Professional Documents

Culture Documents

RA For Site Fabrication Work - 05

RA For Site Fabrication Work - 05

Uploaded by

alla malikOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RA For Site Fabrication Work - 05

RA For Site Fabrication Work - 05

Uploaded by

alla malikCopyright:

Available Formats

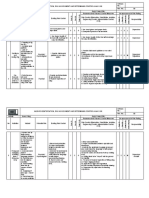

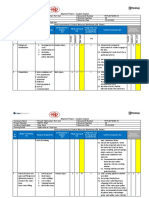

Elephant Project – Sayakha Gujarat

Company Name : Trimurti Fabrication Pvt. Ltd. Document Number : TFPL/APG/RA-005

Project Number : 506111-2041 Revision Number : 01

Location Applicable : Pipe Rack Area, Site Office Area Revision Date : 07/01/2022

Activity/Event : Fabrication work including cutting, Grinding, Argon- Arc welding and painting work.

Risk A Risk Assessment & Control Measure Worksheet (RA Sheet)

Consequence / If high risk, can

Sr. Steps in Activity Initial risk level Residual

Hazard / Aspect (2) Impact the hazard be Control measures (6)

No. (1) (4) risk level (7)

(3) avoided? (5)

Likelihood

Likelihood

Risk Level

Risk Level

Severity

Severity

Y/N

1 Preparation 1. Unauthorized Body injury 1 2 N Y 1.1. Option safe work permit before 1 1 L

work execute the work.

2. Unknown 2.1. Unknown person does not enter

person can enter in to work area

3. Incompetent 2.2. Area barricading, signage

workers display

3.1. All the workers should be

competent and trained related

to hot work.

2 Machinery equipment 1. Trip hazards Body 1 2 L Y 1.1. Ensure area are obstruction 1 1 1

selection 2. Falling hazards injury/Property free.

damage 2.1. Ensure access should be clean

and tidy

3 Electrical Supply 1. Electrocution Human 3 3 H Y 1.1. Inspection of power tools with 1 2 L

2. Fire injury/Fatality/ checklist

property 1.2 All power supply connection

damage should be industrial type fitted

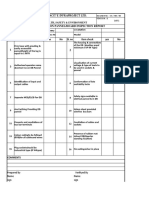

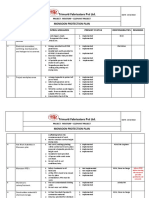

Elephant Project – Sayakha Gujarat

Company Name : Trimurti Fabrication Pvt. Ltd. Document Number : TFPL/APG/RA-005

Project Number : 506111-2041 Revision Number : 01

Location Applicable : Pipe Rack Area, Site Office Area Revision Date : 07/01/2022

Activity/Event : Fabrication work including cutting, Grinding, Argon- Arc welding and painting work.

Risk A Risk Assessment & Control Measure Worksheet (RA Sheet)

Consequence / If high risk, can

Sr. Steps in Activity Initial risk level Residual

Hazard / Aspect (2) Impact the hazard be Control measures (6)

No. (1) (4) risk level (7)

(3) avoided? (5)

with breakers

1.3 Power supply go through 30

mA ELCB/RCCB.

1.4 Proper cabling overhead with

insulated stand

1.5 Suitable resistant mat to be

provide in front of panel

1.6 Suitable shock proof gloves to

be use by electrician

1.7 Insulated hand tools must be

use

2.1. Keep CO2 fire extinguisher

near panel

2.2. Proper access provided for

emergency

Welding (Argon, Arc) 1. Electrocution Human 3 3 H Y 1.1. Ensure the welding equipment 1 2 L

2. Fire injury/Fatality (torch, cable, electrode holder,

3. Damage cable connector, plugs, sockets

machine etc) are free from any defect.

4. Eye 2.1. Keep portable fire Extinguisher

Injury/Flying near hot work area with fire

Spark/ watcher.

