Professional Documents

Culture Documents

Ch7 - Storage and Preservation

Ch7 - Storage and Preservation

Uploaded by

Pavan Sushant0 ratings0% found this document useful (0 votes)

137 views3 pagesPropellers require proper storage and preservation to prevent corrosion and damage during periods of non-use. Procedures include:

1) Performing regular engine runs and greasing for propellers in flyable storage or temporary storage up to 3 months.

2) For storage over 3 months, flushing propeller mechanisms with inhibiting oil, treating external parts with rust preventatives, and regularly exercising variable pitch propellers.

3) For indefinite storage, using preservation oil blended with engine oil and flown for 30 minutes every 12 months, applying protective coatings, and re-inhibiting or overhauling components every 3 years.

Original Description:

Original Title

Ch7- Storage and Preservation

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPropellers require proper storage and preservation to prevent corrosion and damage during periods of non-use. Procedures include:

1) Performing regular engine runs and greasing for propellers in flyable storage or temporary storage up to 3 months.

2) For storage over 3 months, flushing propeller mechanisms with inhibiting oil, treating external parts with rust preventatives, and regularly exercising variable pitch propellers.

3) For indefinite storage, using preservation oil blended with engine oil and flown for 30 minutes every 12 months, applying protective coatings, and re-inhibiting or overhauling components every 3 years.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

137 views3 pagesCh7 - Storage and Preservation

Ch7 - Storage and Preservation

Uploaded by

Pavan SushantPropellers require proper storage and preservation to prevent corrosion and damage during periods of non-use. Procedures include:

1) Performing regular engine runs and greasing for propellers in flyable storage or temporary storage up to 3 months.

2) For storage over 3 months, flushing propeller mechanisms with inhibiting oil, treating external parts with rust preventatives, and regularly exercising variable pitch propellers.

3) For indefinite storage, using preservation oil blended with engine oil and flown for 30 minutes every 12 months, applying protective coatings, and re-inhibiting or overhauling components every 3 years.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

CHAPTER 7-PROPELLER STORAGE AND PRESERVATION

1)What should be performed during propeller storage and preservation?

In general the storage status of an aircraft listed in three categories flyable,

temporary and indefinite. And the long term storage means any propeller not in

service or new propeller not flown, or overhauled and waiting for installation, or

propeller removed from the aircraft

The following should be done during propeller storage and preservation

1. When the propeller aircraft is in flyable storage the aircraft should fly at least

once in a month for 30 minutes

2. Aircraft should be greased every 6months or every 100hrs and when aircraft is

operated in unfavorable condition

3. Temporary storage is when propeller aircraft is not used for 3 months. During

this period propeller governor, accumulator, plugs, cylinders etc should be

protected and periodic checks for corrosion should be performed

4. The internal parts of a variable-pitch propeller will be protected by exercising

the propeller during weekly engine runs where these are possible, but, if the

engine cannot be run, the propeller should be feathered and unfeathered

using the feathering pump

5. If the engine is likely to be out of use for more than three months, the

propeller mechanism should be flushed with inhibiting oil, and all external

parts of the propeller should be treated with lanolin or an approved rust

preventative.

6. The propeller operating mechanism should be covered with waxed paper, and

all visible parts should be regularly inspected for corrosion.

7. Two-bladed propellers are usually stored in racks to permit free circulation of

air, but propellers with more than two blades may be stored vertically, on

stands, to minimise the amount of floor space they occupy.

8. When a variable-pitch propeller is disassembled for storage, individual

mechanical parts should be immersed in inhibiting oil, then allowed to drain,

bearings should be coated with mineral jelly, and electrical connections should

be smeared with petroleum jelly.

9. When assembled propeUers or pre-loaded blade· assemblies are held in

storage, the bearings must be exercised after six months and nine months. At

the end of twelve months in storage the bearings must be removed and

examined for brinelling and corrosion, and, if they are found to be satisfactory,

they should be cleaned, greased, and reassembled on the blade. They will then

be satisfactory for a further six months storage.

10.Under indefinite storage regular engine is replaced with MIL-C-6529 type 2 and

then aircraft is flown for 30minutes for circulation of oil. This oil is blended

with engine oil (75% engine oil and 25% preservation oil)

11.Thin protective film of MIL-C-16173 should be applied on metal propeller. This

coating should not be applied on rubber components like de-icing overshoes,

boots etc.

