Professional Documents

Culture Documents

C.E On Preventing Pollution

C.E On Preventing Pollution

Uploaded by

winhlaingooCopyright:

Available Formats

You might also like

- Ows PDFDocument34 pagesOws PDFHope Ikue-John100% (2)

- Risk MatrixDocument27 pagesRisk Matrixwinhlaingoo100% (2)

- Opito Oco DiagramDocument21 pagesOpito Oco DiagramwinhlaingooNo ratings yet

- Marine Engineering KnowledgeDocument1,055 pagesMarine Engineering Knowledgesamanthalal100% (14)

- BP Crane OpsDocument63 pagesBP Crane OpsJack Tan100% (6)

- JRC JHS-183 SOFTWARE 04 2019 E JD-1387-19 RevDocument26 pagesJRC JHS-183 SOFTWARE 04 2019 E JD-1387-19 RevSKY MARINENo ratings yet

- Supervision of Crude Oil Washing (COW) OperationsDocument6 pagesSupervision of Crude Oil Washing (COW) Operationstony100% (1)

- Disposal For Spilled Oil and Prevention For Secondary DisasterDocument4 pagesDisposal For Spilled Oil and Prevention For Secondary DisasterIonescu EdaNo ratings yet

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7From EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7No ratings yet

- Oil Record 15.10.2018Document18 pagesOil Record 15.10.2018Popa VasileNo ratings yet

- Crude Oil Washing 2Document8 pagesCrude Oil Washing 2Subir BairagiNo ratings yet

- Marineserv LTD.: Main Engine Failure Check ListDocument1 pageMarineserv LTD.: Main Engine Failure Check ListShakti Swarup PatnaikNo ratings yet

- Battery Room Ventilationa and Proper UpkeepingDocument2 pagesBattery Room Ventilationa and Proper Upkeepingdassi99No ratings yet

- Gas CargoesDocument56 pagesGas CargoesTom AlexNo ratings yet

- LIFEBOAT INSPECTION Equipment & FittingsDocument20 pagesLIFEBOAT INSPECTION Equipment & FittingsReinard BadenhorstNo ratings yet

- Cma CGM Tanger: 4Th Engineer Hand Over ReportDocument8 pagesCma CGM Tanger: 4Th Engineer Hand Over ReportFaical EljarmouniNo ratings yet

- E23a ISGOTT Bunker ChklistDocument4 pagesE23a ISGOTT Bunker Chklistvic.barca2012100% (1)

- L3-Care of Cargo During Carriage (Part 2)Document26 pagesL3-Care of Cargo During Carriage (Part 2)Ganesh Bharath Kumar100% (1)

- ORB HOW-TO Ver 1 8Document13 pagesORB HOW-TO Ver 1 8kojet90100% (1)

- Pub Flag State RequirementsDocument14 pagesPub Flag State RequirementsOmar F. Mauco100% (1)

- Orb Criminal Cases PDFDocument27 pagesOrb Criminal Cases PDFvivek100% (1)

- Fire Fighting On BoardDocument13 pagesFire Fighting On BoardAnton Valentin100% (1)

- 8.04 Carriage of Coal in BulkDocument49 pages8.04 Carriage of Coal in BulkRoken Zgoul100% (2)

- Revised MARPOL Annex VDocument6 pagesRevised MARPOL Annex VDiana MoralesNo ratings yet

- Marine Cargo OperationDocument15 pagesMarine Cargo OperationJohn Raj100% (1)

- Cold Weather PrecautionsDocument6 pagesCold Weather PrecautionsGAMMA FACULTYNo ratings yet

- How To Prepare For Vetting Inspection in The Engine Room?Document4 pagesHow To Prepare For Vetting Inspection in The Engine Room?saket007iNo ratings yet

- Your Options For Emissions Compliance Guidance For Shipowners and Operators On The Annex VI SOx and NOx Regulations PDFDocument64 pagesYour Options For Emissions Compliance Guidance For Shipowners and Operators On The Annex VI SOx and NOx Regulations PDFnacer zidiNo ratings yet

- MarPol Annex VI Reg 16-18 PresentationDocument48 pagesMarPol Annex VI Reg 16-18 PresentationZtik PeraltaNo ratings yet

- Fire in Engine Room: Ship'S NameDocument2 pagesFire in Engine Room: Ship'S NameMehmet BakışkanNo ratings yet

- MARPOL ANNEX 4 ExplainedDocument10 pagesMARPOL ANNEX 4 ExplainedORLANDONo ratings yet

- Inert Gas OverviewDocument6 pagesInert Gas OverviewRahulChoudharyNo ratings yet

- 15 Important Points To Consider For Efficient Tanker Ship OperationsDocument13 pages15 Important Points To Consider For Efficient Tanker Ship OperationsDaniel Castillo100% (1)

- 001 Pcsopep Annex ArielDocument18 pages001 Pcsopep Annex ArielCatalin SevastianNo ratings yet