Ultraviolet & 2.2. Remove all combustible

Infrared Material before start welding

Elephant Project – Sayakha Gujarat

Company Name : Trimurti Fabrication Pvt. Ltd. Document Number : TFPL/APG/RA-005

Project Number : 506111-2041 Revision Number : 01

Location Applicable : Pipe Rack Area, Site Office Area Revision Date : 07/01/2022

Activity/Event : Fabrication work including cutting, Grinding, Argon- Arc welding and painting work.

Risk A Risk Assessment & Control Measure Worksheet (RA Sheet)

Consequence / If high risk, can

Sr. Steps in Activity Initial risk level Residual

Hazard / Aspect (2) Impact the hazard be Control measures (6)

No. (1) (4) risk level (7)

(3) avoided? (5)

radiation work

5. Incompetent 2.3. Fire blanket required wherever

operator required in site Hot work booth

6. Toxic Fumes

to be provide with fire blanket.

2.4. Fire watcher must check hot

7. Dislocation /

Fall of the job work area after 20 minutes of

pices due to completing of job

faulty clamping 3.1. Make sure welding machine

8. Loose must be checked APG as

connection checklist.

/loose

4.1. Use of Proper PPE.

insulation

9. Flammable 4.2. Welding shield attached with

gases helmet to be provide

10. Poor 4.3. Suitable hand gloves, hand

ventilation sleeves, apron and leg sleeves

to be worn

5.1. Allow to weld only competent &

trained workers

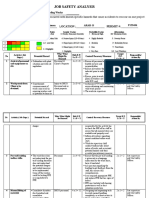

Grinding, cutting 1. Electrocution Human 3 3 H Y 1.1. Use only electrical certified 1 2 L

2. Fire injury/property Power tools must carry valid

Elephant Project – Sayakha Gujarat

Company Name : Trimurti Fabrication Pvt. Ltd. Document Number : TFPL/APG/RA-005

Project Number : 506111-2041 Revision Number : 01

Location Applicable : Pipe Rack Area, Site Office Area Revision Date : 07/01/2022

Activity/Event : Fabrication work including cutting, Grinding, Argon- Arc welding and painting work.

Risk A Risk Assessment & Control Measure Worksheet (RA Sheet)

Consequence / If high risk, can

Sr. Steps in Activity Initial risk level Residual

Hazard / Aspect (2) Impact the hazard be Control measures (6)

No. (1) (4) risk level (7)

(3) avoided? (5)

3. Eye damage monthly color code

Injury/Flying 1.2. Ensure power cable free from

Spark any damages.

4. High Noise 2.1. Remove combustible material

5. Incompetent minimum 10 Mt from grinding

operator area.

6. Unguarded 2.2. Hot work booth to be provide

machine with fire blanket

7. Breaking of 2.3. Suitable type fire extinguisher

wheel to be available at work

8. Inadequate location

PPE 3.1. Use screen to arrest spark

9. Electric Shock which will generate from

repeated grinding Face shield attaching

10. Vibration with helmet to be use

11. Accidental 4.1. Use proper PPE ear plug/ear

operation muff to be use

5.1. Trained and Competent

person only use grinding

machine

6.1. Grinding m/c guard must be

there.

7.1. Store person will ensure that

Elephant Project – Sayakha Gujarat

Company Name : Trimurti Fabrication Pvt. Ltd. Document Number : TFPL/APG/RA-005

Project Number : 506111-2041 Revision Number : 01

Location Applicable : Pipe Rack Area, Site Office Area Revision Date : 07/01/2022

Activity/Event : Fabrication work including cutting, Grinding, Argon- Arc welding and painting work.

Risk A Risk Assessment & Control Measure Worksheet (RA Sheet)

Consequence / If high risk, can

Sr. Steps in Activity Initial risk level Residual

Hazard / Aspect (2) Impact the hazard be Control measures (6)

No. (1) (4) risk level (7)

(3) avoided? (5)

grinding wheel must not be in

contact with moisture.

7.2. Ensure that not to use expire

date wheel.

7.3. Trained and competent

person only use grinding

machine.

8.1. Use proper PPE as per

mention in PTW

8.2. Face Shield & Ear plug

compulsory.

9.1. Single switch & single socket

to be used.