12.A wooden propeller should be placed horizontally for the moisture balance in

the blades

13.Components during long storage can be protected by plating, coating and

warping. The warping substance should be non-hygroscopic and varies in terms

of material ranging from coated paper products, plastic to sturdy vinyl

14.Storage bags, vacuum container or container filled with dry nitrogen should be

used for storage of components. The desiccants are used in such container to

absorb moisture

15.If the propeller, or individual components, are not' retained in the original

packing, they will normally require re-inhibiting every twelve months, a over-

hauling after three years.

16.Propeller should not be stored by resting on their blade tips

17.The propeller hub is sealed with appropriate plug

18.Governor should be oiled while in storage to prevent moisture and mechanical

damage

19.After 3yr storage of propeller must be inspected for external corrosion and

damage

20.Controllable-pitch propellers that are in storage for periods exceeding 5 years

may require the replacement of rubber parts and an internal inspection for

corrosion before returning the propeller to service.

21.inspect the components of the propeller anti-icing or de-icing system for

defects. Repair or replace parts as necessary.

22.Ensure that the O-ring, if used, is properly installed in the hub or on the

propeller shaft. Align the propeller so that the blades will be at the specified

clock angle.

23.Loose rubber components should t,e stored in the dark in an unstressed

condition, and retained in the manufacturer's packing until required for use.

24.Properly install the propeller bolts and torque as directed. Often the torque is

rechecked after 25 hours of operation.

25.After the propeller has been installed, remove any preservative film placed on

the exterior of the propeller and propeller blades.

26.Connect de-icing wires or anti-icing plumbing, if used. Align the index marks

between the spinner and spinner bulkhead and fasten the spinner to the

spinner bulkhead using the appropriate hardware.

27.During testing the propeller, the technician should perform a static rpm test to

verify power output

IMPORTANT POINTS TO REMEMBER

You might also like

- Fabrication PlanDocument1 pageFabrication PlanVũ GiangNo ratings yet

- Material ManagementDocument106 pagesMaterial ManagementRomi AfriansyahNo ratings yet

- Eil Tender List: S.No Project Name Bidding/Document NoDocument2 pagesEil Tender List: S.No Project Name Bidding/Document NoarshadbayaNo ratings yet

- Mab Basic Hdpe Repair Options Mab4 PDFDocument10 pagesMab Basic Hdpe Repair Options Mab4 PDFJohnny Condori MarcapuraNo ratings yet

- TCS 518-618!46!47RH 48RE Transmission Schematic Parts Nov2012 1Document5 pagesTCS 518-618!46!47RH 48RE Transmission Schematic Parts Nov2012 1hidraulicNo ratings yet

- LIBROSDocument6 pagesLIBROSOmar VillarNo ratings yet

- STTFFD LV m3 0001 Rev.b Spare Parts For Start Up CommissioningDocument1 pageSTTFFD LV m3 0001 Rev.b Spare Parts For Start Up Commissioningcuongpham301No ratings yet

- Shipping Storage and Preservation GuidelineDocument13 pagesShipping Storage and Preservation GuidelinePaul Gianmarco Melendez VasquezNo ratings yet

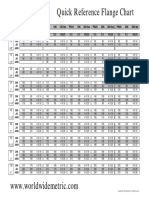

- Flange ChartDocument4 pagesFlange ChartEddie SantillánNo ratings yet

- Technical Notice SLS 6 Rev 2 - Fire Protection Systems Appliances and Compressed Gas Cylinder - Periodic Inspection Maintenance and TestingDocument17 pagesTechnical Notice SLS 6 Rev 2 - Fire Protection Systems Appliances and Compressed Gas Cylinder - Periodic Inspection Maintenance and TestingLuke WilsonNo ratings yet

- Ei2303 Ii Ii 4&5Document23 pagesEi2303 Ii Ii 4&5Ramanathan SunderNo ratings yet

- Guide - Foam Glass InsulationDocument25 pagesGuide - Foam Glass InsulationChristian DoriaNo ratings yet

- Cathodic Protection Cable Installation-Tmg OkDocument4 pagesCathodic Protection Cable Installation-Tmg Okarif rhNo ratings yet

