Professional Documents

Culture Documents

Estimate of Cycle Stand Extension Situated at Bhagat Singh College Jaora, Dist. Ratlam

Estimate of Cycle Stand Extension Situated at Bhagat Singh College Jaora, Dist. Ratlam

Uploaded by

aasifah0 ratings0% found this document useful (0 votes)

127 views5 pagesThis document provides an estimate for the cycle stand extension situated at Bhagat Singh College in Jaora, Ratlam district. It includes 13 line items estimating costs for activities like clearing jungle, earthwork excavation, cement concrete work, reinforcement for RCC work, brickwork, filling excavated earth, centering and shuttering, and cement plastering. The total estimated cost is Rs. 4,58,418.

Original Description:

estimate

Original Title

cycle stand

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides an estimate for the cycle stand extension situated at Bhagat Singh College in Jaora, Ratlam district. It includes 13 line items estimating costs for activities like clearing jungle, earthwork excavation, cement concrete work, reinforcement for RCC work, brickwork, filling excavated earth, centering and shuttering, and cement plastering. The total estimated cost is Rs. 4,58,418.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

127 views5 pagesEstimate of Cycle Stand Extension Situated at Bhagat Singh College Jaora, Dist. Ratlam

Estimate of Cycle Stand Extension Situated at Bhagat Singh College Jaora, Dist. Ratlam

Uploaded by

aasifahThis document provides an estimate for the cycle stand extension situated at Bhagat Singh College in Jaora, Ratlam district. It includes 13 line items estimating costs for activities like clearing jungle, earthwork excavation, cement concrete work, reinforcement for RCC work, brickwork, filling excavated earth, centering and shuttering, and cement plastering. The total estimated cost is Rs. 4,58,418.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

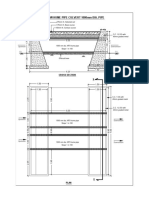

Estimate Of Cycle Stand Extension Situated At Bhagat Singh College Jaora, Dist.

Ratlam

S.No. Perticulars No L B D Qty Unit Rate Amount

2.2 Clearing jungle including uprooting of rank

vegetation, grass, brush wood, trees and saplings

1 of girth up to 30 cm measured at a height of 1 m

above ground level and removal of rubbish up to a

distance of 50 m outside the periphery of the area

cleared.

1 30 9 270 Sqm 4.14 1118

2.6 Earth work in excavation by mechanical

means (Hydraulic excavator) / manual means over

areas (exceeding 30cm in depth. 1.5m in width as

well as 10 sqm on plan) including dressing of sides

2 and ramming of bottom disposal of excavated

earth, lead up to 50m and lift up to 1.5m,

disposed earth to be levelled and neatly dressed.

(No extra lift is payable if work is done by

mechanical means) All kinds of soil

Col. 20 1.20 1.20 1.20 34.560

Total 34.560 Cum 129.00 4458

4.1.2.2 Providing and laying in position cement

concrete of specified grade excluding the cost of

3 centering and shuttering - All work upto plinth

level : M-10 Nominal (Mix -1 Cement : 3 sand : 6

graded stone aggregate)

Col 20 1.20 1.20 0.15 4.320

Ramp 1 3.00 1.50 0.15 0.675

Total 4.995 Cum 3808.00 19021

5.16.3 Reinforcement for R.C.C. work

includingstraightening, cutting, bending, placing

inposition and binding including cost of

bindingwire all wastages and overlaps, couplers

(overlaps shall be provided as per

requirement ofIS13920 for ductile detalingIS456

RCC Design & SP 34 Reinforcementdetailing ) etc.