9.2 All electrical cable must be

contact through 30 mA ELCB

10 Suitable type hand gloves to be

provide

11 Ensure functional dead men

switch with grinder machine

12 Holding handle must attached full

time with grinder machine

Gas cutting Separate 1. Defective Tools Human 3 3 H Y 1.1. Ensure the gas cutting equipment 1 2 L

RA to be prepare for 2. Radiation from injury/Fatality (blowpipe, hoses, oxy-acetylene

Gas cutting and Rays (Flash cylinders, pressure gauge) are free

from defect.

Elephant Project – Sayakha Gujarat

Company Name : Trimurti Fabrication Pvt. Ltd. Document Number : TFPL/APG/RA-005

Project Number : 506111-2041 Revision Number : 01

Location Applicable : Pipe Rack Area, Site Office Area Revision Date : 07/01/2022

Activity/Event : Fabrication work including cutting, Grinding, Argon- Arc welding and painting work.

Risk A Risk Assessment & Control Measure Worksheet (RA Sheet)

Consequence / If high risk, can

Sr. Steps in Activity Initial risk level Residual

Hazard / Aspect (2) Impact the hazard be Control measures (6)

No. (1) (4) risk level (7)

(3) avoided? (5)

cylinder Eye) 1.2. Fuel & Oxygen hoses should be

handling/storage 3. Exposure to lashed

Fumes 1.3. Check for hose leakage using soap

4. Burns for any leakage

5. Falling of 2.1. Wear protective goggles &

Sparks Clothing.

6. Flash Back Fire 3.1. Ensure proper ventilation and

7. Oxy-acetylene fume extraction

Cylinder near 4.1. Wear long sleeved coverall,

the Hot Work leather apron; face shield.

5.1. Barricading surrounding the work

area

area

6.1. Provide a check valve (flash back

arrester) between oxy-acetylene

hose & gas regulator.

7.1. Maintain DA / oxy – acetylene

cylinders at least 5 meters away

from hot work area.

7.2. Isolate the cylinder when not in

use.

7.3. Cylinders should not be exposed to

naked sunlight

7.4. Training of the persons

Availability of fire

extinguishers

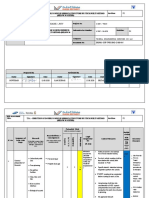

Elephant Project – Sayakha Gujarat

Company Name : Trimurti Fabrication Pvt. Ltd. Document Number : TFPL/APG/RA-005

Project Number : 506111-2041 Revision Number : 01

Location Applicable : Pipe Rack Area, Site Office Area Revision Date : 07/01/2022

Activity/Event : Fabrication work including cutting, Grinding, Argon- Arc welding and painting work.

Risk A Risk Assessment & Control Measure Worksheet (RA Sheet)

Consequence / If high risk, can

Sr. Steps in Activity Initial risk level Residual

Hazard / Aspect (2) Impact the hazard be Control measures (6)

No. (1) (4) risk level (7)

(3) avoided? (5)

Chemical cleaning 1. Eye irritation Human health 1 2 L Y 1.1. Only competent person 1 1 L

2. Skin Burn injury should be allowed to use

of Pickling paste.

2.1. Make sure all required PPE

must be used

(Hand/Eye/Face

protection)

2.2. Portable eye wash must be

available full time at site

during work

2.3. Workers to use full body

chemical protection suite

Painting work Separate RA to Spillage of paint Body injury 2 2 M Y Paint bucket must be free from any 1 1 L

be prepare Eye injury damages.

Irritation Make sure use Eye protection

Improper way of Make sure paint not should be contact

Handling. with body.

STF (Slip, Trip & Fall) Extra care should be taken while

Sharp edge handling paint.

Skin Contact Area should be free from any STF (Slip,

Inhalation Trip & Fall) Hazard.

Fire All Sharp edge must be identified and

Improper Tools take extra care for handling with Sharp

(Painting Brush)

Elephant Project – Sayakha Gujarat

Company Name : Trimurti Fabrication Pvt. Ltd. Document Number : TFPL/APG/RA-005

Project Number : 506111-2041 Revision Number : 01

Location Applicable : Pipe Rack Area, Site Office Area Revision Date : 07/01/2022

Activity/Event : Fabrication work including cutting, Grinding, Argon- Arc welding and painting work.