- TCVN 9385 - 2012 - BS 6651 - 1999 - 998433 EN VerDocument118 pagesTCVN 9385 - 2012 - BS 6651 - 1999 - 998433 EN VerNam NguyenNo ratings yet

- 2 - A - Technical - Bid - Part - II - Supply - Erection - of - 220kV - Lines PDFDocument30 pages2 - A - Technical - Bid - Part - II - Supply - Erection - of - 220kV - Lines PDFKassem Baalbaki100% (1)

- Design Change Request Form 2013-08 Rev 2Document5 pagesDesign Change Request Form 2013-08 Rev 2Amjid AliNo ratings yet

- Sp-Me-0103 - Specification For Drain Transfer Pumps (Rev.a) - Returned (P-1401)Document9 pagesSp-Me-0103 - Specification For Drain Transfer Pumps (Rev.a) - Returned (P-1401)Panisa BanimaNo ratings yet

- 01-01-1865-D ELDS Technical Manual Iss13Document221 pages01-01-1865-D ELDS Technical Manual Iss13Alberyt099No ratings yet

- 2.7. 3403 Rev 3Document6 pages2.7. 3403 Rev 3sumit kumarNo ratings yet

- Is 6938Document13 pagesIs 6938Dhanashri Patil100% (1)

- 14.2kg LPG CylinderDocument14 pages14.2kg LPG CylinderNikhil GupthaNo ratings yet

- BAB I PENGANTAR Hukum Kontrak InternasionalDocument19 pagesBAB I PENGANTAR Hukum Kontrak InternasionalHarialdi Dharmawan SNo ratings yet

- Iom S e 01 - SCFDocument39 pagesIom S e 01 - SCFRodrigo LimaNo ratings yet

- Manufacturers Data Report (MDR) - Plant Projects EP-08-030-37Document17 pagesManufacturers Data Report (MDR) - Plant Projects EP-08-030-37MekhmanNo ratings yet

- Ti e Protegol 32-55 RRM Nov 07Document4 pagesTi e Protegol 32-55 RRM Nov 07A MahmoodNo ratings yet

- SOW Fabrikasi C-335-01 - 19.116.1Document1 pageSOW Fabrikasi C-335-01 - 19.116.1AlfanNo ratings yet

- 02 - Ab-Pf1a-C000-B13-Spec-0007 - 02C2.1Document38 pages02 - Ab-Pf1a-C000-B13-Spec-0007 - 02C2.1Walid BdeirNo ratings yet

- Pipes FittingsDocument7 pagesPipes FittingsTushar ArekarNo ratings yet

- Conduit Installation GuideDocument10 pagesConduit Installation GuidelaxmandohanNo ratings yet

- Supplier Deliverable RegisterDocument4 pagesSupplier Deliverable RegisterTadaya KasaharaNo ratings yet

- MS Insulation and Painting Rev 0Document25 pagesMS Insulation and Painting Rev 0Zainul Abid100% (1)

- CES-164 Assembly and Mounting 87-88 ActuatorDocument57 pagesCES-164 Assembly and Mounting 87-88 ActuatorJorge SanchezNo ratings yet

- General Works To Support Pipeline-Non Pipeline Activities-Tmg OkDocument5 pagesGeneral Works To Support Pipeline-Non Pipeline Activities-Tmg Okarif rhNo ratings yet

- Technical Proposal Descaling Removal Pulai - A (2013 ASD)Document22 pagesTechnical Proposal Descaling Removal Pulai - A (2013 ASD)hash117No ratings yet

- SVI Sludge Volume Index, ML/GDocument2 pagesSVI Sludge Volume Index, ML/GLye YpNo ratings yet

- 6.1.7 Electrical Heat Tracing SpecificationDocument16 pages6.1.7 Electrical Heat Tracing SpecificationMohamed FaroukNo ratings yet

- Blackmer LGLD3F Self Priming Specs Sheet PDFDocument2 pagesBlackmer LGLD3F Self Priming Specs Sheet PDFRomnick Dela Cruz GasparNo ratings yet

- Colour Coding As Per BHELDocument7 pagesColour Coding As Per BHELKedar Choksi0% (1)

