Professional Documents

Culture Documents

Method Statement For Foundation WaterProofing

Method Statement For Foundation WaterProofing

Uploaded by

Muhammad Sami ParvezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement For Foundation WaterProofing

Method Statement For Foundation WaterProofing

Uploaded by

Muhammad Sami ParvezCopyright:

Available Formats

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

SUD-PVS-FQC-MS-WP-001-0

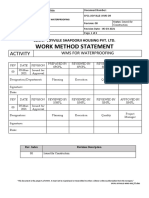

METHOD OF STATEMENT FOR ROOF WATERPROOFING

Project Company SUDAIR ONE RENEWABLE ENERGY COMPANY

Main Contractor LARSEN & TOUBRO SAUDI ARABIA LLC

Discipline CIVIL

Document No. METHOD OF STATEMENT FOR FOUNDATIONS WATERPROOFING

SUD-PVS-FQC-MS-WP-001-0

DATE REV. REVISION DESCRIPTION PREPARED BY CHECKED BY APPROVED BY

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

SUD-PVS-FQC-MS-WP-001-0

METHOD OF STATEMENT FOR FOUNDATIONS WATERPROOFING

TABLE OF CONTENTS

1.0 PURPOSE

Page 3

2.0 SCOPE

Page 3

3.0 REFERENCES

Page 3

4.0 ABBREVIATION & DEFINATIONS

Page 3-4

5.0 GENERAL & SAFETY REQUIREMENTS

Page 4

6.0 RESPONSIBILITIES

Page 4-6

7.0 TOOLS & EQUIPMENTS

Page 6-7

8.0 WORK METHODOLOGY

Page 7-11

9.0 TESTING

Page 12

10.0 HEALTH, SAFETY & RISK ASSESMENT

Page 12-13

1.0 PURPOSE

The purpose of this method of statement is to provide information on the method of doing foundations

water proofing works and to ensure in accordance with the project specifications.

Page 2 of 9

Sensitivity: LNT Construction Internal Use

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

SUD-PVS-FQC-MS-WP-001-0

METHOD OF STATEMENT FOR FOUNDATIONS WATERPROOFING

2.0 SCOPE OF WORK

This Method Statement covers work sequence intended for the foundations waterproofing including

substrate preparation, applications, membrane installation and testing, Activities shall be carried out in

accordance with good working practice and shall comply with project 's Specification and acceptable

international standards.

3.0 REFERENCES

Approved Engineering Drawings/layouts (SUD-1SS-A-DLD-010-0IFA)

Project Quality Plan

Technical Specifications & Standards

Owner’s Technical Specifications (OTS)

Work permit/Approvals (SUD-HSE-PR-014)

Approved HSE & Security Management plan (SUD-HSE-PL-002 & SUD-HSE-PL-006)

Relevant Codes / standards

4.0 ABBREVIATIONS & DEFINITIONS

IFC -- Issued for construction

HSE -- Health Safety and Environment

OTS -- Owner’s Technical Specifications

QA/QC -- Quality Assurance / Quality Control

EHS -- Environmental, Health & Safety

PPE -- Personal Protective Equipment

ITP -- Inspection & Testing Plan

JSA -- Job Safety Analysis

MS -- Method of Statement

Page 3 of 9

Sensitivity: LNT Construction Internal Use

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

SUD-PVS-FQC-MS-WP-001-0

METHOD OF STATEMENT FOR FOUNDATIONS WATERPROOFING

CSSP -- Contractor Site Safety Plan

HIP -- Hazard Identification Program

CSM -- Common Safety Methods

PVC -- Poly Vinyl Chloride

5.0 GENERAL AND SAFETY REQUIREMENTS

Risk Assessment shall be prepared including mitigation measures, and responsibility for

implementation. This shall be coordinated with site Safety In-charge and attach to this method

statement.

Before commencing any work, all permits shall be checked and ensured that they are valid until

completion of activity.

All works shall be referred to the approved Drawings and specifications.

All staff and workmen shall wear Personnel Protective Equipment (PPE).

All personnel shall be cautioned while working near live lines and other services.