- VLSFO FUEL CharacterDocument5 pagesVLSFO FUEL CharacterDad’s Adventures LanderoNo ratings yet

- 14.incineration12 02 08Document15 pages14.incineration12 02 08nilakhan456790100% (1)

- Skip To ContentDocument71 pagesSkip To ContentRushabh PatelNo ratings yet

- CrudeDocument12 pagesCrudeZtik Peralta100% (1)

- Inerting of Cargo TanksDocument20 pagesInerting of Cargo TanksFlexi100% (1)

- 20 FireonBoardDocument98 pages20 FireonBoardSeba BayramNo ratings yet

- Tanker Questions From Ship EducationDocument33 pagesTanker Questions From Ship EducationAshok YNo ratings yet

- Marine Cargo Operations MCAO1010 Course Notes Tankers - Cargo Equipment (Basic)Document12 pagesMarine Cargo Operations MCAO1010 Course Notes Tankers - Cargo Equipment (Basic)sukhjit78No ratings yet

- DrydockDocument8 pagesDrydockRavindar AnandanNo ratings yet

- Bulk Carrier Inspection in Critical AreasDocument5 pagesBulk Carrier Inspection in Critical AreasAbdel Nasser Al-sheikh YousefNo ratings yet

- Oil Record Book: Commonwealth of DominicaDocument75 pagesOil Record Book: Commonwealth of DominicaSandeep MalakarNo ratings yet

- Watchkeeping and TroubleshootingDocument16 pagesWatchkeeping and TroubleshootingAditya Joglekar100% (1)

- SOP On Cleanliness and Hygiene PDFDocument12 pagesSOP On Cleanliness and Hygiene PDFtesteNo ratings yet

- Safety & Risk During Bunkering Procedures: The Marpol RegulationsDocument47 pagesSafety & Risk During Bunkering Procedures: The Marpol Regulationsoto saviourNo ratings yet

- Microsoft Power Point - Session 4 Secondary Venting (Compatibility Mode)Document31 pagesMicrosoft Power Point - Session 4 Secondary Venting (Compatibility Mode)paulholl100% (3)

- Engine Room DocumentsDocument5 pagesEngine Room DocumentsФурад ДжакумовNo ratings yet

- Oil Record Book For Ships: Check OneDocument23 pagesOil Record Book For Ships: Check OnefordNo ratings yet

- Confined Space Safe Practice: (2000) Rev.1 (October 2003) Rev.2 (April 2007)Document24 pagesConfined Space Safe Practice: (2000) Rev.1 (October 2003) Rev.2 (April 2007)Karwan Dilmany100% (1)

- Chemical Tanker: Main Characteristics of Chemical TankersDocument6 pagesChemical Tanker: Main Characteristics of Chemical TankersTri Wahyu PrastiyoNo ratings yet

- MEO Class 1 Written Examinations Model QuestionsDocument4 pagesMEO Class 1 Written Examinations Model QuestionsPraveen AbisakeNo ratings yet

- UK P I Bunkers and BunkeringDocument48 pagesUK P I Bunkers and BunkeringGeorgios Papakostas100% (1)

- BTSSIGFC Competency 1Document302 pagesBTSSIGFC Competency 1Upinderjeet Singh100% (1)

- LP Briefing - Tanker Management Self AssessmentDocument10 pagesLP Briefing - Tanker Management Self AssessmentcolymbosNo ratings yet

- Bunkering Is Dangerous: Procedure For Bunkering Operation On A ShipDocument3 pagesBunkering Is Dangerous: Procedure For Bunkering Operation On A ShipSurajitSarkar100% (1)

- Ballast Water Management: S M Tomiz Uddin:1055 Mfa 25, A1MC20180601-A (24) ALAM015268Document9 pagesBallast Water Management: S M Tomiz Uddin:1055 Mfa 25, A1MC20180601-A (24) ALAM015268Taufiq JahanNo ratings yet

- Passenger Ship Outbreak Management Manual AppendixDocument82 pagesPassenger Ship Outbreak Management Manual AppendixNestor Matus100% (1)

- Class Notes Questions Class 1Document2 pagesClass Notes Questions Class 1Swarg Vibha0% (1)

- Careclean Alkaline ExtraDocument2 pagesCareclean Alkaline ExtraMohamed ElsemanNo ratings yet

- PSC14EDocument62 pagesPSC14ENguyen Huu TriNo ratings yet

- IMO, International Convention On Salvage, 1989Document12 pagesIMO, International Convention On Salvage, 1989moe_htwe_1No ratings yet

- C.E On DrydockDocument3 pagesC.E On DrydockwinhlaingooNo ratings yet

- Newlightmyanmar 01 05 2022Document15 pagesNewlightmyanmar 01 05 2022winhlaingooNo ratings yet

- 29 Feb 22 GNLMDocument15 pages29 Feb 22 GNLMwinhlaingooNo ratings yet

- Five-Point Road Map of The State Administration CouncilDocument15 pagesFive-Point Road Map of The State Administration CouncilwinhlaingooNo ratings yet

