Professional Documents

Culture Documents

VCM Purity Analysis

VCM Purity Analysis

Uploaded by

Mohammed SolimanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VCM Purity Analysis

VCM Purity Analysis

Uploaded by

Mohammed SolimanCopyright:

Available Formats

Model 150 SCE

Vinyl Chloride Monomer Purity Analysis System

The levels of trace impurities in polymer grade VCM are extremely important in the manufacture

and application of PVC. The analysis of trace level impurities in such a high purity single

component matrix always presents special challenges to the analyst. Many of the meth-

All New Design ods currently in use by the VCM manufacturers are based upon outdated packed column

technologies which have remained unchanged over many years

The new Model 150 VCM purity analyzer is a state of the art, multidimensional GC, PLOT capil-

lary based analytical system now available from Microanalytics.

The new Model 150SCE, based upon our original VCM design used worldwide for over a decade, ushers

in a new level of sophistication for the automated analysis of VCM.

· Meets and exceeds current ASTM Standard D-5507-94 methodology.

· Full EPC (electronic pressure control) of column and midpoint pressures and detector gases..

· Complete integrated design into the industry standard Agilent Model 6890 gas chromatograph

· Automated vaporizing injector is integrated into the standard 6890 valve oven. No external valve

oven or vaporizer assemblies.

· All metal Sil\tite™ nuts arid ferrules insures years of leak-free service and inertness.

· Ease of Installation. System is shipped ready to run, with columns installed and methods for calibra-

tion gases and samples. Requires only power and gas connections.

· All residual VCM is ducted to a single vent point for connection to a gas scrubber or vent hood. Help

reduce VCM production costs through energy conservation and reduction in product rerun/

downgrade.

· Improve reliability and precision of purity data.

· Improves peak resolution; especially at sub-ppm levels.

· Eliminates analyst introduced data variability.

Features and Benefits

Features Enables complete purity analysis with a single GC run

Benefit Faster, more precise and reliable data

Feature Single GC, Dual FID, PLOT column based technology

Benefit Greater durability and better resolution through higher column efficiencies

Feature Unique automated sample introduction method for precise liquid-vapor conversion

Benefit Eliminates analyst introduced data variability

Feature Multidimensional GC based separation

Benefit Automated heartcutting and cryogenic trapping resolves all impurities in a single run

PARTIAL LIST OF VCM 150 USERS

Dow Chemical—Texas Operations Geismar, LA

PEMEX Petroquimica Mexico

Formosa Plastics Baton Rouge, LA

Georgia Gulf Chemical Lake Charles, LA

PHH Monomers Westlake, LA

Microanalytics™ Gas Chromatography Systems and Services

A MOCON© Company 2011A Lamar Drive - Round Rock, TX 78664 www.mdgc.com

Standard Configurations

M150SCE-001 Model 150, Multidimensional GC VCM Purity Analyzer

Standard Configurations Include:

· Agilent Technologies Model 6890 Gas Chromatograph

· Fully integrated block-bleed automated vaporizing injector for HP liquid VCM stream.

· Two (2) G1562A Flame ionization detectors (FID) with EPC

· G1570A Auxiliary EPC controller for precolumn and midpoint pressure

· Heartcut valve with inert gas sweep

· Liquid CO2 cryofocusing system

· Application specific PLOT column set with particle traps

· Start/stop and analog signal cables for external integrator support (if necessary)

Sample Chromatograms

Precolumn Separation minus Heartcuts

1st Heartcut 2nd Heartcut

C4’s

1,2 EDC

Separation of Heartcuts on Second Column

Ethylene

Acetylene

VCM Peaks

Propylene

from heartcuts

Propadiene

Methyl Chloride

1,3 Butadiene

Vinyl Acetylene

Ethyl Chloride

Repeatability Data

Retention Time Drift Quantitative - Short Term Quantitative - Long Term

6 sequential runs - 24 hours 6 sequential runs - 24 hours 10 sequential runs - 9 days

Compound Mean SD %RSD Mean SD %RSD Mean SD %RSD

Name Ret. Time PPM PPM

Methyl Chloride 11.02 0.02 0.20% 29.50 0.12 0.40% 34.48 0.60 1.70%

1,3-Butadiene 17.48 0.01 0.10% 2.75 0.02 0.70% 3.27 0.06 1.80%

Vinyl Acetylene 17.86 0.01 0.10% 5.23 0.03 0.60% 10.09 0.14 1.39%

Ethyl Chloride 18.14 0.01 0.10% 17.44 0.09 0.50% 19.23 0.29 1.51%

Gas Chromatography Systems and Services Microanalytics™

2011A Lamar Drive - Round Rock, TX 78664 www.mdgc.com A MOCON© Company

MOCON is a registered trademark and MICROANALYTICS and AROMATRAX are trademarks of MOCON, Inc.

