Professional Documents

Culture Documents

Chairman's Office & Head Quarters Group Companies: B Fouress Pvt. LTD

Chairman's Office & Head Quarters Group Companies: B Fouress Pvt. LTD

Uploaded by

Shankey JAlanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chairman's Office & Head Quarters Group Companies: B Fouress Pvt. LTD

Chairman's Office & Head Quarters Group Companies: B Fouress Pvt. LTD

Uploaded by

Shankey JAlanCopyright:

Available Formats

Chairman’s Office & Head Quarters Group Companies

Mahalaxmi Chambers, 22, Bhulabhai Desai Road, B Fouress Pvt. Ltd.

MUMBAI - 400 026 Plot No:7, KIADB Indl.Area, HOSKOTE – 562 114

Tel: +91 22 2353 4400-05 Bengaluru District, Karnataka

Fax: +91 22 2351 7544 Tel: +91 80 2797 1641

E-mail: hq@fouressindia.com Fax: +91 80 2797 1455

Website: www.fouressindia.com E-mail: info@bflhydro.com

Website: www.bflhydro.com

Plants PEE Industrial Valves Pvt. Ltd.

Fouress Engineering (India) Ltd.

Plot No: B-63(A), SIPCOT Industrial Complex

Plot No.A-324, Road No:21, Wagle Indl. Estate

GUMMIDIPOONDI - 601 201, Tamil Nadu

THANE – 400 604 Maharashtra

Tel: +91 44 2792 3050

Tel: +91 22 2582 3806 / 3602

Fax: +91 44 2792 3099

Fax: +91 22 2582 3603

E-mail: petrochemical@vsnl.com

E-mail: byp@fouressindia.com

Fouress Marketing (Intnl.) Pvt. Ltd.

Fouress Engineering (India) Ltd.

A-1/842, GIDC Indl.Estate, Makarpura

Plot 2, Phase II, Peenya Industrial Area

VADODARA - 390 010, Gujarat

BENGALURU - 560 058, Karnataka

Tel: +91 265 658 1245

Tel: +91 80 2839 5734 2839 5494

Fax: +91 265 264 6518

Fax: +91 80 2839 5176

E-mail: info@fmiplbrd.com

E-mail: info@fouressindia.com

Bombay Engineering Industries

Fouress Engineering (India) Ltd.

A-186, IV Cross, Ist Phase, Peenya Industrial Estate

C-2, MIDC Industrial Area, Paithan - 431 148

BENGALURU-560 058, Karnataka

AURANGABAD, Maharashtra

Tel: +91 80 2839 3849

Tel: +91 2431 232 074, 232190

Fax: +91 80 2839 9605

Fax: +91 2431 232 058

E-mail: beibangalore@yahoo.com

E-mail: aurangabad@fouressindia.com

The Rubber Products Ltd.

