Professional Documents

Culture Documents

VDSRL 20 - 34 /APP: Sequence

VDSRL 20 - 34 /APP: Sequence

Uploaded by

Sachin RamadasanCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Voslp /F 12: Overcenter ValvesDocument2 pagesVoslp /F 12: Overcenter ValvesSachin RamadasanNo ratings yet

- Voslp /F 38: Overcenter ValvesDocument2 pagesVoslp /F 38: Overcenter ValvesSachin RamadasanNo ratings yet

- VOSLP /F 34 (100) : Overcenter ValvesDocument2 pagesVOSLP /F 34 (100) : Overcenter ValvesSachin RamadasanNo ratings yet

- VDSD /B 12: SequenceDocument2 pagesVDSD /B 12: SequenceSachin RamadasanNo ratings yet

- Pressure Relief Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesPressure Relief Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNo ratings yet

- VDSD /B 100: SequenceDocument2 pagesVDSD /B 100: SequenceSachin RamadasanNo ratings yet

- Pressure Relief Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesPressure Relief Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNo ratings yet

- VDSD /B 34: SequenceDocument2 pagesVDSD /B 34: SequenceSachin RamadasanNo ratings yet

- Overcenter Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesOvercenter Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNo ratings yet

- 3aa00100 PDFDocument2 pages3aa00100 PDFSachin RamadasanNo ratings yet

- 3aa00200 PDFDocument2 pages3aa00200 PDFSachin RamadasanNo ratings yet

- VDFR 38-12: Flow Regulator Pressure CompensatedDocument2 pagesVDFR 38-12: Flow Regulator Pressure CompensatedSachin RamadasanNo ratings yet

- Pressure Relief Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesPressure Relief Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNo ratings yet

- Vaddl /va 12: Pressure Relief ValvesDocument2 pagesVaddl /va 12: Pressure Relief ValvesSachin RamadasanNo ratings yet

- 6H000200 PDFDocument2 pages6H000200 PDFSachin RamadasanNo ratings yet

- Vabal /SF 12: Overcenter ValvesDocument2 pagesVabal /SF 12: Overcenter ValvesSachin RamadasanNo ratings yet

- Vabal 38: Overcenter ValvesDocument2 pagesVabal 38: Overcenter ValvesSachin RamadasanNo ratings yet

- Vaa /ru /DL 12: Pressure Relief ValvesDocument2 pagesVaa /ru /DL 12: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Vabal /SF 38: Overcenter ValvesDocument2 pagesVabal /SF 38: Overcenter ValvesSachin RamadasanNo ratings yet

- Vabal 34: Overcenter ValvesDocument2 pagesVabal 34: Overcenter ValvesSachin RamadasanNo ratings yet

- VADDL /VA 34 (100) : Pressure Relief ValvesDocument2 pagesVADDL /VA 34 (100) : Pressure Relief ValvesSachin RamadasanNo ratings yet

- Vaa /ru /DL 38: Pressure Relief ValvesDocument2 pagesVaa /ru /DL 38: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Sd4 / Iam: SequenceDocument2 pagesSd4 / Iam: SequenceSachin RamadasanNo ratings yet

- VIA/AP 10-12: SequenceDocument2 pagesVIA/AP 10-12: SequenceSachin RamadasanNo ratings yet

- Sd11 / Iam: SequenceDocument2 pagesSd11 / Iam: SequenceSachin RamadasanNo ratings yet

- Vail /va 12: Pressure Relief ValvesDocument2 pagesVail /va 12: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Vaddl /va 38: Pressure Relief ValvesDocument2 pagesVaddl /va 38: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Vail /va 34: Pressure Relief ValvesDocument2 pagesVail /va 34: Pressure Relief ValvesSachin RamadasanNo ratings yet

- 1H050200 PDFDocument2 pages1H050200 PDFSachin RamadasanNo ratings yet

- 1H050100 PDFDocument2 pages1H050100 PDFSachin RamadasanNo ratings yet

- En Series Chemical CompositionDocument3 pagesEn Series Chemical CompositionAyanBiswas22100% (1)

