Professional Documents

Culture Documents

Approach For Cost Determination of Electro-Mechani

Approach For Cost Determination of Electro-Mechani

Uploaded by

Frezer SolomonCopyright:

Available Formats

You might also like

- Runoff River Plant Statusand ProspectsDocument5 pagesRunoff River Plant Statusand ProspectsJanaisha Bai TitoNo ratings yet

- Cost 2222Document22 pagesCost 2222Habte TokichawNo ratings yet

- Design of A Water Wheel For A Low Head Micro Hydro PDFDocument7 pagesDesign of A Water Wheel For A Low Head Micro Hydro PDFGaurav RanmaleNo ratings yet

- Sustainable Energy Technologies and Assessments: Krishna Kumar, R.P. SainiDocument21 pagesSustainable Energy Technologies and Assessments: Krishna Kumar, R.P. Sainijuan vargas tarazonaNo ratings yet

- Ajol File Journals - 483 - Articles - 123631 - Submission - Proof - 123631 5701 338116 1 10 20151009Document12 pagesAjol File Journals - 483 - Articles - 123631 - Submission - Proof - 123631 5701 338116 1 10 20151009Ha ApaNo ratings yet

- Modelling of Underground Cables For High Voltage TransmissionDocument12 pagesModelling of Underground Cables For High Voltage TransmissionErgin ÖzdikicioğluNo ratings yet

- Introduction Pinaka Final 2Document20 pagesIntroduction Pinaka Final 2Birthley RagasaNo ratings yet

- SeletionofturbinesDocument8 pagesSeletionofturbinesrrNo ratings yet

- Vineet K SinghDocument5 pagesVineet K SingholongkodokNo ratings yet

- PDFDocument7 pagesPDFAhmad FahrudinNo ratings yet

- Design of Micro-Hydro-Electric Power StationDocument10 pagesDesign of Micro-Hydro-Electric Power StationRiana KuliahNo ratings yet

- Design of Micro-Hydro-Electric Power StationDocument10 pagesDesign of Micro-Hydro-Electric Power StationCY KangNo ratings yet

- Review of Optimal Selection of Turbines For Hydroelectric ProjectsDocument7 pagesReview of Optimal Selection of Turbines For Hydroelectric ProjectsephremNo ratings yet

- Vineet K SinghDocument5 pagesVineet K SinghparthasutradharNo ratings yet

- Modelling and Simulation of Micro Hydro Power Plant Using Matlab SimulinkDocument14 pagesModelling and Simulation of Micro Hydro Power Plant Using Matlab Simulinkcontrol roomNo ratings yet

- Harvesting Electricity From Water Mains Hydropower System Generates Power From Water PipelinesDocument8 pagesHarvesting Electricity From Water Mains Hydropower System Generates Power From Water PipelinesFares NasserNo ratings yet

- 416 432ijecs PDFDocument17 pages416 432ijecs PDFPaul CarcasiNo ratings yet

- Uttarakhand MHPDocument10 pagesUttarakhand MHPVineet SinghNo ratings yet

- Small, Mini, Micro and Pico Hydro Power Plant Scope Challenges Deployment in Indian Context-34921 PDFDocument10 pagesSmall, Mini, Micro and Pico Hydro Power Plant Scope Challenges Deployment in Indian Context-34921 PDFGAURANGNo ratings yet

- Micro Hydro Power Plant Using Sewage Water of Hayatabad PeshawarDocument6 pagesMicro Hydro Power Plant Using Sewage Water of Hayatabad PeshawarShahzaib KhanNo ratings yet

- Captive Power Plant - A Case Study of Cetp Ichalkaranji, MaharashtraDocument6 pagesCaptive Power Plant - A Case Study of Cetp Ichalkaranji, MaharashtraesatjournalsNo ratings yet

- Small Mini Hydro Plants - EL6010Document77 pagesSmall Mini Hydro Plants - EL6010k4nishkkNo ratings yet

- Abubakar Proposal OldDocument5 pagesAbubakar Proposal OldAbubakar QaziNo ratings yet

- Designing of Load Response Generation Synchronized 15MW Hydropower Station and Simulation Based Electromechanical and Structural AnalysisDocument17 pagesDesigning of Load Response Generation Synchronized 15MW Hydropower Station and Simulation Based Electromechanical and Structural AnalysismilanNo ratings yet

- Hydropower Plant Report 4 PDFDocument17 pagesHydropower Plant Report 4 PDFadigkpupNo ratings yet

- Prediction of Small Hydropower Plant Power Production in Himreen Lake Dam (HLD) Using Artificial Neural NetworkDocument11 pagesPrediction of Small Hydropower Plant Power Production in Himreen Lake Dam (HLD) Using Artificial Neural NetworkJesus Miguel RamosNo ratings yet

- Hydro-Power Generation For A Water Treatment System and Method of Supplying Electricity Using A Flow of LiquidDocument8 pagesHydro-Power Generation For A Water Treatment System and Method of Supplying Electricity Using A Flow of LiquidRianna RamosNo ratings yet

- Exemple de Calcul D'ampacité PDFDocument11 pagesExemple de Calcul D'ampacité PDFjagayaNo ratings yet

- Determination of Installation Capacity in Reservoir Hydro-Power Plants Considering Technical, Economical and Reliability IndicesDocument10 pagesDetermination of Installation Capacity in Reservoir Hydro-Power Plants Considering Technical, Economical and Reliability IndicesNov Dion FuadillahNo ratings yet

- Water Turbine SystemDocument9 pagesWater Turbine SystemTarajneet SinghNo ratings yet

- IV ReportDocument22 pagesIV ReportHemant ZopeNo ratings yet

- Design N Consid Derations Sofmic Cro-Hydr Ro-Electr Ric Powe Er PlantDocument11 pagesDesign N Consid Derations Sofmic Cro-Hydr Ro-Electr Ric Powe Er PlanttsuakNo ratings yet

