorate Of Technical Education Karnataka State 15AT41T Page 10

TEN MARK QUESTIONS

1. Explain the construction and working of poppet valve with a neat sketch. (U)

2. Explain the construction and working of ball valve with a neat sketch. (U)

3. Explain the construction and working of flap valve with a neat sketch. (U)

4. Explain the construction and working of rotary disc valve with a neat sketch.

(U)

5. Explain the construction and working of rotary spool valve with a neat sketch.

(U)

6. Explain the construction and working of sliding spool valve with a neat sketch.

(U)

7. Explain working of pressure control valve with a neat sketch .(U)

8. Explain working of pressure relief valve with a neat sketch. (U)

9. Explain working of pressure reducing valve with a neat sketch. (U).

10. Explain working of pressure balance valve with a neat sketch. U)

11. Explain working of 2/2 direction control valve with a neat sketch. (U)

12. Explain working of 3/2 direction control valve with a neat sketch. (U)

13. Explain working of 4/2 direction control valve with a neat sketch. (U)

14. Explain working of 5/2 direction control valve with a neat sketch. (U)

15. Explain working of 5/3 direction control valve with a neat sketch. (U)

16. Explain working manually controlled valve with a neat sketch. (U)

17. Explain working mechanically controlled valve with a neat sketch. (U)

18. Explain working hydraulically controlled valve with a neat sketch. (U)

19. Explain working pneumatically controlled valve with a neat sketch. (U)

20. Explain working hydro pneumatically controlled valve with a neat sketch. (U)

21. Explain working electro hydraulically controlled valve with a neat sketch. (U)

22. Explain working electro pneumatically controlled valve with a neat sketch.(U)

23. Explain working flow control valve with a neat sketch. (U)

24. Explain working non-return control valve with a neat sketch. (U)

25. Explain working non-return/check control valve with a neat sketch.(U)

26. Explain working pilot operated sequence valve with a neat sketch. (U)

27. Explain actuator and write the classification of actuators. (U)

28. Explain working of single acting actuator with a neat sketch. (U)

29. Explain working of double acting actuator with a neat sketch. (U)

30. Explain working of rotary/gear actuator with a neat sketch. (U)

31. Explain working of bidirectional actuator with a neat sketch. (U)

Directorate Of Technical Education Karnataka State 15AT41T Page 11

CO3:Explain purpose, applications, types, construction and working of different

components of pneumatic system.

FIVE MARK QUESTIONS

1. Explain hydraulics and its applications. (U)

2. Write the requirements of hydraulic fluids? (A)

3. Write the classification of hydraulic pumps. (A)

4. Draw hydraulic system components symbol for: –

Pumps unidirectional, bidirectional-hydraulic flow line-reservoir vented-fixed

restriction flow-single acting cylinder-double acting cylinder-electric motor-

accumulators spring loaded, gas loaded-filter-heater-cooler-intensifier-check

valve-shut off valve-pressure relief valve-lever operated valve. (U)

5. Explain the importance of hydraulic accumulators. (A)

6. Explain working of spring loaded accumulator with a neat sketch. (U)

7. Explain working of gas loaded accumulator with a neat sketch. (U)

8. Explain construction of hydraulic reservoir with a neat sketch. (U)

9. Explain the symbolic method of ports and position marking. (U)

10. List the common faults in hydraulic system. (A)

11. Explain the visual check procedure of oil. (U)

12. Write the causes for contamination of oil. (A)

13. List the preventive measures of hydraulic system. (R)

14. Write maintenance schedule of hydraulic system. (U)

TEN MARK QUESTIONS

4. Explain working of gear pump with a neat sketch. (U)

5. Explain working of vane pump with a neat sketch. (U)

6. Explain working of lobe pump with a neat sketch. (U)

7. Explain working of Piston-radial pump with a neat sketch. (U)

8. Explain working of hydraulic intensifier with a neat sketch .(U)

9. Explain the symbolic method of ports and position marking. (U)

10. Explain working of meter in circuit. (U)

11. Explain working of meter out circuit. (U)

12. Explain working of bleed-off circuit. (U)

13. Explain working of accumulator circuit. (U)

14. Explain working of regenerative circuit. (U)

15. Explain working of pressure reducing valve circuit. (U)

16. Draw hydraulic brake system circuit of an automobile and label the parts. (U)

17. Draw hydraulic clutch system circuit of an automobile and label the parts. (U)

18. Draw hydraulic steering system circuit of an automobile and label the parts.

(U)