4 complete. (Note:-

1.Spacer bars (chairs) shall bepaidseparately as

shown in the drawing and as perdirection of

engineer incharge. 2.No extra payment shall be

doneforoverlaps and/or couplers. 3.Couplers shall

be conforming to IS code on“Reinforcement

Couplers for Mechanical Splices of Bars for

Concrete Reinforcement-Specification”)

Footing Jali @ 10mm Dia 20 x 16 1.10 0.617 217.180

For Column @ 12mm Dia 10 x 4 4.75 0.888 168.720

For Column @ 12mm Dia 10 x 4 2.55 0.888 90.570

Total Stirups @ 8mm Dia 330 0.85 0.395 110.790

LW Plinth Beam Bottom @ 12mm Dia 2 x 3 25.00 0.888 133.200

LW Plinth Beam Top @ 10mm Dia 2 x 2 25.00 0.617 61.700

S.No. Perticulars No L B D Qty Unit Rate Amount

CW Plinth Beam Bottom @ 12mm Dia 2x3 8.20 0.888 43.680

CW Plinth Beam Top @ 10mm Dia 2x2 8.20 0.617 20.230

Total Stirups @ 8mm Dia 330 1.00 0.395 130.350

Total 976.420 Kg 62.90 61417

5.1 Providing and laying in position specified

grade of reinforced cement concrete (with 20mm

nominal size graded stone aggregate) excluding

5

the cost of centering, shuttering, finishing and

reinforcement - All work up to plinth level :

5.1.2 For Footing 20 1.10 1.10 0.30 7.260

Total 7.260 Cum 5397.00 39182

5.1.1 Col. Upto Plinth 20 0.20 0.20 1.15 0.920

Plinth Beam LW 2 25.00 0.20 0.30 3.000

Plinth Beam CW 2 7.80 0.20 0.30 0.936

Total 4.856 Cum 5796.00 28145

5.2 Reinforced cement concretework (with 20mm

nominal sizegraded stone aggregate)in walls (any

thickness), includingattached pilasters,

buttresses, plinth andstring courses, fillets,

6

columns, pillars,posts and struts etc. above plinth

level andupto floor two level excluding cost

ofcentering, shuttering, finishing

andreinforcement:

10 0.20 0.20 3.00 1.200

10 0.20 0.20 0.80 0.320

5.2.1 Col Upto Roof Total 1.520 Cum 5865.00 8915

2.24 Filling available excavated earth(excluding

hard rock/Ordinary rock) intrenches, plinth, sides

offoundationsetc. in layers not exceeding

7 20cmindepth, consolidating eachdepositedlayer

by ramming and watering, lead upto 50 m and lift

upto 1.5m.

Excavation Vide I/2 Of Col. 34.560

Deduction Qty Of PCC, Footing And Col (-) -16.436

Total 18.124 Cum 72.00 1305

5.9 Centering and shuttering includingstrutting,

8 propping etc. and removal of formfor:

5.9.1 Footing 20 x 4 1.10 0.30 26.400

Col 20 0.80 1.15 18.400

Beam Outside 2 25.00 0.30 15.000

2 8.20 0.30 4.920

Beam Inside 2 24.60 0.30 14.760

S.No. Perticulars No L B D Qty Unit Rate Amount

2 7.80 0.30 4.680

Total 84.160 Sqm 190.60 16041

5.9.6 For Columns

10 0.80 3.00 24.000

10 0.80 0.80 6.400

30.400 Sqm 471.20 14324

6.3 Brick work with well burnt chimney bricks in

bullspatterntrench kiln manufactured by

gholprocess, crushing strength notlessthan 40kg

9 /cm2and water absorptionnot more than 15%

infoundationand plinth i/c curing etc.complete.

6.3.2 At Plinth LW 2 23.20 0.20 0.20 1.856

At Plinth CW 2 7.60 0.20 0.20 0.608

Total 2.464 Cum 5061.00 12470

6.7.2.2 Brick work with fly ash lime bricks (FALG

Bricks) conforming to IS:12894-2002, in super

10 structure above plinth level up to floor two level

in : Cement mortar 1:6 (1 cement : 6

sand)

6.4.2 Long Wall 1 23.20 0.20 3.00 13.920

1 20.10 0.20 0.80 3.216

Cross Wall 2 7.60 0.20 0.80 2.432

Total 19.568 Cum 5049.00 98799

2.27.1 Supplying and filling in plinth underfloors

including watering rammingconsolidating in layers

not exceeding20cm in depth and dressing

complete. With hard muram having CBR >12 %

atunder floors including watering,ramming and

11

compacting (minimumcompaction 95% of MDD)

in layers notexceeding 20cm in thickness

anddressing complete. (Note:-maximumthickness

of thislayer to be providedshall be 30cm)