- Run Off River Plant: Status and Prospects: Hemant Sharma, Jasvir SinghDocument4 pagesRun Off River Plant: Status and Prospects: Hemant Sharma, Jasvir SinghArvin SlayerNo ratings yet

- Fluid Power Engineering PDFDocument164 pagesFluid Power Engineering PDFAkki100% (1)

- Micro Hydropower Plant With Rotor's Pintle and Hydrodynamic Profile of BladesDocument4 pagesMicro Hydropower Plant With Rotor's Pintle and Hydrodynamic Profile of Bladesadan25tulaNo ratings yet

- Analysis On Hydrokinetic TurbineDocument10 pagesAnalysis On Hydrokinetic TurbineKartik AtriNo ratings yet

- Modeling and Control of Isolated Micro-Hydro Power Plant With Battery Storage SystemDocument7 pagesModeling and Control of Isolated Micro-Hydro Power Plant With Battery Storage SystemZainal Arif RochimNo ratings yet

- Renewable and Sustainable Energy Reviews: A B C D e A F G H I J KDocument18 pagesRenewable and Sustainable Energy Reviews: A B C D e A F G H I J KNabilaDheaAmmaraNo ratings yet

- Sustainable Energy Handbook: HydroelectricityDocument12 pagesSustainable Energy Handbook: Hydroelectricitypradip panthaNo ratings yet

- A Review On Technology, Configurations, and Performance of Cross Flow Hydrokinetic TurbinesDocument41 pagesA Review On Technology, Configurations, and Performance of Cross Flow Hydrokinetic TurbinestonybezerraNo ratings yet

- M.tech .Tech SynopsisDocument6 pagesM.tech .Tech SynopsisAnupNo ratings yet

- Power Grid Synchronization by Controlling Frequency For Hydropower PlantsDocument47 pagesPower Grid Synchronization by Controlling Frequency For Hydropower PlantsTadele AmogneNo ratings yet

- 20 Art BostanDocument4 pages20 Art Bostanplamadeala.vasile.tudorNo ratings yet

- A Technology Review and Simulation BasedDocument6 pagesA Technology Review and Simulation BasedSantiago GuagalangoNo ratings yet

- Micro Hydro Basics and Status in NepalDocument30 pagesMicro Hydro Basics and Status in NepalOne Line ResourcesNo ratings yet

- ASET DesignofHydro-powerPlantforEnergyGenerationDocument7 pagesASET DesignofHydro-powerPlantforEnergyGenerationGustavo Niedermayer WagnerNo ratings yet

- Review TemplateDocument23 pagesReview Templatealfa ageng santosoNo ratings yet

- 1 s2.0 S2352484722024234 MainDocument9 pages1 s2.0 S2352484722024234 Mainrodden chikonzoNo ratings yet

- Design and Analysis of Hydroelectric Generation Using WaterwheelDocument6 pagesDesign and Analysis of Hydroelectric Generation Using WaterwheelVinu KohliNo ratings yet

- Ast PDFDocument6 pagesAst PDFJasmin WahyudiNo ratings yet

- Paper 1Document1 pagePaper 1Muhammad MohsinNo ratings yet

- Calculo de Una Central MinihidraulicaDocument13 pagesCalculo de Una Central MinihidraulicacarcobyNo ratings yet

- Renewable and Sustainable Energy Reviews: SciencedirectDocument18 pagesRenewable and Sustainable Energy Reviews: SciencedirectLeidy Katherine Suarez GNo ratings yet

- 2017 Prediction of Small Hydropower Plant Power Production in Himreen Lake Dam (HLD) Using Artificial Neural NetworkDocument11 pages2017 Prediction of Small Hydropower Plant Power Production in Himreen Lake Dam (HLD) Using Artificial Neural NetworkJuancito ZcNo ratings yet

- Design Methodology and Structural Analysis of Cross Flow TurbineDocument10 pagesDesign Methodology and Structural Analysis of Cross Flow TurbineAdson JuniorNo ratings yet

- Internship Report FinalDocument8 pagesInternship Report FinalrehanNo ratings yet

- Ppe Project.Document8 pagesPpe Project.bagwanhaji644No ratings yet

- University Insitute of Engineering Electrical EngineeringDocument20 pagesUniversity Insitute of Engineering Electrical EngineeringPyrenean IbexNo ratings yet

- Introduction to Electricity Supply and Regulation in IndiaFrom EverandIntroduction to Electricity Supply and Regulation in IndiaNo ratings yet

- [1553779X - International Journal of Emerging Electric Power Systems] Simultaneous Energy and Reserve Market Clearing with Consideration of Interruptible Loads as One of Demand Response Resources and Differen.pdfDocument20 pages[1553779X - International Journal of Emerging Electric Power Systems] Simultaneous Energy and Reserve Market Clearing with Consideration of Interruptible Loads as One of Demand Response Resources and Differen.pdfJEFFERSON GARCIA SERNANo ratings yet

- Product Model Number Guide 120417Document12 pagesProduct Model Number Guide 120417Ernesto Emmanuel Garza SalazarNo ratings yet

- BE Semester-7 (Mechanical) Question Bank Subject Name:: Internal Combustion Engines (Ep-I)Document2 pagesBE Semester-7 (Mechanical) Question Bank Subject Name:: Internal Combustion Engines (Ep-I)Namra KhanNo ratings yet

- Rinisis ProfileDocument12 pagesRinisis ProfileKumar ReddyNo ratings yet

- Big History 3Document285 pagesBig History 3Elaine RobinsonNo ratings yet

- Dstar Ehandbook v5.0Document381 pagesDstar Ehandbook v5.0RobertoNo ratings yet

- Rental Power 70 KW: Specification SheetDocument4 pagesRental Power 70 KW: Specification SheetDulguunkherlen BudkhandNo ratings yet

- Closed Loop Buck & Boost Converter Mathematical Modeling, Analysis and Simulation Using MATLABDocument9 pagesClosed Loop Buck & Boost Converter Mathematical Modeling, Analysis and Simulation Using MATLAB7031 GauravNo ratings yet