Branches & Representatives Plot C-44, Road No: 28, Wagle Industrial Estate

Mumbai feilmumbai@fouressindia.com THANE – 400 604, Maharashtra

Baroda feilbaroda@fouressindia.com Tel: +91 22 2582 2551 - 53

Delhi feildelhi@fouressindia.com Fax: +91 22 2582 0876

Hyderabad feilhyd@fouressindia.com E-mail: rpl@rubpro.com

Pune feilpune@fouressindia.com Website: www.rubpro.com

Vizag Rep. feilvizag@fouressindia.com

Chennai feilchennai@fouressindia.com

Nagpur Rep. feilnagpur@fouressindia.com

Kolkata feilkolkata@fouressindia.com

Bhubaneshwar feilbnrs@fouressindia.com

International Agency Division

iad@fouressindia.com

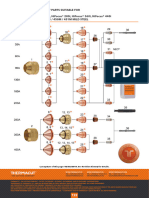

PRODUCT

PORTFOLIO

Product Size Range Maximum

Min. Max. Temp. Pressure

INDUSTRIAL VALVES FOR FLUID ISOLATION & REGULATION

1. Wedge Gate, Globe and Check Valves

- Forged Construction

Gate Valve 1/4" 2" - 800 # -2500 #

Globe Valve 1/4" 1.5" - 800 # - 2500 #

Check Valve 1/4" 1.5" - 800 # - 2500 #

- Cast Construction

Gate Valve 2" 64" - 150 # - 2500 #

Globe Valve 2" 20" - 150 # - 2500 #

Check Valve 2" 36" - 150 # - 2500 #

Dual Plate Check Valve 2" 48" - 150 # - 600 #

2. Dual Plate Check valve (metal seated & rubber seated) 2” 48”

3. Single/Double Eccentric Butterfly Valve 100mm 4000mm 1800C 40 kg/cm2

Bangalore Plant

Valves And Gas Tight Isolators , 4. Compact Seal Butterfly Valves 50mm 600mm 1200C 10 kg/cm2

Damper For Power, Water, 5. High Performance Butterfly Valves 4S-V5422 & 4S-V30 #300 50mm 600mm 2300C 20 kg/cm2

Wastewater, Steel, Cement, 6. Pump Discharge Buttefly Valves 450mm 3500mm Ambient 16 kg/cm2

