Professional Documents

Culture Documents

CDX Series Catalogue

CDX Series Catalogue

Uploaded by

Ramraj EnterprisesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CDX Series Catalogue

CDX Series Catalogue

Uploaded by

Ramraj EnterprisesCopyright:

Available Formats

Atlas Copco

Heatless Adsorption Compressed Air Dryers

CDX series

Absolutely moisture free clean air

CDX – dryers for demanding applications

Moisture: an avoidable threat ?

Compressed air entering the air net is always 100 %

saturated with water vapour. When cooling down, this

moisture will condense, causing damage to your air

system… and to your finished products. The amount of

water is directly proportional to the flow and although an

aftercooler will eliminate 2/3 of the moisture, the

remaining third can still be very destructive in many

applications, such as instrument air, dry powder

conveying or processes with rapid air expansion.

Maximum performance for minimum cost

The robust design of CDX ensures that the complete range operates with total reliability,

producing the desired pressure dew point even in the most difficult conditions. Coupled with the

most advanced control systems, the CDX range provides the best quality air for the lowest

possible cost.

Atlas Copco’s dew point dependent purge control significantly reduces energy costs while

ensuring a totally stable and reliable dew point. Using the unique microprocessor based in

combination with a top class PDP sensor, a payback period of less than 6 months is not Stainless steel 3-way switching valve

uncommon.

CDX totally eliminates moisture

Atlas Copco CDX adsorption dryers eliminate the moisture before it can cause any damage.

Even the possibility of freezing is non-existent. The CDX dryers ensure a reliable process and

impeccable end products by offering absolutely dry air to your compressed air system, with a

pressure dew point of -40°C or even-70°C

Purge control technology

CDX 120 - 1050 – High performance for critical application

� Wide dessicant vessels

� Pneumatically operated switching valves

� Silencers with integrated Safety valves

� Robust frame with fork lift slots and lifting eyes

� Integrated filter pack

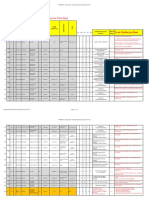

Technical Specifications

Inlet capacity Inlet capacity Inlet/outlet

11 bar variant at 7 bar g 16 bar variant at 12.5 bar g Connections

CDX

DRYER TYPE I/s cfm I/s cfm ANSI

CDX 120 120 252 144 305 1 ½”

CDX 180 180 381 215 456 1 ½”

CDX 220 220 466 265 562 1 ½”

CDX 300 300 636 360 763 2”

CDX 350 360 763 430 911 2”

CDX 400 400 844 N/A N/A 3”

CDX 520 520 1101 N/A N/A 3”

CDX 780 780 1651 N/A N/A 4”

CDX 1050 1050 2223 N/A N/A 4”

Reference Conditions:

Compresser air inlet temperature:

35OC/ 100OF

1 ACTIVATED ALUMINA

Inlet relative humidity: (UNSATURATED)

100% 2 ACTIVATED ALUMINA

(SATURATED)

Dryer inlet pressure for 11 bar variants, after inlet filtration:

7 bar(g)/ 102 psi(g) 3 SWITCHING VALVE

4 SILENCER

Dryer inlet pressure for 16 bar variants, after inlet filtration:

12.5 bar(g)/ 181 psi(g) 5 FILTER

6 PDP SENSOR

To adjust the performance of each dryer for different inlet conditions, 7 STAINLESS STEEL

PURGE NOZZLE

use the correction factors below.

Pressure dew point correction (Kd)

Pressure °C -20 -40 -70

dew point °F -4 -40 -100

CDX 120-1050 Kd 1 1 0.8

Inlet pressure correction factor(Kp)

11 bar(g)/160 psi(g) version 16 bar(g)/232 psi(g) version

Inlet pressure bar (g) 4 5 6 7 8 9 10 11 12.5 13 14 15 16

psi (g) 58 73 87 102 116 131 145 160 181 189 203 218 232

CDX 120 -1050 Kp 0.47 0.68 0.84 1 1.1 1.2 1.3 1.38 1 1.04 1.11 1.19 1.24

Inlet temperature correction factor (Kt ) Example:

What is the capacity of an CDX120, working at 8 bar(g)/116 psi(g), with an inlet temperature of

