Professional Documents

Culture Documents

Campus® Datasheet: Durethan Bcf30H2.0Ef 900111 - Pa6-Cf30 Lanxess Deutschland GMBH

Campus® Datasheet: Durethan Bcf30H2.0Ef 900111 - Pa6-Cf30 Lanxess Deutschland GMBH

Uploaded by

Luis PalenzuelaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Campus® Datasheet: Durethan Bcf30H2.0Ef 900111 - Pa6-Cf30 Lanxess Deutschland GMBH

Campus® Datasheet: Durethan Bcf30H2.0Ef 900111 - Pa6-Cf30 Lanxess Deutschland GMBH

Uploaded by

Luis PalenzuelaCopyright:

Available Formats

CAMPUS® Datasheet

Durethan BCF30H2.0EF 900111 - PA6-CF30

LANXESS Deutschland GmbH

Product Texts

ISO 16396-PA 6,CF30,GHR,S10-250

PA 6, 30 % carbon fibers, injection molding, improved flowability, heat-aging stabilized, improved electrical conductivity

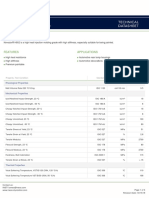

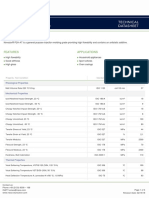

Rheological properties dry / cond Unit Test Standard

Molding shrinkage, parallel 0.1 / * % ISO 294-4, 2577

Molding shrinkage, normal 0.5 / * % ISO 294-4, 2577

Mechanical properties dry / cond Unit Test Standard

Tensile modulus 23000 / 11500 MPa ISO 527-1/-2

Stress at break 225 / 135 MPa ISO 527-1/-2

Strain at break 1.7 / 3.5 % ISO 527-1/-2

Charpy impact strength, +23°C 50 / 55 kJ/m² ISO 179/1eU

Charpy impact strength, -30°C 45 / 40 kJ/m² ISO 179/1eU

Charpy notched impact strength, +23°C - / 15 kJ/m² ISO 179/1eA

Puncture - maximum force, +23°C 850 / 1100 N ISO 6603-2

Puncture - maximum force, -30°C 675 / 700 N ISO 6603-2

Puncture energy, +23°C 1.7 / 3.7 J ISO 6603-2

Puncture energy, -30°C 1 / 1.3 J ISO 6603-2

Thermal properties dry / cond Unit Test Standard

Melting temperature, 10°C/min 221 / * °C ISO 11357-1/-3

Temp. of deflection under load, 1.80 MPa 210 / * °C ISO 75-1/-2

Temp. of deflection under load, 0.45 MPa 220 / * °C ISO 75-1/-2

Coeff. of linear therm. expansion, parallel 10 / * E-6/K ISO 11359-1/-2

Coeff. of linear therm. expansion, normal 90 / * E-6/K ISO 11359-1/-2

Other properties dry / cond Unit Test Standard

Water absorption 7.5 / * % Sim. to ISO 62

Humidity absorption 2.2 / * % Sim. to ISO 62

Density 1260 / - kg/m³ ISO 1183

Test specimen production Value Unit Test Standard

Injection Molding, melt temperature 280 °C ISO 294

Injection Molding, mold temperature 80 °C ISO 294

Last update: 2021-10-13 Source: https://www.campusplastics.com Page: 1/3

Durethan BCF30H2.0EF 900111 - PA6-CF30

LANXESS Deutschland GmbH

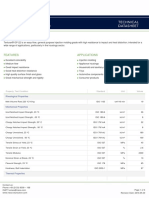

Diagrams

Stress-strain Stress-strain

Stress-strain Stress-strain

Durethan BCF30H2.0EF 900111 (dry) Durethan BCF30H2.0EF 900111 (cond.)

250 23 °C 200 0 °C

40 °C B 23 °C

B 60 °C 40 °C

80 °C 60 °C

200

100 °C 80 °C

150

B 120 °C 100 °C

140 °C B

160 °C B - Break

Stress in MPa

Stress in MPa

150

B 180 °C B

200 °C 100

B

B

100 B - Break B

B B

B

B

B 50

50 B

B

www.campusplastics.com www.campusplastics.com

0 0

0 0.5 1 1.5 2 2.5 3 3.5 0 0.5 1 1.5 2 2.5 3 3.5

Strain in % Strain in %

Secant modulus-strain Secant modulus-strain

Secant modulus-strain Secant modulus-strain

Durethan BCF30H2.0EF 900111 (dry) Durethan BCF30H2.0EF 900111 (cond.)