- Description Value: Printed From Grundfos CAPSDocument4 pagesDescription Value: Printed From Grundfos CAPSDima ArfNo ratings yet

- Power Systems Analysis Software - Open ElectricalDocument12 pagesPower Systems Analysis Software - Open ElectricalYousif_Abdalhalim100% (1)

- Kstar Inverosores DatasheetDocument1 pageKstar Inverosores DatasheetJosueLopesFariasNo ratings yet

- Specifications: D 30-32 Diesel Pile Hammer: Dimensions ApproxDocument1 pageSpecifications: D 30-32 Diesel Pile Hammer: Dimensions ApproxMelliza FranciliaNo ratings yet

- Moran Introduction To Thermal Systems Engineering Thermodynamics Fluid Mechanics and Heat Transfer 2002 09Document5 pagesMoran Introduction To Thermal Systems Engineering Thermodynamics Fluid Mechanics and Heat Transfer 2002 09Marco GassaniNo ratings yet

- Gases As Insulating MediaDocument10 pagesGases As Insulating MediasmileniravNo ratings yet

- Catalogue Price List - Adisa - EN PDFDocument78 pagesCatalogue Price List - Adisa - EN PDFVlad BalanNo ratings yet

- BP Solar 230 WP Endura ModuleDocument2 pagesBP Solar 230 WP Endura ModuleDeep PatelNo ratings yet

- Design of Single-Tuned Harmonic Passive Filters For DC Electric Railway Traction Power Supply SystemDocument8 pagesDesign of Single-Tuned Harmonic Passive Filters For DC Electric Railway Traction Power Supply SystemDeep ShikhaNo ratings yet

- Installation and Operating Instructions KEY-START Series: Energy DivisionDocument20 pagesInstallation and Operating Instructions KEY-START Series: Energy DivisionAnonymous RcxX0FcNo ratings yet

- LV Cable SizingDocument9 pagesLV Cable Sizingsrsureshrajan100% (1)

- Vegetable Oil-Filled Transformers For A Sustainable Future: TransmissionDocument2 pagesVegetable Oil-Filled Transformers For A Sustainable Future: TransmissionAbe KobNo ratings yet

- New Microsoft Word DocumentDocument11 pagesNew Microsoft Word DocumentSandesh HakkiNo ratings yet

- 100 KW DPRDocument48 pages100 KW DPRJayanth Nataraja Moorthi100% (1)

- Transient Recovery Voltages During The Switching Under Out-of-Phase ConditionsDocument5 pagesTransient Recovery Voltages During The Switching Under Out-of-Phase ConditionsRoberto SuNo ratings yet

- Ijpec100203 Rivera 146785last Version April19Document38 pagesIjpec100203 Rivera 146785last Version April19Michi HenaoNo ratings yet

- Doubly Fed Induction Generator Based Wind Turbine System With Voltage RegulationDocument336 pagesDoubly Fed Induction Generator Based Wind Turbine System With Voltage RegulationHazrul_Mohamed_BasriNo ratings yet

- Three-Phase Transformerless Shunt Active Power Filter With Reduced Switch Count For Harmonic Compensation in Grid-Connected ApplicationsDocument14 pagesThree-Phase Transformerless Shunt Active Power Filter With Reduced Switch Count For Harmonic Compensation in Grid-Connected ApplicationsTRIAD TECHNO SERVICESNo ratings yet

- Electrical Thumb Rules You MUST Follow4Document4 pagesElectrical Thumb Rules You MUST Follow4Karthick RathinasamyNo ratings yet

- Pipe Preboard 1Document10 pagesPipe Preboard 1Chyno Kang100% (1)

- PHASE FAULT OVER CURRENT RELAY SETTING (WRKNG)Document35 pagesPHASE FAULT OVER CURRENT RELAY SETTING (WRKNG)Madhu DuraichamyNo ratings yet

Approach For Cost Determination of Electro-Mechani

Approach For Cost Determination of Electro-Mechani

Uploaded by

Frezer SolomonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Approach For Cost Determination of Electro-Mechani

Approach For Cost Determination of Electro-Mechani

Uploaded by

Frezer SolomonCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/267418529

Approach for Cost Determination of Electro-Mechanical Equipment in RoR

SHP Projects

Article in Smart Grid and Renewable Energy · January 2011

DOI: 10.4236/sgre.2011.22008

CITATIONS READS

18 247

3 authors, including:

Sachin Mishra Dheeraj K Khatod

Lovely Professional University Indian Institute of Technology Roorkee

27 PUBLICATIONS 222 CITATIONS 63 PUBLICATIONS 2,186 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

virtual power plant View project

Variable Frequency Transformer View project

All content following this page was uploaded by Sachin Mishra on 20 August 2015.

The user has requested enhancement of the downloaded file.

Smart Grid and Renewable Energy, 2011, 2, 63-67 63

doi:10.4236/sgre.2011.22008 Published Online May 2011 (http://www.SciRP.org/journal/sgre)

Approach for Cost Determination of

Electro-Mechanical Equipment in RoR SHP

Projects

Sachin Mishra, Sunil Kumar Singal, Dheeraj Kumar Khatod

Alternate Hydro Energy Centre, Indian Institute of Technology Roorkee, Roorkee, India.

Email: rite2sm@gmail.com

Received February 13th, 2011; revised March 5th, 2011; accepted March 8th, 2011.

ABSTRACT

Electricity is one of the most widely used forms of energy. Being a renewable source of energy small hydropower is

considered as an environment—friendly and cheap source of electricity. The installation cost of the small hydropower

project depends mainly on two parts—civil works and electromechanical equipment. One of the most important element

on the recovery of a small hydro-power plant is the electromechanical equipment (turbine-alternator). The present pa-

per intends to develop a correlation to determine the cost based on the cost influencing parameters as power and head

using three different methods, namely; sigma plot method, linest method and logest method. An attempt has also been

made to identify the best correlation among the three models closer to the actual cost of electro-mechanical equipment

as collected from recently developed projects.