- Trane Condensing UnitDocument16 pagesTrane Condensing Unitahmed abdelghanyNo ratings yet

- Rocket Engines - Origin, Developments and FutureDocument13 pagesRocket Engines - Origin, Developments and FutureDeepak Rawat100% (1)

- Acoples Rotex CatalogoDocument342 pagesAcoples Rotex CatalogoMichelle PedrozaNo ratings yet

- 175 325100Document2 pages175 325100sridhar100% (1)

- Viscous Fluid Flow: 5.1 ViscosityDocument6 pagesViscous Fluid Flow: 5.1 Viscositypasser byNo ratings yet

- Zkke With Ezdr HoistDocument64 pagesZkke With Ezdr HoistAnand PatelNo ratings yet

- ACI - Rectangular Tanks 2010Document18 pagesACI - Rectangular Tanks 2010Yulian Jesús100% (1)

- Bahrain World Trade Center BWTC The First Large-Scale Integration of Wind Turbines in A BuildingDocument11 pagesBahrain World Trade Center BWTC The First Large-Scale Integration of Wind Turbines in A Buildingrjchp100% (1)

- First Law of ThermodynamicsDocument57 pagesFirst Law of ThermodynamicsBhuvan Jit100% (1)

- Catalogo Brownings GeneralDocument66 pagesCatalogo Brownings GeneralReinaldo AzocarNo ratings yet

- ED1000Document4 pagesED1000Mohamed TahounNo ratings yet

- VOITH Retarder 115H-Axor After Sales Service ManualDocument135 pagesVOITH Retarder 115H-Axor After Sales Service ManualTautvydas Simukevičius100% (3)

- Jadwal PMTDocument7 pagesJadwal PMTManikNo ratings yet

- M Tech Dissertation Power SystemDocument7 pagesM Tech Dissertation Power SystemWriteMyStatisticsPaperAkron100% (1)

- JCB50 - JCB51 - JCB55: Mini ExcavatorDocument24 pagesJCB50 - JCB51 - JCB55: Mini ExcavatorNaivaidhNo ratings yet

- Fluid DynamicsDocument44 pagesFluid DynamicsSunmoon Al-HaddabiNo ratings yet

- Literature Review: Rail Structure Interaction Analysis and Its Effect On FoundationDocument11 pagesLiterature Review: Rail Structure Interaction Analysis and Its Effect On FoundationSHRADDHA KADAMNo ratings yet

- Conector TGC PresentacionDocument29 pagesConector TGC PresentaciongusfajNo ratings yet

- RulmanKatalogu 2018 05 18 15 - 24 - 59Document336 pagesRulmanKatalogu 2018 05 18 15 - 24 - 59Alvaro Felipe CharlinNo ratings yet

- Book 14Document6 pagesBook 14ebuka okohNo ratings yet

- Up and Down MillingDocument5 pagesUp and Down MillingranerxNo ratings yet

- Automotive TestingDocument4 pagesAutomotive Testingtahera aqeelNo ratings yet

- PPM Rebuilt Unit Manual: Testing MethodDocument35 pagesPPM Rebuilt Unit Manual: Testing MethodNGUYENTHEPHAT100% (3)

- KREBS Technequip Knife Gate Valves BrochureDocument16 pagesKREBS Technequip Knife Gate Valves Brochuresf wNo ratings yet

- Rakshaflo Taps Booklet 2019 PDFDocument16 pagesRakshaflo Taps Booklet 2019 PDFTabrez AlamNo ratings yet

- Technical CatalogueDocument53 pagesTechnical CatalogueDaniel MilosevskiNo ratings yet

- Applications of Newton's Laws: Equilibrium: Physics 513Document13 pagesApplications of Newton's Laws: Equilibrium: Physics 513Hannah GuillermoNo ratings yet