1 24.60 7.80 0.40 76.752 Cum 300.00 23026

13.2 15 mm cement plaster on the rough side of

12 12mm 15mm

single or half brick wall of mix

Outside 1 21.80 1.10 23.98 -

2 8.20 1.10 18.04 -

Inside 1 25.00 3.00 75.00 -

1 21.80 0.80 - 17.440

2 7.80 0.80 - 12.480

Total 117.02 29.92

S.No. Perticulars No L B D Qty Unit Rate Amount

13.1.2 12 mm cement plaster of mix : 117.020 Sqm 138.00 16149

13.2.2 15 mm cement plaster of mix : 29.920 Sqm 148.00 4428

11.66 Providing and laying factory made machine

pressed precast cement concrete interlocking

paver block of any shape and size conforming to

IS:15658- 2006 and ISI marked of 60 mm

thickness, M-30 grade with grey cement and

13 pigment all as specified. Made by block making

machine with strong vibratory compaction, laid in

required colour and pattern over and including

50mm thick compacted bed of stone dust, filling

the joints with sand etc. all complete as per the

direction of Engineer-in-Charge.

1 24.6 7.8 191.88 Sqm 586 112442

10.14.1 Steel work in built up M.S. tubularsection

(round, square or rectangularhollow tubesetc.)

trusses/frame work etc.including cutting, hoisting,

fixing inposition and applying a priming coat

14

ofapproved steel primer, including weldingand

bolted with special shaped washersetc.complete.

Truss ( Tie 80 x 40 mm ) 2.6mm Th. 8x1 8.200 4.5Kg/Mtr 295.20

Principle Raftar ( 60 x 40 mm ) 2.6mm Th. 8x1 8.350 3.73Kg/Mtr 249.16

Verticle Member ( 60 x 40 mm ) 2.6mm Th. 8x8 0.500 3.73Kg/Mtr 119.36

Struts ( 60 x 40 mm ) 2.6mm Th. 8x7 1.000 3.73Kg/Mtr 208.88

Gusset Plate ( 0.20 x 0.20 x 5 mm) 8x2 1.60Kg/ Each 25.60

Boult 16mm (0.40 Mtr Long) 8x8 0.85Kg/Each 54.40

Front Verticle Pipe Front ( 50 x 50 ) 2.6mm Th. 8 1.500 3.74Kg/Mtr 44.88

Gusset Plate ( 0.20 x 0.20 x 5 mm) 8 1.60Kg/ Each 12.80

Purline ( 60 x 40 mm ) 2.6mm Th. 9 25.00 3.73 Kg/ Mtr 839.25

Total 1849.530 Kg 108.00 199749

12.1.2 Providing corrugated G.S. sheet

roofing including vertical/ curved surface fixed

with polymer coated J or L hooks, bolts and nuts 8

mm diameter with bitumen and G.I. limpet

washers or with G.I. limpet washers filled with

15 white lead and including a coat of approved steel

primer and two coats of approved paint on

overlapping of sheets complete upto any pitch in

horizontal/ vertical or curved surfaces) excluding

the cost of purlins, rafters and trusses and

including cutting to size and shape wherever

required.

1 25.0 8.85 221.25 Sqm 863.0 190939

12.11 Extra for providing and fixing wind

16 ties of 40x 6 mm flat iron section. 2 25.00 50.00 Mtr 121 6050

S.No. Perticulars No L B D Qty Unit Rate Amount

13.46 Wall painting by any mechanical ormanual

means with plastic emulsion paint of approved

17 brandand manufacture to give an even shade:

Twoor more coats on new work

Qty As Per I/12 146.940

Total 146.940 Sqm 64.00 9404

Total 867382

Say 867400

You might also like

- Wbs and Division of Work Excel Spread Sheet1Document12 pagesWbs and Division of Work Excel Spread Sheet1Adrian Christian Lee100% (1)

- BBS Retaining Wall + FootingDocument11 pagesBBS Retaining Wall + FootingmanishjonwNo ratings yet

- Semiotics and Visual Communication Concepts and PracticesDocument353 pagesSemiotics and Visual Communication Concepts and Practicesflagons100% (1)