Keywords: Small Hydropower Plant, Electro-Mechanical Equipments, Linest, Logest

1. Introduction importance due to their relatively low administrative and

executive costs and a short construction time compared

Energy is the basic requirement for economic develop-

to large power plants. These SHPs are mostly in the run of

ment of a country. The growing demand for energy has

river (RoR) category using instantaneous diverted flow of

resulted in a dependency on fossil fuels. The price of fos-

river runoff and consists of diversion weir, water con-

sil fuels and security of energy supply have been a seri-

ductor system (intake channel, desilting tank, power cha-

ous concern in India for many decades. India has a large

hydro potential in the range of medium and bigger size nnel, forebay, penstock), power house and tailrace under

projects. After independence in 1947, large hydroelectric civil works as well as electrical and mechanical equip-

projects were executed, some of them are still under con- ment.

struction and some are planned for the future. The inher- To take investment decision, cost is an important fac-

ent drawbacks associated with large hydro are large ges- tor. The cost of SHP schemes comprises cost of civil works

tation periods, submergence of large areas along with ve- and electro-mechanical equipment. The cost of civil works

getation, and resettlement of the people. Political and can be estimated based on actual quantities of various

environmental implications have made planners to look items as per design drawings, but cost of electro-me-

for alternatives of large hydro. Such alternative could be chanical equipment, depend on budgetary quotations of

small hydro. Electricity from small hydro is probably the the manufactures. Keeping this in view, an attempt has

oldest and reliable renewable energy source. In India, the been made to develop a methodology for computation of

potential for small hydro has been estimated about 15,000 cost of electro-mechanical equipments in the present

MW. Out of total 5,415 potential sites, 760 small hydro study.

schemes with a total installed capacity of nearly 2803

2. Small Hydropower Technology

MW are in operation and 285 schemes with another 940

MW capacity are under various stages of implementation Hydro-turbines convert water pressure into mechanical

[1-3]. shaft power, which can be used to drive an electricity ge-

Small Hydropower Plants (SHPs) have found special nerator, or other machinery. The power available is pro-

Copyright © 2011 SciRes. SGRE

64 Approach for Cost Determination of Electro-Mechanical Equipment in RoR SHP Projects

portional to the product of pressure head and volume flow 3.1. Civil Works

rate. The general expression for power output from a hy-

Civil works of small hydropower scheme comprise of

dropower scheme is given in Equation (1).

following major components [6,7]:

P gQh (1) 1) Diversion weir and intake: required for diverting the

where, P is the mechanical power produced at the turbine flow of water from the river or stream towards the intake

shaft (W), η is the hydraulic efficiency of the turbine, ρ is channel.

the density of water (kg/m3), g is the acceleration due to 2) Intake channel: to convey water diverted from the

gravity (m/s2), Q is the volume flow rate passing through weir.

the turbine (m3/s), and h is the effective pressure head of 3) Desilting tank: to remove silt to minimize erosion.

water at the turbine (m). The best turbines can have hy- 4) Forebay: provided at the end of water conductor

draulic efficiencies in the range 80% to 90% (higher than with some storage capacity to fulfill immediate water de-

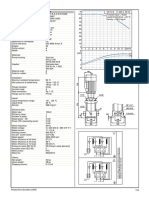

most other prime movers). Figure 1 illustrates a typical mand on starting and to absorb water in case of sudden

RoR small hydro scheme [3]. stoppage of generating unit.

In a typical small hydro power scheme, water is di- 5) Penstock: conduit carrying water from forebay to

verted from the river through an intake weir. The water the turbine.

passes through a desilting tank in which the water is 6) Spilling arrangement: the access flow that enters in-

slowed down sufficiently for suspended particles to settle to the intake during flood or at part load needs to be

down before descending to the turbine. In RoR installa- spilled as early as possible.

tions, water is carried to the forebay by a canal. A pres- 7) Power house building is a simple structure housing

sure pipe, known as a penstock, conveys the water from the generating unit.

the forebay to the turbine [4,5]. 8) Tailrace channel to carry the water coming from the

In India, small hydro schemes are classified as follows turbine and convey back to the flowing stream.

[1,2]: 3.2. Electro-Mechanical Equipment

Class Station Capacity The electro-mechanical equipment are required to con-

Micro upto 100 kW

Mini 101 kW to 2000 kW vert the available energy in flowing water into electrical

Small 2001 kW to 25000 kW energy, to control it and to transmit it to the power grid/

load points.

The major electro-mechanical components of power

3. Cost Estimation plant are the inlet valve, turbine, draft tube, gate, genera-

The basic components of small hydro scheme can be tor, control and protection equipment, Substation for eva-

broadly classified as 1) civil works and 2) electro- cuation of power. Turbines and generators are the major

mechanical equipments. items in terms of cost and space requirement [6-8].

Figure 1. A typical layout of a SHP scheme.

Copyright © 2011 SciRes. SGRE

Approach for Cost Determination of Electro-Mechanical Equipment in RoR SHP Projects 65

D A B

4. Methodology for Cost Estimation Z X Y (7)

C C C

The cost estimation process starts with the collection of

data required for this purpose, which involves various Constants a, b and c are obtained by comparing Equa-

components of civil works and electromechanical equip- tions (4) and (7) through the following expressions:

ment of different projects, executed recently. The cost D

components are then adjusted considering inflation rates a e C

over the years. This data set is then screened to detect out- A

liners which have unreasonable installation cost. The pa- b (8)

C

rameters on which the civil and E&M cost depends are

B

identified. These are installed capacity, head and year of c

commissioning, etc. The cost of the electromechanical C

equipment (turbine, alternator and regulator) is substantial The function of cost will be

in a small hydropower plant.