25000 23 °C 20000 0 °C

40 °C 23 °C

60 °C 40 °C

80 °C 60 °C

20000

100 °C 80 °C

15000

120 °C 100 °C

Secant modulus in MPa

Secant modulus in MPa

140 °C

15000 160 °C B - Break

180 °C

B

200 °C 10000

B

10000 B - Break

B

5000

B

5000 B B B

B BB

BB

B BB

B

www.campusplastics.com www.campusplastics.com

0 0

0 0.5 1 1.5 2 2.5 3 3.5 0 0.5 1 1.5 2 2.5 3 3.5

Strain in % Strain in %

Characteristics

Processing Special Characteristics

Injection Molding Increased electrical conductivity, Heat stabilized or stable to heat

Delivery form Regional Availability

Pellets North America, Europe, Asia Pacific, South and Central America,

Near East/Africa

Last update: 2021-10-13 Source: https://www.campusplastics.com Page: 2/3

Durethan BCF30H2.0EF 900111 - PA6-CF30

LANXESS Deutschland GmbH

Other text information

Injection molding

PREPROCESSING

Residual moisture content: 0.02-0.12 %

Drying temperature dry air dryer: 80 °C

Drying time dry air dryer: 2-6 h

PROCESSING

Melt temperature (Tmin - Tmax): 270-290 °C

Mold temperature: 80-120 °C

This information and our technical advice - whether verbal, in writing or by way of trials - are given in good faith but without warranty, and

this also applies where proprietary rights of third parties are involved. Our advice does not release you from the obligation to verify the

information currently provided - especially that contained in our safety data and technical information sheets - and to test our products as

to their suitability for the intended processes and uses. The application, use and processing of our products and the products manufactured

by you on the basis of our technical advice are beyond our control and, therefore, entirely your own responsibility. Our products are sold in

accordance with the current version of our General Conditions of Sale and Delivery.

Unless specified to the contrary, the values given have been established on standardized test specimens at room temperature. The figures

should be regarded as guide values only and not as binding minimum values. Kindly note that, under certain conditions, the properties can

be affected to a considerable extent by the design of the mould/die, the processing conditions and the coloring.

Please note that our product information and data are subject to ongoing examination and updating. For the latest version go to our

TechCenter.

techcenter.lanxess.com

Last update: 2021-10-13 Source: https://www.campusplastics.com Page: 3/3

You might also like

- Detergent Formulations EncyclopediaDocument768 pagesDetergent Formulations Encyclopediasanjeev gupta93% (14)

- Fiber Analysis: Quantitative: AATCC Test Method 20A-2017Document9 pagesFiber Analysis: Quantitative: AATCC Test Method 20A-2017Milagros Wieczorek50% (2)

- CYCOLOY™ Resin - LG9000 - Europe - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - LG9000 - Europe - Technical - Data - SheetmustafaNo ratings yet

- TDS - Primer - 313 - 81 - MNCKDocument3 pagesTDS - Primer - 313 - 81 - MNCKEduardo NozalNo ratings yet

- VEGA - Indonesia PresentationDocument62 pagesVEGA - Indonesia PresentationSteve WanNo ratings yet

- POLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetDocument2 pagesPOLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetscribdNo ratings yet

- Luran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)Document3 pagesLuran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)rosebifNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- TDS - Lexan 141R (141R-701)Document2 pagesTDS - Lexan 141R (141R-701)It WittayaNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- LEXAN™ Resin - 121R - Europe - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 121R - Europe - Technical - Data - Sheetanggun dewiNo ratings yet

- Elix Pc-Abs 5130Document4 pagesElix Pc-Abs 5130DiegoTierradentroNo ratings yet

- LANXESS Durethan BKV35H2.0 901510 ISO ENDocument3 pagesLANXESS Durethan BKV35H2.0 901510 ISO ENcristinamss33No ratings yet

- Styrolution TDS302200150418Document3 pagesStyrolution TDS302200150418erayNo ratings yet

- Styrolution 3 G55Document3 pagesStyrolution 3 G55John EduardoNo ratings yet

- Nylon 6-BAYER DURATHAN BKV130-901510Document3 pagesNylon 6-BAYER DURATHAN BKV130-901510dcrypto2022No ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Zytel® EFE7374 BK416-gbDocument9 pagesZytel® EFE7374 BK416-gbshahin_723No ratings yet

