Professional Documents

Culture Documents

TDS - Starseal PS-PG

TDS - Starseal PS-PG

Uploaded by

YASHICA VAITTIANATHANOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS - Starseal PS-PG

TDS - Starseal PS-PG

Uploaded by

YASHICA VAITTIANATHANCopyright:

Available Formats

STARSEAL Product Data Sheet

PS-PG

PRODUCT DESCRIPTION

TYPICAL PROPERTIES

STARSEAL PS-PG is the two-part elastomeric Appearance : 2 component,

sealant based on a liquid polysulfide polymer paste

which when mixed with accelerator (curing agent)

cures by chemical reaction to form a tough, Color : Grey (After

flexible rubber seal. This sealant has excellent mixing Base and Hardener)

Fuel resistance, adhesion to different substrates

Application life : 2 hours @ 25°C

like masonry, concrete with excellent movement

accommodation. Initial cure : 24 hours @25°C

APPLICATION Full cure : 7 days @ 25°C

For sealing and maintenance of horizontal joints Elongation (%) : > 300

in

Application temperature : 5 - 50°C

1. Aircraft fueling areas

2. Oil terminals

3. Garage forecourts Operating temperature : -40 to + 80 °C

4. Concrete Roads

5. Parking and cargo areas

6. Warehouses APPLICATION METHOD

7. Industrial Floors

1. Surface should be fully dry, clean and free

8.

from dust, laitance, oil and grease etc.

STANDARD SPECIFICATION 2. Clean with sand paper & wire brush, then

dust and foreign particles to be removed.

STARSEAL PS-PG complies with requirement Subsequently use masking tape at floor

of BS 4254:1983. ASTM C 920-87 Type M class level beside both sides to get sharp edged

25, Federal specs.TT-S-00227 E Type II ClassA neat and clean joint.

3. Avoid adhesion of spill-over material

ADVANTAGES

beside the joint.

4. Use polyurethane Foam (PUF) strips /

1. Easy to use, Cold applied.

2. Pourable & self-leveling baking rods (equivalent) in expansion,

3. Excellent adhesion with many construction & control joints as back up

substrates. material to avoid 3-face adhesion and to

4. Very high thermal flexibility.

avoid contact between joint forming board

5. Good UV, Flame and Fuel Resistance.

& sealant.

5. Use of primer on vertical side faces of the

6. Excellent Water proof

joint is optional to ensure strong bonding

between substrate and sealant. Primer

must be recommended for old concrete.

UAE KSA INDIA

Tel. +971 6 5611411 Tel. +996 12 677 7073 Tel. +91 260 2220241

uae@star-uae.com ksa@star-uae.com india@star-uae.com

www.star-uae.com www.star-uae.com www.star-uae.com

STARSEAL Product Data Sheet

PS-PG

6. Sealant application should start after 30 SHELF LIFE

minutes but not later than 2 hrs. after

priming the surface. 12 months from the date of production when

7. The Base and Accelerator compounds are stored properly in unopened undamaged and

packed in pre-weighed quantity as per the sealed original packaging in cool and dry

mixing ratio. condition at temperature +5°C to +30°C.

8. Mix the material of individual container.

9. Transfer entire quantity of Accelerator to PACKING

the base compound and mix it thoroughly

to a uniform and homogenous Grey color. Available in 1liter & 4 liter kits

10. Mixing can be done manually with

spatula/palette knife or special flat stirrer STORAGE

attached to a low speed electric mixer less

than 500 rpm. Store in a cool dry place under shed away from

heat.

HEALTH & SAFETY

1. STARSEAL PS-PG and primer may

cause sensitization by inhalation and skin

contact.

2. Wear suitable clothing, gloves and

eye/face protection. Barrier creams

provide additional skin protection.

3. Any skin contact occurs; remove

immediately with a resin removing

cream, followed by soap and water. Do

not use solvent.

4. In case of contacts with eyes, rinse with

plenty of clean water and seek medical

advice. Use only in ventilated areas.

5. Fire: Primer is flammable. Do not expose

flames or other sources of ignition. No

smoking. Containers should be tightly

sealed when not in use. In the event of

fire, extinguish with Co2 or foam.