In the present, study an attempt has been made to de- Cost, C a P b H c (9)

velop the cost relationship for electro-mechanical equip- The cost function has been developed which is sensi-

ment of SHP project using three different mathematical tive to the installed capacity and head parameters. The

techniques. The cost correlations obtained from these tech- exponents for these parameters have been obtained by re-

niques are than compared with the cost of actual existing gression analysis. In the first step, analysis is done be-

power plant installed recently. tween installation cost and head to find out the exponent

4.1. Correlation through Sigma Software of head. Then in second step results were analysed with

the installed capacity to find out the coefficient and expo-

The expression of initial cost of electro-mechanical equip- nent of installed capacity. The developed corelation is as

ment is: given by Equation (10) [9].

Cost, C a P b H c (2)

C 6.882 H 0.0782 P 0.6369 (10)

Applying logarithms in the of expression (2), it is ob-

tained 4.2. Correlation through Linest Method

log C log aP Hb c

log a b log P c log H (3) This method calculates the statistics for a line by using the

Carrying out a variable change “least squares” method to calculate a straight line that best

Z logC fits the data, and then returns an array that describes the

line. LINEST [MS office excel – 2007] can also be com-

X logP bined with other functions to calculate the statistics for

Y =logH other types of models that are linear in the unknown pa-

Expression (3) will remain the following way rameters, including polynomial, logarithmic, exponential,

and power series. Because this function returns an array of

Z loga bX cY (4)

values, it must be entered as an array formula.

Substituting data of cost, power and head of every plant The equation for the line is:

whose data are known in the previous expression, it is

y mx b or (11)

obtained

Z1 loga bX 1 cY1 y m1 x1 m2 x2 ... b (if there are multiple ranges of

x-values) (12)

Z 2 loga bX 2 cY2 (5)

where the dependent y-value is a function of the inde-

pendent x-values. The m-values are coefficients corre-

Z n log a bX n cYn sponding to each x-value, and b is a constant value. Note

Then we proceeded to search the plane AX +BY +CZ + that y, x, and m can be vectors. The array that LINEST re-

D = 0 with the best fit to data (Xk, Yk, Zk) and carrying out turns is {mn, mn-1... m1, b}. LINEST can also return addi-

a multiple regression between the independent variables tional regression statistics. The developed corelation is as

(X, Y) and (Z) given by Equation (13).

C 0.136391 P 1.73409 H 524.9 (13)

AX BY CZ D 0 (6)

4.3. Correlation through Logest Method

Working out the value of Z, supposing without restric-

tion as the plane would not be vertical, This method, calculates an exponential curve that fits the

Copyright © 2011 SciRes. SGRE

66 Approach for Cost Determination of Electro-Mechanical Equipment in RoR SHP Projects

data and returns an array of values that describing the 6. Conclusions

curve. Because this function returns an array of values, it

In the present study, an attempt has been made to de-

must be entered as an array formula.

velop a methodology for determination of the cost of

The equation for the curve is:

electro-mechanical equipment based on cost influencing

y b mx or (14) parameters i.e. head and capacity. Mathematical models

were developed using three different methods and the

y b m1x1 m2 x2 (if there are multiple results obtained from these models were compared with

actual cost data as obtained from the recently developed

x-values) (15)

projects. The results obtained from these mathematical

where the dependent y-value is a function of the inde- models show the percentage of error. It is seen that the

pendent x-values. The m-values are bases corresponding

to each exponent x-value, and b is a constant value. Note

that y, x, and m can be vectors. The array that LOGEST

[MS office excel – 2007] returns is mn , mn 1 , , m1 , b .

The developed corelation is as given by Equation (16).

C 664.072 1.00011 0.99865

P H

(16)

5. Results and Discussions

The cost data of electro-mechanical equipment from dif-

ferent existing sites and the manufacturers were collected

and adjusted accordingly considering the inflation over the

years. These cost data were used to develop the corre- Figure 2. Error analysis of analyzed cost and actual project

lations. The results obtained from these correlations were cost using sigma plot method.

verified from the cost data of electro-mechanical equip-

ment of the newly installed SHP projects.

Figure 2 shows the error analysis between the actual

cost and the analyzed cost of electro-mechanical equip-

ment of small hydropower plant using the correlation ob-

tained from the sigma plot software. Overall the data ob-

tained from the mathematical model are very much close

to the actual data with a maximum error of ±10%.

Figure 3 shows the error analysis between the actual

cost and the analyzed cost of electro-mechanical equip-

ment of small hydropower plant using the correlation ob-

tained from the Linest method. Overall the data obtained

from the mathematical model are very much close to the

Figure 3. Error analysis of analyzed cost and actual project

actual data with a maximum error of ±5%. cost using linest method.

Figure 4 shows the error analysis between the actual

cost and the analyzed cost of electro-mechanical equip-

ment of small hydropower plant using the correlation ob-

tained from the Logest method. Overall the data obtained

from the mathematical model are very much close to the

actual data with a maximum error of ±18%.

Figure 5 shows the comparison of cost obtained from

three different mathematical models and actual cost (as

collected) for electro-mechanical equipment of different

capacities at a fixed head of 120 m. The cost obtained

from the mathematical model obtained from sigma plot

and Linest method are closes to the actual cost of electro-

mechanical equipment and can be used for prediction of Figure 4. Error analysis of analyzed cost and actual project

the cost such equipment. cost using logest method.

Copyright © 2011 SciRes. SGRE

Approach for Cost Determination of Electro-Mechanical Equipment in RoR SHP Projects 67

[3] P. S. Nigam, “Hand Book of Hydro Electric Engineer-

ing,” Nem Chand and Brothers, Roorkee, 1985.

[4] J. S. Anagnostopoulos and D. E. Papantonis, “Optimal

Sizing of a Run-of-River Small Hydropower Plant,” En-

ergy Conversion and Management, Vol. 48, No. 10, 2007,

pp. 2663-2670. doi:10.1016/j.enconman.2007.04.016

[5] S. K. Singal and R. P. Saini, “Analytical Approach for

Cost Estimation of Low Head Small Hydro Power

Schemes,” Proceedings of International Conference on

Small Hydropower, Sri Lanka, 22-24 October 2007, pp.

