Professional Documents

Culture Documents

TDS-Starfix C1-SL

TDS-Starfix C1-SL

Uploaded by

YASHICA VAITTIANATHANOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS-Starfix C1-SL

TDS-Starfix C1-SL

Uploaded by

YASHICA VAITTIANATHANCopyright:

Available Formats

Product Data Sheet

C1-SL

PRODUCT DESCRIPTION If the new concrete is not finished with an

appropriate texture, follow surface preparation

STARFIX C1-SL is a free flowing, self-leveling, procedures below for old concrete.

compound specially designed for easy application

over concrete floors as an underlayment for Old concrete must be clean and textured. All oil,

subsequent placement of floor coverings. It is dirt, debris, paint and unsound concrete must be

removed. The surface must be prepared

suitable for use as a repair and leveling course

mechanically using a scrubber, brush hammer or

and may be applied at thickness from shot blast which will give a surface profile similar

featheredge to 25 mm. STARFIX C1-SL is a one to coarse grit sand-paper. The final step in

part system requiring only the addition of water for cleaning should be the complete removal of all

mixing. residue with a vacuum cleaner or pressure

washing.

APPLICATION

Acid etching is acceptable only when, mechanical

Interior sound concrete sub-surface preparation is impractical. It is recommended that

unleveled floors only contractors experienced in the acid etching

Repair of old & worn concrete process use this means of surface preparation.

Wood floors The salts of the reaction must be thoroughly

Old floors with cut back adhesive pressure washed away. Allow the concrete to

Hospitals - hotels floors prior to carpeting complete dry.

Note: Even with proper procedures, an acid

.

etched surface may not provide as strong a bond

ADVANTAGES as those which are mechanically prepared.

Flowable consistency for application All concrete must possess an open surface

Pumpable through standard equipment texture with all curing compounds and sealer

Self-leveling for smooth, flat floor removed.

Exceptional coverage rate for maximum

yield and value Bonding

Minimal shrinkage of resistance to cracking

High early strength for early turn around After the surface has been prepared, prime all

Excellent bond strength for a composite areas.

floor section

Mixing

DIRECTIONS FOR USE

Small quantities of STARFIX C1-SL may be

Surface preparation

bucket mixed with a drill and "jiffy" mixer.

Standard grouting or underlayment equipment

New concrete must be a minimum of 3 days old

should be used for placing large quantities of

and must be broom textured at the time of

material. Add the appropriate amount of water for

placement to secure a good mechanical bond for

the batch size and then add the dry product. Do

the underlayment.

not use water at a rate that will cause bleeding or

segregation. Typical water requirement is 5.8

liter/25 kg bag.

UAE KSA INDIA

Tel. +971 6 5611411 Tel. +996 12 677 7073 Tel. +91 260 2220241

uae@star-uae.com ksa@star-uae.com india@star-uae.com

www.star-uae.com www.star-uae.com www.star-uae.com

Product Data Sheet

C1-SL

Do not add more than 6.5 liter/25 kg bag. Mix for TECHNICAL SPECIFICATION

a minimum of 3 minutes. If bucket mixed, the

product should be quickly transported to the Compressive strength

repair area and placed immediately.

After 2 hrs. 10.0 MPa

Application

After 24 hrs. 16.0 MPa

For applications over 25 mm in thickness, add After 3 days 19.0 MPa

9.0-11.3 kg of 3.2-9.5 mm aggregate to extend

the initial layer. Placement options includes After 28 days 34.0 MPa

screeding or the use of pre placed aggregate

grouting techniques. After 24 hours, prime the Bond strength

surface of the initial layer and place additional

underlayment to achieve the final smooth surface. 5 MPa

After 7 days

After 14 days 7 MPa

Placement

Setting Time

The product must be continuously placed to

provide a smooth and uniform surface. Start in Initial 45 Minutes

one corner placing a continuous stream of

material along one edge of the area and back lap Final 70 Minutes

as soon as possible for a uniform, smooth

surface. Tools such as spiked rollers, notched

PACKAGING SIZE:

squeegees, trowels and smoothers may be used

to assist placement. STARFIX C1-SL is packaged in 25 kg bags that

yield approximately 0.015 m3 material. Coverage

Finishing for one bag is approximately 2.3 m2 at a 6 mm

thickness.