Inlet pressure bar (g) 25 30 35 40 45 50 40°C/104°F with a required pressure dew point of -40°C/-40°F ?

psi (g) 77 86 95 104 113 122 Find each correction factor :

Kd = 1, Kp = 1.1, Kt = 0.84

CDX 120-1050 Kp 1 1 1 0.84 0.71 0.55 Actual capacity = nominal capacity x Kd x Kp x Kt

Actual capacity = 120 x 1 x 1.1 x 0.84

Actual capacity =111 l/s or 235 cfm

Atlas Copco

¢ Global industrial group, headquartered in Stockholm, Sweden.

¢ More than 130 years of experience.

¢ World leader in Compressed Air technology.

¢ More than 26,000 employees worldwide, with sales turnover, over US$ 6 billion.

¢ Manufacturing facilities in 17 countries across 4 continents.

¢ From design to production and delivery of compressors, Atlas Copco adheres to the ISO 9001

management system.

¢ Atlas Copco's Environmental Management System forms an integral part of each business process.

¢ State-of-the-art manufacturing facility in India.

¢ Sales, Service & Dealer network in 150 countries.

R QUALI

TE T

ISTER QU

IS

Y

EG A

D’ S R E G

AS

R

LI

LLOYD’S

TY ASSURA

SURANC

OY

N

IS

O CE

900

1

LL

E

ISO

9001

ISO 9001 ISO 9001

Atlas Copco’s Environmental Management System From design to production and delivery,

Atlas Copco compressors adhere to the

forms an integral part of each business process. ISO 9001 Management Systems

requirements.

Atlas Copco Compressor Sales www.atlascopco.com

(A Division of Atlas Copco (India) Ltd.) Email: qualityair@in.atlascopco.com

HEAD OFFICE & WORKS: Sveanagar, Dapodi, Pune 411012.

Phone: 020 - 3985 2100 Fax: 020 - 2714 5948

9095 3578 00 subject to alteration without prior notice

CUSTOMER CARE CENTRES PHONE MOBILE FAX

4th Floor, 406, Baleshwar Avenue, Opp. Rajpath Club, Sarkej- Gandhinagar Highway, (079)30009693 (0) 9327548191 (079)30009393

AHMEDABAD 380 015.

1-A, 1st floor, Peenya Industrial Area, 2nd phase, BANGALORE 560 058. (080) 39280164/1 (0) 9341280458 (080) 39280145

311 - Yash Kamal Building, Lokmanya Tilak Road, Sayajigunj, BARODA 390 005. (0265) 3024119 (0) 9376216533 (0265)3024129

C/6 Block, 3rd floor, DLF IT Park, Chandigarh Technology Park, CHANDIGARH 160 101. — (0) 9316915466 (0172) 2642171

16, Race Course Road, Guindy, CHENNAI 600 032. (044)22453189 (0) 9382841220 (044) 22452047

6-3-1191, 2nd floor, Brij Tarang, Greenland, Begumpet, HYDERABAD 500 016. (040) 32949090 (0) 9380572236 (040) 23417923

Trinity Plaza, 2nd floor, WestWing, 841/1 A, Topasia Road (South), KOLKATA 700 046. (033) 32949090 (0) 9391370561 (033) 22851043

nd

Mahatma Gandhi Memorial Building, 2 floor Netaji Subhash Road, MUMBAI 400 002. (022) 32949090 (0) 9325383777 (022) 22811463

Ground floor, Wing C, unitech Cyber Park, GURGAON 122001. (0124) 3027945 (0) 9312504774 (0124) 3027924

2nd Floor, Tellus Technoligies Pvt. Ltd. 209/ 1B/ 1A, Range Hills Road. PUNE 411 020. (020) 32949090 (0) 9823014158 (020) 27145778

JUICE/01- 08/5000

DEALERS: Ahmedabad,Aizwal, Amritsar, Angul, Aurangabad, Bangalore, Barbil, Baroda,Bellary, Bhopal, Bhubaneshwar Chandigarh, Chennai, Coimbatore, Aman, Dehradun, Dhanbad, Faridabad,