Risk A Risk Assessment & Control Measure Worksheet (RA Sheet)

Consequence / If high risk, can

Sr. Steps in Activity Initial risk level Residual

Hazard / Aspect (2) Impact the hazard be Control measures (6)

No. (1) (4) risk level (7)

(3) avoided? (5)

material.

Use cut resistant hand gloves

Use proper PPE.

8.1. Use nose mask.

Make sure no any hot work should be

allowed within 10-meter premises of

Painting work.

Make sure proper tools only used for

painting work

Scaffolding work 1. Incompetency Human 2 3 H Y 1. Scaffold should be erected 1 1 L

scaffolder injury/fatality by competent person

2. Scaffolding 2. Scaffold should be erected in

collapse

firm and level surface

3. Man, material fall

3. Use fall protection (FBH)

while working at height

4. Make sure all falling object

should be secured at height

In case of emergency 1. During Human 1 1 L Y 1.1. Follow site emergency

emergency injury/fatality/p plan

roperty 1.2. Active and trained ERT

team Training

Elephant Project – Sayakha Gujarat

Company Name : Trimurti Fabrication Pvt. Ltd. Document Number : TFPL/APG/RA-005

Project Number : 506111-2041 Revision Number : 01

Location Applicable : Pipe Rack Area, Site Office Area Revision Date : 07/01/2022

Activity/Event : Fabrication work including cutting, Grinding, Argon- Arc welding and painting work.

Risk A Risk Assessment & Control Measure Worksheet (RA Sheet)

Consequence / If high risk, can

Sr. Steps in Activity Initial risk level Residual

Hazard / Aspect (2) Impact the hazard be Control measures (6)

No. (1) (4) risk level (7)

(3) avoided? (5)

1.3. Available of first Aider

And first AID kit &

Stretcher

1.4. Emergency vehicle.

1.5. Call to Emergency

Contact numbers

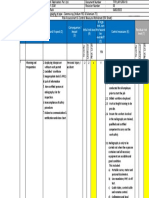

Prepared By Reviewed By Check by Reviewed By Approved By

Area Engineer Area HSE HSE M RCM APG HSE APG Engineer

Name Rahmat Ansari Vijay Sahani Javid

Designation Engg Safety Officer

Signature

Date

Elephant Project – Sayakha Gujarat

Company Name : Trimurti Fabrication Pvt. Ltd. Document Number : TFPL/APG/RA-005

Project Number : 506111-2041 Revision Number : 01

Location Applicable : Pipe Rack Area, Site Office Area Revision Date : 07/01/2022

Activity/Event : Fabrication work including cutting, Grinding, Argon- Arc welding and painting work.

Risk A Risk Assessment & Control Measure Worksheet (RA Sheet)

Consequence / If high risk, can

Sr. Steps in Activity Initial risk level Residual

Hazard / Aspect (2) Impact the hazard be Control measures (6)

No. (1) (4) risk level (7)

(3) avoided? (5)

Guidelines on how to complete the HSRA

1. Record the hazard or aspect, e.g. exposure to noise, entering a confined space, etc.

2. Identify the worst-case effect of the hazard

3. Identify who could be affected by the risk, e.g. Project Team, Sub-consultants/contractors, Members of the public, etc.

4. Evaluate the level of risk for each hazard, by identifying its severity of harm and likelihood, using the risk matrix shown below

5. Ascertain if high risk, can hazard be avoided?

6. Identify control measures, noting that each hazard may require more than one control measure in order to reduce the level of risk to an acceptable level

7. Evaluate the level of risk for each hazard, taking into account the effect of the control measure(s)

8. Identify who is responsible for implementing or ensuring that the control measures have been implemented

9. Record the date the actions completed or due

Risk Level

Severity Probability Severity

Severity of Harm Likelihood Probability Index

Index Index Index

1 2 3

Death or major injury 3 Harm is certain or near certain to occur 3 1 L L M

Lost time injury or illness 2 Harm is likely to occur 2 2 L M H

All other injuries or illnesses 1 Harm is unlikely 1 3 M H H

You might also like

- General MS For Chemical CrackingDocument12 pagesGeneral MS For Chemical CrackingAs-Syaff ResourcesNo ratings yet