- Durethan BKV240 H20 XCP901510 ISOinternetDocument3 pagesDurethan BKV240 H20 XCP901510 ISOinternetshahin_723No ratings yet

- Durethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030Document3 pagesDurethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030zoranNo ratings yet

- PocanB3235000000 GF30 1Document5 pagesPocanB3235000000 GF30 1rihabNo ratings yet

- Styro Lution Tds 401200140448Document3 pagesStyro Lution Tds 401200140448scribdNo ratings yet

- Luran S 777K: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 777K: Acrylonitrile Styrene Acrylate (ASA)Leonardo DguezNo ratings yet

- Durethan B30S 000000 ISO enDocument3 pagesDurethan B30S 000000 ISO enjujuplasticNo ratings yet

- PA6-30GF LANXESS Durethan BKV130P 702214 ISO ENDocument2 pagesPA6-30GF LANXESS Durethan BKV130P 702214 ISO ENKalipse FerreiraNo ratings yet

- Styrolution Basf Terluran GP-22Document3 pagesStyrolution Basf Terluran GP-22medo.k016No ratings yet

- 51 AkulonS223 DHDocument4 pages51 AkulonS223 DHyassineamn115No ratings yet

- Pulse A 35-105 BlackDocument3 pagesPulse A 35-105 BlackTaoufik KheddarNo ratings yet

- ULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Document2 pagesULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Luis Enrique Ramos PérezNo ratings yet

- TDS - TS002 - Durethan AKV30H3.0Document3 pagesTDS - TS002 - Durethan AKV30H3.0oberta.andrzejNo ratings yet

- Lanxess Durethan Bkv130h2.0 901510 Iso enDocument3 pagesLanxess Durethan Bkv130h2.0 901510 Iso enRICARDONo ratings yet

- VictrexTDS150G 151GDocument2 pagesVictrexTDS150G 151GKumaar RanjanNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfDocument4 pagesCAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfAngererNo ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNo ratings yet

- Terluran GP-35: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-35: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroNo ratings yet

- Styrolution TDS400900481370Document3 pagesStyrolution TDS400900481370joshNo ratings yet

- StyrolutionTDS400700190196 PDFDocument3 pagesStyrolutionTDS400700190196 PDFMirella FaresNo ratings yet

- PBT - Lanxess Pocan B3235 000000Document3 pagesPBT - Lanxess Pocan B3235 000000armandoNo ratings yet

- Styrolution TDS401600170785Document3 pagesStyrolution TDS401600170785shahin_723No ratings yet

- CELCONM90Document5 pagesCELCONM90DiegoTierradentroNo ratings yet

- TDS - TS004 - Durethan BKV30H2.0Document3 pagesTDS - TS004 - Durethan BKV30H2.0oberta.andrzejNo ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- Victrex™ Peek 450G™: Product DescriptionDocument2 pagesVictrex™ Peek 450G™: Product DescriptionBerkant CangalNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfDocument5 pagesCAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfdivyarasinNo ratings yet

- Styrolution TDS401100270877Document3 pagesStyrolution TDS401100270877antonio.sevelarNo ratings yet

- Celanex 3300-2 PBTDocument3 pagesCelanex 3300-2 PBTDiegoTierradentroNo ratings yet

- Makrolon RW6267 X ISO enDocument3 pagesMakrolon RW6267 X ISO envahdatvahedyNo ratings yet

- LANXESS Durethan A30SFN31 000000 ISO ENDocument3 pagesLANXESS Durethan A30SFN31 000000 ISO ENNguyen Dinh VinhNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196PrashaNo ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- TDS MakrolonET3113Document3 pagesTDS MakrolonET3113It WittayaNo ratings yet

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 pagesUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoNo ratings yet

- POM Delrin 500Document2 pagesPOM Delrin 500countzeroaslNo ratings yet

- CYCOLOY™ Resin - XCY620 - Asia - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - XCY620 - Asia - Technical - Data - SheetAthiwat TriwattanapornNo ratings yet

- XENOY™ Resin - 5220U - Europe - Technical - Data - SheetDocument2 pagesXENOY™ Resin - 5220U - Europe - Technical - Data - SheetEduardo TreviñoNo ratings yet

- 04 AkulonK222-KGV4Document4 pages04 AkulonK222-KGV4yassineamn115No ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Absolac 300 Ineos AbsDocument2 pagesAbsolac 300 Ineos Absadrian4santanaNo ratings yet