Ghazibad, Goa, Gurgaon, Gwalior, Hyderabad, Indore, Jaipur, Jammu, Jamshedpur, Jhansi, Kanpur, Kolhapur, Kolkata, Kullu, Kunnathur, Ludhiana, Melur, Madurai, Mumbai, Nagpur, Nasik, New Delhi,

Noida, Ongole, Pathankot, Pondichery, Pune, Raipur, Ranchi, Rourkel, Salem, Siliguri, Srinagar, Surat, Tezpur, Udaipur, Visakhapatnam, Dhaka (Bangladesh), Kathmandu (Nepal), Phuntsholing

(Bhutan)

You might also like

- Atlas Copco RS ULTRA MSDSDocument7 pagesAtlas Copco RS ULTRA MSDSRamraj EnterprisesNo ratings yet

- Asl Ga37-55 VSD MK5Document67 pagesAsl Ga37-55 VSD MK5Ramraj Enterprises100% (1)

- Spare Parts Catalog: Generated From DocmineDocument843 pagesSpare Parts Catalog: Generated From Docminefia c.l100% (1)

- PDF Atlas Copco Ewd 330 Manual PDF DDDocument6 pagesPDF Atlas Copco Ewd 330 Manual PDF DDAbdellah Ibrahim100% (2)

- FD TCR Industrial 1Document8 pagesFD TCR Industrial 1HemonNo ratings yet

- Basics of AIR CompressorDocument66 pagesBasics of AIR CompressorRamraj Enterprises100% (4)

- Dryspell Heatless Air Dryers 02Document6 pagesDryspell Heatless Air Dryers 02Vikas PatidarNo ratings yet

- Dryspell Plus: Lasting ValuesDocument2 pagesDryspell Plus: Lasting ValuesReuel TacayNo ratings yet

- Dryspell CatalogDocument2 pagesDryspell CatalogKM KarthikNo ratings yet

- Domnick Hunter Pneudri Dme040 Secador ArDocument23 pagesDomnick Hunter Pneudri Dme040 Secador ArRafael CardosoNo ratings yet

- Accs r407c CatalogueDocument16 pagesAccs r407c CatalogueMohd FirdhausNo ratings yet

- ACCS R407C 50Hz - MS0316C 1213 CatalogDocument16 pagesACCS R407C 50Hz - MS0316C 1213 CatalogPratikno SajaNo ratings yet

- Aftercoolers Waterseparators Leaflet EN 2935083844 PDFDocument6 pagesAftercoolers Waterseparators Leaflet EN 2935083844 PDFleandroniedbalskiNo ratings yet

- DP 18Document2 pagesDP 18sumeet malekarNo ratings yet

- Parker&Hiross Antares Tandem KurutucuDocument8 pagesParker&Hiross Antares Tandem Kurutucumaxigas120No ratings yet

- USAIRTOWER AirtowerSeries 07-2019!46!37027Document8 pagesUSAIRTOWER AirtowerSeries 07-2019!46!37027vkees1987No ratings yet

- Bag Filter Himenviro - O&m - Cement MillDocument51 pagesBag Filter Himenviro - O&m - Cement Millsambhu0% (1)

- Comp Screw SXC-5-19Document8 pagesComp Screw SXC-5-19michael.lie15No ratings yet

- Atlas PDFDocument6 pagesAtlas PDFFlávia GustavoNo ratings yet

- Dunham BushDocument16 pagesDunham Bushhjmm100% (1)

- 2018 Drypoint Ra Brochure_usDocument8 pages2018 Drypoint Ra Brochure_usJuan SantiagoNo ratings yet

- Instrument Air Dryer and Instrument Air ReceiverDocument4 pagesInstrument Air Dryer and Instrument Air ReceiverAzizul HakimNo ratings yet

- Technical Report Azud Helix Automatic FT200 Aa DLP-1Document5 pagesTechnical Report Azud Helix Automatic FT200 Aa DLP-1bedhief ahmedNo ratings yet

- Xas 650 - 900 Jd8 t4f BrochureDocument4 pagesXas 650 - 900 Jd8 t4f BrochureKarlos Miguel Lopez GomezNo ratings yet

- Voltas Cassette AC CatalogueDocument2 pagesVoltas Cassette AC CatalogueairblisssolutionsNo ratings yet