- Guidelines For Energy Conserving Design - PPT Version 1Document62 pagesGuidelines For Energy Conserving Design - PPT Version 1Reymart ManablugNo ratings yet

- Mughal Garden PPT - 01-50-24 - 03 - 12 - 37Document33 pagesMughal Garden PPT - 01-50-24 - 03 - 12 - 37Suraj Rathi100% (2)

- RCC DrainDocument1 pageRCC DrainBadri DhunganaNo ratings yet

- Detail Estimate of Cross Drainage 2.00MX2.00M Slab CulvertDocument3 pagesDetail Estimate of Cross Drainage 2.00MX2.00M Slab Culvertbharatram dehariyaNo ratings yet

- Revised Estimate Draft 24-12-2021Document100 pagesRevised Estimate Draft 24-12-2021Reenu CherianNo ratings yet

- Boundary Wall Estimate S.No Sor No. Decription Boundary Wall Total Qty Unit Rate AmountDocument4 pagesBoundary Wall Estimate S.No Sor No. Decription Boundary Wall Total Qty Unit Rate AmountInterns 2020No ratings yet

- MGR Nagar Paver Block EstimateDocument17 pagesMGR Nagar Paver Block EstimateprasanthNo ratings yet

- Anganwadi Estimate AnthwarDocument12 pagesAnganwadi Estimate AnthwarK KARTHIKNo ratings yet

- Planning and Road Assets Management Centre: Functions of PRAMCDocument33 pagesPlanning and Road Assets Management Centre: Functions of PRAMCGuruprasad PNo ratings yet

- 09 Chapter 2Document25 pages09 Chapter 2lupamudraNo ratings yet

- Mangan D (2018) - The Role of Proof Rolling in Pavement ConstructionDocument10 pagesMangan D (2018) - The Role of Proof Rolling in Pavement Constructionkentong.leeNo ratings yet

- Aor Cantilever 6m SignDocument6 pagesAor Cantilever 6m SignDaljit624No ratings yet

- Boq of Fire StationDocument8 pagesBoq of Fire StationKANWARNo ratings yet

- Estimate of Slab Culvert in Excelxlsx PDF FreeDocument6 pagesEstimate of Slab Culvert in Excelxlsx PDF FreeKshitij NagraleNo ratings yet

- R.C.C. Slab CulvertsDocument4 pagesR.C.C. Slab CulvertsDheeraj TkNo ratings yet

- Concrete Pipe DrawDocument10 pagesConcrete Pipe Drawdhiraj KumarNo ratings yet

- Toilet BlockDocument21 pagesToilet BlocklkovijayNo ratings yet

- SCH-B Pragatipath Navsari DTP80 CRDocument100 pagesSCH-B Pragatipath Navsari DTP80 CRKETANNo ratings yet

- 3.4retaining WallDocument13 pages3.4retaining WallveevimalNo ratings yet

- Double Row Hume Pipe Culvert 1000Mm Dia. Pipe: Upstream DownstreamDocument1 pageDouble Row Hume Pipe Culvert 1000Mm Dia. Pipe: Upstream DownstreamabhishekNo ratings yet

- Ilovepdf Merged PDFDocument215 pagesIlovepdf Merged PDFVicky AnandNo ratings yet

- STNDRD Kilometer Post & Maintainance Marker Post - PDocument1 pageSTNDRD Kilometer Post & Maintainance Marker Post - Palex abestadoNo ratings yet

- M.tech Thesis Opt AqDocument105 pagesM.tech Thesis Opt AqS N satyanarayanaNo ratings yet

- Cremation Shed 2019-20Document29 pagesCremation Shed 2019-20Amjid ManhasNo ratings yet

- Civil Dhanusha 2019-01-05 FinalDocument79 pagesCivil Dhanusha 2019-01-05 FinalrahulNo ratings yet

- 6 M Span CulvertDocument16 pages6 M Span CulvertSUJIT TaLUKDARNo ratings yet

- HPC 1000 Single Row 7.5 MDocument2 pagesHPC 1000 Single Row 7.5 MgagajainNo ratings yet

- Compoundwall Model Estimate 2 1Document271 pagesCompoundwall Model Estimate 2 1Sudeep s.mNo ratings yet