- Varela (2011) - Control of Vibration Induce by People Walking On Large Span Composite Floor Decks PDFDocument10 pagesVarela (2011) - Control of Vibration Induce by People Walking On Large Span Composite Floor Decks PDFJosé Francisco AnunciaçãoNo ratings yet

- A Numerical Approach To Simulate 3D Crack Propagation in Turbine BladesDocument11 pagesA Numerical Approach To Simulate 3D Crack Propagation in Turbine BladesHui JinNo ratings yet

VDSRL 20 - 34 /APP: Sequence

VDSRL 20 - 34 /APP: Sequence

Uploaded by

Sachin RamadasanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VDSRL 20 - 34 /APP: Sequence

VDSRL 20 - 34 /APP: Sequence

Uploaded by

Sachin RamadasanCopyright:

Available Formats

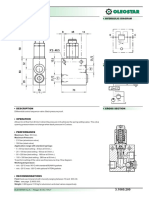

SEQUENCE

VDSRL 20 - 34 /APP

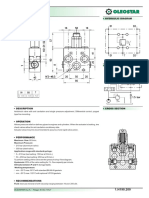

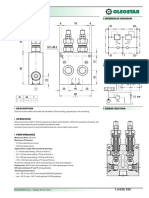

• DIMENSIONS (mm) • HYDRAULIC DIAGRAM

• ASSEMBLY DIAGRAM

• DESCRIPTION • CROSS SECTION

Direct control sequence valve. Back pressure proof.

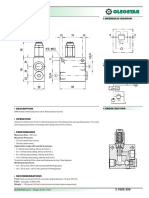

• OPERATION

Allows for oil flow from D into C when the pressure in D achieves the spring setting value. The valve

opening pressure does not change when back pressure in C arises.

• PERFORMANCE

Maximum flow : 120 l/min.

Maximum Pressure:

− 210 bar (aluminium valve)

− 350 bar (steel valve)

Application range with standard springs:

− 5 ÷ 50 bar (test setting: 30 bar at 5 l/min.)

− 20 ÷ 100 bar (test setting: 60 bar at 5 l/min.)

− 50 ÷ 220 bar (test setting: 160 bar at 5 l/min.)

− 180 ÷ 350 bar (test setting: 280 bar at 5 l/min.)

To perform setting of the valve see the pressure drop/ flow diagram.

Working temperature:

− min. -25°C max. 90°C with standard BUNA N gaskets

− min. -20°C max. 120°C with optional VITON gaskets

• RECOMMENDATIONS

Fluid: best use mineral oil with viscosity ranging between 10 and 200 cSt.

Filter: see page Z.9000.000.

Weight: 1.80 kg and 4.04 kg for aluminium and steel valves respectively.

OLEOSTAR S.p.A. – Reggio Emilia ITALY 3.1050.300

18/12/98

Material: internal components made out of high-grade steel duly treated and fabricated.

For more information please ask our technical office.

Variations and modifications of technical features and dimensions are reserved. OLEOSTAR S.p.A. also reserves the right to stop production of

each and any model listed in the catalogue with no notice.

Copyrights on the text contained herein belong to OLEOSTAR S.p.A. . Partial and full reproductions or copies of this catalogue are forbidden.

• RATING DIAGRAMS

• CODE NUMBER

VDSRL 20 - 34 / APP/ pp . S / pp

Pressure settings (bar) Body material

TB) 5÷50 _ Aluminium

TV) 20÷100 ac Steel

TS) 50÷220

TR) 100÷350

3.1050.300

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Voslp /F 12: Overcenter ValvesDocument2 pagesVoslp /F 12: Overcenter ValvesSachin RamadasanNo ratings yet

- Voslp /F 38: Overcenter ValvesDocument2 pagesVoslp /F 38: Overcenter ValvesSachin RamadasanNo ratings yet