Refineries, Petrochemicals &

Process Industries 7. Triple Eccentric multifunction valves 600mm 2000mm 1200C

8. Triple Eccentric Metal seated Butterfly Valve / Pyrogenic / 80mm 2000mm 5500C 16 kg/cm2

Fire Safe Butterfly Valves

9. Four way Flow Reversing Valves 600mm 2200mm Ambient 26 kg/cm2

10. Single door Butterfly Reflux Valve and Multi-door Reflux Valve 500mm 1800mm Ambient 10 kg/cm2

11. Air Release Valve 50mm 250mm

WATER SYSTEMS & HYDRO POWER AUXILLARIES

12. Penstock Protection/Turbine Inlet Butterfly Valve* 300mm 4000mm Ambient 45 kg/cm2

13. Rotary (Spherical) Valve 400mm 1200mm Ambient upto 100 kg/cm2

14. Discharge Regulator & Fixed Cone Dispense Valve 300mm 3000mm Ambient 10 kg/cm2

15. Lattice Blade Valve / Bi-Plane Disc Butterfly Valve* - 4000mm Ambient 45 kg/cm2

16. Plunger Valve 700mm 2000mm

SOLIDS & SLURRIES HANDLING SYSTEMS

17. FOURESS - V336D Knife Gate Valve 50mm 3600 mm upto 2300C 10 kg/cm2

18. FOURESS - V336L Knife Gate Valve 50 mm 600 mm upto 2300C 10 kg/cm2

19. FOURESS - Fully Stainless Steel/Lined Knife Gate Valve customised upto 3600mm

HIGH INTEGRITY GAS-TIGHT ISOLATORS FOR GENERAL INDUSTRIAL APPLICATION WITH FLEXIBLE METALLIC SEALING SYSTEM

20. Gullotine Isolators (tailor made to customer requirement) 500mm duct dimension onwards 6500C ±2500 mm WG

21. Glandular Spade Valve (tailor made to customer requirement) 500mm duct dimension onwards 3500C -800mm to 100mm WG

22. Goggle Spade Valve (tailor made to customer requirement) 500mm duct dimension onwards 3500C -2000mm to+100mm WG

23. Flap Isolators (tailor made to customer requirement) 500mm duct dimension onwards 6500C ±2500 mm WG

24. Twin Seal Flap Isolators (tailor made to customer requirement) 500mm duct dimension onwards 5000C ±2500 mm WG

25. Louvre Dampers (tailor made to customer requirement) 500mm duct dimension onwards 6500C ±2500 mm WG

26. Diverter Flap Valve (tailor made to customer requirement) 500mm duct dimension onwards 6500C ±2500 mm WG

GAS LINE VALVES (INDUSTRIAL VALVES) FOR METALLURGIAL INDUSTRIES AND STEEL MILLS

27. Hot Blast Valves 500mm and above upto 15500C upto 600 kpa

28. Single Disc Gate Valves 300mm 3000mm upto 9000C upto 600 kpa

29. Double Disc Gate Valves 300mm 2600mm upto 9000C upto 600 kpa

30. Slide Plate / Goggle Valvles (no limitation on size) 350mm upto 9000C upto 250 kpa

31. Double Eccentric Butterfly Valves 200mm 4200mm upto 4000C upto 600 kpa

32. Two Lever / Push Lever Valves 500mm 4000mm upto 6000C upto 600 kpa

33. Three Lever Valve 500 mm & above upto 6000C upto 600 kpa

34. Snort Valves 500 mm & above upto 3000C upto 600 kpa

35. Contacting Butterfly Valves 200mm 4200mm upto 9000C upto 600 kpa

36. Non Contacting Butterfly Valves 200mm 4200mm upto 9000C upto 600 kpa

37. Triple Eccentric Butterfly Valves 200 mm 4200mm upto 9000C upto 600 kpa

38. High Temperature Damper (BFV + Gate) 200mm 4000mm upto 16000C upto 6000kpa

39. Pressure Relief & Equalising Valves 250mm & above upto 6000C upto 2 kpa

40. Septum Valve 1200mm 3000mm upto 2000C upto 250 kpa

41. Coffee Pot Valve 400mm & above upto 9000C upto 600 kpa

42. Bleeder Valves (Cap Type) 150mm & above upto 6000C upto 200 kpa

HYDRO POWER GENERATION

43. Hydro Turbines; Francis/Semi-Kaplan/Kaplan; Pelton Wheel

with governor (Hydraulic/Electronic) & Control System & Water to Wire Products Generating Capacity - upto 25 MW

AGENCY PRODUCTS

44. International Agency Division - Water System & Hydro Power

a. SFC Key Interlocks for Plant's safety, Remote Valve Operator and Flame Arrestors cum breather valves

b. Dorot-Surge Protection Control Valve, Environmental Products, RathGibson - SS tubings/coils (USA)

Mumbai Plant (BYP)

Mumbai Plant manufactures Standard and Speciality type Gate,

Globe and Check valves in Carbon steel, Alloy stel, Stainless Steel

(WCB, WC6, WC9, CF8, CF8M, CF3, CF3M, A105, F11, F22 &

others). Manual and electrically operated valves are designed and

manufactured in accordance with the standards of API, ANSI and

BS.

Also, we manufacture Ebonite lined Tamper proof Air Release

Valves (Range 40mm-250mm) for water supply and infrastructure

projects requirement and Sea Water Application . Core Capabilities

Design | Research & Development | Application Engineering | Manufacturing | Quality

Management | Field Service | Project Management | Refurbishment

At the core of Fouress lies its capability in assimilating and adapting technology. Building on early technology

partnerships with world leaders and later

carefully inter-twining easter and

western strengths, Fouress Group

has put in place a sound control,

regulation, propulsion, power

generation and lately, noise and

heat regulation in fluid paths. Flow

model testing and simulation

techniques are routinely applied for

product development, custom-made high-value

jobs such as large gas turbine diverters, Hydraulic research lab and life-cycle

2 3

1 testing facilities to validate the basic designs have contributed to brand

nomination of Fouress products for intensive capital projects. The design

center at Bangalore plant has now been accredited as recognized R&D

center by the Department of Science and Technology, Government of India.

Specialised software and modelling for seismic analysis of equipment for

Nuclear Power Stations, Rotary Air locks for material handling industry, Fire

safety qualification for helicopter’s Fuel Rig valves for Indian Navy are some of the

landmark achievemnts of Fouress R & D.