- The Ultimate Guide To P2P Lending PDFDocument112 pagesThe Ultimate Guide To P2P Lending PDFArthur Liew100% (1)

- 675Document2 pages675Rameese MuhammedNo ratings yet

- AhaDocument6 pagesAhaCarlits MacallaNo ratings yet

- Job Safety Analysis (Jsa) : CONTRACT N° .Document1 pageJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- GD N Bad PracticesDocument11 pagesGD N Bad PracticesViknes RamanNo ratings yet

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

- Abrasive Blasting Check ListDocument2 pagesAbrasive Blasting Check ListSaravanan JambunathanNo ratings yet

- 33 Self Refurbishment Method Statement Phoenix Housing Co OpDocument11 pages33 Self Refurbishment Method Statement Phoenix Housing Co OpthomasNo ratings yet

- Hand Safety MomentDocument2 pagesHand Safety MomentRogelio BetrayerNo ratings yet

- JSA FabricationDocument3 pagesJSA FabricationSwaroop Cherry100% (1)

- Hazard Identification, Risk Assessment and Determining Control AnalysisDocument6 pagesHazard Identification, Risk Assessment and Determining Control AnalysisKhaty JahNo ratings yet

- Risk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)Document3 pagesRisk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)AmeerHamzaWarraichNo ratings yet

- For Electrical PannelDocument2 pagesFor Electrical Panneljithin shankarNo ratings yet

- Idoc - Pub - Task Risk Assessment For RadiographyDocument5 pagesIdoc - Pub - Task Risk Assessment For RadiographySasi YNo ratings yet

- Job Safety Analysis Worksheet: Short Descriptive Title of Task: New Revised ReviewedDocument2 pagesJob Safety Analysis Worksheet: Short Descriptive Title of Task: New Revised ReviewedZulfokar FahdawiNo ratings yet

- Topic For TBMDocument19 pagesTopic For TBMdauxomNo ratings yet

- Risk Assessment Erection of Precast Concrete ElementsDocument2 pagesRisk Assessment Erection of Precast Concrete ElementsBunyamin Selimoglu100% (1)

- Roof Sheeting JSADocument6 pagesRoof Sheeting JSAJogendra BeharaNo ratings yet

- Risk Assesment Form For ScaffoldingDocument1 pageRisk Assesment Form For Scaffoldingchandanprakash30No ratings yet

- Risk Assessment For Curtain Wall & Glazing InstallationDocument4 pagesRisk Assessment For Curtain Wall & Glazing InstallationBulent AkNo ratings yet

- HIRA - Copper Pipe Brazing WorkDocument2 pagesHIRA - Copper Pipe Brazing Workyogeshraut1910No ratings yet

- Risk Assessment For ExcavationDocument8 pagesRisk Assessment For ExcavationAhmed GamalNo ratings yet

- Risk Assessment For ExcavationDocument3 pagesRisk Assessment For Excavationfibin haneefaNo ratings yet

- TCB Work at Height WEBDocument5 pagesTCB Work at Height WEBFaraaz MohammadNo ratings yet

- SOP SOP0022 Concrete Core DrillDocument3 pagesSOP SOP0022 Concrete Core Drillkristian08No ratings yet

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- SWMS - ConcreteDocument10 pagesSWMS - ConcreteMuhammadNo ratings yet

- Demolition RISK AssessmentDocument15 pagesDemolition RISK AssessmentAli KaziNo ratings yet

- 8) SWP-08 Working at HeightsDocument3 pages8) SWP-08 Working at HeightsRachel NoraNo ratings yet

- OSHA Training and Reference Materials Library - PPE AssessmentDocument10 pagesOSHA Training and Reference Materials Library - PPE AssessmentOluwafemi Samuel AdesanmiNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- CamScanner 03-22-2023 07.44Document2 pagesCamScanner 03-22-2023 07.44Umar AliNo ratings yet