1-6.

[6] B. Ogayar and P. G. Vidal, “Cost Determination of the

Figure 5. Comparison of different mathematical models to Electro-Mechanical Equipment of a Small Hydro-Power

that of actual cost. Plant,” Journal of Renewable Energy, Vol. 34, No. 1,

2009, pp. 6-13. doi:10.1016/j.renene.2008.04.039

cost obtained from the mathematical model by using sig- [7] S. K. Singal, R. P. Saini and C. S. Raghuvanshi, “Analy-

ma plot and Linest method are very close to the actual sis for Cost Estimation of Low Head Run-of-River Small

cost of electro-mechanical equipment and can be used for Hydropower Scheme,” Journal of Energy for Sustainable

the prediction of such cost for planning purpose. Development, Vol. 14, No. 2, 2010, pp. 117-126.

[8] G. A. Aggidis, E. Luchinskaya, R. Rothschild and D. C.

7. Acknowledgements Howard, “The Costs of Small-Scale Hydro Power Pro-

The authors greatly acknowledge the financial support duction: Impact on the Development of Existing Poten-

from Ministry of Human Resource Development, Gov- tial,” Journal of Renewable Energy, Vol. 35, No. 12,

2010, pp. 2632-2638. doi:10.1016/j.renene.2010.04.008

ernment of India in the form of research scholarship to

carry out this work. [9] S. Mishra, S. K. Singal and D. K. Khatod, “Costing of

Small Hydropower Projects,” Proceedings of Interna-

tional Conference on Prudent Development and Renew-

REFERENCES able Energy Resources, Chennai, 19-20 February 2011,

[1] “Guidelines for Development of Small Hydro Electric pp. 22-25.

Scheme,” CEA, Government of India, New Delhi, 1982.

[2] B. S. K. Naidu, “Small Hydro,” NPTI Publication, Fari-

dabad, 2005.

Copyright © 2011 SciRes. SGRE

View publication stats

You might also like

- Runoff River Plant Statusand ProspectsDocument5 pagesRunoff River Plant Statusand ProspectsJanaisha Bai TitoNo ratings yet

- Cost 2222Document22 pagesCost 2222Habte TokichawNo ratings yet

- Design of A Water Wheel For A Low Head Micro Hydro PDFDocument7 pagesDesign of A Water Wheel For A Low Head Micro Hydro PDFGaurav RanmaleNo ratings yet

- Sustainable Energy Technologies and Assessments: Krishna Kumar, R.P. SainiDocument21 pagesSustainable Energy Technologies and Assessments: Krishna Kumar, R.P. Sainijuan vargas tarazonaNo ratings yet

- Ajol File Journals - 483 - Articles - 123631 - Submission - Proof - 123631 5701 338116 1 10 20151009Document12 pagesAjol File Journals - 483 - Articles - 123631 - Submission - Proof - 123631 5701 338116 1 10 20151009Ha ApaNo ratings yet

- Modelling of Underground Cables For High Voltage TransmissionDocument12 pagesModelling of Underground Cables For High Voltage TransmissionErgin ÖzdikicioğluNo ratings yet

- Introduction Pinaka Final 2Document20 pagesIntroduction Pinaka Final 2Birthley RagasaNo ratings yet

- SeletionofturbinesDocument8 pagesSeletionofturbinesrrNo ratings yet

- Vineet K SinghDocument5 pagesVineet K SingholongkodokNo ratings yet

- PDFDocument7 pagesPDFAhmad FahrudinNo ratings yet

- Design of Micro-Hydro-Electric Power StationDocument10 pagesDesign of Micro-Hydro-Electric Power StationRiana KuliahNo ratings yet

- Design of Micro-Hydro-Electric Power StationDocument10 pagesDesign of Micro-Hydro-Electric Power StationCY KangNo ratings yet

- Review of Optimal Selection of Turbines For Hydroelectric ProjectsDocument7 pagesReview of Optimal Selection of Turbines For Hydroelectric ProjectsephremNo ratings yet

- Vineet K SinghDocument5 pagesVineet K SinghparthasutradharNo ratings yet

- Modelling and Simulation of Micro Hydro Power Plant Using Matlab SimulinkDocument14 pagesModelling and Simulation of Micro Hydro Power Plant Using Matlab Simulinkcontrol roomNo ratings yet

- Harvesting Electricity From Water Mains Hydropower System Generates Power From Water PipelinesDocument8 pagesHarvesting Electricity From Water Mains Hydropower System Generates Power From Water PipelinesFares NasserNo ratings yet

- 416 432ijecs PDFDocument17 pages416 432ijecs PDFPaul CarcasiNo ratings yet

- Uttarakhand MHPDocument10 pagesUttarakhand MHPVineet SinghNo ratings yet

- Small, Mini, Micro and Pico Hydro Power Plant Scope Challenges Deployment in Indian Context-34921 PDFDocument10 pagesSmall, Mini, Micro and Pico Hydro Power Plant Scope Challenges Deployment in Indian Context-34921 PDFGAURANGNo ratings yet

- Micro Hydro Power Plant Using Sewage Water of Hayatabad PeshawarDocument6 pagesMicro Hydro Power Plant Using Sewage Water of Hayatabad PeshawarShahzaib KhanNo ratings yet

- Captive Power Plant - A Case Study of Cetp Ichalkaranji, MaharashtraDocument6 pagesCaptive Power Plant - A Case Study of Cetp Ichalkaranji, MaharashtraesatjournalsNo ratings yet

- Small Mini Hydro Plants - EL6010Document77 pagesSmall Mini Hydro Plants - EL6010k4nishkkNo ratings yet

- Abubakar Proposal OldDocument5 pagesAbubakar Proposal OldAbubakar QaziNo ratings yet

- Designing of Load Response Generation Synchronized 15MW Hydropower Station and Simulation Based Electromechanical and Structural AnalysisDocument17 pagesDesigning of Load Response Generation Synchronized 15MW Hydropower Station and Simulation Based Electromechanical and Structural AnalysismilanNo ratings yet

