Professional Documents

Culture Documents

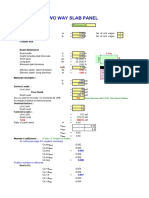

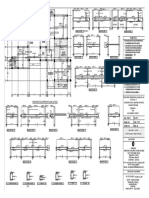

PARKING SHED AT 220kV BHILDI GIS SUB-STATION - Layout1

PARKING SHED AT 220kV BHILDI GIS SUB-STATION - Layout1

Uploaded by

irshad khanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PARKING SHED AT 220kV BHILDI GIS SUB-STATION - Layout1

PARKING SHED AT 220kV BHILDI GIS SUB-STATION - Layout1

Uploaded by

irshad khanCopyright:

Available Formats

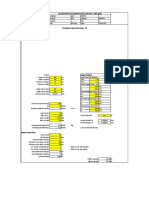

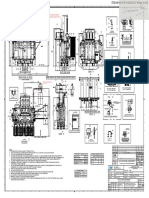

O N M L K J I H G F E D C B A

A GENERAL

1. ALL DIMENSIONS ARE IN MILLIMETER UNLESS OTHERWISE SPECIFIED & LEVELS ARE IN METER

2. DO NOT SCALE THE DRAWING, ONLY WRITTEN DIMENSIONS SHALL BE FOLLOWED.

3. THE DRAWING MUST BE READ IN CONJUNCTION WITH ALL OTHER RELEVANT DRAWING I.E.

ARCHITECTURAL, ELECTRICAL & STRUCTURAL RAWING. (GA DRAWING OF MANUFACTURER).

4. ALL THE WORK SHALL BE CARRIED OUT AS PER RELEVANT FIELD QUALITY PLAN APPROVED BY GETCO.

5. IN CASE OF ANY DOUBT OR DISCREPANCIES, PLEASE CONTACT ENGG. CELL. NO ASSUMPTIONS SHALL BE MADE.

6. ALL SAFETY PRECAUTIONS AS MENTIONED IN ELECTRICAL LAYOUT, SAFETY MANUAL & RELEVAN

8 STANDARD CODES, SHALL BE SCRUPULOUSLY FOLLOWED WHILE EXECUTION OF WORK.

8

B CONCRETE

7. THE CEMENT SHALL BE ORDINARY PORTLAND CEMENT WITH C3A CONTENT FROM 5 TO 8 % FOR

ALL CIVIL WORK.

8. ALL THE RCC WORK SHALL BE CARRIED OUT AS PER IS 456-2000, WITH LATEST REVISION.

9. THE GRADE OF CONCRETE SHALL BE M25, WITH MINIMUM CEMENT CONTENT OF 370 KG/M³.

EXCEPT LEAN CONCRETE MIX DESIGN SHALL BE DONE CONSIDERING 'SEVERE ENVIRONMENT'

EXPOSURE CONDITIONS.

10. THE GRADE OF LEAN CONCRETE SHALL BE M-15

11. CONCRETING OF ALL CIVIL WORKS UNDER BIDDER SCOPE FOR GRADE OF M30 & M20 SHALL BE

DONE WITH THE HELP OF DIGITAL WEIGH BATCHER OR FLOOR ( MOBILE CONCRETE BATCHING PLANT) ONLY.

12. ALL CONCRETE SHALL BE MACHINE MIXED, VIBRATED & CURED FOR MINIMUM 10 DAYS.

13. USE OF NEEDLE VIBRATOR IS COMPULSORY FOR ALL CONCRETE WORKS.

C REINFORCMENT

7 14. TMT (HIGH YIELD STRENGTH DEFORMED STEEL BARS) CRS (CORROSION RESISTANT STEEL) BAR 7

OF GRADE FE-500 D BARS CONFORMING TO IS-1786 SHALL BE USED IN ALL CIVIL WORKS.

15. REINFORCEMENT SHALL BE BENT & FIXED IN ACCORDANCE WITH THE PROCEDURE SPECIFIED IN

IS 2502-1963.