- 5 - May - 22 - GNLM - Myanmar NewspaperDocument15 pages5 - May - 22 - GNLM - Myanmar NewspaperwinhlaingooNo ratings yet

- 4 - May - 22 - GNLM - Myanmar NewspaperDocument15 pages4 - May - 22 - GNLM - Myanmar NewspaperwinhlaingooNo ratings yet

- SV010203 Safety Valve ManualDocument14 pagesSV010203 Safety Valve ManualwinhlaingooNo ratings yet

- BGBC WE 662 15 CoiledTubingServicesDocument120 pagesBGBC WE 662 15 CoiledTubingServiceswinhlaingoo50% (2)

- TC01 Temp Control ManaulDocument8 pagesTC01 Temp Control ManaulwinhlaingooNo ratings yet

- Fleet360 Plant Services Solutions: Customer Success StoriesDocument13 pagesFleet360 Plant Services Solutions: Customer Success StorieswinhlaingooNo ratings yet

- H.1187 - Control Valve - FDDocument55 pagesH.1187 - Control Valve - FDwinhlaingooNo ratings yet

- Instruction Manual For Regulating Valve: Section TitleDocument4 pagesInstruction Manual For Regulating Valve: Section TitlewinhlaingooNo ratings yet

- OMC 80S Seires - Manual (Pneu. Controller)Document17 pagesOMC 80S Seires - Manual (Pneu. Controller)winhlaingooNo ratings yet

- Slip Ring DrawingDocument1 pageSlip Ring DrawingwinhlaingooNo ratings yet

- Minesight Schedule Optimizer - A New Tool: Global Mining Software Solutions Since 1970Document28 pagesMinesight Schedule Optimizer - A New Tool: Global Mining Software Solutions Since 1970Ricardo Contreras BNo ratings yet

- John Aebercrombie Concepts For Jazz Guitar Improvisation AbmajGmDocument3 pagesJohn Aebercrombie Concepts For Jazz Guitar Improvisation AbmajGmIsrael CevallosNo ratings yet

- Inventions and InventorsDocument26 pagesInventions and Inventorstaniaul94No ratings yet

- AMAC Brochures PC12 Revision 19.08.2019 1Document8 pagesAMAC Brochures PC12 Revision 19.08.2019 1Maria Luisa CucunubaNo ratings yet

- BBC Knowledge Asia Edition September 2015Document100 pagesBBC Knowledge Asia Edition September 2015Кристина Харченко100% (1)

- Law of SupplyDocument26 pagesLaw of SupplyamitNo ratings yet

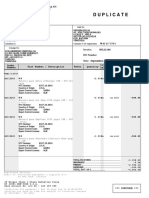

- Duplicate: Invoice: DO NumberDocument2 pagesDuplicate: Invoice: DO NumberLiau Zhan HongNo ratings yet

- AI MCQ QUESTION 100 MCQDocument13 pagesAI MCQ QUESTION 100 MCQdrphysics256No ratings yet

- UV Technology For DisinfectionDocument95 pagesUV Technology For DisinfectionMINEC YARACUYNo ratings yet

- Skin Tear Prevention - Strategies For Preventing Skin Injury in At-Risk PopulationsDocument10 pagesSkin Tear Prevention - Strategies For Preventing Skin Injury in At-Risk PopulationsCarolina RodriguezNo ratings yet

- Ilink400 Single Make Full System Scan Tool User ManualDocument41 pagesIlink400 Single Make Full System Scan Tool User ManualBalaam1No ratings yet

- State of The Geothermal Resources in Bolivia Laguna Colorada ProjectDocument6 pagesState of The Geothermal Resources in Bolivia Laguna Colorada ProjectLuis Rolando SirpaNo ratings yet

- 11th Floor Accomplishment As of 8/9/21 Units 1st Coat 2nd Coat Flood Test Remarks Unit ADocument27 pages11th Floor Accomplishment As of 8/9/21 Units 1st Coat 2nd Coat Flood Test Remarks Unit Afrancis baldonadoNo ratings yet

- Sustainable Development Meaning and Scope PDFDocument12 pagesSustainable Development Meaning and Scope PDFVaibhavi Modi100% (1)

- R S Aggarwal Solution Class 11 Maths Chapter 30 StatisticsDocument29 pagesR S Aggarwal Solution Class 11 Maths Chapter 30 StatisticsTushar RanaNo ratings yet

- Weekly SP Market Report Week Ending April 02nd 2021 Week 13 Report No 13.21Document7 pagesWeekly SP Market Report Week Ending April 02nd 2021 Week 13 Report No 13.21Sandesh Tukaram GhandatNo ratings yet

- Piping Arrangement - Conventional Oil Tanker BasicsDocument11 pagesPiping Arrangement - Conventional Oil Tanker BasicsEmon Anowar100% (1)

- GAILGas ExistingCNGStationsDocument4 pagesGAILGas ExistingCNGStationsclass xNo ratings yet