This product is self-leveling and requires no

finishing or troweling operation.

COVERAGE:

Curing Yield and coverage will vary depending upon the

amount of water mixed with the STARFIX C1-SL.

STARFIX C1-SL does not require curing with The product must not be mixed at a consistency

standard methods for most applications. Under which promotes bleeding and segregation. Under

hot-windy or rapid drying conditions, a fog spray no circumstances add more than 6.5 liters of

or wet cure for 24 hours is recommended after water per 25 kg bag.

final set of material.

Cleaning:

Clean the tools and equipment’s with water

before material get dry.

UAE KSA INDIA

Tel. +971 6 5611411 Tel. +996 12 677 7073 Tel. +91 260 2220241

uae@star-uae.com ksa@star-uae.com india@star-uae.com

www.star-uae.com www.star-uae.com www.star-uae.com

Product Data Sheet

C1-SL

HEALTH & SAFETY

As with all chemicals, caution should always be exercised.

Protective clothing such as gloves and goggles should be

worn.

INHALATION: Inhalation of vapor or mist should be

avoided. If inhaled symptoms include coughing,

wheezing, laryngitis, and shortness of breath, headache,

nausea, and vomiting. Immediately shift victim to fresh air,

and, if needed immediately start artificial respiration. Give

oxygen if breathing is labored. Get emergency medical

help.

EYE CONTACT: Flush eyes with water for 15 minutes and

call for medical help.

INGESTION: Causes nausea, vomiting, and loss of

consciousness. If accidentally swallowed do not induce

vomiting rather call for medical help immediately.

SKIN CONTACT: Flush with water or soap and water until

all traces have been removed. Seek medical attention if

required.

WARRANTY:

The information given is based on our knowledge and

performance of the material. Every precaution is taken in

the manufacture of the product and responsibility is limited

to the quality of supplies with no guarantee of results in the

field, as manufacturer has no control over site conditions or

execution of work.

UAE KSA INDIA

Tel. +971 6 5611411 Tel. +996 12 677 7073 Tel. +91 260 2220241

uae@star-uae.com ksa@star-uae.com india@star-uae.com

www.star-uae.com www.star-uae.com www.star-uae.com

You might also like

- MasterProtect 1891Document2 pagesMasterProtect 1891SHAIK ASIMUDDINNo ratings yet

- Readworks - From One To ManyDocument5 pagesReadworks - From One To ManyPilar Andrea MarquezNo ratings yet

- GD Portfolio Self Critique Report SampleDocument5 pagesGD Portfolio Self Critique Report Sampleirawan50% (2)

- Tds Concrete Patch V - Ver 1.0 Jan24Document2 pagesTds Concrete Patch V - Ver 1.0 Jan24Julie Anne CastroNo ratings yet

- Cap Patch PDFDocument2 pagesCap Patch PDFAnonymous kRIjqBLkNo ratings yet

- Pds CPD SikaLatex UsDocument2 pagesPds CPD SikaLatex Usbartup2No ratings yet

- Weberfloor - 630 - TSC - 01 (1) - 221109 - 183928Document3 pagesWeberfloor - 630 - TSC - 01 (1) - 221109 - 183928Pacific CoastNo ratings yet

- SikaQuick 2500 Patch IdDocument3 pagesSikaQuick 2500 Patch IdRialno TambunanNo ratings yet

- 25 KG Gyproc Elite 100 One Coat Gypsum PlasterDocument3 pages25 KG Gyproc Elite 100 One Coat Gypsum Plastersyedaliabl2023No ratings yet