- CELANEX® 2000-K-EnDocument3 pagesCELANEX® 2000-K-EnCarlos AgianiNo ratings yet

- Metal FabricationsDocument10 pagesMetal FabricationsGhayas JawedNo ratings yet

- Worksheet On MolesDocument4 pagesWorksheet On Moleskavelle chuneNo ratings yet

- Lubricants: Hydraulic Oil Buyer's GuideDocument3 pagesLubricants: Hydraulic Oil Buyer's GuideeroolifyNo ratings yet

- Bid Proposal Project Title Project Name and Title Item No. Description of Work QuantityDocument46 pagesBid Proposal Project Title Project Name and Title Item No. Description of Work QuantityMingVitugNo ratings yet

- Fire Watcher& Safety WatcherDocument6 pagesFire Watcher& Safety WatcherFarman ShaikhNo ratings yet

- Paper IDocument75 pagesPaper IThe AnarchistNo ratings yet

- PP GF30 - Hostacom PC072-3 Naturale-2Document2 pagesPP GF30 - Hostacom PC072-3 Naturale-2armando0% (1)

- RTM Accessories MatrasurDocument3 pagesRTM Accessories MatrasurThanh TruongNo ratings yet

- Technical Specifications: Vlothavenweg 16, 1013 BJ Amsterdam, Tel 020-6820178, Fax 020-6842105, WWW - Hmsa.nl, Info@hmsa - NLDocument12 pagesTechnical Specifications: Vlothavenweg 16, 1013 BJ Amsterdam, Tel 020-6820178, Fax 020-6842105, WWW - Hmsa.nl, Info@hmsa - NLAlexander100% (2)

- Jeffadd Additives: Performance ProductsDocument2 pagesJeffadd Additives: Performance ProductsPhuong The NguyenNo ratings yet

- CE5604-Advanced Concrete Technology: - History and Origins - Greeks: Addition ofDocument27 pagesCE5604-Advanced Concrete Technology: - History and Origins - Greeks: Addition ofzzz_monsterNo ratings yet

- Lecture #9 PET ENG 4210 Cementing 1Document11 pagesLecture #9 PET ENG 4210 Cementing 1حيدر بادي - Haider BadiNo ratings yet

- M3382 Spec (Fusible Link)Document4 pagesM3382 Spec (Fusible Link)DamonNo ratings yet

- Tech. Specs. For Metal Doors, Windows, Ventlators Louvers Etc.Document8 pagesTech. Specs. For Metal Doors, Windows, Ventlators Louvers Etc.SaraswatapalitNo ratings yet

- US20090099048A1 - Functional Fluid Composition For Improving Lubricity of A Braking SystemDocument14 pagesUS20090099048A1 - Functional Fluid Composition For Improving Lubricity of A Braking SystemzodapesssNo ratings yet

- Spare PartsDocument19 pagesSpare PartsSalim ShadmanNo ratings yet

- BERNSTEIN Standard-EnclosuresDocument60 pagesBERNSTEIN Standard-EnclosuresDacar ValladaresNo ratings yet

- Astm D4690 - 1 (En)Document5 pagesAstm D4690 - 1 (En)Emanuele MastrangeloNo ratings yet

- Spinning MillsDocument29 pagesSpinning MillsBDU - GrihayanNo ratings yet

- Nitocote SN511Document2 pagesNitocote SN511Gibbs PerNo ratings yet

- A 109 - A 109M - 03 Qtewos9bmta5tq - PDFDocument9 pagesA 109 - A 109M - 03 Qtewos9bmta5tq - PDFRafael GarciaNo ratings yet

- Cut-Back Asphalt (Rapid-Curing Type) : Standard Specification ForDocument1 pageCut-Back Asphalt (Rapid-Curing Type) : Standard Specification ForKaterin HernandezNo ratings yet

- TUV SUD BSR Test Report PDFDocument2 pagesTUV SUD BSR Test Report PDFAzrof AhmedNo ratings yet

- Bioactive Materials: SciencedirectDocument44 pagesBioactive Materials: SciencedirectAlicia Jara ChavezNo ratings yet

- 113 DR Fixit FastflexDocument3 pages113 DR Fixit FastflexreshmitapallaNo ratings yet

- Technical Bulletin: Thermally Conductive SiliconesDocument2 pagesTechnical Bulletin: Thermally Conductive Siliconesh_878236333No ratings yet