19. Draw hydraulic shock absorber circuit of an automobile and label the parts.

Directorate Of Technical Education Karnataka State 15AT41T Page 12

CO4:Explain purpose, applications, types, construction and working of different

components of pneumatic system.

FIVE MARK QUESTIONS

1. Explain pneumatics and mention its importance. (U)

2. List the different areas of applications of pneumatics in industries. (R)

3. List the different applications of pneumatics in automobiles. (A)

4. Explain humidity. (U)

5. Write the classification of air compressors. (A)

6. Mention the need for multi stage compressor. (A)

7. Explain the functions of air reservoir. (A)

8. Explain the functions of air lubricator. (A)

9. Explain working of FRL and write its symbolic representation. (U)

TEN MARK QUESTIONS

1. Explain properties of air. (U)

2. Explain working of reciprocating type air compressor with a neat sketch. (U)

3. Explain working of diaphragm type air compressor with a neat sketch. (U)

4. Explain working of vane type air compressor with a neat sketch. (U)

5. Explain the construction of air reservoir with a neat sketch. (U)

6. Explain working of screen type air filter with a neat sketch. (U)

7. Explain working of bowl type air filter with a neat sketch. (U)

8. Explain working of diaphragm type pressure regulator with a neat sketch. (U)

9. Explain working of air lubricator with a neat sketch.(U)

10. Explain working of piston motor with a neat sketch. (U)

11. Explain working of gear motor with a neat sketch. (U).

12. Explain working of vane motor with a neat sketch. (U)

CO5: Explain purpose ,types, construction and working and maintenance of different

components of different pneumatic system.

FIVE MARK QUESTIONS

1. Draw Pneumatic system components symbols for: –

Air compressor - air motor – single acting cylinder – 2/2 valve - 3/2 valve -4/2

valve -5/2 valve – 5/3 valve – non return valve – pressure intensifier –

adjustable flow control – silencer – accumulator – filter – water separator –

lubricator – push button control. (R)

2. Draw a basic pneumatic circuit and label the components. (U)

3. List the common faults in pneumatic system.(R)

4. List the preventive measures of pneumatic system. (A)

5. Write maintenance schedule of pneumatic system. (U)

Directorate Of Technical Education Karnataka State 15AT41T Page 13

TEN MARK QUESTIONS

1. Explain control of double acting cylinder using 4/2 DCV with circuit diagram. (U)

2. Explain pilot controlled double acting cylinder using 4/2 DCV with circuit diagram.

(U)

3. Explain speed control circuit of double acting cylinder (U)

4. Explain semiautomatic material handling circuit. (U)

5. Explain time delay circuit. (U)

6. Explain pneumatic tools circuit. (U)

CO6:Explain the merits of combination circuits by understanding the construction and

working of these systems.

FIVE MARK QUESTIONS

1. List the advantages of combined system. (A)

2. List different combined systems with examples. (R)

3. Compare features of hydraulic and pneumatic system. (A)

4. Design power steering circuit of automobile. (hydraulic/Electric) (A)

5. Design power brake circuit of automobile. (A)

6. Design service station hoist circuit of automobile. (A)

TEN MARK QUESTIONS

1. Explain working of air over oil system with circuit diagram. (U)

2. Explain working of air over oil intensifier circuit with circuit diagram. (U)

3. Explain working of mechanical hydraulic servo system with circuit diagram.

(U)