It shall be ensured that all men working in high-level are wearing necessary safety harness

complying with the safety requirements and following precautionary measures on safety aspects.

All equipment shall be calibrated and accompanied by the competent operators prior to

commencement of any works.

6.0 RESPONSIBILITIES

Below mentioned personnel with the responsibilities entrusted to them shall be responsible for carrying

out below mentioned works. In addition to their roles and responsibilities disseminated in the Project

Quality & EHS Plans and the following specific activity functions shall be carried out:

6.1. Construction Manager

Reporting to the Project Manager and assisted by construction team as indicated in the project

organization chart.

Ensure that method statement is prepared, established & control measures taken before starting

the work and guiding the team for implementation.

Page 4 of 9

Sensitivity: LNT Construction Internal Use

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

SUD-PVS-FQC-MS-WP-001-0

METHOD OF STATEMENT FOR FOUNDATIONS WATERPROOFING

Follow-up & coordinate with design engineering team for preparation of Coordinates drawing

Layout.

Conduct training and awareness program for all personnel deployed for the activity.

6.2. Site Engineer

Directly reporting to the Construction Manager.

Prepare method statement, take approval, and implement.

Execute works according to the latest approved method statement, Coordinates drawing Layout,

and contract specifications/OTS.

Orient/train the team to implement the method statements effectively.

Maintain related records.

Coordinate with concerned team members for panel installation & Termination works.

6.3. QA/QC Engineer

Quality Engineer shall review the method statements and ensure all requirements are included.

Schedule inspection of works in coordination with Site Engineer.

Ensure the Quality inspection at all stages of installation & termination works as per approved

ITP/FQP

Prepare and maintain inspection checklists, records, and obtain necessary approval from PC if any.

Verification of all calibration certificates of tools/components being used.

Maintain third party testing reports.

Check the safety precautionary measures before commencing the Electrical works inside the panel.

Ensure the electrical termination activities are done in quality manner.

Review Quality Control records and ensure correctness whenever is required.

6.4. Safety In-charge and requirements

Disseminate HSE requirements specific to the activities involved and facilitate implementation.

Prepare and coordinate the implementation of Risk Assessment plan.

Ensure that work is being carried out in safe manner in coordination with Site Engineer, sub-

contractors, etc.

Page 5 of 9

Sensitivity: LNT Construction Internal Use

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

SUD-PVS-FQC-MS-WP-001-0

METHOD OF STATEMENT FOR FOUNDATIONS WATERPROOFING

All concerned parties shall be exposed to the method statements applicable to their working scope

and must attend a safety briefing prior to carrying out any works on site.

All personnel shall ensure safe working conditions prior to the start of work.

Great emphasis shall be made on all matters of health, safety, and environmental both in the

workplace, and to the public during the execution of works.

Personal Protective Equipment (PPE) shall be issued to all employees and visitors. PPE includes

reflective vest, safety shoes, hard hat, Electric insulated gloves, and safety goggles (if required). The

usage of proper PPE is always mandatory for all personnel they are on site.

Dust masks and eye goggles shall be used in windy weather.

The experienced & well-trained electricians are only permitted to perform the electrical activities.

Prior induction and required warning signage shall be ensured to make awareness of electrical

hazards involved in.

Certified and approved cable Jointer/Electrician shall only be permitted to do any cable joints and

cable termination activities with proper safety measures.

7.0 TOOLS AND EQUIPMENTS

The following are the tools and tackles and Equipment identified for the scope of the work and shall be

deployed as per the requirements:

Torching machine

Gas Cylinder

Rubber Boots

Trowel

Hand Gloves

Cutting tool

Brush

Paint roller

8.0 WORK METHODOLOGY:

8.1. Substrate Preparation:

Concrete surface to be cleaned by air-compressor & brushes.

Page 6 of 9

Sensitivity: LNT Construction Internal Use

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

SUD-PVS-FQC-MS-WP-001-0

METHOD OF STATEMENT FOR FOUNDATIONS WATERPROOFING

Ensure surface is compacted and free from unwanted materials.

8.2. Polyethene Sheet:

Ensure material is approved as per the OTS.