- TDS Weberfloor 620 PMB PlusDocument3 pagesTDS Weberfloor 620 PMB PlusBurak AkyazıNo ratings yet

- LASIQ EASY10 Data SheetDocument2 pagesLASIQ EASY10 Data SheetChristos LeptokaridisNo ratings yet

- Sika PDS - E - Sika Padding MortarDocument2 pagesSika PDS - E - Sika Padding Mortarlwin_oo2435No ratings yet

- Polyalk WP PDFDocument2 pagesPolyalk WP PDFhunky11No ratings yet

- Expangrout GP: General Purpose Non-Shrink Cementitious Grout UsesDocument4 pagesExpangrout GP: General Purpose Non-Shrink Cementitious Grout UsesZaid AhmedNo ratings yet

- Gyproc Supreme 80 One Coat Gypsum PlasterDocument3 pagesGyproc Supreme 80 One Coat Gypsum PlasterSwapnil JadhavNo ratings yet

- MS - Sikalastic-1 KMY For Swimming PoolDocument6 pagesMS - Sikalastic-1 KMY For Swimming PoolXuân Nam NguyễnNo ratings yet

- Acrylic Patch PDS (H11)Document2 pagesAcrylic Patch PDS (H11)Nguyễn ThanhNo ratings yet

- FlotopDocument2 pagesFlotoppravi3434No ratings yet

- Notice Cemaqua 1Document2 pagesNotice Cemaqua 1legrandNo ratings yet

- 0325-11-55-28 Datasheet File Sikagrout 214-11 PDFDocument2 pages0325-11-55-28 Datasheet File Sikagrout 214-11 PDFFajar SodiqNo ratings yet

- Sikafloor® Level 50: Product Data SheetDocument4 pagesSikafloor® Level 50: Product Data SheetChou ButongNo ratings yet

- PDS Sika ChapdurDocument3 pagesPDS Sika ChapdurMuhammad Nurul FajryNo ratings yet

- CONBEXTRA GP - JordanDocument4 pagesCONBEXTRA GP - JordanShabbir HussainNo ratings yet

- Mastertop 530 12-04Document3 pagesMastertop 530 12-04djrote4No ratings yet

- Level Cem GP 2021Document3 pagesLevel Cem GP 2021Joan FosterNo ratings yet

- PDS Sika Chapdur 2019.04.16Document3 pagesPDS Sika Chapdur 2019.04.16Ahmad aliNo ratings yet

- Sikaseal - 105Document3 pagesSikaseal - 105Nader ToutounjiNo ratings yet

- Sikatop - 122Document3 pagesSikatop - 122YOSAFAT YUDHA GUNTORONo ratings yet

- Tds - Emaco s66 CPDocument2 pagesTds - Emaco s66 CPVenkata RaoNo ratings yet

- Datasheet Concrete Resurfacer - 1131 47Document3 pagesDatasheet Concrete Resurfacer - 1131 47miguelq_scribdNo ratings yet

- Non-Shrink Grout: Class A Expanding GroutDocument2 pagesNon-Shrink Grout: Class A Expanding GroutNaba majeadNo ratings yet

- Method Statement - Cementitious GroutingDocument8 pagesMethod Statement - Cementitious GroutingDimitris DountsisNo ratings yet

- Sika PDS E SikaCeram - 191Document3 pagesSika PDS E SikaCeram - 191lwin_oo2435No ratings yet

- RCT-ConGrout GPDocument3 pagesRCT-ConGrout GPfahadNo ratings yet

- Masterflow 980 Tds PDFDocument4 pagesMasterflow 980 Tds PDFAdamo Absalome MulocheNo ratings yet

- TDS - Starbond EP-SL1Document2 pagesTDS - Starbond EP-SL1EssamNo ratings yet

- ST029EN22352910-Epokoat Epoxy PaintDocument3 pagesST029EN22352910-Epokoat Epoxy PaintTan Lun HuiNo ratings yet