- ASHRAE - RP479-Air Source Heat Pump DefrostingDocument145 pagesASHRAE - RP479-Air Source Heat Pump DefrostingIon ZabetNo ratings yet

- Electricity Bill: Due Date: 11-07-2011Document1 pageElectricity Bill: Due Date: 11-07-2011Anjani GroverNo ratings yet

- Determination of Aspirin Using Back TitrationDocument7 pagesDetermination of Aspirin Using Back TitrationChilaNo ratings yet

- Proposal Rev 02Document30 pagesProposal Rev 02suronocaturatmojo100% (1)

- Example Lab ReportDocument20 pagesExample Lab ReportbobtentpegNo ratings yet

- HeatPAC Specification (HeatPAC-708)Document2 pagesHeatPAC Specification (HeatPAC-708)Thanh Trung Nguyen PhanNo ratings yet

- Unit 4 Flow of Water in SoilDocument31 pagesUnit 4 Flow of Water in SoilKhalil FanousNo ratings yet

- JsjadcxDocument18 pagesJsjadcxAlvin Tyantyan Tayas100% (4)

- The Physiology of The Lymphatic System: Melody A. SwartzDocument18 pagesThe Physiology of The Lymphatic System: Melody A. SwartzFeña Peña GonzalezNo ratings yet

- Lecture 1 - Map and Directions - 19492161 - 2023 - 07 - 15 - 04 - 47Document47 pagesLecture 1 - Map and Directions - 19492161 - 2023 - 07 - 15 - 04 - 47Rajbala SharmaNo ratings yet

C.E On Preventing Pollution

C.E On Preventing Pollution

Uploaded by

winhlaingooOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C.E On Preventing Pollution

C.E On Preventing Pollution

Uploaded by

winhlaingooCopyright:

Available Formats

1

(G.E.K) JULY-93: QUES: 1

(G.E.K) OCT-1995:QUES:1

ADMINISTRATIVE RESPONSIBLITES OF CHIEF ENGINEER ENVIROMENTAL POLLUTION.

(FOR AVOIDING POLUTTION OF SEA BY OIL)

To prevent sea pollution and air pollution C/E must know the following

rules and let other engineers and crew, (E/R personal) understand and

strictly follow.

Oils discharge criteria (machinery operation only) the operation must

be done with the (1) approval of C/E, to (2) inform bridge and must be (3)

used oily water separator.

For preventing the pollution of air, dark smoke shall not be emitter

from the vessel and if on any day, dark smoke is so emitted, the owner

the master or person in-charge of the vessel shall be guilty of an

offence. The dark smoke may comes out from main engine, auxiliary engine

and boilers. It is realized that emissions of dark smoke are sometimes

unavoidable, as for instance in lighting up a boiler when cold, while

soot blowing, cleaning fires and so on. So the sources from which dark

smoke can be emitted from the vessel must be maintained at regular

interval to minimized the dark smoke emitting period, to be within the

allowable limit, the following maintenance must be kept up to date, such

as

1. Fuel valves overhauling, checked the pump timing. M.E and Generator

engines.

2. Suitable fuel oil must be used

3. Burners from boiler must be cleaned frequently

4. Oil fire boiler air inlet duct must be cleaned regularly.

5. In oil fire boiler, correct amount of air/ fuel ratio to be maintained

by adjusting the air damper.

6. Soot on boiler tubes must be cleaned regularly

7. Never allow to overload the engine

Air pollution act

So as to prevent emission of black smoke from ships which can lead

pollution of air space, many countries have there own regulations that

not to be violated (give respect).

Smoke from the vessel is checked for “Blackness” by comparison with

“Ringelmann Scale Chart” or other many smoke meters, such as filter

Soiling spot meters, Opacimeter etc.

The degrees of obscuration listed are numbered 1,2,3, and 4 Ringelman.

On this scale, the white card is number 0 and totally black card is ‘5’.

If the smoke becomes darker than shade 4 is considered to be a black

smoke.

Sometime, the black smoke is inevitable (ra7SmifvGJEdSifaom) when flashing

up or any problems occur. Therefore, there has been a specific time

limit during which black smoke emission is not penalized.

01 Continuous production of black smoke must not longer than 4 minutes

02 Where there are number short emissions, the aggregate (pkpkaygif;

t7nftwGuf) time must be limited to 3 minutes in every 20 minutes

period.

03 Another part of ruling limits emission to not more than 10 minutes

in the aggregate in any 2 hours period.

2

Oil pollution act

The MARPOL regulations governing precise effluent qualities of oil

water mixture being discharge affect tankers over 150 GT and other ship

over 400 GT.

Protection of environmental pollution including control of

operational discharge and accidentally discharge.

In operational discharge ship must be -

1. Protected by Regulation for control of discharge.

Consideration should also be given to specific IMCO regulations

concerning "special areas" where discharge of any kind is emitted for

vessel. These areas include the Mediterranean Sea, Baltic sea, Red sea,

Black sea, (Gulfs) Gulf of Aden, Persian gulf and North sea, Antarctic

Area, Wider Caribbean Area and other sea area. The numbers of discharge

rules also appliance on many inland waterways.