4. Explain working of electro hydraulic servo system with circuit diagram. (U)

Directorate Of Technical Education Karnataka State 15AT41T Page 14

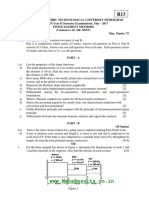

MODEL QUESTION PAPER Code: 15AT41T

IV- Semester Diploma Examination

FLUID POWER TRANSMISSION AND CONTROL

Time: 3 Hours] [Max Marks: 100

Note: Answer any SIX from Part A and any SEVEN from Part B

Section A

1. Explain Pascal’s law with examples .

2. Mention the importance of fluid power engineering in Industries.

3. Draw a neat sketch of poppet valve and label the parts.

4. Define the actuator and write the classification of actuators

5. Explain working of gas loaded accumulator with a sketch.

6. Explain the visual check procedure of oil.

7. Write the classification of air comparisons.

8. Write the maintenance schedule of pneumatic system.

9. List the common faults in pneumatic system

Section B

1. Explain working of 3/2 direction control valve with a neat sketch.

2. Explain working of bidirectional actuator with a neat sketch.

3. a. Write the functions of valves. 5marks

b. Draw the symbols for fallowing hydraulic components. 5marks

ß Unidirectional pump.

ß Double acting cylinder

4. Explain working of gear pump with a sketch.

5. Explain working of regenerative circuit.

6. a. List the different areas of applications of pneumatics. 5marks

7. b. Explain working of FRL unit. 5marks

8. Explain the working of air lubricator with a neat sketch.

9. a. Draw a basic pneumatic system and label the components. 5marks

10. b. Design power steering circuit of automobile. 5marks

11. Explain the speed control circuits of double acting cylinder.

12. Design circuit diagram of mechanical hydraulic servo system and explain its working.

Directorate Of Technical Education Karnataka State 15AT41T Page 15

You might also like

- Heui Fuel System c9 EngineDocument25 pagesHeui Fuel System c9 Enginebabaisandip91% (53)

- Isa-Tr75 25 02-2000Document40 pagesIsa-Tr75 25 02-2000Daniel Leonardo Barrera EspartaNo ratings yet

- P&ID AbbreviationDocument4 pagesP&ID AbbreviationDjil Rezoug100% (5)

- 3.fluid Power EngineeringDocument13 pages3.fluid Power Engineeringsnemo30No ratings yet

- Hyd& PneumaticsDocument18 pagesHyd& PneumaticssathishNo ratings yet

- FM - FP - CompressedDocument215 pagesFM - FP - CompressedKumar SubramanianNo ratings yet

- Hyd & Pneumatics LabDocument6 pagesHyd & Pneumatics LabPepe AkashNo ratings yet

- 2171912Document3 pages2171912Krupal VithlaniNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19Chandler BingNo ratings yet

- Hydraulics and Pneumatics SyllabusDocument2 pagesHydraulics and Pneumatics SyllabusMulu Girmay67% (3)

- Amt 1201 Midterm Lab Module 1Document11 pagesAmt 1201 Midterm Lab Module 1stzy405No ratings yet

- 2 Basic Thermal Engg.Document19 pages2 Basic Thermal Engg.Pepe AkashNo ratings yet

- Course Title Advanced Fluid Mechanics Course Level: UG Credit Units: 04 Course Code: MAE304Document4 pagesCourse Title Advanced Fluid Mechanics Course Level: UG Credit Units: 04 Course Code: MAE304Surjit DuttaNo ratings yet

- 3.automobile Engineering-IDocument14 pages3.automobile Engineering-IAmrithNo ratings yet

- Advanced Automotive SystemsDocument14 pagesAdvanced Automotive SystemsVikram Athreya VNo ratings yet

- AICTE Model Curriculum Scheme2020-2021 - 06.02.2021Document55 pagesAICTE Model Curriculum Scheme2020-2021 - 06.02.2021Deedad SaleemNo ratings yet

- Sona College of Technology: Department of Mechatronics EngineeringDocument41 pagesSona College of Technology: Department of Mechatronics EngineeringKanishk KannaNo ratings yet