- RISK ASSESSMENT (Backfilling of Excavated Area)Document2 pagesRISK ASSESSMENT (Backfilling of Excavated Area)Raza Muhammad SoomroNo ratings yet

- Risk Assessment/ JSA Lifting &rigging OperationDocument5 pagesRisk Assessment/ JSA Lifting &rigging Operationuz9143895No ratings yet

- Example RA Working at Height Risk AssessmentDocument6 pagesExample RA Working at Height Risk AssessmentYossef K FawzyNo ratings yet

- HLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistDocument1 pageHLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistLemuel Petronio100% (3)

- 18 - RA Roadworks Risk AssessmentDocument1 page18 - RA Roadworks Risk Assessmentkumar100% (1)

- 23 JSA For Block WorkDocument2 pages23 JSA For Block WorkWakil AhmadNo ratings yet

- Lecture 3.2.3: Erection III: Steel Construction: Fabrication and ErectionDocument4 pagesLecture 3.2.3: Erection III: Steel Construction: Fabrication and ErectionMihajloDjurdjevicNo ratings yet

- Scaffolding Risk AssessmentDocument4 pagesScaffolding Risk AssessmentDARENo ratings yet

- Excavation ManuallyDocument1 pageExcavation ManuallyJack PNo ratings yet

- Safe Work Procedure Steel FixDocument3 pagesSafe Work Procedure Steel FixMunaku TafadzwaNo ratings yet

- Explosives in Demolition - Exclusive ZoneDocument2 pagesExplosives in Demolition - Exclusive ZoneVignesh KmNo ratings yet

- Job Safety Analysis Sheet: Mechanical ExcavationDocument1 pageJob Safety Analysis Sheet: Mechanical ExcavationjoshuaNo ratings yet

- Hira - NRV ServicingDocument11 pagesHira - NRV ServicingAbzad HussainNo ratings yet

- Tra-Derrick Module Assembly Below 30 MetersDocument37 pagesTra-Derrick Module Assembly Below 30 MetersBenasher IbrahimNo ratings yet

- PCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Document17 pagesPCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Geethika SandaruwanNo ratings yet

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- Compressed Gas Safety HSE Presentation HSE FormatsDocument45 pagesCompressed Gas Safety HSE Presentation HSE FormatsasepNo ratings yet

- Mobile Scaffolding Inspection Checklist: Project Name: DateDocument1 pageMobile Scaffolding Inspection Checklist: Project Name: DateMehtab Uddin mmNo ratings yet

- Jsa For Dismantel of StructureDocument2 pagesJsa For Dismantel of StructureBaiju SinghNo ratings yet

- Risk Assessment of ShutteringDocument4 pagesRisk Assessment of ShutteringMAB AliNo ratings yet

- 10.1 Jha Box-Up Spool or Valve 19.11.15Document6 pages10.1 Jha Box-Up Spool or Valve 19.11.15RahimNo ratings yet

- Jha Lin FillingDocument6 pagesJha Lin FillingLuqman OsmanNo ratings yet

- Scaffolding: Your Key To Stability: By: Georgia Tech Occupational Safety and Health ProgramDocument33 pagesScaffolding: Your Key To Stability: By: Georgia Tech Occupational Safety and Health ProgramShalimar Ladenne Figuracion BuaquiñaNo ratings yet

- Columns An IntroductionDocument5 pagesColumns An IntroductionkennysawegNo ratings yet

- Welding SopDocument6 pagesWelding SopNikhil VaidyaNo ratings yet

- Jsa Fall ProtectionDocument3 pagesJsa Fall ProtectionASLAM MULANINo ratings yet

- HSMC Employee Induction Procedure (Offices)Document3 pagesHSMC Employee Induction Procedure (Offices)Anonymous 4e7GNjzGWNo ratings yet

- Access Equipment Pre-Use Checklist: General: Identity Mark/ladder Tag in Place/legibleDocument2 pagesAccess Equipment Pre-Use Checklist: General: Identity Mark/ladder Tag in Place/legiblehasibuddinhNo ratings yet

- 400 Ton Crane DocumentsDocument7 pages400 Ton Crane Documentsalla malikNo ratings yet