Any discharge into the sea of oil or oily mixture from ship shall be

prohibited except the following conditions are satisfied.

a. The ship is not within a special area.

b. The ship is more than 12 N miles from the nearest land.

c. The ship is proceeding enroute.

d. The pumping out with moderate rate.

e. On an oil discharge monitoring and control system, oily water

separating equipment with alarm arrangement and an automatic 15

PPM stopping device oil filtering system or other installation.

f. On oil tanker, the bilge water does not originate from cargo pump

room bilge and the bilge water is not mixed with oil cargo

residues.

2. Must have slop tank for tankers

3. Must have S.B.T, C.B.T, C.O.W for tanker

4. Fitted the pumping and piping arrangement.

5. Fitted Oily water interface detector

6. Oil record book and cargo record book.

All leakage of machinery must be stopped and engine room tank tops

keep clean and painted with white color for immediate inspection for oil

leakage. Which can mix with bilge water and cause pollution.

All engine room person must be trained for independently operation of

oily separator.

For accidentally discharge ship must be posses

1. Tank size limitation, use large number of smaller tank is reduced

pollution then small number of large tank.

2. Fitted sub-division and stability tank

3. Also fitted Segregated Ballast Tank plus Protective Location, that

means use doubled hull or wind tank.

For tanker, tank-cleaning medium must be as possible as minimum to

avoid environmental pollution and keep in the slop tank. So now a day

the crude oil washing system is the best method for oil tanker.

The crude oil washing is carried out while the cargo discharging used

with fixed piping to permanent positioned tank cleaning nozzles. Oil

residues are pumps ashore with a cargo. An inert gas system must be used

during tank cleaning.

Crude oil washing must be completed before the vessel leaving port, a

completely different routine form that of water washing, when used is

carried out between ports and these are kept in slop tank and discharge

by shore facility when arriving port.

Regulation for the prevention of pollution by oil (MARPOL) which came

into force and October 1983 is to reduce the practice of using cargo

tanks for S.W ballast alternatively with cargo.

No discharge into the sea shall contain chemicals or other substances,

which are hazardous to the marine environment, chemical or other

3

substances introduce for the purpose of circumventing (csDK;azguf) the

condition of discharge specified in this regulation.

An entering must be made into oil record book or logbook consisting of

1 Quantity of discharge

2 Service of discharge

3 Duration of discharge

4 Ship position

5 The date and it must be signed by the master and C/E

Detector should be provided to measure the oil content from overboard

waters. It measured the pump of oil at all time 15 PPM and then the oily

water separator should be stopped immediately if the density exceed the

percent.

Regular maintenance of oily water separator must be done, filter

elements cleaning photo electric cell cleaning and testing etc. must be

done for efficient separation of oil and water.

Every E/R personnel's must be ordered not to throw oily rags and used

oil into the bilge and sea.

The incinerator incinerates them, the incinerator keep in good running

condition.

At bunkering period, care must be taken to avoid overflow such as all

scupper holes are plugged and sealed off, clear the overflow tank. Oil

leakage's from any machinery parts should be checked all the time and

rectified completely.

Sewage plant

Cleaning of the plant must be performed at sea only and not within

economic regions of any country.

For bio-chemical plant chemical used is AMDA-P or Sodium hypo

chloride.

Now a day used the zero discharge type sewage plants are design for

prevent environmental pollution.

Not for exam:

Untreated faces and sewage removes O2 from the water thus stimulating

the growth of algae (yifv,fa7arSmf) which in turn consumes the removing O 2.

At this stage are life dies through the lack of O2.

You might also like

- Ows PDFDocument34 pagesOws PDFHope Ikue-John100% (2)

- Risk MatrixDocument27 pagesRisk Matrixwinhlaingoo100% (2)

- Opito Oco DiagramDocument21 pagesOpito Oco DiagramwinhlaingooNo ratings yet

- Marine Engineering KnowledgeDocument1,055 pagesMarine Engineering Knowledgesamanthalal100% (14)

- BP Crane OpsDocument63 pagesBP Crane OpsJack Tan100% (6)

- JRC JHS-183 SOFTWARE 04 2019 E JD-1387-19 RevDocument26 pagesJRC JHS-183 SOFTWARE 04 2019 E JD-1387-19 RevSKY MARINENo ratings yet

- Supervision of Crude Oil Washing (COW) OperationsDocument6 pagesSupervision of Crude Oil Washing (COW) Operationstony100% (1)

- Disposal For Spilled Oil and Prevention For Secondary DisasterDocument4 pagesDisposal For Spilled Oil and Prevention For Secondary DisasterIonescu EdaNo ratings yet

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7From EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7No ratings yet

- Oil Record 15.10.2018Document18 pagesOil Record 15.10.2018Popa VasileNo ratings yet