- FD FX Brochure Update 072020Document9 pagesFD FX Brochure Update 072020Alex PomaNo ratings yet

- XK Series BrochureDocument12 pagesXK Series BrochureVALNo ratings yet

- Cool Only / Heat Pump: CassetteDocument2 pagesCool Only / Heat Pump: Cassettebram samyNo ratings yet

- CRDC DryerDocument4 pagesCRDC Dryerjaypc10No ratings yet

- Woman On TopDocument17 pagesWoman On ToplwinooNo ratings yet

- Xas 1150 Cd8 t4f Leaflet UsaDocument4 pagesXas 1150 Cd8 t4f Leaflet UsaGuptaNo ratings yet

- FD 100 VSD - Oct 28 2020Document1 pageFD 100 VSD - Oct 28 2020gilbert fristartoNo ratings yet

- Consult The CAGI Website,, For A List of Participants in The Third Party Verification ProgramDocument1 pageConsult The CAGI Website,, For A List of Participants in The Third Party Verification ProgramSteveNo ratings yet

- 2022 Brochure Drypoint RaDocument12 pages2022 Brochure Drypoint RaMiszael EspinosaNo ratings yet

- Zero Loss Level Sensing Automatic Drain ValveDocument2 pagesZero Loss Level Sensing Automatic Drain ValveEMS GlobalNo ratings yet

- ACCS 50-60Hz R407C-R410A MS0327D-0719R1 Lo 0Document20 pagesACCS 50-60Hz R407C-R410A MS0327D-0719R1 Lo 0Eduardo Luis SouzaNo ratings yet

- Dasco Louvers PDFDocument52 pagesDasco Louvers PDFali_habib_41No ratings yet

- Dalgakiran Refrigeration Air DryersDocument2 pagesDalgakiran Refrigeration Air DryersJunaid AhmedNo ratings yet

- GasniZagrevaci 3 MASTERDocument25 pagesGasniZagrevaci 3 MASTERZoran JurakNo ratings yet

- FX 400-2000Document8 pagesFX 400-2000francisco jose arruda de sousaNo ratings yet

- Atlas Copco Portable Air Compressors: 43 To 69 L/s (70 To 147 Cu - Ft/min) - 7 Bar (102 Psig)Document6 pagesAtlas Copco Portable Air Compressors: 43 To 69 L/s (70 To 147 Cu - Ft/min) - 7 Bar (102 Psig)Thierry Nolla100% (1)

- Ebac CD100 BrochureDocument2 pagesEbac CD100 BrochureCarlos MartinezNo ratings yet

- Брошюра - Осушители Bd100-3000Document8 pagesБрошюра - Осушители Bd100-3000airpartNo ratings yet

- Purgeur UFM-D130Document4 pagesPurgeur UFM-D130youcef alimNo ratings yet

- Dunham Bush Package UnitsDocument8 pagesDunham Bush Package UnitsStephanie StewartNo ratings yet

- CSC Series: Csc09Ca Csc09Cd Csc12Ca Csc12Cd Csc18Cd Csc24Cd Csc30Cd Csc36CdDocument3 pagesCSC Series: Csc09Ca Csc09Cd Csc12Ca Csc12Cd Csc18Cd Csc24Cd Csc30Cd Csc36CdEliezer OcañaNo ratings yet

- CondensateManangement Antwerp Leaflet EN 2935083846Document12 pagesCondensateManangement Antwerp Leaflet EN 2935083846Max LimNo ratings yet

- Compressed Air Dryer: Industrial Ammonia SystemsDocument8 pagesCompressed Air Dryer: Industrial Ammonia Systemsfernando_tkm_65065No ratings yet

- Ceccato CDX 4 840 6999100156 Eng LRDocument6 pagesCeccato CDX 4 840 6999100156 Eng LRKing MaxNo ratings yet

- 40QDS-W - Catalog (FCU - Floor Stand-Big)Document2 pages40QDS-W - Catalog (FCU - Floor Stand-Big)nok.naingoo100% (1)

- Fd60hz Secador Atlas Copco - ManualDocument8 pagesFd60hz Secador Atlas Copco - ManualEdvaldo França100% (1)