16. CLEAR COVER TO THE REINFORCEMENT SHALL BE AS UNDER

TOP BOTTOM SIDES

* FOOTING (RAFT & ISOLATED) 50 75 50

* PILE CAPS 50 100 50

* PILE 75 75 75

* GRADE BEAM 40 40 40

* COLUMNS & PEDESTALS 50 - 50

* BEAMS ABOVE GROUND LEVEL 35 35 35

* GRADE SLAB 25 25 25

* LINTEL BEAMS 25 25 25

* SLABS & STAIRCASE 25 25 25

* CABLE TRENCHES BASE SLAB 20 35 35

6 * WALL 20 35 35 6

17. LAP LENGTH SHOULD BE 50 TIMES OF DIA..

18. LAP AT SUPPORT SECTION, JOINT SECTION & MID SPAN SHALL BE AVOIDED.

19. OVERLAPPING OF REINFORCEMENT SHALL BE STAGGERED.

20. UNLESS OTHERWISE SPECIFIED DISTN., STEEL SHOULD BE 8 MM. TOR @ 200 MM. C/C.

21. IN CASE OF CONTINUOUS SUPPORT, REINFORCEMENTS ARE DEFERENT FOR TWO ADJACENT BEAMS / SLABS,

THE HIGHER SUPPORT REINFORCEMENT OF THE TWO SHALL BE PROVIDED AT THE SUPPORT.

D FOUNDATION

22. IN THE COURSE OF EXCAVATION, IF, SUB SOIL STRATA DIFFERS IN COMPARE TO SBC REPORT. THE SAME

SHALL BE REPORTED TO THE CONCERN FOR NECESSARY STEPS BY THE ENGINEERING CELL.

23. LAY-OUT, LINE-OUT & ORIENTATION SHALL BE CHECKED JOINTLY BY E. E. / D. E. - (CIVIL) & E. E. / D. E. -(CONST),

ON THE BASIS OF APPROVED ELECTRICAL LAY-OUT, GA DRAWING & THIS DRAWING, PRIOR TOSTART THE WORK.

FOR OPEN FOUNDATION

24. NO FOUNDATION SHALL BE RESTED ON FILLED-UP SOIL / BLACK COTTON SOIL.

* IF FILLED UP SOIL ENCOUNTERED, FOUNDATION SHALL BE TAKEN 300 MM BELOW VIRGIN SOIL.

5 * IF FOUNDATION FALLS ON EXCAVATED TRENCHES OF ADJOINING FOUNDATION, THAN FOUNDATION SHALL

5

EXTENDED UP TO THE DEPTH OF ADJOINING FOUNDATION.

* IF BLACK COTTON SOIL ENCOUNTERED, AT FOUNDATION DEPTH, THAN FOUNDATION SHALL REST ON

COMPACTED SAND BED OF 300MM THICK.

25. BACK FILLING OF FOUNDATION TRENCHES SHALL BE DONE WITH USE OF NON COHESIVE SOIL ONLY.

* THE BACK FILLING AROUND THE FOUNDATION SHALL BE ADEQUATE TO ACHIEVE THE PROCTOR DENSITY OF 95%.

FOR PILE FOUNDATION (IF REQUIRED)

26. THE GRADE OF CONCRETE SHALL BE M-30 FOR PILE CAP, COLUMN, BEAM, RAFT, ETC., EXCEPT LEAN CONCRETE.

27. THE GRADE OF CONCRETE FOR PILE SHALL BE M-30, CONFIRMING TO IS 456 WITH MINIMUM CEMENT

CONTENT AS 400 kg. / M³. WITH TREMIE CONCRETE.

28. CONCRETE SLUMP SHALL BE 120 TO 150MM. (VERY HIGH DEGREE OF WORKABILITY) FOR PILE FOUNDATION

WITH TREMIE CONCRETE.