- Crude Oil Washing 2Document8 pagesCrude Oil Washing 2Subir BairagiNo ratings yet

- Marineserv LTD.: Main Engine Failure Check ListDocument1 pageMarineserv LTD.: Main Engine Failure Check ListShakti Swarup PatnaikNo ratings yet

- Battery Room Ventilationa and Proper UpkeepingDocument2 pagesBattery Room Ventilationa and Proper Upkeepingdassi99No ratings yet

- Gas CargoesDocument56 pagesGas CargoesTom AlexNo ratings yet

- LIFEBOAT INSPECTION Equipment & FittingsDocument20 pagesLIFEBOAT INSPECTION Equipment & FittingsReinard BadenhorstNo ratings yet

- Cma CGM Tanger: 4Th Engineer Hand Over ReportDocument8 pagesCma CGM Tanger: 4Th Engineer Hand Over ReportFaical EljarmouniNo ratings yet

- E23a ISGOTT Bunker ChklistDocument4 pagesE23a ISGOTT Bunker Chklistvic.barca2012100% (1)

- L3-Care of Cargo During Carriage (Part 2)Document26 pagesL3-Care of Cargo During Carriage (Part 2)Ganesh Bharath Kumar100% (1)

- ORB HOW-TO Ver 1 8Document13 pagesORB HOW-TO Ver 1 8kojet90100% (1)

- Pub Flag State RequirementsDocument14 pagesPub Flag State RequirementsOmar F. Mauco100% (1)

- Orb Criminal Cases PDFDocument27 pagesOrb Criminal Cases PDFvivek100% (1)

- Fire Fighting On BoardDocument13 pagesFire Fighting On BoardAnton Valentin100% (1)

- 8.04 Carriage of Coal in BulkDocument49 pages8.04 Carriage of Coal in BulkRoken Zgoul100% (2)

- Revised MARPOL Annex VDocument6 pagesRevised MARPOL Annex VDiana MoralesNo ratings yet

- Marine Cargo OperationDocument15 pagesMarine Cargo OperationJohn Raj100% (1)

- Cold Weather PrecautionsDocument6 pagesCold Weather PrecautionsGAMMA FACULTYNo ratings yet

- How To Prepare For Vetting Inspection in The Engine Room?Document4 pagesHow To Prepare For Vetting Inspection in The Engine Room?saket007iNo ratings yet

- Your Options For Emissions Compliance Guidance For Shipowners and Operators On The Annex VI SOx and NOx Regulations PDFDocument64 pagesYour Options For Emissions Compliance Guidance For Shipowners and Operators On The Annex VI SOx and NOx Regulations PDFnacer zidiNo ratings yet

- MarPol Annex VI Reg 16-18 PresentationDocument48 pagesMarPol Annex VI Reg 16-18 PresentationZtik PeraltaNo ratings yet

- Fire in Engine Room: Ship'S NameDocument2 pagesFire in Engine Room: Ship'S NameMehmet BakışkanNo ratings yet

- MARPOL ANNEX 4 ExplainedDocument10 pagesMARPOL ANNEX 4 ExplainedORLANDONo ratings yet

- Inert Gas OverviewDocument6 pagesInert Gas OverviewRahulChoudharyNo ratings yet

- 15 Important Points To Consider For Efficient Tanker Ship OperationsDocument13 pages15 Important Points To Consider For Efficient Tanker Ship OperationsDaniel Castillo100% (1)

- 001 Pcsopep Annex ArielDocument18 pages001 Pcsopep Annex ArielCatalin SevastianNo ratings yet

- VLSFO FUEL CharacterDocument5 pagesVLSFO FUEL CharacterDad’s Adventures LanderoNo ratings yet

- 14.incineration12 02 08Document15 pages14.incineration12 02 08nilakhan456790100% (1)

- Skip To ContentDocument71 pagesSkip To ContentRushabh PatelNo ratings yet

- CrudeDocument12 pagesCrudeZtik Peralta100% (1)

- Inerting of Cargo TanksDocument20 pagesInerting of Cargo TanksFlexi100% (1)

- 20 FireonBoardDocument98 pages20 FireonBoardSeba BayramNo ratings yet

- Tanker Questions From Ship EducationDocument33 pagesTanker Questions From Ship EducationAshok YNo ratings yet

- Marine Cargo Operations MCAO1010 Course Notes Tankers - Cargo Equipment (Basic)Document12 pagesMarine Cargo Operations MCAO1010 Course Notes Tankers - Cargo Equipment (Basic)sukhjit78No ratings yet

- DrydockDocument8 pagesDrydockRavindar AnandanNo ratings yet

- Bulk Carrier Inspection in Critical AreasDocument5 pagesBulk Carrier Inspection in Critical AreasAbdel Nasser Al-sheikh YousefNo ratings yet

- Oil Record Book: Commonwealth of DominicaDocument75 pagesOil Record Book: Commonwealth of DominicaSandeep MalakarNo ratings yet