- Hydropower Plant Report 4 PDFDocument17 pagesHydropower Plant Report 4 PDFadigkpupNo ratings yet

- Prediction of Small Hydropower Plant Power Production in Himreen Lake Dam (HLD) Using Artificial Neural NetworkDocument11 pagesPrediction of Small Hydropower Plant Power Production in Himreen Lake Dam (HLD) Using Artificial Neural NetworkJesus Miguel RamosNo ratings yet

- Hydro-Power Generation For A Water Treatment System and Method of Supplying Electricity Using A Flow of LiquidDocument8 pagesHydro-Power Generation For A Water Treatment System and Method of Supplying Electricity Using A Flow of LiquidRianna RamosNo ratings yet

- Exemple de Calcul D'ampacité PDFDocument11 pagesExemple de Calcul D'ampacité PDFjagayaNo ratings yet

- Determination of Installation Capacity in Reservoir Hydro-Power Plants Considering Technical, Economical and Reliability IndicesDocument10 pagesDetermination of Installation Capacity in Reservoir Hydro-Power Plants Considering Technical, Economical and Reliability IndicesNov Dion FuadillahNo ratings yet

- Water Turbine SystemDocument9 pagesWater Turbine SystemTarajneet SinghNo ratings yet

- IV ReportDocument22 pagesIV ReportHemant ZopeNo ratings yet

- Design N Consid Derations Sofmic Cro-Hydr Ro-Electr Ric Powe Er PlantDocument11 pagesDesign N Consid Derations Sofmic Cro-Hydr Ro-Electr Ric Powe Er PlanttsuakNo ratings yet

- Run Off River Plant: Status and Prospects: Hemant Sharma, Jasvir SinghDocument4 pagesRun Off River Plant: Status and Prospects: Hemant Sharma, Jasvir SinghArvin SlayerNo ratings yet

- Fluid Power Engineering PDFDocument164 pagesFluid Power Engineering PDFAkki100% (1)

- Micro Hydropower Plant With Rotor's Pintle and Hydrodynamic Profile of BladesDocument4 pagesMicro Hydropower Plant With Rotor's Pintle and Hydrodynamic Profile of Bladesadan25tulaNo ratings yet

- Analysis On Hydrokinetic TurbineDocument10 pagesAnalysis On Hydrokinetic TurbineKartik AtriNo ratings yet

- Modeling and Control of Isolated Micro-Hydro Power Plant With Battery Storage SystemDocument7 pagesModeling and Control of Isolated Micro-Hydro Power Plant With Battery Storage SystemZainal Arif RochimNo ratings yet

- Renewable and Sustainable Energy Reviews: A B C D e A F G H I J KDocument18 pagesRenewable and Sustainable Energy Reviews: A B C D e A F G H I J KNabilaDheaAmmaraNo ratings yet

- Sustainable Energy Handbook: HydroelectricityDocument12 pagesSustainable Energy Handbook: Hydroelectricitypradip panthaNo ratings yet

- A Review On Technology, Configurations, and Performance of Cross Flow Hydrokinetic TurbinesDocument41 pagesA Review On Technology, Configurations, and Performance of Cross Flow Hydrokinetic TurbinestonybezerraNo ratings yet

- M.tech .Tech SynopsisDocument6 pagesM.tech .Tech SynopsisAnupNo ratings yet

- Power Grid Synchronization by Controlling Frequency For Hydropower PlantsDocument47 pagesPower Grid Synchronization by Controlling Frequency For Hydropower PlantsTadele AmogneNo ratings yet

- 20 Art BostanDocument4 pages20 Art Bostanplamadeala.vasile.tudorNo ratings yet

- A Technology Review and Simulation BasedDocument6 pagesA Technology Review and Simulation BasedSantiago GuagalangoNo ratings yet

- Micro Hydro Basics and Status in NepalDocument30 pagesMicro Hydro Basics and Status in NepalOne Line ResourcesNo ratings yet

- ASET DesignofHydro-powerPlantforEnergyGenerationDocument7 pagesASET DesignofHydro-powerPlantforEnergyGenerationGustavo Niedermayer WagnerNo ratings yet

- Review TemplateDocument23 pagesReview Templatealfa ageng santosoNo ratings yet

- 1 s2.0 S2352484722024234 MainDocument9 pages1 s2.0 S2352484722024234 Mainrodden chikonzoNo ratings yet

- Design and Analysis of Hydroelectric Generation Using WaterwheelDocument6 pagesDesign and Analysis of Hydroelectric Generation Using WaterwheelVinu KohliNo ratings yet

- Ast PDFDocument6 pagesAst PDFJasmin WahyudiNo ratings yet

- Paper 1Document1 pagePaper 1Muhammad MohsinNo ratings yet

- Calculo de Una Central MinihidraulicaDocument13 pagesCalculo de Una Central MinihidraulicacarcobyNo ratings yet

- Renewable and Sustainable Energy Reviews: SciencedirectDocument18 pagesRenewable and Sustainable Energy Reviews: SciencedirectLeidy Katherine Suarez GNo ratings yet

- 2017 Prediction of Small Hydropower Plant Power Production in Himreen Lake Dam (HLD) Using Artificial Neural NetworkDocument11 pages2017 Prediction of Small Hydropower Plant Power Production in Himreen Lake Dam (HLD) Using Artificial Neural NetworkJuancito ZcNo ratings yet

- Design Methodology and Structural Analysis of Cross Flow TurbineDocument10 pagesDesign Methodology and Structural Analysis of Cross Flow TurbineAdson JuniorNo ratings yet

- Internship Report FinalDocument8 pagesInternship Report FinalrehanNo ratings yet

- Ppe Project.Document8 pagesPpe Project.bagwanhaji644No ratings yet

- University Insitute of Engineering Electrical EngineeringDocument20 pagesUniversity Insitute of Engineering Electrical EngineeringPyrenean IbexNo ratings yet