Copyright ©2003 MOCON, Inc.

MOCON reserves the right to change specifications without notice as part of our continuous program of product improvement.

You might also like

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Southern Blot Lab ReportDocument10 pagesSouthern Blot Lab ReportPeter Ickes0% (1)

- High Performance Liquid Chromatography (HPLC), Method DevelopmentDocument4 pagesHigh Performance Liquid Chromatography (HPLC), Method DevelopmentAmirul Azhar100% (9)

- PNS en 14103 - Fame PDFDocument13 pagesPNS en 14103 - Fame PDFWynona BasilioNo ratings yet

- Oil and Gas Production Measurement: From Wellhead To PipelineDocument12 pagesOil and Gas Production Measurement: From Wellhead To PipelinemusaNo ratings yet

- 5.GCMSMS FS Mit 07052020Document89 pages5.GCMSMS FS Mit 07052020Duc Nhon LENo ratings yet

- APP - Determination of Ethylene Glycol 012090 - 01Document3 pagesAPP - Determination of Ethylene Glycol 012090 - 01Lely Zikri ZulhidayahNo ratings yet

- Teknokroma Capillary Columns: TRB-1 Equivalent PhaseDocument2 pagesTeknokroma Capillary Columns: TRB-1 Equivalent PhasechiralicNo ratings yet

- GC PDFDocument28 pagesGC PDFccsllNo ratings yet

- GC PDFDocument28 pagesGC PDFccsllNo ratings yet

- 03 - 20190114 - PepTalk 2019 - Celltheon and Pall Workflow FinalDocument28 pages03 - 20190114 - PepTalk 2019 - Celltheon and Pall Workflow FinalDaniel AraújoNo ratings yet

- Acid Number Measurements of Crude Oil and Petroleum Products Using ASTM D8045Document4 pagesAcid Number Measurements of Crude Oil and Petroleum Products Using ASTM D8045Corina Stanculescu100% (1)

- Brochure - DMA-80 Evo - 220309 - 202322Document8 pagesBrochure - DMA-80 Evo - 220309 - 202322Ayman KamounNo ratings yet

- Determination of Impurities in Methyl Tert-Butyl Ether - ASTM D5441Document2 pagesDetermination of Impurities in Methyl Tert-Butyl Ether - ASTM D5441abdurahman143No ratings yet

- Butyl Mercaptan TertDocument1 pageButyl Mercaptan TertOETINCA OETINCANo ratings yet

- Oligosaccharides On PA200 - 1x250mm by Dual EGC ReportDocument6 pagesOligosaccharides On PA200 - 1x250mm by Dual EGC ReportjuakfuenmayorNo ratings yet

- Art Cat GC - Column - Catalog 2005-ExtractoDocument3 pagesArt Cat GC - Column - Catalog 2005-ExtractoJosé Ignacio Gómez CívicosNo ratings yet

- PSPS EX EN-Cyclohexane-PlantDocument10 pagesPSPS EX EN-Cyclohexane-PlantULLAS KRISHNAN J NNo ratings yet

- EN 14103 - ThermoDocument4 pagesEN 14103 - ThermoLuciana TrisnaNo ratings yet

- GR00005800B 13aDocument251 pagesGR00005800B 13aLuis David Leon GarciaNo ratings yet

- GCMS PT Lotne ENDocument16 pagesGCMS PT Lotne ENpeeping.dogNo ratings yet

- Determination of Mtbe, Etbe, Tame, Dipe, Tertiary-Amyl Alcohol and C Toc Alcohols in Gasoline by Gas ChromatographyDocument10 pagesDetermination of Mtbe, Etbe, Tame, Dipe, Tertiary-Amyl Alcohol and C Toc Alcohols in Gasoline by Gas Chromatographysiddiqabdillah09No ratings yet

- Crystal E Series: Ultrapure Water SystemsDocument3 pagesCrystal E Series: Ultrapure Water SystemsRamad DhanNo ratings yet

- 6 - Polyesters - 2012 - Permeability Properties of Plastics and ElastomersDocument18 pages6 - Polyesters - 2012 - Permeability Properties of Plastics and ElastomersAnuNo ratings yet

- Astm d6730 AppDocument5 pagesAstm d6730 AppRuồi SữaNo ratings yet

- Dictionar de Abrevieri Englez - RomanDocument6 pagesDictionar de Abrevieri Englez - RomanAndra ApostolNo ratings yet

- Gc/Ms Analysis of Pcbs in Waste Oil Using The Backflush Capability of The Agilent Quickswap AccessoryDocument6 pagesGc/Ms Analysis of Pcbs in Waste Oil Using The Backflush Capability of The Agilent Quickswap AccessoryKung KleeNo ratings yet