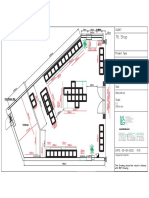

Manufacturing Capabilities

We manufacture our products in three major plants at different locations in India. The production activities are

4 5 6 supported by workforce of over 1000 and modern manufacturing facilities at Mumbai, Bangalore and Aurangabad.

Three more subsidiary plants are in Baroda, Chennai and Bangalore. For better control on quality and delivery, the

emphasis has always been on substantial manufacture, in-house. Eight production centers of Fouress Group in various

parts of India have been equipped with extensive manufacturing, material handling and surface treatment capabilities to

create a high-end but complementary production infrastructure.

Some High Points

• 60-ton single piece handling facility • 100000 sq. ft. under crane

• Vertical turning/boring capacity up to 6000mm • 3-dimensional profie checking for propellers and

• Shaft turning up to 15000 mm between centers turbine blades

• Hollow boring up to 7500 mm • Instruments and gauge calibration facilities relation to

8 • 250 ton press brake and shearing, 300 ton forming press national standards

7 9

• TIG/MIG/MMA and submerged arc welding up to 200 mm • CNC Gas & Plasma curring for CS & SS plates

1. 8" x 12" x 300 # WCB Gate Valves to Essar Refinery, 4. 1” - 1 1/2” x 800# Forged Steel Globe valves to Haldia 7. 8" Air Release Valves to SMC Infrastructure Pvt Ltd., Mumbai • Full penetration butt weld (Automatic & semi-automatic) • CNC Drilling

Jamnagar for Speciality Sour Service Application Petrochemicals Ltd., Kolkata 8. 2" x 600#, 4" x 150#, 6" x 150# Globe Valves to • Super finishing equipment for cylindrical and flat surface • Full back-up DG captive power

2. 6" - 16" 150# WCB Check Valves to Siemens Vai, 5. 1/2" - 2" x 800# Forged Steel Gate Valves to Blue Star Reliance Petroleum Ltd.

• FEA, Solid Modulling

Kolkata, a/c Tata Steel Ltd. Ltd., Kolkatta 9. 6” 150# WCB - Gate Vales to IOCL Panipat through

3. 6” x 600# WC6 Globe Valve to Cobepex SA., Belgium 6. 3/4" - 2" x 800# Forged Steel Check Valves to Axtel Petron Engineering Construction Ltd., Mumbai

Industries Ltd., Baroda

Bangalore Plant (BGP) Aurangabad Plant (AGP)

The Bangalore Plant manufactures a range of Butterfly valves, Way back in 1983, Fouress commenced manufacture of steel

Gas Tight Isolators, Exhaust Systems for the Gas Turbine Power plant valves, blast furnace auxiliaries and other associated

Plants, Knife Gate valves, High performance valves, Fire safe and equipment under license from M/s. Herman Rappold and Co.

Pyrogenic valves. GmbH (RACO). Complete range of valves and equipment for

major steel plant and mini blast furnace are manufactured in our

BGP is our largest and most prestigious profit centre and a plant at Aurangabad, which is specially set up for this industry.

manufacturing complex of the group backed by sophisticated Over the years, we have absorbed the technology and we have

Design and R&D facilities. BGP products have also qulaified for been supplying our products based on our experience and

supply to European Union countries through CE marking. feedback from our customers worldwide.

We are manufacturing these valves for over 31 years and more

than 7000 of our valves are operating satisfactorily at various plants.

Aurangabad plant also manufacturers standard and special type Gate, Globe, Check and Dual Plate Check valves in Carbon

Steel, Alloy Steel, Stainless Steel (WCB, WC6, CF8, CF8M, CF3, CF3M, A105, F11, F22). Manual and Electrically operated

valves are designed and manufactured in accordance with the standard of API, ANSI and BS with various testing speciality.