- ВИНТОВЫЕ КОМПРЕССОРЫ (англ.) ИНСТРУКЦИЯ ПРИМЕНЕНИЯ DNKP07100054-RU+ (en)Document58 pagesВИНТОВЫЕ КОМПРЕССОРЫ (англ.) ИНСТРУКЦИЯ ПРИМЕНЕНИЯ DNKP07100054-RU+ (en)Sergey Spil'nikNo ratings yet

- ChicagoPneumatic CPX 21-5040 ENDocument2 pagesChicagoPneumatic CPX 21-5040 ENJorge ValenciaNo ratings yet

- Drying - DRYPOINT AC 119 - AC 196: Compressed Air of High QualityDocument4 pagesDrying - DRYPOINT AC 119 - AC 196: Compressed Air of High QualityJuan BarrientosNo ratings yet

- Freeze Dryuer Configuration PDFDocument8 pagesFreeze Dryuer Configuration PDFMuhammad AminNo ratings yet

- ChicagoPneumatic CPF 200 CPVS 250 Instruction Book EN 6230579965Document32 pagesChicagoPneumatic CPF 200 CPVS 250 Instruction Book EN 6230579965osmanyildirim85No ratings yet

- Instrument Air Dryer and Instrument Air ReceiverDocument1 pageInstrument Air Dryer and Instrument Air ReceiverAimanNo ratings yet

- 2.0 - XRVS 1000 CD XC4004 Product Reference SheetDocument9 pages2.0 - XRVS 1000 CD XC4004 Product Reference Sheetirwan triadi100% (1)

- 1000 CFM Non Datasheet - Docx 1Document3 pages1000 CFM Non Datasheet - Docx 1Ingeniería AplicacionesNo ratings yet

- Bulatt 03 enDocument8 pagesBulatt 03 enJas SumNo ratings yet

- 21 02 2200786800 Ed 01 (EN)Document36 pages21 02 2200786800 Ed 01 (EN)makcimmischenkoNo ratings yet

- Dental XDocument16 pagesDental XindraNo ratings yet

- 6 Series US Range Metspray Mobile Compressor XAS-146DDDocument5 pages6 Series US Range Metspray Mobile Compressor XAS-146DDPhilip La TrobeNo ratings yet

- RS Ultra Latest MSDSDocument2 pagesRS Ultra Latest MSDSRamraj EnterprisesNo ratings yet

- RS Ultra Latest 09.03.2020Document1 pageRS Ultra Latest 09.03.2020Ramraj EnterprisesNo ratings yet

- RIFNduranceDocument12 pagesRIFNduranceRamraj EnterprisesNo ratings yet

- GA 15-22 Redesign PPT - LDocument11 pagesGA 15-22 Redesign PPT - LRamraj EnterprisesNo ratings yet

- 3 Phase Electric PowerDocument7 pages3 Phase Electric PowerRamraj EnterprisesNo ratings yet

- GA - The Street-Fighter: K.J WaniDocument22 pagesGA - The Street-Fighter: K.J WaniRamraj EnterprisesNo ratings yet

- Part List GA55+90 MKVDocument68 pagesPart List GA55+90 MKVRamraj EnterprisesNo ratings yet

- ASL GAe18-30 VSDDocument48 pagesASL GAe18-30 VSDRamraj EnterprisesNo ratings yet

- Atlas Capco Air Oil Separator ReferenceDocument6 pagesAtlas Capco Air Oil Separator ReferenceRamraj Enterprises100% (1)

- Bin Card RreDocument1 pageBin Card RreRamraj EnterprisesNo ratings yet

- Job DetailsDocument1 pageJob DetailsRamraj EnterprisesNo ratings yet

- CPB Partlist 13.02.13LDocument18 pagesCPB Partlist 13.02.13LRamraj EnterprisesNo ratings yet

- Natural Gas Systems InspectionDocument2 pagesNatural Gas Systems Inspectionrieza_fNo ratings yet

- VISCOSITYDocument17 pagesVISCOSITYAnonymous MxVWU4No ratings yet

- Air Panel Filter New Brochure .PDF May 2023 - CompressedDocument26 pagesAir Panel Filter New Brochure .PDF May 2023 - CompressedHerlangga Sapardi SHNo ratings yet