- Upstream Process Engineering Course: 4. SeparationDocument46 pagesUpstream Process Engineering Course: 4. SeparationReza SalimiNo ratings yet

- CVT Transmission C: SyntheticDocument2 pagesCVT Transmission C: SyntheticTaller MarioNo ratings yet

- Preparation of Calcined Petroleum Coke Samples For AnalysisDocument4 pagesPreparation of Calcined Petroleum Coke Samples For AnalysisLito EstimosNo ratings yet

- RMT-E SalesDocument4 pagesRMT-E SalesPraveshGuptaNo ratings yet

- Advantages and Disadvantages of High-End Mass Spectrometry in A Forensic Toxicology LabDocument28 pagesAdvantages and Disadvantages of High-End Mass Spectrometry in A Forensic Toxicology LabFadli SukandiarsyahNo ratings yet

- DO-C10011-CT-Cat-Fines-Test Kit PDFDocument1 pageDO-C10011-CT-Cat-Fines-Test Kit PDFStefas DimitriosNo ratings yet

- APTA - Presentation Diesel Aftertreatment SystemsDocument37 pagesAPTA - Presentation Diesel Aftertreatment SystemsCris YocumNo ratings yet

- Apl 220014Document2 pagesApl 220014Elprince MidoNo ratings yet

- FCC LabDocument12 pagesFCC LabHassanNo ratings yet

- Small em Oil Sealed Rotary Vane PumpsDocument12 pagesSmall em Oil Sealed Rotary Vane PumpsVratNo ratings yet

- RSTPro Vs RSTDocument12 pagesRSTPro Vs RSTDil Dhadakne DoNo ratings yet

- Aplicaciones RTX-2887Document2 pagesAplicaciones RTX-2887Francisco Pérez ChaniqueNo ratings yet

- Agilent Cannabis Beverages ExtractionDocument8 pagesAgilent Cannabis Beverages ExtractionNurlyana IshakNo ratings yet

- Fuel Conditioning System Web Email SMDocument4 pagesFuel Conditioning System Web Email SMammakhomsamNo ratings yet

- PP PROCESS PUMP (Chemical Process & Barrel Pump) 2016Document4 pagesPP PROCESS PUMP (Chemical Process & Barrel Pump) 2016juan c. condori ch.No ratings yet

- Motor 2.4L MMC - 4.3L GM - Manual de Serviço (2007)Document116 pagesMotor 2.4L MMC - 4.3L GM - Manual de Serviço (2007)José MaliciaNo ratings yet

- CRSS Desalination IIT KGP Tata Steel 24-01-14Document36 pagesCRSS Desalination IIT KGP Tata Steel 24-01-14Omkar ShindeNo ratings yet

- D6891 - 21 Standard Test Method For Evaluation of Automotive Engine Oils in The Sequence IVA Spark-Ignition EngineDocument46 pagesD6891 - 21 Standard Test Method For Evaluation of Automotive Engine Oils in The Sequence IVA Spark-Ignition EngineProvocateur SamaraNo ratings yet

- Element Brochure 9 3Document6 pagesElement Brochure 9 301DOGG01No ratings yet

- ORFOM SX80 Solvent Extraction DiluentDocument1 pageORFOM SX80 Solvent Extraction DiluentSpark GuildNo ratings yet

- Basics of OIl RefineryDocument28 pagesBasics of OIl RefineryDebasis Kumar Saha50% (2)

- Innovo Brochure 2017Document4 pagesInnovo Brochure 2017Manojj NatarrajanNo ratings yet

- 2021 Fuce Cell Course Note1Document137 pages2021 Fuce Cell Course Note1Alya penta agharidNo ratings yet

- Ethanol CromatografiaDocument8 pagesEthanol CromatografiasampablotheonlyoneNo ratings yet

- Battery Reference 6Document13 pagesBattery Reference 6zaheer hussainNo ratings yet

- 5989 8441enDocument8 pages5989 8441enG_ASantosNo ratings yet

- XMTC DatasheetDocument4 pagesXMTC DatasheetSelva RajNo ratings yet

- SMC Cdu FlyerDocument1 pageSMC Cdu FlyerJohn EdardsNo ratings yet

- E4 Series 60 HZ: Reverse Osmosis Machine 2,200 To 13,200 Gallons Per DayDocument2 pagesE4 Series 60 HZ: Reverse Osmosis Machine 2,200 To 13,200 Gallons Per DayROLANDONo ratings yet

- Tesis 580Document4 pagesTesis 580jesusito07No ratings yet

- GC-2010 Plus: Capillary Gas ChromatographDocument24 pagesGC-2010 Plus: Capillary Gas ChromatographWhite MirageNo ratings yet