- Pow Const of Drainage Canal - StationDocument16 pagesPow Const of Drainage Canal - StationDA 3No ratings yet

- BarrageDocument29 pagesBarrageTaha UsamaNo ratings yet

- Mechanical Electronic CSR For Year 2023 24Document169 pagesMechanical Electronic CSR For Year 2023 24sujit tiwariNo ratings yet

- AoR-2020 (MGNREGA), Vol-IDocument135 pagesAoR-2020 (MGNREGA), Vol-ISaroj ChakmaNo ratings yet

- Longitudinal Section: Drain From Alok Nagar To ManikpurDocument9 pagesLongitudinal Section: Drain From Alok Nagar To ManikpurDipankarHaloiNo ratings yet

- Bore WellDocument3 pagesBore WelltubaiNo ratings yet

- Field Density Test (SRM)Document2 pagesField Density Test (SRM)manish upadhyay0% (1)

- Estimate of Aqueduct at KM 0.263Document2 pagesEstimate of Aqueduct at KM 0.263gurumurthy38100% (1)

- Boundary FootingDocument46 pagesBoundary FootingANKESH SHRIVASTAVANo ratings yet

- Analysis of Steel ShutterDocument30 pagesAnalysis of Steel Shuttersalahuddin sakuNo ratings yet

- Cost Estimate DhanauraDocument124 pagesCost Estimate DhanauraCivil EngineeringNo ratings yet

- District Rural Development Agency Golaghat-AssamDocument4 pagesDistrict Rural Development Agency Golaghat-AssamBISWA GOGOINo ratings yet

- Rough SL TH CalDocument53 pagesRough SL TH CalAnkita PalNo ratings yet

- Design Planning and Cost Estimation of A G 1 School Building - Formatted PaDocument12 pagesDesign Planning and Cost Estimation of A G 1 School Building - Formatted PajerryNo ratings yet

- Jute Geotextiles-Srtabilisation of SlopesDocument70 pagesJute Geotextiles-Srtabilisation of Slopesnimm1962No ratings yet

- Check List For Siding PlansDocument6 pagesCheck List For Siding PlansNitesh KumarNo ratings yet

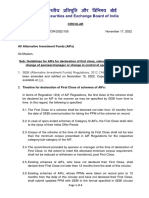

- CircularDocument4 pagesCircularyashNo ratings yet

- Overhead SignDocument3 pagesOverhead SignBilal A BarbhuiyaNo ratings yet

- Design of Over Head Tank and Water DistributionDocument21 pagesDesign of Over Head Tank and Water DistributionSrikanth GangadharaNo ratings yet

- 02.94 921-RA Bill No-9 - VUP - ApproachesDocument61 pages02.94 921-RA Bill No-9 - VUP - ApproachesAshok KumarNo ratings yet

- Lecture 8 - DR Bhupinder SinghDocument132 pagesLecture 8 - DR Bhupinder SinghAaron WilsonNo ratings yet

- C A Over Head Water Tank (Final)Document23 pagesC A Over Head Water Tank (Final)usama buttNo ratings yet

- VennerDocument2 pagesVennerSENCPWD, MALDANo ratings yet

- Dynamic Analysis and Design of UG WATER TANK ONEWAYDocument38 pagesDynamic Analysis and Design of UG WATER TANK ONEWAYyedida viswanadhNo ratings yet

- Data Impervious CoatDocument1 pageData Impervious CoatD V BHASKARNo ratings yet

- BBS Deck Slab-For One SpanDocument1 pageBBS Deck Slab-For One SpanRavindra RaoNo ratings yet

- 100m Taper 45 M Straight 100m Taper: NotesDocument1 page100m Taper 45 M Straight 100m Taper: NotesSaudagar BiswalNo ratings yet

- Farm Pond DrawingDocument1 pageFarm Pond DrawingMani KumarNo ratings yet

- Toilet EstimateDocument24 pagesToilet EstimatePartha Pratim DasNo ratings yet

- Well Foundation - RVNLDocument9 pagesWell Foundation - RVNLVenkateswarlu DanduNo ratings yet

