Professional Documents

Culture Documents

Voslp /F 12: Overcenter Valves

Voslp /F 12: Overcenter Valves

Uploaded by

Sachin RamadasanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Voslp /F 12: Overcenter Valves

Voslp /F 12: Overcenter Valves

Uploaded by

Sachin RamadasanCopyright:

Available Formats

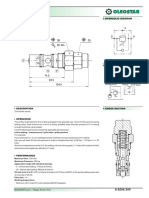

OVERCENTER VALVES

VOSLP /F 12

• DIMENSIONS (mm) • HYDRAULIC DIAGRAM

• ASSEMBLY DIAGRAM

• DESCRIPTION

Single overcenter valves, external pilot operated type, face mounting. Cartridge construction.

• OPERATION

The oil flow is allowed from D1 to U1 and is stopped in the opposite way (from U1 to D1) up to the spring setting value. Free oil flow from U1 to D1 is

strictly possible when the pilot pressure in P is strong enough to pilot the valve poppet.

Use the following formula to assert the applicable pilot pressure:

(valve setting – load pressure) ÷ pilot ratio = pilot pressure

For example:

If your pilot ratio is 1:4, your setting pressure is 250 bar and your load pressure is 130 bar

then you will need 30 bar pilot pressure in order to displace the load. [(250 bar – 130 bar) ÷ 4 = 30 bar)].

Should counterpressure arise in D1, the setting value of valve poppet (1:1 ratio) will increase and the pilot pressure be negatively affected (1:1 ratio).

Lack of overcenter stability and troublesome motion even after complete valve assembly, will suggest that the valve application may require a PG

version. Please contact our technical service for action.

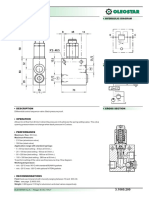

• PERFORMANCE

Maximum flow: 70 l/min

Maximum Pressure:

− Aluminium body: 210 bar

− Steel body: 350 bar

Application range with standard springs:

− 5 - 210 bar (test setting: 170 bar at 5 l/min)

− 50 - 350 bar (test setting: 280 bar at 5 l/min)

− 100 - 700 bar (test setting: 350 bar at 5 l/min)

Oil leak from U1 to D1: 0.25 cc/minute (5 drops) at 210 bar and 80% of the spring setting value with oil viscosity of 46 cSt

Pilot ratio:

− 1:7 (standard type)

OLEOSTAR S.p.A. – Reggio Emilia ITALY 6.2500.200

31/05/1999

− 1:3 (on request only)

Working temperature:

− Minimum -25°C max 90°C with standard BUNA N gaskets

− Minimum -20°C max 120°C with optional VITON gaskets

• RECOMMENDATIONS

Fluid: best use mineral oil with viscosity ranging between 10 and 200 cSt

Filter: see page Z.9000.000.

Weight: aluminium body: 0.96 kg - steel body: 1.86 kg

Overcenter cartridge: see page 1.2000.200.

Material: internal components made out of high grade steel duly treated and fabricated.

For more information please ask our technical office.

Variations and modifications of technical features and dimensions are reserved. OLEOSTAR S.p.A. also reserves the right to stop production of

each and any model listed in the catalogue with no notice.

Copyrights on the text contained herein belong to OLEOSTAR S.p.A. .Partial and full reproductions or copies of this catalogue are forbidden.

• RATING DIAGRAMS

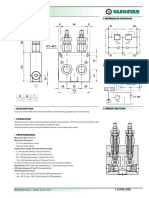

• CODE NUMBER

VOSLP /F 12 / p . S .pp . pp . pp / pp

Pressure Pilot ratio Type of pilot Check valve seat Body

settings (bar) material

p3)1:3 (s tandard ) _ without damper (standard) _ See body

TS) 5÷210 p7) 1:7 PG)with damper VRR) Hardened steel _ Aluminium

TR) 50÷350 (s tandard ) ac Steel

TG) 100÷700

6.2500.200

You might also like

- English Translation of A Birth Certificate From Honduras PDFDocument1 pageEnglish Translation of A Birth Certificate From Honduras PDFDulce m vazquez67% (6)