- A. CCC GeneralDocument12 pagesA. CCC GeneralMuhammadAsimNo ratings yet

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- Introduction & Analysis (TLC)Document5 pagesIntroduction & Analysis (TLC)Syaza Izzah Athirah Bt SpaieeNo ratings yet

- Formal Report Expt 5Document6 pagesFormal Report Expt 5AnonymouscatNo ratings yet

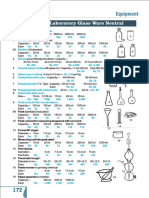

- Glassware and PlasticwareDocument23 pagesGlassware and PlasticwareAmna ZafarNo ratings yet

- Guía Rápida Purificación GFP Quick GuideDocument5 pagesGuía Rápida Purificación GFP Quick GuideManuel Fernandez RisquezNo ratings yet

- Datasheet 108665Document3 pagesDatasheet 108665BAUTISTA DIPAOLANo ratings yet

- HPLC - Determination of Caffeine in SodaDocument4 pagesHPLC - Determination of Caffeine in SodasusanaNo ratings yet

- Alkhidmat Diagnostic Center Blood Bank: Virology & Genetic LabDocument1 pageAlkhidmat Diagnostic Center Blood Bank: Virology & Genetic LabNum RahNo ratings yet

- Proses Pemurnian Fraksi Kaya Rhodinol Minyak Sereh Wangi Menggunakan Spinning Band DistillationDocument10 pagesProses Pemurnian Fraksi Kaya Rhodinol Minyak Sereh Wangi Menggunakan Spinning Band DistillationDicky GabrielNo ratings yet

- PermethrinDocument4 pagesPermethrinVenugopal GowdaNo ratings yet

- Microbiology Work InstructionsDocument58 pagesMicrobiology Work InstructionsJam SanchezNo ratings yet

- Teknik PemisahanDocument77 pagesTeknik PemisahanAku AmelNo ratings yet

- RF Value CalculationDocument6 pagesRF Value Calculationnavoditgoel1985100% (2)

- History of CentrifugesDocument2 pagesHistory of Centrifugesvijay kumar honnaliNo ratings yet

- Wizard SV Genomic Dna Purification System Quick Protocol PDFDocument4 pagesWizard SV Genomic Dna Purification System Quick Protocol PDFSergio UcNo ratings yet

- Shimadzu Uvmini-1240 and Biospec-Mini Uv/Visible Scanning SpectrophotometersDocument1 pageShimadzu Uvmini-1240 and Biospec-Mini Uv/Visible Scanning SpectrophotometersYehya EljoneidNo ratings yet

- MLS109Lab LabApp&MicroscopeDocument4 pagesMLS109Lab LabApp&MicroscopeMyedelle SeacorNo ratings yet

- KT60 GFP Cloning Teaching KitDocument11 pagesKT60 GFP Cloning Teaching KitHemant KawalkarNo ratings yet

- Hema Activity 1Document6 pagesHema Activity 1Rakia PillayNo ratings yet

- PTH 403 Report UpdatedDocument9 pagesPTH 403 Report Updatedanand reddyNo ratings yet

- Activity 1 - MicroscopeDocument4 pagesActivity 1 - MicroscopeYousra Mae CadienteNo ratings yet

- DCFDA-H2DCFDA-Cellular ROS-Assay-Kit-protocol-book-v12-ab113851 (Website)Document23 pagesDCFDA-H2DCFDA-Cellular ROS-Assay-Kit-protocol-book-v12-ab113851 (Website)Raji SivarupaNo ratings yet

- Catalog Biocraft Lab GlasswareDocument2 pagesCatalog Biocraft Lab GlasswareHmmNo ratings yet

- Anintroduction Tomulti-Component Peakpurity: Marcv. Gorenstein, Ph.D.And Jeanneb. Li, PH.DDocument4 pagesAnintroduction Tomulti-Component Peakpurity: Marcv. Gorenstein, Ph.D.And Jeanneb. Li, PH.DEsteban FernandezmNo ratings yet

- Chemical Testing of Hedysarum Alpinum Seeds For The Neurotoxin beta-ODAPDocument8 pagesChemical Testing of Hedysarum Alpinum Seeds For The Neurotoxin beta-ODAPalatnabirdNo ratings yet

- Purification Methods FlashcardsDocument35 pagesPurification Methods FlashcardsLejNo ratings yet

- UHPLC and HPLC Method Optimization07112017Document54 pagesUHPLC and HPLC Method Optimization07112017DarshanaNo ratings yet

- Exp 2 Protein DeterminationDocument5 pagesExp 2 Protein DeterminationNur Fadhilah100% (1)

- Protein Assay by The Bradford Method FinaleDocument44 pagesProtein Assay by The Bradford Method FinaleEfraim Jeric Eustacio100% (1)