- Mepla GBP Web PDFDocument62 pagesMepla GBP Web PDFJagadish KumarNo ratings yet

- Test and Drain ValveDocument4 pagesTest and Drain ValveAhrian BenaNo ratings yet

- Fourth ExperimentDocument4 pagesFourth ExperimentJCAdlawanNo ratings yet

- Get The Best Performance From Your Cascade Attachment With Hydraulic Valve KitsDocument3 pagesGet The Best Performance From Your Cascade Attachment With Hydraulic Valve KitsVictor ValenciaNo ratings yet

- Macam-Macam Artificial LiftDocument52 pagesMacam-Macam Artificial LiftRichard Arnold SimbolonNo ratings yet

- Watts Premier INSTALLATION, OPERATION AND MAINTENANCE MANUAL WP5Document28 pagesWatts Premier INSTALLATION, OPERATION AND MAINTENANCE MANUAL WP5Jack AillonNo ratings yet

- Plant Design 02 PDFDocument10 pagesPlant Design 02 PDFNazar AhmedNo ratings yet

- Ecm585 Mcii Serial X011173ca Parts ManualDocument578 pagesEcm585 Mcii Serial X011173ca Parts ManualHassan ZAFFA CISNEROS100% (1)

- Vilas Javdekar Avenue Plumbing WorkDocument1 pageVilas Javdekar Avenue Plumbing WorkbillingNo ratings yet

- Rotating Equipment Training Manual - CompressedDocument39 pagesRotating Equipment Training Manual - CompressedOscar DuranNo ratings yet

- CTR-12 - FPSO Firenze - Clarification Report - Ph-1 Presv ItemsDocument3 pagesCTR-12 - FPSO Firenze - Clarification Report - Ph-1 Presv ItemsSri100% (1)

- OQ AVL-ValvesDocument3 pagesOQ AVL-ValvesMDhana SekarNo ratings yet

- SBIInstructionManual17 03 2014Document11 pagesSBIInstructionManual17 03 2014ramon duldulaoNo ratings yet

- 106Document1 page106ahm3d16n100% (1)

- A Practical Method To Predict Performance Curves of Centrifugal Water PumpsDocument6 pagesA Practical Method To Predict Performance Curves of Centrifugal Water Pumps1940LaSalleNo ratings yet

- 2 Hydrostatics ContinuationDocument5 pages2 Hydrostatics ContinuationPritz Jay Magno TorresNo ratings yet

- Numerical Investigation of The 3D Flow Structures Nearby Cooling HolesDocument9 pagesNumerical Investigation of The 3D Flow Structures Nearby Cooling Holeskang_2010No ratings yet

- Celdek VS AspenDocument2 pagesCeldek VS AspenVidysagar VvecNo ratings yet

- Large Eddy Simulation of Non-Reacting Flow and Mixing Fields in A Rotating Detonation EngineDocument16 pagesLarge Eddy Simulation of Non-Reacting Flow and Mixing Fields in A Rotating Detonation Enginethomas williansNo ratings yet

- EngineeringDocument23 pagesEngineeringmgkvpr100% (1)

- Tahanan Kapal (Minggu - 4) : Jurusan Teknik Sistem Perkapalan ITS SurabayaDocument28 pagesTahanan Kapal (Minggu - 4) : Jurusan Teknik Sistem Perkapalan ITS SurabayaErwin Paulian SihombingNo ratings yet

- Line Sizing: Liquid Phase CaseDocument13 pagesLine Sizing: Liquid Phase CaseEngr Theyji0% (1)

- 16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideDocument2 pages16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideBhaumik BhuvaNo ratings yet

- General FE Chem Exam PDFDocument21 pagesGeneral FE Chem Exam PDFN100% (1)

- "Hygate AFC" Cast Iron Gate Valves PN 10: Tender SpecificationDocument1 page"Hygate AFC" Cast Iron Gate Valves PN 10: Tender SpecificationIrudhayarajAnthonySamyNo ratings yet

- Problem Set A Fluid StaticsDocument7 pagesProblem Set A Fluid StaticsDesireine Louise JacintoNo ratings yet