- New SyllabusDocument4 pagesNew Syllabuspriyankaraut0014No ratings yet

- Ihp PDFDocument9 pagesIhp PDFKalpesh MadhaviNo ratings yet

- 1.elements of Mechanical Engineering Science-1Document17 pages1.elements of Mechanical Engineering Science-1Ashrit sarurNo ratings yet

- Lab Manual Hydraulics and Pneumatics .Document56 pagesLab Manual Hydraulics and Pneumatics .Aniket ChavanNo ratings yet

- Gujarat Technological University: Semester - IV Subject Name: Oil Hydraulics and PneumaticsDocument4 pagesGujarat Technological University: Semester - IV Subject Name: Oil Hydraulics and PneumaticsNisarg ShahNo ratings yet

- 2.industrial ElectronicsDocument12 pages2.industrial ElectronicsNIKHIL ASNo ratings yet

- Nowledge of Science,: Course Outcome CLDocument15 pagesNowledge of Science,: Course Outcome CLAbhishek DadhichNo ratings yet

- Hydraulic & Pneumatic ControlsDocument9 pagesHydraulic & Pneumatic ControlsVikram Rao100% (1)

- 4th Sem NEP SyllabusDocument11 pages4th Sem NEP SyllabusVikram C KNo ratings yet

- BE MechanicalDocument162 pagesBE Mechanicalsatish kurraNo ratings yet

- Instruction: 4 Lectures & 1 Tutorial / Week Sessional Marks: 40 End Exam: 3 Hours End Exam Marks: 60Document3 pagesInstruction: 4 Lectures & 1 Tutorial / Week Sessional Marks: 40 End Exam: 3 Hours End Exam Marks: 60Palaka RahulNo ratings yet

- Course CurriculumDocument4 pagesCourse CurriculumPRASENJIT MUKHERJEENo ratings yet

- HVACR 10 Module 1 (FINAL)Document56 pagesHVACR 10 Module 1 (FINAL)Homer R. MagistradoNo ratings yet

- 3rd Year Copy 2Document43 pages3rd Year Copy 2sai jaswanth putturuNo ratings yet

- H & P SyllabusDocument3 pagesH & P SyllabusDrPrashant NeheNo ratings yet

- Automotive Electrical and Elctronics SystemsDocument15 pagesAutomotive Electrical and Elctronics SystemsAmrithNo ratings yet

- MechatronicsDocument3 pagesMechatronicsAshutosh KumarNo ratings yet

- Fluid Power Engineering FPE 18ME55 Syllabus 2018 19Document3 pagesFluid Power Engineering FPE 18ME55 Syllabus 2018 19ChinthanNo ratings yet

- Course plan-MFE303Document6 pagesCourse plan-MFE303sureshNo ratings yet

- ME8694 Hydraulics and Pneumatics SyllabusDocument2 pagesME8694 Hydraulics and Pneumatics SyllabusThangamKumarNo ratings yet

- Birla Institute of Technology and Science-Pilani - Hyderabad CampusDocument3 pagesBirla Institute of Technology and Science-Pilani - Hyderabad CampusAgtNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19Pratik VishwakarmaNo ratings yet

- Anna University Semester II Syllabus (Regulation 2017)Document10 pagesAnna University Semester II Syllabus (Regulation 2017)BENHAR ARVINDNo ratings yet

- Production Handbook - Facilities & MaintenanceDocument454 pagesProduction Handbook - Facilities & MaintenancePerfect Trend Energy100% (1)

- Transmision Distribution and UtilisationDocument24 pagesTransmision Distribution and UtilisationVijaya BhaskerNo ratings yet

- P1icic03 Ic Engines SyllabusDocument8 pagesP1icic03 Ic Engines SyllabusSriramulu JaichandarNo ratings yet

- ME453 - 1 IntroDocument55 pagesME453 - 1 IntroElormeNo ratings yet

- Syllabus Hydraulics and Pneumatics (Me8694) (III Year Vi Sem Mech) (r2017)Document2 pagesSyllabus Hydraulics and Pneumatics (Me8694) (III Year Vi Sem Mech) (r2017)ganeshNo ratings yet