200-micron sheet shall be laid

Unroll the polyethene roll in latitudinal & longitudinal direction

Lapping shall be 100mm to 150mm

From the peripheral area, 100mm extra shall be cut out

8.3. Water Proofing Membrane

Ensure surface is free from loose/unwanted material

Ensure approval of material.

Prior to placement of waterproofing membrane, primer to

be applied on the surface where waterproofing membrane to

be placed.

Primer to be applied on surface area uniformly with roller

or brush.

Primer is allowed to dry.

Waterproofing membrane is then unrolled by heating the lower

surface of the membrane by torching method, hence

making bonding to primed surface as membrane is hot.

The membrane is fully bonded to substrate by heating with a

blowtorch with 10cm to 150cm laps.

Waterproofing membrane is then terminated into the preformed

groove at the ground/end level.

Bitumen paint coats to be applied over the footing surface.

Bitumen coat / membrane to be applied on vertical surface

leaving some area from top of footing as per approved drawings.

8.4. Protection Layer Screed(Horizontal):

Ensure screed is tested sound before pouring by Third Party Technician.

Screed shall be poured above water proofing membrane over blinding.

Page 7 of 9

Sensitivity: LNT Construction Internal Use

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

SUD-PVS-FQC-MS-WP-001-0

METHOD OF STATEMENT FOR FOUNDATIONS WATERPROOFING

Thickness of screed shall be as per the approved drawings.

8.5. Protection Layer Board(Vertical):

Ensure material is approved.

Shall not be rotted out.

Protection board shall be placed to membrane

by slightly warming the outer sides of board.

9.0 HEALTH, SAFETY AND RISK ASSESSMENT

To ensure security directives during the execution of earth works, all activities shall be monitored in

compliance with relevant standards, codes and procedures described in the HSE manual and project

specification as minimum as follows:

a. A safety officer shall be at site during the execution of works.

b. Daily toolbox meetings shall be conducted as mandatory.

c. Safety barricade shall be prepared wherever necessary.

d. Necessary safety sign boards shall be provided as required.

e. All workers shall be provided with job specific personal protective Equipment.

f. Safety flickering lights shall be provided for night-time indication.

g. All equipment shall be inspected by the approving authority prior to start of the work.

h. Working equipment shall be equipped with amber lights, homes, safety guards etc. as required per

safety provisions.

i. Any incident at site shall be immediately reported to company and recorded.

j. Weekly safety statistics report and safety performance reports shall be prepared and recorded.

Page 8 of 9

Sensitivity: LNT Construction Internal Use

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

SUD-PVS-FQC-MS-WP-001-0

METHOD OF STATEMENT FOR FOUNDATIONS WATERPROOFING

RISK ASSESSMENT

Page 9 of 9

Sensitivity: LNT Construction Internal Use

You might also like

- Method Statement - Site RehabilitationDocument10 pagesMethod Statement - Site RehabilitationaceNo ratings yet

- English For Engineering Teacher's BookDocument128 pagesEnglish For Engineering Teacher's BookTomcio Dymczyk82% (34)

- Method Statement For Door and Window Installation PDFDocument13 pagesMethod Statement For Door and Window Installation PDFpp100% (2)

- MasterSeal 700BG PDFDocument108 pagesMasterSeal 700BG PDFHoang An ViNo ratings yet

- Method Statement For Wall Panels InstallationDocument11 pagesMethod Statement For Wall Panels InstallationChristos LoutrakisNo ratings yet

- WaterproofingDocument2 pagesWaterproofingyusz780% (2)

- Project: Mars Factory Extension Project at Jafza: Consultant Client ContractorDocument9 pagesProject: Mars Factory Extension Project at Jafza: Consultant Client ContractorAzhar Shaikh100% (1)

- Method Statement For Railing WorksDocument6 pagesMethod Statement For Railing WorksMin LuoNo ratings yet

- Method Statement For Site Preparation, Excavation & Backfilling WorksDocument9 pagesMethod Statement For Site Preparation, Excavation & Backfilling WorksMuhammad Sami ParvezNo ratings yet

- Construction Method for Pump Station - معدلDocument36 pagesConstruction Method for Pump Station - معدلM.ZEKEBA100% (1)