- VOSLP /F 34 (100) : Overcenter ValvesDocument2 pagesVOSLP /F 34 (100) : Overcenter ValvesSachin RamadasanNo ratings yet

- VDSD /B 12: SequenceDocument2 pagesVDSD /B 12: SequenceSachin RamadasanNo ratings yet

- Pressure Relief Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesPressure Relief Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNo ratings yet

- VDSD /B 100: SequenceDocument2 pagesVDSD /B 100: SequenceSachin RamadasanNo ratings yet

- Pressure Relief Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesPressure Relief Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNo ratings yet

- VDSD /B 34: SequenceDocument2 pagesVDSD /B 34: SequenceSachin RamadasanNo ratings yet

- Overcenter Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesOvercenter Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNo ratings yet

- 3aa00100 PDFDocument2 pages3aa00100 PDFSachin RamadasanNo ratings yet

- 3aa00200 PDFDocument2 pages3aa00200 PDFSachin RamadasanNo ratings yet

- VDFR 38-12: Flow Regulator Pressure CompensatedDocument2 pagesVDFR 38-12: Flow Regulator Pressure CompensatedSachin RamadasanNo ratings yet

- Pressure Relief Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesPressure Relief Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNo ratings yet

- Vaddl /va 12: Pressure Relief ValvesDocument2 pagesVaddl /va 12: Pressure Relief ValvesSachin RamadasanNo ratings yet

- 6H000200 PDFDocument2 pages6H000200 PDFSachin RamadasanNo ratings yet

- Vabal /SF 12: Overcenter ValvesDocument2 pagesVabal /SF 12: Overcenter ValvesSachin RamadasanNo ratings yet

- Vabal 38: Overcenter ValvesDocument2 pagesVabal 38: Overcenter ValvesSachin RamadasanNo ratings yet

- Vaa /ru /DL 12: Pressure Relief ValvesDocument2 pagesVaa /ru /DL 12: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Vabal /SF 38: Overcenter ValvesDocument2 pagesVabal /SF 38: Overcenter ValvesSachin RamadasanNo ratings yet

- Vabal 34: Overcenter ValvesDocument2 pagesVabal 34: Overcenter ValvesSachin RamadasanNo ratings yet

- VADDL /VA 34 (100) : Pressure Relief ValvesDocument2 pagesVADDL /VA 34 (100) : Pressure Relief ValvesSachin RamadasanNo ratings yet

- Vaa /ru /DL 38: Pressure Relief ValvesDocument2 pagesVaa /ru /DL 38: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Sd4 / Iam: SequenceDocument2 pagesSd4 / Iam: SequenceSachin RamadasanNo ratings yet

- VIA/AP 10-12: SequenceDocument2 pagesVIA/AP 10-12: SequenceSachin RamadasanNo ratings yet

- Sd11 / Iam: SequenceDocument2 pagesSd11 / Iam: SequenceSachin RamadasanNo ratings yet

- Vail /va 12: Pressure Relief ValvesDocument2 pagesVail /va 12: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Vaddl /va 38: Pressure Relief ValvesDocument2 pagesVaddl /va 38: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Vail /va 34: Pressure Relief ValvesDocument2 pagesVail /va 34: Pressure Relief ValvesSachin RamadasanNo ratings yet

- 1H050200 PDFDocument2 pages1H050200 PDFSachin RamadasanNo ratings yet

- 1H050100 PDFDocument2 pages1H050100 PDFSachin RamadasanNo ratings yet

- En Series Chemical CompositionDocument3 pagesEn Series Chemical CompositionAyanBiswas22100% (1)

- Trane Condensing UnitDocument16 pagesTrane Condensing Unitahmed abdelghanyNo ratings yet

- Rocket Engines - Origin, Developments and FutureDocument13 pagesRocket Engines - Origin, Developments and FutureDeepak Rawat100% (1)

- Acoples Rotex CatalogoDocument342 pagesAcoples Rotex CatalogoMichelle PedrozaNo ratings yet