- SY BTech Mech Syllabus AutonomousDocument30 pagesSY BTech Mech Syllabus Autonomousjeetupatilp7No ratings yet

- Fluid Power SystemDocument2 pagesFluid Power SystemVijay Shakar0% (1)

- Aeronautical Engineering 4th YearDocument19 pagesAeronautical Engineering 4th YearMuskan RawatNo ratings yet

- Vel Tech High Tech DR - Ranagarajan DR - Sakunthala Engineering College - Department of ECEDocument27 pagesVel Tech High Tech DR - Ranagarajan DR - Sakunthala Engineering College - Department of ECEkarthikapecNo ratings yet

- 5th Sem Course SyllabusDocument9 pages5th Sem Course SyllabusSahiti DarikaNo ratings yet

- Automobile Sem 5 PDFDocument49 pagesAutomobile Sem 5 PDFFiroz AminNo ratings yet

- Basic Hydraulic Systems and ComponentsDocument67 pagesBasic Hydraulic Systems and Componentsnareshkumaran100% (8)

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

- Distillation Design and Control Using Aspen SimulationFrom EverandDistillation Design and Control Using Aspen SimulationRating: 5 out of 5 stars5/5 (2)

- Decoding Reliability-Centered Maintenance Process for Manufacturing Industries 10th Discipline of World Class Maintenance Management: 1, #7From EverandDecoding Reliability-Centered Maintenance Process for Manufacturing Industries 10th Discipline of World Class Maintenance Management: 1, #7No ratings yet

- Process System Value and Exergoeconomic Performance of Captive Power PlantsFrom EverandProcess System Value and Exergoeconomic Performance of Captive Power PlantsNo ratings yet

- Small Unmanned Fixed-wing Aircraft Design: A Practical ApproachFrom EverandSmall Unmanned Fixed-wing Aircraft Design: A Practical ApproachNo ratings yet

- Multivariable Predictive Control: Applications in IndustryFrom EverandMultivariable Predictive Control: Applications in IndustryNo ratings yet

- WWW - Manaresults.Co - In: (Common To Ae, Me, MSNT)Document3 pagesWWW - Manaresults.Co - In: (Common To Ae, Me, MSNT)Sreedhar MNo ratings yet

- WWW - Manaresults.Co - In: (Common To Me, Ae, MSNT)Document2 pagesWWW - Manaresults.Co - In: (Common To Me, Ae, MSNT)Sreedhar MNo ratings yet

- WWW - Manaresults.Co - In: (Common To AE, MSNT, ME)Document3 pagesWWW - Manaresults.Co - In: (Common To AE, MSNT, ME)Sreedhar MNo ratings yet

- Sme 3033 Finite Element Method Steady STDocument37 pagesSme 3033 Finite Element Method Steady STSreedhar MNo ratings yet

- Chap 5 Finite Elements For Heat Transfer Problems: Finite Element Analysis and Design Nam-Ho Kim Audio by Raphael HaftkaDocument16 pagesChap 5 Finite Elements For Heat Transfer Problems: Finite Element Analysis and Design Nam-Ho Kim Audio by Raphael HaftkaSreedhar MNo ratings yet

- JNTUH - B Tech - 2019 - 3 2 - May - R18 - MECH - 136BW FEM Finite Element MethodsDocument2 pagesJNTUH - B Tech - 2019 - 3 2 - May - R18 - MECH - 136BW FEM Finite Element MethodsSreedhar MNo ratings yet

- F Inite Element MethodDocument66 pagesF Inite Element MethodSreedhar MNo ratings yet

- Micro Level Lesson Planning: Department of Mechanical EngineeringDocument2 pagesMicro Level Lesson Planning: Department of Mechanical EngineeringSreedhar MNo ratings yet

- 5.syllabus Copy and Brief On PrerequisitesDocument3 pages5.syllabus Copy and Brief On PrerequisitesSreedhar MNo ratings yet

- R16 Nano Technology-SyllabusDocument2 pagesR16 Nano Technology-SyllabusSreedhar MNo ratings yet