- SRP 1212Document27 pagesSRP 1212waleedyehia100% (4)

- SRP 1010Document29 pagesSRP 1010waleedyehia100% (1)

- GDI DENSO InjectorsDocument19 pagesGDI DENSO InjectorsPāvels SmilgaNo ratings yet

- Transformation Leadership in A Digital Era: EY StrategyDocument24 pagesTransformation Leadership in A Digital Era: EY StrategyakashNo ratings yet

- Vail 5 - PP: Pressure Relief ValvesDocument2 pagesVail 5 - PP: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Mitsubishi Modelo S12h-Y1pta-3 - Mny1000 PDFDocument3 pagesMitsubishi Modelo S12h-Y1pta-3 - Mny1000 PDFSalvador Millán EstradaNo ratings yet

- Vabal /SF 12: Overcenter ValvesDocument2 pagesVabal /SF 12: Overcenter ValvesSachin RamadasanNo ratings yet

- 6H000200 PDFDocument2 pages6H000200 PDFSachin RamadasanNo ratings yet

- Voslp /F 38: Overcenter ValvesDocument2 pagesVoslp /F 38: Overcenter ValvesSachin RamadasanNo ratings yet

- Vabal 38: Overcenter ValvesDocument2 pagesVabal 38: Overcenter ValvesSachin RamadasanNo ratings yet

- Vabal /SF 38: Overcenter ValvesDocument2 pagesVabal /SF 38: Overcenter ValvesSachin RamadasanNo ratings yet

- Vabal 34: Overcenter ValvesDocument2 pagesVabal 34: Overcenter ValvesSachin RamadasanNo ratings yet

- VOSLP /F 34 (100) : Overcenter ValvesDocument2 pagesVOSLP /F 34 (100) : Overcenter ValvesSachin RamadasanNo ratings yet

- Overcenter Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesOvercenter Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNo ratings yet

- Overcenter Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesOvercenter Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNo ratings yet

- Vabal/Sc/F 12/omr: Overcenter Valves (Danfoss Motor)Document2 pagesVabal/Sc/F 12/omr: Overcenter Valves (Danfoss Motor)jbsb1No ratings yet

- Vaddl /va 12: Pressure Relief ValvesDocument2 pagesVaddl /va 12: Pressure Relief ValvesSachin RamadasanNo ratings yet

- 1H050200 PDFDocument2 pages1H050200 PDFSachin RamadasanNo ratings yet

- Vaddl 12: Pressure Relief ValvesDocument2 pagesVaddl 12: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Vaddl /va 38: Pressure Relief ValvesDocument2 pagesVaddl /va 38: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Vail /va 12: Pressure Relief ValvesDocument2 pagesVail /va 12: Pressure Relief ValvesSachin RamadasanNo ratings yet

- 1H000200 PDFDocument2 pages1H000200 PDFSachin RamadasanNo ratings yet

- VAIL 10 - PP: Pressure Relief ValvesDocument2 pagesVAIL 10 - PP: Pressure Relief ValvesSachin RamadasanNo ratings yet

- 1H000200 PDFDocument2 pages1H000200 PDFSachin RamadasanNo ratings yet

- 1H000200 PDFDocument2 pages1H000200 PDFSachin RamadasanNo ratings yet

- Vaa /ru /DL 12: Pressure Relief ValvesDocument2 pagesVaa /ru /DL 12: Pressure Relief ValvesSachin RamadasanNo ratings yet

- 1H050100 PDFDocument2 pages1H050100 PDFSachin RamadasanNo ratings yet

- 1H050100 PDFDocument2 pages1H050100 PDFSachin RamadasanNo ratings yet

- 1H050100 PDFDocument2 pages1H050100 PDFSachin RamadasanNo ratings yet

- Hydac Return Line Filter RFDDocument4 pagesHydac Return Line Filter RFDCarlos Andrés CuelloNo ratings yet

- Local Solutions For Individual Customers Worldwide: Accumulators & AccessoriesDocument20 pagesLocal Solutions For Individual Customers Worldwide: Accumulators & Accessoriesamjed_de_enimNo ratings yet