- Glass Tile ApplicationDocument2 pagesGlass Tile ApplicationdipeshNo ratings yet

- TALYEES-G100 Data SheetDocument3 pagesTALYEES-G100 Data SheetChristos LeptokaridisNo ratings yet

- Ideal Pavi Tec EngDocument2 pagesIdeal Pavi Tec EngPedroNo ratings yet

- PLANITOPDocument4 pagesPLANITOPRuiNo ratings yet

- Sikagrout 214 - 11: High Strength Non-Shrink Cementitious GroutDocument2 pagesSikagrout 214 - 11: High Strength Non-Shrink Cementitious GroutDani LerviNo ratings yet

- Datasheet File Conbextra GP PremixDocument4 pagesDatasheet File Conbextra GP PremixLftea AdiNo ratings yet

- BOSTIK Flowfill NonShrinkGroutGP Rev1Document3 pagesBOSTIK Flowfill NonShrinkGroutGP Rev1Antonette Marie ElgarioNo ratings yet

- Screedmaster: Rapid Repair MortarDocument2 pagesScreedmaster: Rapid Repair MortarAlex BocicaNo ratings yet

- Brushcrete: Acrylic Polymer For Concrete & MasonryDocument2 pagesBrushcrete: Acrylic Polymer For Concrete & MasonryPrasanta100% (1)

- Dura Grout: A.B.E. Construction ChemicalsDocument3 pagesDura Grout: A.B.E. Construction ChemicalsVirah Sammy ChandraNo ratings yet

- SikaTop Seal-107 PDFDocument4 pagesSikaTop Seal-107 PDFDan BermasNo ratings yet

- Sika Grout 212, 215 - PDSDocument3 pagesSika Grout 212, 215 - PDSasdfzzzxxxcccvvvNo ratings yet

- SikaMonoTop 615SD en MY (11 2018) 1 1Document3 pagesSikaMonoTop 615SD en MY (11 2018) 1 1chanqiming51No ratings yet

- Sikafloor Level Pro SdsDocument3 pagesSikafloor Level Pro SdsMarkSomniumNo ratings yet

- Sikafloor - 957 SSDDocument3 pagesSikafloor - 957 SSDRodo Samuel SitorusNo ratings yet

- TDS - Emaco S68 PlusDocument3 pagesTDS - Emaco S68 PlusVenkata RaoNo ratings yet

- Waterproofing - Sikacrete - Floor - LevelDocument3 pagesWaterproofing - Sikacrete - Floor - LevelCC Cost AdvisoryNo ratings yet

- Level Top PC-AGG: Polishable Self-Leveling Overlayment With Natural AggregateDocument3 pagesLevel Top PC-AGG: Polishable Self-Leveling Overlayment With Natural AggregateKen SuNo ratings yet

- PDS - Sika Chapdur - 20190416 - 221102 - 110241Document4 pagesPDS - Sika Chapdur - 20190416 - 221102 - 110241Andre SitumeangNo ratings yet

- Mastertop 195: Thin-Set Concrete Floor Re-Surfacing SystemDocument2 pagesMastertop 195: Thin-Set Concrete Floor Re-Surfacing SystemFrancois-No ratings yet

- 2 Bostik Fixall Tds Fa Rev1Document3 pages2 Bostik Fixall Tds Fa Rev1Reychiel HinloNo ratings yet

- Envirostik Flexi Bond PDSDocument2 pagesEnvirostik Flexi Bond PDSMc YonNo ratings yet

- Chemxseal 32-17 - MSDSDocument4 pagesChemxseal 32-17 - MSDSYASHICA VAITTIANATHAN0% (1)

- Ribbon Blender-Eng - DrawingDocument1 pageRibbon Blender-Eng - DrawingYASHICA VAITTIANATHANNo ratings yet