- Ep 08 030 37Document18 pagesEp 08 030 37Muhammad AwaluddinNo ratings yet

- Pipewrap BT: DescriptionDocument2 pagesPipewrap BT: DescriptionVineet KhanduriNo ratings yet

- Document Title: Technical Proposal For 6500cbm LNG Storage TankDocument4 pagesDocument Title: Technical Proposal For 6500cbm LNG Storage Tankroni_arsyahNo ratings yet

- LCMDocument37 pagesLCMMajdi GUEBIBIANo ratings yet

- Case-Record NLIU SIAC LL-Partners Justice R.K. - Tankha Memorial International Moot 2020Document40 pagesCase-Record NLIU SIAC LL-Partners Justice R.K. - Tankha Memorial International Moot 2020Rahul BarnwalNo ratings yet

- Cistern InstallationDocument3 pagesCistern InstallationAubrey EllisNo ratings yet

- ONGC OES - Vendor Checklist - Rev 5 - 06 11 2013 PDFDocument6 pagesONGC OES - Vendor Checklist - Rev 5 - 06 11 2013 PDFsac84hinNo ratings yet

- ITB-spc For Tape Coating For UG Piping PDFDocument15 pagesITB-spc For Tape Coating For UG Piping PDFShyam Sundar GayenNo ratings yet

- Is 6044 1-2013Document17 pagesIs 6044 1-2013tapas bera0% (1)

- CS 5200 SC01 Ope PRC 253007 - A - C2Document78 pagesCS 5200 SC01 Ope PRC 253007 - A - C2chancele nguepdjopNo ratings yet

- Nalco Idler-S409/1 - 37870/8200004980/IDLERS&ROLLERSDocument2 pagesNalco Idler-S409/1 - 37870/8200004980/IDLERS&ROLLERSAlok NayakNo ratings yet

- WPS and MOS For Welder TestDocument8 pagesWPS and MOS For Welder TestDo Van HUNGNo ratings yet

- Installation/Operation Manual Pig Launcher: Franz Schuck GMBHDocument28 pagesInstallation/Operation Manual Pig Launcher: Franz Schuck GMBHWan Ah-LunNo ratings yet

- Wall Thickness Calculations - Using B31.4 Code: T P D S FDocument1 pageWall Thickness Calculations - Using B31.4 Code: T P D S FRamalingam PrabhakaranNo ratings yet

- Dimensions, Sizes and Specification of JIS B2220 Standard Steel Flanges PDFDocument8 pagesDimensions, Sizes and Specification of JIS B2220 Standard Steel Flanges PDFMohamad RifkiNo ratings yet

- 6001F Rev 07 Material, Fabrication and Installation StructureDocument83 pages6001F Rev 07 Material, Fabrication and Installation StructurePatrickioNo ratings yet

- Anvil SNubberDocument4 pagesAnvil SNubberashutoshNo ratings yet

- HR RPP-40736 R1 - Freight Container Lifting StandardsDocument28 pagesHR RPP-40736 R1 - Freight Container Lifting StandardsMinh Nguyen VanNo ratings yet

- Excavation Man Hour: Post Author:info - Projectestimate Post Published:november 10, 2019 Post category:MAN-HOURDocument5 pagesExcavation Man Hour: Post Author:info - Projectestimate Post Published:november 10, 2019 Post category:MAN-HOURAl Patrick Dela CalzadaNo ratings yet

- Mesc Spe 76 121 2016Document6 pagesMesc Spe 76 121 2016Salahuddin FarooquiNo ratings yet

- Thakur Institute of Aviation TechnologyDocument3 pagesThakur Institute of Aviation TechnologyAshwini ChaurasiaNo ratings yet

- Sec1: Engine Preservation and Storage: Figure ? - Aircraft Powerplant StorageDocument11 pagesSec1: Engine Preservation and Storage: Figure ? - Aircraft Powerplant StorageABDELRHMAN ALINo ratings yet

- Preservado de Motor Io-360hDocument8 pagesPreservado de Motor Io-360haviacion gnaNo ratings yet

- Caip-II Apu & Engine Storage by Aviator-ArifDocument25 pagesCaip-II Apu & Engine Storage by Aviator-ArifAparna RNo ratings yet

- Lubritech Product Range Special Application Lubricants en 12 2019Document76 pagesLubritech Product Range Special Application Lubricants en 12 2019Waheed AhmedNo ratings yet