- Pressure Relief Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesPressure Relief Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNo ratings yet

- VADDL /VA 34 (100) : Pressure Relief ValvesDocument2 pagesVADDL /VA 34 (100) : Pressure Relief ValvesSachin RamadasanNo ratings yet

- VRPRL 38: Pressure Reducing ValvesDocument2 pagesVRPRL 38: Pressure Reducing ValvesHELY PEÑANo ratings yet

- VDSD /B 12: SequenceDocument2 pagesVDSD /B 12: SequenceSachin RamadasanNo ratings yet

- Prop. Pressure-Reducing/Relieving Cartridge, Size SAE 08Document6 pagesProp. Pressure-Reducing/Relieving Cartridge, Size SAE 08galih kalokaNo ratings yet

- Vaa /ru /DL 38: Pressure Relief ValvesDocument2 pagesVaa /ru /DL 38: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Brueninghaus Hydromatik Rexroth A4VSG Pump: Closed Circuit Variable Hydraulic Piston A4VG PumpDocument14 pagesBrueninghaus Hydromatik Rexroth A4VSG Pump: Closed Circuit Variable Hydraulic Piston A4VG PumpLuciano Alencastro100% (1)

- A7volrdh163p PPB02Document19 pagesA7volrdh163p PPB02Jose Maria CuencaNo ratings yet

- 1377 Duragauge Pressure Gauge: Data SheetDocument4 pages1377 Duragauge Pressure Gauge: Data SheetkarthikNo ratings yet

- 3042F331 DATA CatalogDocument2 pages3042F331 DATA CatalogMilanNo ratings yet

- Sequence: Dimensions (MM) Hydraulic DiagramDocument2 pagesSequence: Dimensions (MM) Hydraulic DiagramSachin RamadasanNo ratings yet

- Specifications: DaikinDocument17 pagesSpecifications: DaikinyoyokNo ratings yet

- 9900 Series DatasheetDocument3 pages9900 Series DatasheetHans HongNo ratings yet

- VSO-DE Pilot Operated Check, DualDocument2 pagesVSO-DE Pilot Operated Check, DualHector MoragaNo ratings yet

- Pressure Reducing and Relieving, Direct Acting Spool Damped TypeDocument2 pagesPressure Reducing and Relieving, Direct Acting Spool Damped TypetecnicomanelNo ratings yet

- Arv Facts PDFDocument9 pagesArv Facts PDFReyNo ratings yet

- 9452 SamsungDocument13 pages9452 SamsungEdward José Chacín R.No ratings yet

- Single Counterbalance: A-VBSO-SE-33-PL 08.45.85 - X - Y - ZDocument2 pagesSingle Counterbalance: A-VBSO-SE-33-PL 08.45.85 - X - Y - ZAndon XhumbaNo ratings yet

- Vail /va 34: Pressure Relief ValvesDocument2 pagesVail /va 34: Pressure Relief ValvesSachin RamadasanNo ratings yet

- PU126TI E1F MotorDocument2 pagesPU126TI E1F MotorANGEL UQUILLASNo ratings yet

- Od92x12y00 Re18323-62Document4 pagesOd92x12y00 Re18323-62pttNo ratings yet

- Check d180 - HR KRDocument4 pagesCheck d180 - HR KRDANIZACHNo ratings yet

- Ingersoll Rand p425 Wip Rev SeccionDocument27 pagesIngersoll Rand p425 Wip Rev SeccionMartin RamirezNo ratings yet

- Rexroth Bomba HidraulicaDocument52 pagesRexroth Bomba HidraulicaHernan LopezNo ratings yet

- Rexroth Dual Counterbalance ValveDocument2 pagesRexroth Dual Counterbalance ValveLucas ScioscioliNo ratings yet

- Model GP-1000 SeriesDocument13 pagesModel GP-1000 SeriesivorypearlsbNo ratings yet

- Od940118yz Re18323-65Document4 pagesOd940118yz Re18323-65Mechanical2022No ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- VDSD /B 12: SequenceDocument2 pagesVDSD /B 12: SequenceSachin RamadasanNo ratings yet