- Inspection & Test Plan For Screed WorksDocument2 pagesInspection & Test Plan For Screed WorksIbrahim Mohammed0% (1)

- Method Statement For False Ceiling WorksDocument2 pagesMethod Statement For False Ceiling WorksTAHER AMMAR33% (3)

- Method Statement For HospitalDocument3 pagesMethod Statement For HospitalKaşhıf Iqbal0% (1)

- MOS WaterproofingDocument18 pagesMOS WaterproofingHenry Ambau100% (2)

- QA/Qc - Checklist Sewer LineDocument2 pagesQA/Qc - Checklist Sewer Lineyash shah100% (2)

- Method Statement For Underground Concrete Waterproofing Rev.01Document9 pagesMethod Statement For Underground Concrete Waterproofing Rev.01Alvene TagocNo ratings yet

- Method Statement For Brickworks: Pembinaan Infra E&J SDN BHDDocument5 pagesMethod Statement For Brickworks: Pembinaan Infra E&J SDN BHDChezy6290% (1)

- Waterproofing Check List PDFDocument20 pagesWaterproofing Check List PDFErdem Sarıeyyüpoğlu100% (2)

- Method Statement For Planter WaterproofingDocument8 pagesMethod Statement For Planter WaterproofingMonali Varpe0% (1)

- Membrane Waterproofing-Method StatementDocument5 pagesMembrane Waterproofing-Method StatementMahmoud100% (3)

- Method Statement For PS Concrete WorksDocument12 pagesMethod Statement For PS Concrete WorksMuhammad Sami ParvezNo ratings yet

- MOS-002B Door Frame, Door Leaf & IronmongeriesDocument6 pagesMOS-002B Door Frame, Door Leaf & IronmongeriesChezy629No ratings yet

- Method Statement For Coring WorkDocument6 pagesMethod Statement For Coring Workadeniyi abiolaNo ratings yet

- Method Statement For Marble Stone InstallationDocument6 pagesMethod Statement For Marble Stone Installationchinna_p_123No ratings yet

- Inspection & Test Plan: Stone Works As Shown in The DrawingsDocument2 pagesInspection & Test Plan: Stone Works As Shown in The DrawingsharikrishnaNo ratings yet

- 29 Method Statement BRICK WORKDocument6 pages29 Method Statement BRICK WORKSusil Kumar SahooNo ratings yet

- Work Procedure For Concreting Along With ChecklistDocument13 pagesWork Procedure For Concreting Along With ChecklistNaveed AhsanNo ratings yet

- Methos Statement For SubstructureDocument14 pagesMethos Statement For SubstructureĐărsĥąna RanasingheNo ratings yet

- 016 Bricklaying WorkDocument4 pages016 Bricklaying WorkFara Atika Bha Ney100% (1)

- MTS-Hard Landscaping & Road WorksDocument7 pagesMTS-Hard Landscaping & Road WorksAshimolowo BabatundeNo ratings yet

- SEP 01 ZAA 1DC 002 Method Statement For Block Work 1Document8 pagesSEP 01 ZAA 1DC 002 Method Statement For Block Work 1usman malik100% (1)

- Screeding WorksDocument1 pageScreeding WorksCindy AmyzaNo ratings yet

- Cms 0031 Concrete Crack Repair at WWTP Rev. ADocument10 pagesCms 0031 Concrete Crack Repair at WWTP Rev. AzahangirNo ratings yet

- Ceramic Tile Fixing StatementDocument5 pagesCeramic Tile Fixing StatementAmit KhazanchiNo ratings yet

- Alubond Method of StatementDocument2 pagesAlubond Method of StatementHaneefa ChNo ratings yet

- Method Statement For Installation For Curtain Wall Unitized PDFDocument38 pagesMethod Statement For Installation For Curtain Wall Unitized PDFAshimolowo BabatundeNo ratings yet

- Interlocking & Curb Stone Rev.1Document3 pagesInterlocking & Curb Stone Rev.1Shaddy Joseph Endrawes100% (1)

- 01 ITP TemplateDocument6 pages01 ITP TemplateHelsy FuentesNo ratings yet

- Specifications For Waterproofing WorksDocument16 pagesSpecifications For Waterproofing WorkssplashierprinceNo ratings yet