- Planetary Mixer-SpecificationDocument2 pagesPlanetary Mixer-SpecificationYASHICA VAITTIANATHANNo ratings yet

- Craybond 2070 Pu-TdsDocument3 pagesCraybond 2070 Pu-TdsYASHICA VAITTIANATHANNo ratings yet

- MaterialData 196958Document1 pageMaterialData 196958YASHICA VAITTIANATHANNo ratings yet

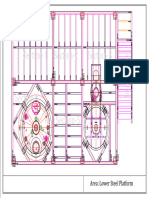

- Steel Platform DrawingDocument11 pagesSteel Platform DrawingYASHICA VAITTIANATHANNo ratings yet

- Craybond 81-10 MSDSDocument4 pagesCraybond 81-10 MSDSYASHICA VAITTIANATHANNo ratings yet

- KF 90 NS DatasheetDocument1 pageKF 90 NS DatasheetYASHICA VAITTIANATHANNo ratings yet

- Cyber Saftey (Yaashica Vaittianathan, 2C)Document15 pagesCyber Saftey (Yaashica Vaittianathan, 2C)YASHICA VAITTIANATHANNo ratings yet

- Crayseal 732 TDSDocument4 pagesCrayseal 732 TDSYASHICA VAITTIANATHANNo ratings yet

- Sikagrout Cable PtsaDocument3 pagesSikagrout Cable PtsaYASHICA VAITTIANATHANNo ratings yet

- Craybond 3022-TDSDocument2 pagesCraybond 3022-TDSYASHICA VAITTIANATHANNo ratings yet

- Sika Anchorfix - 1Document5 pagesSika Anchorfix - 1YASHICA VAITTIANATHANNo ratings yet

- Role of Pesticide Formulations For Sustainable Crop Protection and Environment Management: A ReviewDocument8 pagesRole of Pesticide Formulations For Sustainable Crop Protection and Environment Management: A ReviewYASHICA VAITTIANATHAN100% (1)

- Sikagrout - 105Document3 pagesSikagrout - 105YASHICA VAITTIANATHANNo ratings yet

- Sikagrout - 214 SaDocument3 pagesSikagrout - 214 SaYASHICA VAITTIANATHANNo ratings yet

- Sikagrout - 114Document3 pagesSikagrout - 114YASHICA VAITTIANATHANNo ratings yet

- Sikagrout - 212 SaDocument3 pagesSikagrout - 212 SaYASHICA VAITTIANATHANNo ratings yet

- MSDS Starcem 2K-LIQUIDDocument5 pagesMSDS Starcem 2K-LIQUIDYASHICA VAITTIANATHANNo ratings yet

- Sikagrout Cable PTDocument3 pagesSikagrout Cable PTYASHICA VAITTIANATHANNo ratings yet

- Kraton D1101 A - TDSDocument2 pagesKraton D1101 A - TDSYASHICA VAITTIANATHANNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingYASHICA VAITTIANATHANNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingYASHICA VAITTIANATHANNo ratings yet

- Dibutyl Pthalate. DBP: Technical Data SheetDocument1 pageDibutyl Pthalate. DBP: Technical Data SheetYASHICA VAITTIANATHANNo ratings yet

- Product Data Sheet: Product Description Technical SpecificationDocument1 pageProduct Data Sheet: Product Description Technical SpecificationYASHICA VAITTIANATHANNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingYASHICA VAITTIANATHANNo ratings yet

- LG SBR1502 - TDSDocument1 pageLG SBR1502 - TDSYASHICA VAITTIANATHANNo ratings yet

- Starproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingDocument1 pageStarproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingYASHICA VAITTIANATHANNo ratings yet

- Marble & Granite Glue: Product Data SheetDocument2 pagesMarble & Granite Glue: Product Data SheetYASHICA VAITTIANATHANNo ratings yet

- Falcomer 5010 TDS PDF 2020Document1 pageFalcomer 5010 TDS PDF 2020YASHICA VAITTIANATHANNo ratings yet