- Watchkeeping and TroubleshootingDocument16 pagesWatchkeeping and TroubleshootingAditya Joglekar100% (1)

- SOP On Cleanliness and Hygiene PDFDocument12 pagesSOP On Cleanliness and Hygiene PDFtesteNo ratings yet

- Safety & Risk During Bunkering Procedures: The Marpol RegulationsDocument47 pagesSafety & Risk During Bunkering Procedures: The Marpol Regulationsoto saviourNo ratings yet

- Microsoft Power Point - Session 4 Secondary Venting (Compatibility Mode)Document31 pagesMicrosoft Power Point - Session 4 Secondary Venting (Compatibility Mode)paulholl100% (3)

- Engine Room DocumentsDocument5 pagesEngine Room DocumentsФурад ДжакумовNo ratings yet

- Oil Record Book For Ships: Check OneDocument23 pagesOil Record Book For Ships: Check OnefordNo ratings yet

- Confined Space Safe Practice: (2000) Rev.1 (October 2003) Rev.2 (April 2007)Document24 pagesConfined Space Safe Practice: (2000) Rev.1 (October 2003) Rev.2 (April 2007)Karwan Dilmany100% (1)

- Chemical Tanker: Main Characteristics of Chemical TankersDocument6 pagesChemical Tanker: Main Characteristics of Chemical TankersTri Wahyu PrastiyoNo ratings yet

- MEO Class 1 Written Examinations Model QuestionsDocument4 pagesMEO Class 1 Written Examinations Model QuestionsPraveen AbisakeNo ratings yet

- UK P I Bunkers and BunkeringDocument48 pagesUK P I Bunkers and BunkeringGeorgios Papakostas100% (1)

- BTSSIGFC Competency 1Document302 pagesBTSSIGFC Competency 1Upinderjeet Singh100% (1)

- LP Briefing - Tanker Management Self AssessmentDocument10 pagesLP Briefing - Tanker Management Self AssessmentcolymbosNo ratings yet

- Bunkering Is Dangerous: Procedure For Bunkering Operation On A ShipDocument3 pagesBunkering Is Dangerous: Procedure For Bunkering Operation On A ShipSurajitSarkar100% (1)

- Ballast Water Management: S M Tomiz Uddin:1055 Mfa 25, A1MC20180601-A (24) ALAM015268Document9 pagesBallast Water Management: S M Tomiz Uddin:1055 Mfa 25, A1MC20180601-A (24) ALAM015268Taufiq JahanNo ratings yet

- Passenger Ship Outbreak Management Manual AppendixDocument82 pagesPassenger Ship Outbreak Management Manual AppendixNestor Matus100% (1)

- Class Notes Questions Class 1Document2 pagesClass Notes Questions Class 1Swarg Vibha0% (1)

- Careclean Alkaline ExtraDocument2 pagesCareclean Alkaline ExtraMohamed ElsemanNo ratings yet

- PSC14EDocument62 pagesPSC14ENguyen Huu TriNo ratings yet

- IMO, International Convention On Salvage, 1989Document12 pagesIMO, International Convention On Salvage, 1989moe_htwe_1No ratings yet

- C.E On DrydockDocument3 pagesC.E On DrydockwinhlaingooNo ratings yet

- Newlightmyanmar 01 05 2022Document15 pagesNewlightmyanmar 01 05 2022winhlaingooNo ratings yet

- 29 Feb 22 GNLMDocument15 pages29 Feb 22 GNLMwinhlaingooNo ratings yet

- Five-Point Road Map of The State Administration CouncilDocument15 pagesFive-Point Road Map of The State Administration CouncilwinhlaingooNo ratings yet

- 5 - May - 22 - GNLM - Myanmar NewspaperDocument15 pages5 - May - 22 - GNLM - Myanmar NewspaperwinhlaingooNo ratings yet

- 4 - May - 22 - GNLM - Myanmar NewspaperDocument15 pages4 - May - 22 - GNLM - Myanmar NewspaperwinhlaingooNo ratings yet

- SV010203 Safety Valve ManualDocument14 pagesSV010203 Safety Valve ManualwinhlaingooNo ratings yet

- BGBC WE 662 15 CoiledTubingServicesDocument120 pagesBGBC WE 662 15 CoiledTubingServiceswinhlaingoo50% (2)

- TC01 Temp Control ManaulDocument8 pagesTC01 Temp Control ManaulwinhlaingooNo ratings yet

- Fleet360 Plant Services Solutions: Customer Success StoriesDocument13 pagesFleet360 Plant Services Solutions: Customer Success StorieswinhlaingooNo ratings yet

- H.1187 - Control Valve - FDDocument55 pagesH.1187 - Control Valve - FDwinhlaingooNo ratings yet

- Instruction Manual For Regulating Valve: Section TitleDocument4 pagesInstruction Manual For Regulating Valve: Section TitlewinhlaingooNo ratings yet

- OMC 80S Seires - Manual (Pneu. Controller)Document17 pagesOMC 80S Seires - Manual (Pneu. Controller)winhlaingooNo ratings yet