- Fluid Power Systems Theory, Worked Examples and Problems by A. B. Goodwin (Auth.)Document221 pagesFluid Power Systems Theory, Worked Examples and Problems by A. B. Goodwin (Auth.)Sreedhar MNo ratings yet

- Pressure Control Equipment PDFDocument5 pagesPressure Control Equipment PDFben mohamed SofianeNo ratings yet

- 3 Element ControllerDocument3 pages3 Element ControllermgkvprNo ratings yet

- Roc On Water Control ValveDocument4 pagesRoc On Water Control ValveSBeardNo ratings yet

- A A10VSO140 DFR1 31R-VPB12N00 - R910945253 - en - 202311333Document23 pagesA A10VSO140 DFR1 31R-VPB12N00 - R910945253 - en - 202311333motasem alqaisiNo ratings yet

- C4 - Components in Hydraulic SystemDocument64 pagesC4 - Components in Hydraulic SystemKubheran SelvathuraiNo ratings yet

- 357 Series Control Valves (Obsolete Product)Document17 pages357 Series Control Valves (Obsolete Product)Yogurtu NngeNo ratings yet

- Electronic Controlled Fuel SystemDocument34 pagesElectronic Controlled Fuel SystemMohamed ZakiNo ratings yet

- 5-1. Machatronics SystemDocument50 pages5-1. Machatronics Systemmarcelo rojas100% (1)

- Techno News: Introduction of Safety Screen Filter For Control Valve With FIVA / ELFI / ELVADocument6 pagesTechno News: Introduction of Safety Screen Filter For Control Valve With FIVA / ELFI / ELVASrivatsanNo ratings yet

- c4 - Components in Hydraulic SystemDocument65 pagesc4 - Components in Hydraulic SystemBazil Suhaimi100% (1)

- Liu Gong Hydraulic System PDFDocument86 pagesLiu Gong Hydraulic System PDFYadi100% (3)

- April 15, 1969: R. G., McintyreDocument9 pagesApril 15, 1969: R. G., McintyregorgiNo ratings yet

- GP 15-09-01 Control ValvesDocument23 pagesGP 15-09-01 Control ValvesAllia-Europe100% (1)

- Industrial Automation Engineers Interview QuestionsDocument5 pagesIndustrial Automation Engineers Interview QuestionsJêmš NavikNo ratings yet

- Proces ValveDocument98 pagesProces Valvehimansh871100% (1)

- Mokveld-Product Sheet Axial Control ValveDocument2 pagesMokveld-Product Sheet Axial Control Valveจตุพล กมลเลิศNo ratings yet

- Development of 360 Degree Rotating VehicleDocument4 pagesDevelopment of 360 Degree Rotating VehicleIJIRST57% (7)

- Control Narratives - Drum Level ControlDocument6 pagesControl Narratives - Drum Level ControlRahul AnandNo ratings yet

- Servo Valve OperationDocument16 pagesServo Valve OperationBhagat ShardanandNo ratings yet

- Mohamad Safuan Sheafi (CD 5000)Document24 pagesMohamad Safuan Sheafi (CD 5000)givepleaseNo ratings yet

- Fundamentals of Final Control ElementsDocument57 pagesFundamentals of Final Control ElementshazemNo ratings yet

- Series: CC CCT CCVS/CCVLDocument15 pagesSeries: CC CCT CCVS/CCVLxmen norNo ratings yet

- Man B&W: GeneralDocument18 pagesMan B&W: GeneralFelipe RibasNo ratings yet

- H CONTROLAIR Valves PDFDocument18 pagesH CONTROLAIR Valves PDFebrahem khderNo ratings yet

- What Is Pneumatic SystemDocument2 pagesWhat Is Pneumatic SystemAiman ShukriNo ratings yet

- Westlock IOM TECHUK-20 ATEX ICoT 5000Document38 pagesWestlock IOM TECHUK-20 ATEX ICoT 5000Smith IncheonNo ratings yet

- High Plains Engineering: HPE-TR-1999-05-01aDocument20 pagesHigh Plains Engineering: HPE-TR-1999-05-01azanazan110% (1)