- Criminal SociologyDocument66 pagesCriminal SociologySal McGaundieNo ratings yet

- Tem 3546892 0101Document75 pagesTem 3546892 0101mossaabNo ratings yet

- Sam Sandan EssayDocument3 pagesSam Sandan Essayjose simplicio NetoNo ratings yet

- Ujian Setara 1 2017 KimiaDocument9 pagesUjian Setara 1 2017 KimiaZulkifli Bin PariNo ratings yet

- Elforoom 2 - 3-17Document44 pagesElforoom 2 - 3-17bogdan TanasieNo ratings yet

- Sesame Cultivation SlidesDocument51 pagesSesame Cultivation Slidesraaa guyNo ratings yet

- Manual Lab Anatomy of Breast - LA RPS2 W3Document6 pagesManual Lab Anatomy of Breast - LA RPS2 W3Maharani KartikaNo ratings yet

- Anzai: What Is Respiratory Gating System ?Document2 pagesAnzai: What Is Respiratory Gating System ?Andreas RonaldNo ratings yet

- Economic Factors in Materials SelectionDocument19 pagesEconomic Factors in Materials SelectionAnonymous S9qBDVkyNo ratings yet

- Power Supply System Guardian Access 3U Instruction ManualDocument54 pagesPower Supply System Guardian Access 3U Instruction ManualMohammad KilaniNo ratings yet

- Pressure Vessel DesignDocument46 pagesPressure Vessel DesignAxenta0% (1)

- Synthesis of Reactive Mgo From Reject Brine Via The Addition of Nh4OhDocument29 pagesSynthesis of Reactive Mgo From Reject Brine Via The Addition of Nh4OhDl Divakar LNo ratings yet

- Resume DraftDocument2 pagesResume Draftapi-300443689No ratings yet

- Oral Care: Marlon C. Soliman, MAN, RNDocument25 pagesOral Care: Marlon C. Soliman, MAN, RNSoliman C. MarlonNo ratings yet

- Author Guidline. CPSPDocument4 pagesAuthor Guidline. CPSPMuhammad MoazzamNo ratings yet

- Ajax DPC-2803 PDFDocument304 pagesAjax DPC-2803 PDFPaul Villa100% (3)

- 2012 Building Code OverviewDocument155 pages2012 Building Code OverviewAhmed MianNo ratings yet

- Sample QuestionnaireDocument5 pagesSample QuestionnaireAudi Kyle SaydovenNo ratings yet

- Rr410802 Chemical Reaction Engineering IIDocument9 pagesRr410802 Chemical Reaction Engineering IISrinivasa Rao G100% (1)

- As 2610.1-2007 Spa Pools Public SpasDocument7 pagesAs 2610.1-2007 Spa Pools Public SpasSAI Global - APACNo ratings yet

- A Detailed Lesson Plan in Science For Grade 7 - Animal and PlantDocument6 pagesA Detailed Lesson Plan in Science For Grade 7 - Animal and PlantKresha LluismaNo ratings yet

- H&C Analysis Unit 3 09Document22 pagesH&C Analysis Unit 3 09Seenu PusuluruNo ratings yet

- Pneumonia MCQDocument9 pagesPneumonia MCQrumi bhandariNo ratings yet

- UwuwDocument6 pagesUwuwArifa MaulianaNo ratings yet

- Letter of Offer TemplateDocument8 pagesLetter of Offer TemplateDavid Susilo NugrohoNo ratings yet

- Endocrine and Urinary SystemDocument5 pagesEndocrine and Urinary SystemShereen ManabilangNo ratings yet

- Nursing Care Plan - Using NandaDocument16 pagesNursing Care Plan - Using NandaWardinatul ImanNo ratings yet

- Method Statement For Repair of Bulged Concrete UsingDocument8 pagesMethod Statement For Repair of Bulged Concrete Usingbureau servicesNo ratings yet