29. FOR CONSTRUCTION SPECIFICATION OF IS 2911 (PART-III), LATEST REVISION SHALL BE FOLLOWED.

30. THE PILE SHOULD PROJECT 100MM. IN TO THE PILE CAP CONCRETE.

31. INTEGRITY TEST TO BE DONE FOR ALL PILES, PRIOR TO CAST PILE CAP.

32. INITIAL & ROUTINE PILE LOAD TEST SHALL BE CARRIED OUT ON ANY ONE PILE & SHALL BE COMPARE WITH

4 VALUE OF SBC REPORT.PAIOR TO START CONCRETING WORK. 4

SPECIAL NOTES

33. ALL DIMENSION ARE TO BE CHECKED AND VERIFIED BY GROUND LAY-OUT.

34. ALL THE STRUCTURES AFTER FABRICATION SHALL BE CONTROL ASSEMBLED TO MATCH THE MATCHING

DIMENSIONS AND CONNECTIONS OF DIFFERENT ERECTION MARKS BEFORE DESPATCH TO SITE.

35. ALL CONNECTIONS ARE 8mm CONTINUOUS FILLET WELDS UNLESS OTHERWISE SPECIFIED.

36. ALL WELDS SHALL BE 8mm FILLET WELDS FOR SHOP FABRICATION AND 8mm FOR SITE WELDING UNLESS

OTHERWISE SPECIFIED.

37. ALL STRUCTURAL STEEL ROLLED SECTIONS AND PLATES SHALL CONFORM TO I.S. 226-1975 & I.S. 2062-1984.

38. ALL WELDING SHALL CONFORM TO I.S. 816-1969.

39. ALL ELECTRODES SHALL CONFORM TO I.S. 814 (PART-1)1974.

40. WELDING SYMBOLS ARE AS PER I.S. 813-1961, WHERE USED.

41. ALL M.S. BLACK BOLTS AND NUTS SHALL CONFORM TO I.S. 1363 (PART 1 TO 3)-1967.

42. ALL WASHERS SHALL CONFORM TO I.S. 5369-1975 I.S. 5370 -1969, I.S. 5372-1975, OR I.S. 5374-1975.

43. ZINC CHROMAT PREMIER, SYNTHETIC ENAMEL PAINT, STEEL GRAY SHED.

44. ALL GUSSET PLATES ARE 10 mm THICK UNLESS OTHERWISE NOTED.

3 45. 2MM THICK CORRUGATED FRP SHEET, PERLIN SPACING NOT MORE THAN 900C/C 3

R0 04.05.2022 SUBMITTED FOR APPROVAL GSP AK IK

REV. NO. DATE DESCRIPTION PREPD CHECKED APPROVED

G

2 E

T

2

C

O

JIANGSU JINGKE - SMART ELECTRIC CO.,LTD

1 1

SIZE SCALE SHEET REV.

O N M L K J I H G F E D C B A

You might also like

- Client:: Structural Analysis and Design Report StadiumDocument39 pagesClient:: Structural Analysis and Design Report StadiumRoshan KejariwalNo ratings yet

- Comparison of HILTI and Fisher BoltDocument2 pagesComparison of HILTI and Fisher BoltSuresh D100% (1)

- Tension Structures EngineerDocument3 pagesTension Structures EngineerChezben ShopNo ratings yet

- Design Calculation Report For Lazaro PDFDocument4 pagesDesign Calculation Report For Lazaro PDFFerdie TolosaNo ratings yet

- Hanging Device Structural and Stability CalculationsDocument13 pagesHanging Device Structural and Stability CalculationsAhmed AliNo ratings yet

- Design Brief IKK R00 2023.05Document20 pagesDesign Brief IKK R00 2023.05Syarief AbdurrachmanNo ratings yet

- Ae3 18 087Document26 pagesAe3 18 087Fadi AlatrashNo ratings yet

- Planning, Analysis and Design of Open Air Cricket Stadium: Presented byDocument12 pagesPlanning, Analysis and Design of Open Air Cricket Stadium: Presented byCatherine J. RoseNo ratings yet