- Introduction to Electricity Supply and Regulation in IndiaFrom EverandIntroduction to Electricity Supply and Regulation in IndiaNo ratings yet

- [1553779X - International Journal of Emerging Electric Power Systems] Simultaneous Energy and Reserve Market Clearing with Consideration of Interruptible Loads as One of Demand Response Resources and Differen.pdfDocument20 pages[1553779X - International Journal of Emerging Electric Power Systems] Simultaneous Energy and Reserve Market Clearing with Consideration of Interruptible Loads as One of Demand Response Resources and Differen.pdfJEFFERSON GARCIA SERNANo ratings yet

- Product Model Number Guide 120417Document12 pagesProduct Model Number Guide 120417Ernesto Emmanuel Garza SalazarNo ratings yet

- BE Semester-7 (Mechanical) Question Bank Subject Name:: Internal Combustion Engines (Ep-I)Document2 pagesBE Semester-7 (Mechanical) Question Bank Subject Name:: Internal Combustion Engines (Ep-I)Namra KhanNo ratings yet

- Rinisis ProfileDocument12 pagesRinisis ProfileKumar ReddyNo ratings yet

- Big History 3Document285 pagesBig History 3Elaine RobinsonNo ratings yet

- Dstar Ehandbook v5.0Document381 pagesDstar Ehandbook v5.0RobertoNo ratings yet

- Rental Power 70 KW: Specification SheetDocument4 pagesRental Power 70 KW: Specification SheetDulguunkherlen BudkhandNo ratings yet

- Closed Loop Buck & Boost Converter Mathematical Modeling, Analysis and Simulation Using MATLABDocument9 pagesClosed Loop Buck & Boost Converter Mathematical Modeling, Analysis and Simulation Using MATLAB7031 GauravNo ratings yet

- Description Value: Printed From Grundfos CAPSDocument4 pagesDescription Value: Printed From Grundfos CAPSDima ArfNo ratings yet

- Power Systems Analysis Software - Open ElectricalDocument12 pagesPower Systems Analysis Software - Open ElectricalYousif_Abdalhalim100% (1)

- Kstar Inverosores DatasheetDocument1 pageKstar Inverosores DatasheetJosueLopesFariasNo ratings yet

- Specifications: D 30-32 Diesel Pile Hammer: Dimensions ApproxDocument1 pageSpecifications: D 30-32 Diesel Pile Hammer: Dimensions ApproxMelliza FranciliaNo ratings yet

- Moran Introduction To Thermal Systems Engineering Thermodynamics Fluid Mechanics and Heat Transfer 2002 09Document5 pagesMoran Introduction To Thermal Systems Engineering Thermodynamics Fluid Mechanics and Heat Transfer 2002 09Marco GassaniNo ratings yet

- Gases As Insulating MediaDocument10 pagesGases As Insulating MediasmileniravNo ratings yet

- Catalogue Price List - Adisa - EN PDFDocument78 pagesCatalogue Price List - Adisa - EN PDFVlad BalanNo ratings yet

- BP Solar 230 WP Endura ModuleDocument2 pagesBP Solar 230 WP Endura ModuleDeep PatelNo ratings yet

- Design of Single-Tuned Harmonic Passive Filters For DC Electric Railway Traction Power Supply SystemDocument8 pagesDesign of Single-Tuned Harmonic Passive Filters For DC Electric Railway Traction Power Supply SystemDeep ShikhaNo ratings yet

- Installation and Operating Instructions KEY-START Series: Energy DivisionDocument20 pagesInstallation and Operating Instructions KEY-START Series: Energy DivisionAnonymous RcxX0FcNo ratings yet

- LV Cable SizingDocument9 pagesLV Cable Sizingsrsureshrajan100% (1)

- Vegetable Oil-Filled Transformers For A Sustainable Future: TransmissionDocument2 pagesVegetable Oil-Filled Transformers For A Sustainable Future: TransmissionAbe KobNo ratings yet

- New Microsoft Word DocumentDocument11 pagesNew Microsoft Word DocumentSandesh HakkiNo ratings yet

- 100 KW DPRDocument48 pages100 KW DPRJayanth Nataraja Moorthi100% (1)

- Transient Recovery Voltages During The Switching Under Out-of-Phase ConditionsDocument5 pagesTransient Recovery Voltages During The Switching Under Out-of-Phase ConditionsRoberto SuNo ratings yet

- Ijpec100203 Rivera 146785last Version April19Document38 pagesIjpec100203 Rivera 146785last Version April19Michi HenaoNo ratings yet

- Doubly Fed Induction Generator Based Wind Turbine System With Voltage RegulationDocument336 pagesDoubly Fed Induction Generator Based Wind Turbine System With Voltage RegulationHazrul_Mohamed_BasriNo ratings yet

- Three-Phase Transformerless Shunt Active Power Filter With Reduced Switch Count For Harmonic Compensation in Grid-Connected ApplicationsDocument14 pagesThree-Phase Transformerless Shunt Active Power Filter With Reduced Switch Count For Harmonic Compensation in Grid-Connected ApplicationsTRIAD TECHNO SERVICESNo ratings yet

- Electrical Thumb Rules You MUST Follow4Document4 pagesElectrical Thumb Rules You MUST Follow4Karthick RathinasamyNo ratings yet

- Pipe Preboard 1Document10 pagesPipe Preboard 1Chyno Kang100% (1)

- PHASE FAULT OVER CURRENT RELAY SETTING (WRKNG)Document35 pagesPHASE FAULT OVER CURRENT RELAY SETTING (WRKNG)Madhu DuraichamyNo ratings yet

![[1553779X - International Journal of Emerging Electric Power Systems] Simultaneous Energy and Reserve Market Clearing with Consideration of Interruptible Loads as One of Demand Response Resources and Differen.pdf](https://imgv2-2-f.scribdassets.com/img/document/454428457/149x198/206577f9c9/1585770060?v=1)