- Safety Observtion Register FarhadDocument2 pagesSafety Observtion Register Farhadalla malikNo ratings yet

- Pipe Supports z4Document5 pagesPipe Supports z4alla malikNo ratings yet

- RA Flushing &Hydro-TestingDocument8 pagesRA Flushing &Hydro-Testingalla malikNo ratings yet

- 011 - WMS For Equipment ErectionDocument7 pages011 - WMS For Equipment Erectionalla malikNo ratings yet

- SOR Updated (Sandip Akole)Document20 pagesSOR Updated (Sandip Akole)alla malikNo ratings yet

- Transmittal FormatDocument1 pageTransmittal Formatalla malikNo ratings yet

- RA-22 For Grating Floorplate Installation ModificationDocument12 pagesRA-22 For Grating Floorplate Installation Modificationalla malikNo ratings yet

- Elcb-Mcb Inspection On Ele. Equipments-Eb-PdbDocument6 pagesElcb-Mcb Inspection On Ele. Equipments-Eb-Pdballa malikNo ratings yet

- Ra-20 Lifting and Errection of ChimneyDocument8 pagesRa-20 Lifting and Errection of Chimneyalla malikNo ratings yet

- Safety Calendar Oct'-22Document3 pagesSafety Calendar Oct'-22alla malikNo ratings yet

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- 001 - WMS - For - Unloading & Erection - of - Pipe Spools in Pipe Rack AreaDocument9 pages001 - WMS - For - Unloading & Erection - of - Pipe Spools in Pipe Rack Areaalla malikNo ratings yet

- Incident ReportDocument2 pagesIncident Reportalla malikNo ratings yet

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- 007 - WMS of K2 PasteDocument6 pages007 - WMS of K2 Pastealla malikNo ratings yet

- RA For Hydrostatic Pneumatic-Test and Flushing of Pipeline and Equipment - 17Document9 pagesRA For Hydrostatic Pneumatic-Test and Flushing of Pipeline and Equipment - 17alla malik100% (1)

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- RA For Air Compressor-RA 15Document8 pagesRA For Air Compressor-RA 15alla malikNo ratings yet

- Trimurti Fabricators PVT LTD.: Monsoon Protection PlanDocument4 pagesTrimurti Fabricators PVT LTD.: Monsoon Protection Planalla malikNo ratings yet

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- Traffic Management PLANDocument12 pagesTraffic Management PLANalla malikNo ratings yet

- 001 - WMS - For - Unloading & Erection - of - Pipe Spools in Pipe Rack Area PS29 To PS38Document7 pages001 - WMS - For - Unloading & Erection - of - Pipe Spools in Pipe Rack Area PS29 To PS38alla malikNo ratings yet

- Hearing Conservation Program For ConstructionDocument14 pagesHearing Conservation Program For Constructionalla malikNo ratings yet

- Gas Cylinders RADocument5 pagesGas Cylinders RAalla malikNo ratings yet

- 002 - WMS - For - Scaffolding & Erection of Pipe Rack Area PS29 To PS38Document7 pages002 - WMS - For - Scaffolding & Erection of Pipe Rack Area PS29 To PS38alla malikNo ratings yet

- Ra Radiography 10Document1 pageRa Radiography 10alla malikNo ratings yet

- RA For Chemical and Painting Activities - 07Document6 pagesRA For Chemical and Painting Activities - 07alla malikNo ratings yet

- Risk Assessment & Control Measure Worksheet (RA Sheet)Document5 pagesRisk Assessment & Control Measure Worksheet (RA Sheet)alla malikNo ratings yet

- RA - 11 (K2 Paste.Document4 pagesRA - 11 (K2 Paste.alla malikNo ratings yet

- Unit 25 Global Business EnvironmentDocument7 pagesUnit 25 Global Business Environmentumairali.taNo ratings yet

- 9 Golden RulesDocument39 pages9 Golden RuleskhurramNo ratings yet

- Bane NOR Eiendom AS - Company Presentation: Norway's Leading Hub DeveloperDocument36 pagesBane NOR Eiendom AS - Company Presentation: Norway's Leading Hub DeveloperDiego García VaqueroNo ratings yet