- General Sheet NotesDocument1 pageGeneral Sheet NotesManoj JaiswalNo ratings yet

- ReportDocument52 pagesReportFeroz Khan PatthanNo ratings yet

- Oil City Division: Rev. Description Date BY CH'KDocument1 pageOil City Division: Rev. Description Date BY CH'KHendrias ari sujarwoNo ratings yet

- Welding Quality Control: TopicsDocument26 pagesWelding Quality Control: TopicsKamarul NizamNo ratings yet

- Designed Job No Checked Contract Conn - No Rev 0 Date Code For Maximum Moment Mz-Case - P2Document12 pagesDesigned Job No Checked Contract Conn - No Rev 0 Date Code For Maximum Moment Mz-Case - P2kyatoor prashanthNo ratings yet

- Aster Private Limited Ibo Division - Secunderabad: Foundation Design For Tower Type Da Foundation Type-1Document9 pagesAster Private Limited Ibo Division - Secunderabad: Foundation Design For Tower Type Da Foundation Type-1svrao4uNo ratings yet

- PEB Room RevisedDocument19 pagesPEB Room RevisedAbdul BasithNo ratings yet

- Fea 40mm End Clamp r0Document12 pagesFea 40mm End Clamp r0Prince MittalNo ratings yet

- Comparative Study of Supporting System of Elevated Billboard (Hoarding) Structures Having Different ConfigurationDocument5 pagesComparative Study of Supporting System of Elevated Billboard (Hoarding) Structures Having Different ConfigurationBhavin JoshiNo ratings yet

- Foundation of Chiller Model - Rfal0070sc - Rev - 1Document2 pagesFoundation of Chiller Model - Rfal0070sc - Rev - 1ghansaNo ratings yet

- 2013 07 27 Manapakkam House Vamsi WD 03 04 Terrace Floor PlanDocument1 page2013 07 27 Manapakkam House Vamsi WD 03 04 Terrace Floor PlanJuly RaviNo ratings yet

- Allowable Load PlanDocument6 pagesAllowable Load Planmomin76No ratings yet

- STAAD - PRO - Single PoleDocument2 pagesSTAAD - PRO - Single PoleAmol GoleNo ratings yet

- 38 Gfc-P2c3-Tu02-Crp-Dr-Btn-73111-01-ADocument1 page38 Gfc-P2c3-Tu02-Crp-Dr-Btn-73111-01-ASUBHASH KUMARNo ratings yet

- S-1 General NotesDocument1 pageS-1 General NotesEngr. Robnick PaduaNo ratings yet

- 420 Transformer FDN For Panjarpur-6.0mtr26.5.06Document21 pages420 Transformer FDN For Panjarpur-6.0mtr26.5.06Zulkifli BasriNo ratings yet

- IBC 2009E (Building)Document14 pagesIBC 2009E (Building)Mahmoud HamedNo ratings yet

- Design Basis ReportDocument26 pagesDesign Basis Reportnikki naidu100% (1)

- Crack Width Check (CoP Concrete 2013) CPRDocument4 pagesCrack Width Check (CoP Concrete 2013) CPRAndrew WtchengNo ratings yet

- Steel Connection DesignDocument81 pagesSteel Connection DesignAnkan SarkarNo ratings yet

- Design of Shear Wall For Shear & Torsionl (ACI318-05) R0 - DAR...Document4 pagesDesign of Shear Wall For Shear & Torsionl (ACI318-05) R0 - DAR...Mohammed HanafiNo ratings yet

- RCC51 Column Load Take-Down DesignDocument7 pagesRCC51 Column Load Take-Down DesignMohammad Twaha JaumbocusNo ratings yet

- Design Calculation Rev00Document134 pagesDesign Calculation Rev00jabo01123397170No ratings yet

- NEW KST Presentation Green Telecom TowersDocument8 pagesNEW KST Presentation Green Telecom TowersKannanShreenivas WindenggNo ratings yet