UAE KSA INDIA

Tel. +971 6 5611411 Tel. +996 12 677 7073 Tel. +91 260 2220241

uae@star-uae.com ksa@star-uae.com india@star-uae.com

www.star-uae.com www.star-uae.com www.star-uae.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Planetary Mixer-SpecificationDocument2 pagesPlanetary Mixer-SpecificationYASHICA VAITTIANATHANNo ratings yet

- Ribbon Blender-Eng - DrawingDocument1 pageRibbon Blender-Eng - DrawingYASHICA VAITTIANATHANNo ratings yet

- Crayseal 732 TDSDocument4 pagesCrayseal 732 TDSYASHICA VAITTIANATHANNo ratings yet

- Cooling Tower-20 TRDocument1 pageCooling Tower-20 TRYASHICA VAITTIANATHANNo ratings yet

- Chemxseal 32-17 - MSDSDocument4 pagesChemxseal 32-17 - MSDSYASHICA VAITTIANATHAN0% (1)

- Steel Platform DrawingDocument11 pagesSteel Platform DrawingYASHICA VAITTIANATHANNo ratings yet

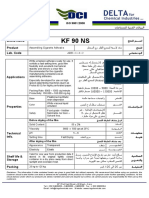

- KF 90 NS DatasheetDocument1 pageKF 90 NS DatasheetYASHICA VAITTIANATHANNo ratings yet

- Craybond 2070 Pu-TdsDocument3 pagesCraybond 2070 Pu-TdsYASHICA VAITTIANATHANNo ratings yet

- Chemxglue 81-10 MSDSDocument6 pagesChemxglue 81-10 MSDSYASHICA VAITTIANATHANNo ratings yet

- Craybond 3022-TDSDocument2 pagesCraybond 3022-TDSYASHICA VAITTIANATHANNo ratings yet

- Cyber Saftey (Yaashica Vaittianathan, 2C)Document15 pagesCyber Saftey (Yaashica Vaittianathan, 2C)YASHICA VAITTIANATHANNo ratings yet

- MaterialData 196958Document1 pageMaterialData 196958YASHICA VAITTIANATHANNo ratings yet

- Craybond 81-10 MSDSDocument4 pagesCraybond 81-10 MSDSYASHICA VAITTIANATHANNo ratings yet

- Kraton D1101 A - TDSDocument2 pagesKraton D1101 A - TDSYASHICA VAITTIANATHANNo ratings yet

- Sika Anchorfix - 1Document5 pagesSika Anchorfix - 1YASHICA VAITTIANATHANNo ratings yet

- Sikagrout - 214 SaDocument3 pagesSikagrout - 214 SaYASHICA VAITTIANATHANNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingYASHICA VAITTIANATHANNo ratings yet

- Role of Pesticide Formulations For Sustainable Crop Protection and Environment Management: A ReviewDocument8 pagesRole of Pesticide Formulations For Sustainable Crop Protection and Environment Management: A ReviewYASHICA VAITTIANATHAN100% (1)

- Sikagrout - 212 SaDocument3 pagesSikagrout - 212 SaYASHICA VAITTIANATHANNo ratings yet

- Sikagrout - 114Document3 pagesSikagrout - 114YASHICA VAITTIANATHANNo ratings yet

- Sikagrout Cable PTDocument3 pagesSikagrout Cable PTYASHICA VAITTIANATHANNo ratings yet

- Sikagrout Cable PtsaDocument3 pagesSikagrout Cable PtsaYASHICA VAITTIANATHANNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingYASHICA VAITTIANATHANNo ratings yet

- Starproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingDocument1 pageStarproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingYASHICA VAITTIANATHANNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingYASHICA VAITTIANATHANNo ratings yet

- Sikagrout - 105Document3 pagesSikagrout - 105YASHICA VAITTIANATHANNo ratings yet

- Marble & Granite Glue: Product Data SheetDocument2 pagesMarble & Granite Glue: Product Data SheetYASHICA VAITTIANATHANNo ratings yet

- MSDS Starcem 2K-LIQUIDDocument5 pagesMSDS Starcem 2K-LIQUIDYASHICA VAITTIANATHANNo ratings yet

- Product Data Sheet: Product Description Technical SpecificationDocument1 pageProduct Data Sheet: Product Description Technical SpecificationYASHICA VAITTIANATHANNo ratings yet

- TDS-Starfix C1-SLDocument3 pagesTDS-Starfix C1-SLYASHICA VAITTIANATHANNo ratings yet