- Nit Schedule For The Construction of S.D.M. Office Building at Balaghat, Dist-Balaghat M.PDocument31 pagesNit Schedule For The Construction of S.D.M. Office Building at Balaghat, Dist-Balaghat M.PDADADADGGGNo ratings yet

- PR Estimate 398.050 To 408.000 NH-52Document59 pagesPR Estimate 398.050 To 408.000 NH-52Bilal A BarbhuiyaNo ratings yet

- S.D.M. Office First Floor Estimate: Staire Case ColDocument7 pagesS.D.M. Office First Floor Estimate: Staire Case Colaasifah100% (1)

- Case Studies Sem-6 MohiniDocument1 pageCase Studies Sem-6 MohiniMohiniNo ratings yet

- Technological Institute of The PhilippinesDocument4 pagesTechnological Institute of The PhilippinesMel CoderesNo ratings yet

- Architecture Urbanism Design and Behavio PDFDocument26 pagesArchitecture Urbanism Design and Behavio PDFAlejandra Gu-CeNo ratings yet

- Simpolo Sanitaryware Products PDFDocument32 pagesSimpolo Sanitaryware Products PDFABHINAV KUMARNo ratings yet

- Clarens Hotel GurgaonDocument4 pagesClarens Hotel GurgaonsbalindiaNo ratings yet

- Masonry Fire ResistenceDocument5 pagesMasonry Fire ResistenceJawad HussainNo ratings yet

- The Skyscrapers: Presented By-Ujjwal Taneja (17BAR1055)Document8 pagesThe Skyscrapers: Presented By-Ujjwal Taneja (17BAR1055)Sona TanejaNo ratings yet

- Manpower & Material OutputDocument22 pagesManpower & Material OutputMesfinNo ratings yet

- SYSTEM SELECTION EditedDocument23 pagesSYSTEM SELECTION EditedAkash ChaurasiaNo ratings yet

- Baroque Architecture (1550-1790)Document10 pagesBaroque Architecture (1550-1790)Jersey Mae PerlasNo ratings yet

- Unit 3 - Composite MaterialsDocument8 pagesUnit 3 - Composite Materialsvsrinath7_102555994No ratings yet

- Design Criterion For Civil, Structural & Architechtural Works - Pe-Dc-435-600-C001-R1Document67 pagesDesign Criterion For Civil, Structural & Architechtural Works - Pe-Dc-435-600-C001-R1Muhammad HasanNo ratings yet

- New Boq of Circulating AreaDocument8 pagesNew Boq of Circulating Areaapi-3823524No ratings yet

- Hardened ConcreteDocument20 pagesHardened Concretefaimy josephNo ratings yet

- Shiv Mandir DrawingsDocument11 pagesShiv Mandir DrawingsRooking Ewondo SfuutNo ratings yet

- Design of Corbel - Workshop Cum Office BuildingDocument2 pagesDesign of Corbel - Workshop Cum Office BuildingMuhammad HasanNo ratings yet

- Unit 2Document27 pagesUnit 2Ziyanda Lethu100% (1)

- Tadao Ando PDFDocument14 pagesTadao Ando PDFanuragNo ratings yet

- Understanding Building Construction Types - Firefighter Nation PDFDocument3 pagesUnderstanding Building Construction Types - Firefighter Nation PDFRakeshNo ratings yet

- Group 5 Final PlateDocument14 pagesGroup 5 Final PlateCyrus De LeonNo ratings yet

- ESTIMATEDocument7 pagesESTIMATEMac KYNo ratings yet

- Wollastonite Irjet PDFDocument5 pagesWollastonite Irjet PDFChidananda GNo ratings yet

- Climatic Analysis of A Haveli in Shekhawati Region, RajasthanDocument7 pagesClimatic Analysis of A Haveli in Shekhawati Region, Rajasthanchirag100% (1)

- Cable Net Facade SystemDocument4 pagesCable Net Facade SystemBalagopal U RNo ratings yet

- 2016-0629 Callisto Tower 1 - Project Presentation PDFDocument90 pages2016-0629 Callisto Tower 1 - Project Presentation PDFShop HereNo ratings yet

- 2131 Spec For Vitrified TilesDocument2 pages2131 Spec For Vitrified TilesChirag TanavalaNo ratings yet