- CMU Wall DesignDocument4 pagesCMU Wall DesignamitkuknaNo ratings yet

- Wing Wall Design CalculationsDocument19 pagesWing Wall Design CalculationsNandikaNo ratings yet

- Is.14946.2001 Zinc Content in Paint Film PDFDocument17 pagesIs.14946.2001 Zinc Content in Paint Film PDFajayukarandeNo ratings yet

- Tecnhip Shear Key PDFDocument16 pagesTecnhip Shear Key PDFdeep35akNo ratings yet

- Ahmed Ragab - Senior Structural Engineer - UAEDocument3 pagesAhmed Ragab - Senior Structural Engineer - UAEAhmed Ragab Abul-ElaNo ratings yet

- Circular Cover SlabDocument1 pageCircular Cover Slabvikash kumarNo ratings yet

- Rev - Foundation PlanDocument1 pageRev - Foundation PlanVarun TyagiNo ratings yet

- Title: Document/Drawing Approval/Comment Transmital ProjectDocument2 pagesTitle: Document/Drawing Approval/Comment Transmital ProjectPritom AhmedNo ratings yet

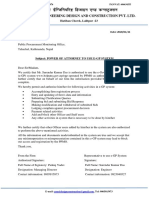

- A One Engineering Design and Construction Pvt. LTD.: Hatiban Chowk, Lalitpur - 23Document1 pageA One Engineering Design and Construction Pvt. LTD.: Hatiban Chowk, Lalitpur - 23rahul100% (2)

- CV Arash PDFDocument3 pagesCV Arash PDFDhina KaranNo ratings yet

- Rebar TableDocument4 pagesRebar TableyadavniranjanNo ratings yet

- Design of Face Mounted BracketDocument4 pagesDesign of Face Mounted Bracketvishal tomarNo ratings yet

- Slab and Beam Design CalculationsDocument29 pagesSlab and Beam Design CalculationsAwais HameedNo ratings yet

- Skylight StructureDocument16 pagesSkylight Structuremsiddiq1No ratings yet

- AEL-TM607-MEC-001-D-00001 - DBR - Comments by VPDocument13 pagesAEL-TM607-MEC-001-D-00001 - DBR - Comments by VPmondaldgpNo ratings yet

- 2013 07 27 Manapakkam House Vamsi STR 03 Ground Floor Roof Slab and Beam DetailsDocument1 page2013 07 27 Manapakkam House Vamsi STR 03 Ground Floor Roof Slab and Beam DetailsJuly RaviNo ratings yet

- DD (Raised Chimney) #FoundationDesign Submission - Rev DDocument387 pagesDD (Raised Chimney) #FoundationDesign Submission - Rev DHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- CIVIL Drawings: 220/66kV ITI S/s Drawings Required Very Urgent Submissi On Date Engg Remarks Action byDocument6 pagesCIVIL Drawings: 220/66kV ITI S/s Drawings Required Very Urgent Submissi On Date Engg Remarks Action byUmamaheshwarrao VarmaNo ratings yet

- Place:-Petrochemical Building Conference Hall Date Agenda: - School of Design Building Time Chair Person: - Attendees: - DesignationDocument2 pagesPlace:-Petrochemical Building Conference Hall Date Agenda: - School of Design Building Time Chair Person: - Attendees: - DesignationRushi KadgaonkarNo ratings yet

- Cost Estimate of WarehouseDocument16 pagesCost Estimate of WarehouseAnil SuryawanshiNo ratings yet

- Summary Safe of Structural Design of Box and WallDocument7 pagesSummary Safe of Structural Design of Box and WallRatul PalodhiNo ratings yet

- Section 5 - 5: Switch Board MCC Room Genset RoomDocument3 pagesSection 5 - 5: Switch Board MCC Room Genset RoomBandilung TzNo ratings yet

- Ar2-En-005-0004-00 Gantry Tower Structural Details Rev. 1Document2 pagesAr2-En-005-0004-00 Gantry Tower Structural Details Rev. 1harold de guzmanNo ratings yet