- 175 325100Document2 pages175 325100sridhar100% (1)

- Viscous Fluid Flow: 5.1 ViscosityDocument6 pagesViscous Fluid Flow: 5.1 Viscositypasser byNo ratings yet

- Zkke With Ezdr HoistDocument64 pagesZkke With Ezdr HoistAnand PatelNo ratings yet

- ACI - Rectangular Tanks 2010Document18 pagesACI - Rectangular Tanks 2010Yulian Jesús100% (1)

- Bahrain World Trade Center BWTC The First Large-Scale Integration of Wind Turbines in A BuildingDocument11 pagesBahrain World Trade Center BWTC The First Large-Scale Integration of Wind Turbines in A Buildingrjchp100% (1)

- First Law of ThermodynamicsDocument57 pagesFirst Law of ThermodynamicsBhuvan Jit100% (1)

- Catalogo Brownings GeneralDocument66 pagesCatalogo Brownings GeneralReinaldo AzocarNo ratings yet

- ED1000Document4 pagesED1000Mohamed TahounNo ratings yet

- VOITH Retarder 115H-Axor After Sales Service ManualDocument135 pagesVOITH Retarder 115H-Axor After Sales Service ManualTautvydas Simukevičius100% (3)

- Jadwal PMTDocument7 pagesJadwal PMTManikNo ratings yet

- M Tech Dissertation Power SystemDocument7 pagesM Tech Dissertation Power SystemWriteMyStatisticsPaperAkron100% (1)

- JCB50 - JCB51 - JCB55: Mini ExcavatorDocument24 pagesJCB50 - JCB51 - JCB55: Mini ExcavatorNaivaidhNo ratings yet

- Fluid DynamicsDocument44 pagesFluid DynamicsSunmoon Al-HaddabiNo ratings yet

- Literature Review: Rail Structure Interaction Analysis and Its Effect On FoundationDocument11 pagesLiterature Review: Rail Structure Interaction Analysis and Its Effect On FoundationSHRADDHA KADAMNo ratings yet

- Conector TGC PresentacionDocument29 pagesConector TGC PresentaciongusfajNo ratings yet

- RulmanKatalogu 2018 05 18 15 - 24 - 59Document336 pagesRulmanKatalogu 2018 05 18 15 - 24 - 59Alvaro Felipe CharlinNo ratings yet

- Book 14Document6 pagesBook 14ebuka okohNo ratings yet

- Up and Down MillingDocument5 pagesUp and Down MillingranerxNo ratings yet

- Automotive TestingDocument4 pagesAutomotive Testingtahera aqeelNo ratings yet

- PPM Rebuilt Unit Manual: Testing MethodDocument35 pagesPPM Rebuilt Unit Manual: Testing MethodNGUYENTHEPHAT100% (3)

- KREBS Technequip Knife Gate Valves BrochureDocument16 pagesKREBS Technequip Knife Gate Valves Brochuresf wNo ratings yet

- Rakshaflo Taps Booklet 2019 PDFDocument16 pagesRakshaflo Taps Booklet 2019 PDFTabrez AlamNo ratings yet

- Technical CatalogueDocument53 pagesTechnical CatalogueDaniel MilosevskiNo ratings yet

- Applications of Newton's Laws: Equilibrium: Physics 513Document13 pagesApplications of Newton's Laws: Equilibrium: Physics 513Hannah GuillermoNo ratings yet

- Varela (2011) - Control of Vibration Induce by People Walking On Large Span Composite Floor Decks PDFDocument10 pagesVarela (2011) - Control of Vibration Induce by People Walking On Large Span Composite Floor Decks PDFJosé Francisco AnunciaçãoNo ratings yet

- A Numerical Approach To Simulate 3D Crack Propagation in Turbine BladesDocument11 pagesA Numerical Approach To Simulate 3D Crack Propagation in Turbine BladesHui JinNo ratings yet