- Method Statement Sample.Document16 pagesMethod Statement Sample.fabinNo ratings yet

- 9.Ms-METHOD STATEMENT FOR TILING, SKIRTING, TOILET DADO & KITCHEN PLATFORM WORKDocument15 pages9.Ms-METHOD STATEMENT FOR TILING, SKIRTING, TOILET DADO & KITCHEN PLATFORM WORKShenbagaraja Pandian100% (2)

- Method Statement of Earth WorkDocument13 pagesMethod Statement of Earth WorkSainbayar SBNo ratings yet

- Method Statement Wet Areas (600) NDocument16 pagesMethod Statement Wet Areas (600) NmastercssiNo ratings yet

- Method Statement For Water Proofing Self Adhesive Membrane PDFDocument3 pagesMethod Statement For Water Proofing Self Adhesive Membrane PDFNonie NNo ratings yet

- Method of Statement For WaterproofingDocument10 pagesMethod of Statement For WaterproofingJoe PsNo ratings yet

- RC RepairDocument4 pagesRC RepairPcEngNo ratings yet

- Vetonit Spatter Dash-MC SDM212Document2 pagesVetonit Spatter Dash-MC SDM212toni mujiyono100% (1)

- METHOD STATEMENT FOR Cast in Situ Concrete - Rev 0Document7 pagesMETHOD STATEMENT FOR Cast in Situ Concrete - Rev 0Osama MZ100% (1)

- WATERPROOFDocument1 pageWATERPROOFKarthick NatrajanNo ratings yet

- 5.Ms-Internal Plaster WorkDocument8 pages5.Ms-Internal Plaster WorkShenbagaraja PandianNo ratings yet

- MS # 00 Method Statement For Waterproofing MembraneDocument9 pagesMS # 00 Method Statement For Waterproofing MembraneMGNo ratings yet

- Method Statement of Plastering: Pembinaan Infra E&J SDN BHDDocument5 pagesMethod Statement of Plastering: Pembinaan Infra E&J SDN BHDChezy629No ratings yet

- Method StatementDocument13 pagesMethod StatementGrace tpplNo ratings yet

- Method Statement For Cement Board Dry Wall PartitionsDocument10 pagesMethod Statement For Cement Board Dry Wall PartitionsComet GroupNo ratings yet

- Material Approval & Specification Comparison SheetDocument3 pagesMaterial Approval & Specification Comparison Sheetfrancisbautista100% (1)

- Method Statement For Finishing WorkspdfDocument7 pagesMethod Statement For Finishing Workspdfmohamed nabilNo ratings yet

- Method Statement For Sign Board Excavation & Installation - Safe Work Method of StatementDocument2 pagesMethod Statement For Sign Board Excavation & Installation - Safe Work Method of StatementUmair AslamNo ratings yet

- Checklist For Plaster PreparationDocument1 pageChecklist For Plaster PreparationMani AppaNo ratings yet

- Method Statement FALSE CEILING-1Document7 pagesMethod Statement FALSE CEILING-1beshnu garanaik100% (1)

- Method Statement For ScaffoldingDocument3 pagesMethod Statement For ScaffoldingDouglas JambaNo ratings yet

- 5.method Statement Shuttering and Form WorkDocument4 pages5.method Statement Shuttering and Form Workشاز إياس100% (1)

- Ms 103 EarthworksDocument8 pagesMs 103 EarthworksMaddala Srinivasa Rao100% (1)

- Method Statement For Site Preparation, Excavation & Backfilling WorksDocument9 pagesMethod Statement For Site Preparation, Excavation & Backfilling WorksNaveen GladsonNo ratings yet

- Method Statement: Plumbing & Ug Piping WorksDocument17 pagesMethod Statement: Plumbing & Ug Piping WorksMuhammad Sami ParvezNo ratings yet

- Method Statement For PS Concrete WorksDocument12 pagesMethod Statement For PS Concrete WorksMuhammad Sami ParvezNo ratings yet

- Method Statement For Lifting Operations - Builders SafetyDocument2 pagesMethod Statement For Lifting Operations - Builders SafetyMuhammad Sami Parvez100% (1)