- Shed Sample JobDocument14 pagesShed Sample Jobarchdesign.ouniNo ratings yet

- Notes: - : Plan of Deck SlabDocument1 pageNotes: - : Plan of Deck SlabNirajan MarwaitNo ratings yet

- 6312 e Civ DTR DC V I 002 Burnt Oil Pit Signed 23-09-2020Document1 page6312 e Civ DTR DC V I 002 Burnt Oil Pit Signed 23-09-2020manikandanNo ratings yet

- NotesDocument1 pageNotesMohammad AlkahteebNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- D SMS Bhildi Bulding Architectural DetailsDocument2 pagesD SMS Bhildi Bulding Architectural Detailsirshad khanNo ratings yet

- Holiday Home Manali SNOWVIEWDocument6 pagesHoliday Home Manali SNOWVIEWirshad khanNo ratings yet

- KJ 00004723855Document4 pagesKJ 00004723855irshad khanNo ratings yet

- Critical Thinking - RISK CLASS HandoutDocument75 pagesCritical Thinking - RISK CLASS Handoutirshad khanNo ratings yet

- Design Check Calculation of Tension PolesDocument34 pagesDesign Check Calculation of Tension Polesirshad khanNo ratings yet

- RAFT STAAD - MergedDocument133 pagesRAFT STAAD - Mergedirshad khanNo ratings yet

- RFI - Tunnel Ventilation SystemsDocument10 pagesRFI - Tunnel Ventilation Systemsirshad khanNo ratings yet

- Quazi Mohd Faizanuddin - Medical CertificateDocument4 pagesQuazi Mohd Faizanuddin - Medical Certificateirshad khanNo ratings yet

- Pole DetailsDocument2 pagesPole Detailsirshad khanNo ratings yet

- SLD SheetDocument1 pageSLD Sheetirshad khanNo ratings yet

- PQC Panel Repair MethodologyDocument14 pagesPQC Panel Repair Methodologyirshad khanNo ratings yet

- Approved Report For Other EpcDocument41 pagesApproved Report For Other Epcirshad khanNo ratings yet

- CRS - BotDocument1 pageCRS - Botirshad khanNo ratings yet

- Door-Window Partitions DetailsDocument1 pageDoor-Window Partitions Detailsirshad khanNo ratings yet

- 63MVA Power Trafo ToshibaDocument47 pages63MVA Power Trafo Toshibairshad khanNo ratings yet

- 63MVA Power Trafo Toshiba 1Document1 page63MVA Power Trafo Toshiba 1irshad khanNo ratings yet

- Compliance & Response Sheet: Sensitivity: LNT Construction Internal UseDocument1 pageCompliance & Response Sheet: Sensitivity: LNT Construction Internal Useirshad khanNo ratings yet

- I-28 First Floor Thokar No.4 Abul Fazal Enclave Part-1, Jamia Nagar Okhla Delhi-110025Document2 pagesI-28 First Floor Thokar No.4 Abul Fazal Enclave Part-1, Jamia Nagar Okhla Delhi-110025irshad khanNo ratings yet

- Kharkopar ROBDocument1 pageKharkopar ROBirshad khanNo ratings yet

- ConferenceDocument2 pagesConferenceirshad khanNo ratings yet

- Macalloy PT BarsDocument12 pagesMacalloy PT Barsirshad khanNo ratings yet

- Final Soil Report of ShimlaDocument20 pagesFinal Soil Report of Shimlairshad khan0% (1)

- Jasai ROBDocument1 pageJasai ROBirshad khanNo ratings yet

- Decorative Metals (r1)Document23 pagesDecorative Metals (r1)irshad khanNo ratings yet

- Travel Itinerary: Iztc2ADocument3 pagesTravel Itinerary: Iztc2Airshad khanNo ratings yet

- Thin Film DepositionDocument13 pagesThin Film DepositionMustakim MdNo ratings yet

- Air ContentDocument31 pagesAir ContentJenny Kia TanNo ratings yet

- Drawing (p15 Ace 857)Document14 pagesDrawing (p15 Ace 857)ritoh8657No ratings yet