- Voslp /F 38: Overcenter ValvesDocument2 pagesVoslp /F 38: Overcenter ValvesSachin RamadasanNo ratings yet

- VOSLP /F 34 (100) : Overcenter ValvesDocument2 pagesVOSLP /F 34 (100) : Overcenter ValvesSachin RamadasanNo ratings yet

- VDSD /B 34: SequenceDocument2 pagesVDSD /B 34: SequenceSachin RamadasanNo ratings yet

- Overcenter Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesOvercenter Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNo ratings yet

- Pressure Relief Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesPressure Relief Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNo ratings yet

- Pressure Relief Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesPressure Relief Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNo ratings yet

- VDSD /B 100: SequenceDocument2 pagesVDSD /B 100: SequenceSachin RamadasanNo ratings yet

- Pressure Relief Valves: Dimensions (MM) Hydraulic DiagramDocument2 pagesPressure Relief Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNo ratings yet

- 3aa00200 PDFDocument2 pages3aa00200 PDFSachin RamadasanNo ratings yet

- 6H000200 PDFDocument2 pages6H000200 PDFSachin RamadasanNo ratings yet

- 3aa00100 PDFDocument2 pages3aa00100 PDFSachin RamadasanNo ratings yet

- VDFR 38-12: Flow Regulator Pressure CompensatedDocument2 pagesVDFR 38-12: Flow Regulator Pressure CompensatedSachin RamadasanNo ratings yet

- Vaddl /va 38: Pressure Relief ValvesDocument2 pagesVaddl /va 38: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Vabal /SF 38: Overcenter ValvesDocument2 pagesVabal /SF 38: Overcenter ValvesSachin RamadasanNo ratings yet

- Vabal 34: Overcenter ValvesDocument2 pagesVabal 34: Overcenter ValvesSachin RamadasanNo ratings yet

- Vabal /SF 12: Overcenter ValvesDocument2 pagesVabal /SF 12: Overcenter ValvesSachin RamadasanNo ratings yet

- Sd4 / Iam: SequenceDocument2 pagesSd4 / Iam: SequenceSachin RamadasanNo ratings yet

- Vabal 38: Overcenter ValvesDocument2 pagesVabal 38: Overcenter ValvesSachin RamadasanNo ratings yet

- VIA/AP 10-12: SequenceDocument2 pagesVIA/AP 10-12: SequenceSachin RamadasanNo ratings yet

- Vaddl /va 12: Pressure Relief ValvesDocument2 pagesVaddl /va 12: Pressure Relief ValvesSachin RamadasanNo ratings yet

- VADDL /VA 34 (100) : Pressure Relief ValvesDocument2 pagesVADDL /VA 34 (100) : Pressure Relief ValvesSachin RamadasanNo ratings yet

- Vaa /ru /DL 38: Pressure Relief ValvesDocument2 pagesVaa /ru /DL 38: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Sd11 / Iam: SequenceDocument2 pagesSd11 / Iam: SequenceSachin RamadasanNo ratings yet

- Vaa /ru /DL 12: Pressure Relief ValvesDocument2 pagesVaa /ru /DL 12: Pressure Relief ValvesSachin RamadasanNo ratings yet

- 1H050200 PDFDocument2 pages1H050200 PDFSachin RamadasanNo ratings yet

- Vail /va 34: Pressure Relief ValvesDocument2 pagesVail /va 34: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Vail /va 12: Pressure Relief ValvesDocument2 pagesVail /va 12: Pressure Relief ValvesSachin RamadasanNo ratings yet

- 1H050100 PDFDocument2 pages1H050100 PDFSachin RamadasanNo ratings yet

- Vaddl 12: Pressure Relief ValvesDocument2 pagesVaddl 12: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Chapter 10 - Rock FoundationsDocument16 pagesChapter 10 - Rock FoundationsLupyana wa LupyanaNo ratings yet

- C2a. Logic SimplificationDocument53 pagesC2a. Logic SimplificationNicolaas LimNo ratings yet

- UEFA Financial Fair Play, Club Toolkit 2013Document110 pagesUEFA Financial Fair Play, Club Toolkit 2013Tifoso BilanciatoNo ratings yet