- Foamglas For The Building Envelope: Cellular Glass Insulation GuideDocument48 pagesFoamglas For The Building Envelope: Cellular Glass Insulation GuideAlejandro Vargas CalderonNo ratings yet

- Bauder LiquiFINISH Product Data SheetDocument2 pagesBauder LiquiFINISH Product Data Sheetshivarajs12340987No ratings yet

- Kingspan 20insulation Thermaroof 20tr22Document8 pagesKingspan 20insulation Thermaroof 20tr22Ady SasuNo ratings yet

- Method Statement Method Statement For ApDocument6 pagesMethod Statement Method Statement For Apmahmoud husseinNo ratings yet

- Concrete Repair & ProtectionDocument20 pagesConcrete Repair & ProtectionmohsinNo ratings yet

- Waterproofing Applications: Established in 1959Document16 pagesWaterproofing Applications: Established in 1959Chesca DacquelNo ratings yet

- Fosroc Waterproofing B2R-BOQ (Revised 24th)Document38 pagesFosroc Waterproofing B2R-BOQ (Revised 24th)폴로 쥰 차67% (3)

- Glove Care InstructionsDocument1 pageGlove Care InstructionsErnesto UhalteNo ratings yet

- 113 DR Fixit FastflexDocument3 pages113 DR Fixit FastflexreshmitapallaNo ratings yet

- Multi ChemDocument5 pagesMulti ChemKiran Kumar JhaNo ratings yet

- Aquastop Nanoflex ExternalDocument3 pagesAquastop Nanoflex ExternalRonald TranNo ratings yet

- Types of Construction WorkDocument6 pagesTypes of Construction WorkKalsoma CarlsNo ratings yet

- Method STMT S327 Reroofing Extisting Concrete Roof Kasban CasDocument2 pagesMethod STMT S327 Reroofing Extisting Concrete Roof Kasban CasSBW ReportingNo ratings yet

- KCS-Standards (1 de 2)Document85 pagesKCS-Standards (1 de 2)vladibladeNo ratings yet

- TDS Fosroc Polyurea WH 200 IndiaDocument4 pagesTDS Fosroc Polyurea WH 200 Indiaprem prakash mishraNo ratings yet

- Method Statment (Structural Works)Document9 pagesMethod Statment (Structural Works)Hazem Shaker Abu Shaaban100% (2)

- Astm D5147 - D5147M-18Document3 pagesAstm D5147 - D5147M-18Senthilkumar NarayananNo ratings yet

- Sika Injectoflex System (Type HP)Document2 pagesSika Injectoflex System (Type HP)Lim Yew KwangNo ratings yet

- Waterproofing Membrane With InsulationDocument3 pagesWaterproofing Membrane With InsulationAljon Angeles TanNo ratings yet

- Geniosil W180Document3 pagesGeniosil W180Locer2011No ratings yet

- BQ - SUTD Housing & Sports Facilites - (KL Staff) 020412Document108 pagesBQ - SUTD Housing & Sports Facilites - (KL Staff) 020412Fatin HanunNo ratings yet

- Metahybrid BrochureDocument6 pagesMetahybrid Brochuregeometric steelsNo ratings yet

- 2018 RIDE Catalog Riders Equipment - Pdf.asset.1531864237860Document47 pages2018 RIDE Catalog Riders Equipment - Pdf.asset.1531864237860Adrian OvelarNo ratings yet

- Improving Detailing For MasonryDocument10 pagesImproving Detailing For MasonryAdam JonesNo ratings yet

- Engineering Manual: Concrete Pressure PipeDocument176 pagesEngineering Manual: Concrete Pressure Pipeahmad elnggarNo ratings yet

- Cement Modifier (Primer) : Areas of Application IncludeDocument3 pagesCement Modifier (Primer) : Areas of Application IncludeChiara JayneNo ratings yet

- Masterspec Table of Contents MF04Document30 pagesMasterspec Table of Contents MF04Terrence ReddNo ratings yet

- Work Method Statement: ActivityDocument5 pagesWork Method Statement: ActivityamolNo ratings yet