- LVM Catalog 2013 Electric MotorDocument228 pagesLVM Catalog 2013 Electric MotorvikzefgNo ratings yet

- Failure Behaviour of Radial Spherical Plain Bearing (RSPB) Joints ForDocument15 pagesFailure Behaviour of Radial Spherical Plain Bearing (RSPB) Joints ForLuis Lozada100% (1)

- Catalogo ProdottiDocument21 pagesCatalogo Prodottiferguson distributionNo ratings yet

- Week 02-03 ME 308 Rolling Contact BearingsDocument52 pagesWeek 02-03 ME 308 Rolling Contact BearingsErtürk ErdiNo ratings yet

- TO Turbovisory Instruments Surajit Ghosh Sr. Supdt (C&I), BTPSDocument72 pagesTO Turbovisory Instruments Surajit Ghosh Sr. Supdt (C&I), BTPSVishal Kumar Laddha100% (1)

- Troubleshooting: Problem Symptoms TableDocument19 pagesTroubleshooting: Problem Symptoms TableHugo VillcaNo ratings yet

- Pump SpecificationDocument8 pagesPump SpecificationsumitanuragNo ratings yet

- 4-TOP MCQs On Classification of Lubricating System - 1 and Answers 2023Document6 pages4-TOP MCQs On Classification of Lubricating System - 1 and Answers 2023Yaseen RashidNo ratings yet

- R0 - 32.73m Continous Span BearingsDocument26 pagesR0 - 32.73m Continous Span BearingsSaurav Voktz BhaktaNo ratings yet

- Sievert DW 3000 Leaflet - English - 2018Document8 pagesSievert DW 3000 Leaflet - English - 2018NataliNo ratings yet

- Catalogs/ofite/instructions/120-75 CONSISTOMETER, ATMOSPHERIC PDFDocument9 pagesCatalogs/ofite/instructions/120-75 CONSISTOMETER, ATMOSPHERIC PDFFurqon SatriaNo ratings yet

- Tough Crushing: Smooth OperatingDocument16 pagesTough Crushing: Smooth OperatingManuel GagnoNo ratings yet

- Thrust BearingsDocument112 pagesThrust BearingsMohammad Ali ZamanNo ratings yet

- R3540-2002-A Drive AssemblyDocument1 pageR3540-2002-A Drive AssemblyKarikalan JayNo ratings yet

- TBMT Assembly Guide Rev01Document126 pagesTBMT Assembly Guide Rev01Juan Valle LunaNo ratings yet

- Ingenious Mechanisms Volume 2Document272 pagesIngenious Mechanisms Volume 2ka_Sarathi100% (1)

- 9.4.6 Goulds 320L Spec Sheet7313Document7 pages9.4.6 Goulds 320L Spec Sheet7313LeonelleNo ratings yet

- 13715-2 S2255RT & 2755RT Repair Parts Manual Nov.2012Document112 pages13715-2 S2255RT & 2755RT Repair Parts Manual Nov.2012miquel villarNo ratings yet

- Utk 1Document4 pagesUtk 1Rammy BaggaNo ratings yet

- Development and Application of Geneva Mechanism For Bottle Washing.Document11 pagesDevelopment and Application of Geneva Mechanism For Bottle Washing.AJER JOURNALNo ratings yet

- The Main Types of Bearings PDFDocument9 pagesThe Main Types of Bearings PDFThomas KamongNo ratings yet

- Moline Mounted Ball Bearings Catalog JECDocument55 pagesMoline Mounted Ball Bearings Catalog JECCHUYML MLNo ratings yet

- Astm D-6439-2005Document29 pagesAstm D-6439-2005MasNo ratings yet

- DODGE Plummer BlocksDocument40 pagesDODGE Plummer Blocksgrupa2904100% (2)

- Bearings Product ListDocument124 pagesBearings Product ListAnonymous pm1hDaNo ratings yet

- SBP17 Indar GeneratorsDocument20 pagesSBP17 Indar GeneratorsyijnuusNo ratings yet

- Catalogo General SKF Ingles - UnlockedDocument1,126 pagesCatalogo General SKF Ingles - UnlockedGuadalupe OjedaNo ratings yet