- 009 (MEP COMPARE) 19-01-15 - ONYX Reply - 19-01-16 - PB - JVDocument31 pages009 (MEP COMPARE) 19-01-15 - ONYX Reply - 19-01-16 - PB - JVJimmy WalkerNo ratings yet

- Social MediaDocument1 pageSocial MediaReham Al-EkhtiarNo ratings yet

- Summer Internship File Very ImportantDocument32 pagesSummer Internship File Very ImportantYash SharmaNo ratings yet

- Simple Circuit Design Tutorial For PoE ApplicationsDocument10 pagesSimple Circuit Design Tutorial For PoE ApplicationsTayyeb AliNo ratings yet

- CandidateHallTicket PDFDocument1 pageCandidateHallTicket PDFAditya YadavNo ratings yet

- AGA Dry Ice Brochure A4 UK - tcm639-101282Document20 pagesAGA Dry Ice Brochure A4 UK - tcm639-101282শুভঙ্করNo ratings yet

- 096 Floor Statement On Presidents Decision To Increase Troops in Iraq Obama SpeechDocument3 pages096 Floor Statement On Presidents Decision To Increase Troops in Iraq Obama SpeechDivya Deepika MaddireddyNo ratings yet

- Vood 100 200 ConfigDocument118 pagesVood 100 200 ConfigasgariNo ratings yet

- 02 Security Market Indices and Market Efficiency PDFDocument27 pages02 Security Market Indices and Market Efficiency PDFNgân Hà NguyễnNo ratings yet

- The Constitution of BD With Comments N Case Laws by Latifur RahmanDocument275 pagesThe Constitution of BD With Comments N Case Laws by Latifur RahmanMd Ahsan-Ul- Kabir100% (1)

- Nestle Waters Forecasting Improv Ment SlidesDocument37 pagesNestle Waters Forecasting Improv Ment Slidesamitwin1983No ratings yet

- 1-5 Highway ProgrammingDocument12 pages1-5 Highway ProgrammingBeau NorNo ratings yet

- Rights in Land and Pattadar Pass Books Rules 1989Document42 pagesRights in Land and Pattadar Pass Books Rules 1989raju634No ratings yet

- Raxxess Commercial Product Catalog June 2010Document48 pagesRaxxess Commercial Product Catalog June 2010Today's NameNo ratings yet

- The Rise of Judicial Governance in The Supreme Court of IndiaDocument56 pagesThe Rise of Judicial Governance in The Supreme Court of IndiaMAHANTESH GNo ratings yet

- Recereum WhitePaperDocument23 pagesRecereum WhitePaperLord VNo ratings yet

- Ge MMWDocument7 pagesGe MMWJunjie Dela RamosNo ratings yet

- Vacio REF-SVG001-EN EvacuationDocument16 pagesVacio REF-SVG001-EN EvacuationRuiz Caldera Eloy E.No ratings yet

- JP Programme Officer PAK-OxfamNDocument2 pagesJP Programme Officer PAK-OxfamNxtremist2001No ratings yet

- Mathematics7 Q4 Mod3 PresentationofData-v3Document29 pagesMathematics7 Q4 Mod3 PresentationofData-v3charitocalangan605No ratings yet

- Honor H30-U10 V100R001C432B109 Upgrade GuidelineDocument15 pagesHonor H30-U10 V100R001C432B109 Upgrade GuidelineFahad HussainNo ratings yet

- CMD Message: Deepak Kumar Hota Chairman & Managing Director BemlDocument1 pageCMD Message: Deepak Kumar Hota Chairman & Managing Director BemlMadhurya KrishnaNo ratings yet

- Quick Installation Guide: Connecting The Ramp Timer Pro To Your LED Light(s)Document6 pagesQuick Installation Guide: Connecting The Ramp Timer Pro To Your LED Light(s)maoescobarNo ratings yet

- Explained - Hydrophobic and HydrophilicDocument2 pagesExplained - Hydrophobic and HydrophilicSiddhartha Narasimha Reddy MNo ratings yet

- Mitac 8066mpDocument154 pagesMitac 8066mpcosminconstantinNo ratings yet