- Ctdcha 2Document10 pagesCtdcha 2TKNo ratings yet

- Somi Conveyer Beltings LTDDocument74 pagesSomi Conveyer Beltings LTDAnirudhNo ratings yet

- 1000 XXXX HY80 HSLA100Document2 pages1000 XXXX HY80 HSLA100srb metallurgNo ratings yet

- 10th STD Science Lesson Plan LDocument31 pages10th STD Science Lesson Plan Lyotoheg662No ratings yet

- GUID - 3 en-USDocument2 pagesGUID - 3 en-USDilawar BakhtNo ratings yet

- DR008 - Earthing of PipingDocument3 pagesDR008 - Earthing of PipingMadhan RajNo ratings yet

- Process and Product Audit Plan For Cup-Cone For The Year of 2018Document11 pagesProcess and Product Audit Plan For Cup-Cone For The Year of 2018অর্ঘ্য রায়No ratings yet

- Instructions For The Safe Use Of: Roundslings: Storing and Handling RoundslingsDocument2 pagesInstructions For The Safe Use Of: Roundslings: Storing and Handling Roundslingsreda mesbahNo ratings yet

- ARMOX500TDocument2 pagesARMOX500TKalpesh JainNo ratings yet

- MatterDocument38 pagesMattergabbie dumpNo ratings yet

- Properties of Metakaolin Based Geopolymer Incorporating Calcium Carbonate (Aboulayt-2017)Document9 pagesProperties of Metakaolin Based Geopolymer Incorporating Calcium Carbonate (Aboulayt-2017)juan diazNo ratings yet

- PI - Technicoll - 9260 - GB - TDS PVAcDocument2 pagesPI - Technicoll - 9260 - GB - TDS PVAcThịnh HuỳnhNo ratings yet

- The Electric Arc FurnaceDocument22 pagesThe Electric Arc FurnaceKingsley Posiyano100% (2)

- New Dimensions of SoftnessDocument9 pagesNew Dimensions of SoftnessEugene PaiNo ratings yet

- Astm A112-76Document3 pagesAstm A112-76AlbertoNo ratings yet

- SPECIFICATION-FOR-ALUMINIUM-SULPHATE (Alum) Used For Potable Water SupplyDocument5 pagesSPECIFICATION-FOR-ALUMINIUM-SULPHATE (Alum) Used For Potable Water SupplyWeida KuchingNo ratings yet

- 3LPE Low Temp Pipe CoatingDocument2 pages3LPE Low Temp Pipe CoatingChegg ChemNo ratings yet

- Cromarod Duplex B-1Document1 pageCromarod Duplex B-1Matija BušićNo ratings yet

- Mata Pelajaran: Kimia Tingkatan:: Kontrak Latihan Murid 5Document2 pagesMata Pelajaran: Kimia Tingkatan:: Kontrak Latihan Murid 5hazilah1969100% (1)

- .Study of Mechanical Properties of Concrete With Zeolite Powder and Steel SlagDocument7 pages.Study of Mechanical Properties of Concrete With Zeolite Powder and Steel Slagalaa albalahNo ratings yet

- Preliminary EstimateDocument558 pagesPreliminary Estimatesurendra_pangaNo ratings yet

- First Schedule (Customs Tariff 51 99)Document353 pagesFirst Schedule (Customs Tariff 51 99)Adnan KhanNo ratings yet

- Astm D6677 18Document2 pagesAstm D6677 18David Manuel Mendoza MoralesNo ratings yet

- Indian Standard For Drinking Water As Per BIS Specifications - 2010Document26 pagesIndian Standard For Drinking Water As Per BIS Specifications - 2010Ayush Jain100% (1)

- Preparation of Mohr SaltDocument1 pagePreparation of Mohr SaltSHADOWNo ratings yet

- Tsubaki Agriculture Brochure Final VersionDocument28 pagesTsubaki Agriculture Brochure Final VersionpppopNo ratings yet