- Funeral Poverty Individual AssingmentDocument10 pagesFuneral Poverty Individual AssingmentMuhamad Nur HijirahNo ratings yet

- AI Adoption in Capital MarketsDocument16 pagesAI Adoption in Capital MarketsoghaffariNo ratings yet

- Rbs & Risk Based Internal Audit 22122022Document73 pagesRbs & Risk Based Internal Audit 22122022Sunny Kumar GuptaNo ratings yet

- Construction Regulations, 2003Document31 pagesConstruction Regulations, 2003Mercedes Cano MeseguerNo ratings yet

- Ism Chap - 1Document11 pagesIsm Chap - 1ShubhamNo ratings yet

- B. Technical Guide Notes - EnglishDocument45 pagesB. Technical Guide Notes - EnglishArman BentainNo ratings yet

- Press Publication 2009 Annual Report UkDocument268 pagesPress Publication 2009 Annual Report UkMalkeet SinghNo ratings yet

- DRRR - Q2 - Week 6Document5 pagesDRRR - Q2 - Week 6Shekaina Faith LozadaNo ratings yet

- L6 CTSE STO023 EPA AG Issue 2.1 - New Amended Version of Apprentice Handbook (6) (Part Version - Extracts Only)Document7 pagesL6 CTSE STO023 EPA AG Issue 2.1 - New Amended Version of Apprentice Handbook (6) (Part Version - Extracts Only)Laura CuestaNo ratings yet

- Notes For RiDocument25 pagesNotes For Rikk kkNo ratings yet

- Enabling Rural Coverage English February 2018 PDFDocument42 pagesEnabling Rural Coverage English February 2018 PDFtpat1No ratings yet

- BECK, U. Remapping Social Inequalities in An Age of Climate Change..for A Cosmopolitan Renewal of SociologyDocument17 pagesBECK, U. Remapping Social Inequalities in An Age of Climate Change..for A Cosmopolitan Renewal of SociologyrobertoNo ratings yet

- A Smarter Way of Preventative Maintenance 02Document21 pagesA Smarter Way of Preventative Maintenance 02HugoCabanillasNo ratings yet

- 2011 SRA Final ProgramDocument212 pages2011 SRA Final ProgramJuan CarlosNo ratings yet

- Module 8 Theories of EntrepreneurshipDocument48 pagesModule 8 Theories of EntrepreneurshipNikita SangalNo ratings yet

- Factsheet GB en Gb00byvxbg82Document9 pagesFactsheet GB en Gb00byvxbg82RocketNo ratings yet

- Tutorial Letter 204/0/2020: Information SecurityDocument7 pagesTutorial Letter 204/0/2020: Information SecurityEarnest KeteloNo ratings yet

- Essential Knowledge For Potential Offshore Installation ManagersDocument101 pagesEssential Knowledge For Potential Offshore Installation Managersseahorse88No ratings yet

- KettlewellDocument8 pagesKettlewellMusab HashmiNo ratings yet

- Module 4 - 8 - unified-course-pack-CWTS-1Document24 pagesModule 4 - 8 - unified-course-pack-CWTS-1Chloe CabingatanNo ratings yet

- Elective Paper BIL PDocument762 pagesElective Paper BIL PKashish Rana100% (1)

- Safety Management Plan TemplateDocument3 pagesSafety Management Plan TemplateMun ZiiNo ratings yet

- 2023-05 Bullets Point From The Final Agreements of The 6th CZWH in EcotoxicologyDocument3 pages2023-05 Bullets Point From The Final Agreements of The 6th CZWH in EcotoxicologyemmaNo ratings yet

- GMO Quarterly Letter-My Sister's Pension Assets 0412 GMO-GranthamDocument11 pagesGMO Quarterly Letter-My Sister's Pension Assets 0412 GMO-GranthamMarko AleksicNo ratings yet

- Capstone Project Report: "Factors Affecting The Trust of Customer in Online Shopping"Document25 pagesCapstone Project Report: "Factors Affecting The Trust of Customer in Online Shopping"Ekta Bansal50% (2)