- Slip Ring DrawingDocument1 pageSlip Ring DrawingwinhlaingooNo ratings yet

- Minesight Schedule Optimizer - A New Tool: Global Mining Software Solutions Since 1970Document28 pagesMinesight Schedule Optimizer - A New Tool: Global Mining Software Solutions Since 1970Ricardo Contreras BNo ratings yet

- John Aebercrombie Concepts For Jazz Guitar Improvisation AbmajGmDocument3 pagesJohn Aebercrombie Concepts For Jazz Guitar Improvisation AbmajGmIsrael CevallosNo ratings yet

- Inventions and InventorsDocument26 pagesInventions and Inventorstaniaul94No ratings yet

- AMAC Brochures PC12 Revision 19.08.2019 1Document8 pagesAMAC Brochures PC12 Revision 19.08.2019 1Maria Luisa CucunubaNo ratings yet

- BBC Knowledge Asia Edition September 2015Document100 pagesBBC Knowledge Asia Edition September 2015Кристина Харченко100% (1)

- Law of SupplyDocument26 pagesLaw of SupplyamitNo ratings yet

- Duplicate: Invoice: DO NumberDocument2 pagesDuplicate: Invoice: DO NumberLiau Zhan HongNo ratings yet

- AI MCQ QUESTION 100 MCQDocument13 pagesAI MCQ QUESTION 100 MCQdrphysics256No ratings yet

- UV Technology For DisinfectionDocument95 pagesUV Technology For DisinfectionMINEC YARACUYNo ratings yet

- Skin Tear Prevention - Strategies For Preventing Skin Injury in At-Risk PopulationsDocument10 pagesSkin Tear Prevention - Strategies For Preventing Skin Injury in At-Risk PopulationsCarolina RodriguezNo ratings yet

- Ilink400 Single Make Full System Scan Tool User ManualDocument41 pagesIlink400 Single Make Full System Scan Tool User ManualBalaam1No ratings yet

- State of The Geothermal Resources in Bolivia Laguna Colorada ProjectDocument6 pagesState of The Geothermal Resources in Bolivia Laguna Colorada ProjectLuis Rolando SirpaNo ratings yet

- 11th Floor Accomplishment As of 8/9/21 Units 1st Coat 2nd Coat Flood Test Remarks Unit ADocument27 pages11th Floor Accomplishment As of 8/9/21 Units 1st Coat 2nd Coat Flood Test Remarks Unit Afrancis baldonadoNo ratings yet

- Sustainable Development Meaning and Scope PDFDocument12 pagesSustainable Development Meaning and Scope PDFVaibhavi Modi100% (1)

- R S Aggarwal Solution Class 11 Maths Chapter 30 StatisticsDocument29 pagesR S Aggarwal Solution Class 11 Maths Chapter 30 StatisticsTushar RanaNo ratings yet

- Weekly SP Market Report Week Ending April 02nd 2021 Week 13 Report No 13.21Document7 pagesWeekly SP Market Report Week Ending April 02nd 2021 Week 13 Report No 13.21Sandesh Tukaram GhandatNo ratings yet

- Piping Arrangement - Conventional Oil Tanker BasicsDocument11 pagesPiping Arrangement - Conventional Oil Tanker BasicsEmon Anowar100% (1)

- GAILGas ExistingCNGStationsDocument4 pagesGAILGas ExistingCNGStationsclass xNo ratings yet

- ASHRAE - RP479-Air Source Heat Pump DefrostingDocument145 pagesASHRAE - RP479-Air Source Heat Pump DefrostingIon ZabetNo ratings yet

- Electricity Bill: Due Date: 11-07-2011Document1 pageElectricity Bill: Due Date: 11-07-2011Anjani GroverNo ratings yet

- Determination of Aspirin Using Back TitrationDocument7 pagesDetermination of Aspirin Using Back TitrationChilaNo ratings yet

- Proposal Rev 02Document30 pagesProposal Rev 02suronocaturatmojo100% (1)

- Example Lab ReportDocument20 pagesExample Lab ReportbobtentpegNo ratings yet

- HeatPAC Specification (HeatPAC-708)Document2 pagesHeatPAC Specification (HeatPAC-708)Thanh Trung Nguyen PhanNo ratings yet

- Unit 4 Flow of Water in SoilDocument31 pagesUnit 4 Flow of Water in SoilKhalil FanousNo ratings yet

- JsjadcxDocument18 pagesJsjadcxAlvin Tyantyan Tayas100% (4)

- The Physiology of The Lymphatic System: Melody A. SwartzDocument18 pagesThe Physiology of The Lymphatic System: Melody A. SwartzFeña Peña GonzalezNo ratings yet

- Lecture 1 - Map and Directions - 19492161 - 2023 - 07 - 15 - 04 - 47Document47 pagesLecture 1 - Map and Directions - 19492161 - 2023 - 07 - 15 - 04 - 47Rajbala SharmaNo ratings yet