1

3

1 2 3 2

4 5 6

8

4 5

7 9

1. 4000mm Goggle Valve to JSW Steel Ltd., Bellary,

Karnataka

2. 42" x 300# C S Gate Valve to Reliance Petroleum Ltd.,

Jamnagar Refinery.

3. 2"-24", 150# - 600# Cast steelgate valves to BHEL,

Trichy

4. 10" x 300# Cast Steel Check Valves to TISCO,

Jamshedpur

7 8 9 5. 900 mm to 2800 mm Butterfly Dampers to SMS

Demag, Iskenderum Demir VE, Celik AS, Turkey

1 Electrically Operated Guillotine Isolator for Siemens V94.2 4 Fouress Blackhall Larner Jhonson Flow Control Valve 7. 17500 mm x 4012 mm Electro-hydraulically operated 6. 1100 mm Fouress-Raco Hot Blast, Valve (Egypt).

Gas Turbine. Project: NTPC, Faridabad. (1350mmx762mmx1350mm) supplied to Municipal Multi-Louvre Damper to Taichung Power Station, Taiwan 7. 1300 mm Hot Blast Valves to Mittal Steel, Kazakhstan.

2. Electrically Operated Diverter Damper supplied for GE Corporation of Greater Mumbai. (MCGM) through Mitsui Babcock, UK.

10 11 8. 3”-20”, 150#-600 # Cast Steel Globe Valves to JSW

Frame 9E Gas Turbine. Project: GIPCL, Baroda. 5. 3600 mm Electrically operated Knife Gate Valve with Super 8. 3100 mm Hydraulically operated Penstock Protection Valve Steel, Bellary.

3. 1400MM Electrically Operated Butterfly Valve supplied to Duplex SS blade and lining. Project: Harbor Area Treatment supplied to Wyangala Hydro Electric Power Station, Australia.

Scheme, Stone Cutter Island Hong Kong.. 9. CI Wafer Type Dual Plate Check valve in sizes 20” & 16” 10. 2200 mm Two lever valve to Alstom Projects, Delhi.

NKK, Japan 9. 1500 mm Multi-door Reflux Valve supplied to Bangalore

PN 0.6 class supplied to Dhariwal Infrastructure Ltd. 2x300 MW 11. Clean Gas Throttle Valve (Septum valve) size ND2800

6. Pneumatically Operated Multi-louver Damper internally Water Supply and Sewage Board (BWSSB)

Thermal Power Proj. Chandrapur Dist. through Punj Lloyd Ltd. supplied to RINL – Visakhapatnam Steel Plant thru Siemens

lined with Hastalloy C276 for FGD Plant. Project: JSW,

Ratnagiri. VAI Metal Technologies (P) Ltd

Bangalore Plant (BGP) Aurangabad Plant (AGP)

The Bangalore Plant manufactures a range of Butterfly valves, Way back in 1983, Fouress commenced manufacture of steel

Gas Tight Isolators, Exhaust Systems for the Gas Turbine Power plant valves, blast furnace auxiliaries and other associated

Plants, Knife Gate valves, High performance valves, Fire safe and equipment under license from M/s. Herman Rappold and Co.

Pyrogenic valves. GmbH (RACO). Complete range of valves and equipment for

major steel plant and mini blast furnace are manufactured in our

BGP is our largest and most prestigious profit centre and a plant at Aurangabad, which is specially set up for this industry.

manufacturing complex of the group backed by sophisticated Over the years, we have absorbed the technology and we have

Design and R&D facilities. BGP products have also qulaified for been supplying our products based on our experience and

supply to European Union countries through CE marking. feedback from our customers worldwide.

We are manufacturing these valves for over 31 years and more

than 7000 of our valves are operating satisfactorily at various plants.

Aurangabad plant also manufacturers standard and special type Gate, Globe, Check and Dual Plate Check valves in Carbon

Steel, Alloy Steel, Stainless Steel (WCB, WC6, CF8, CF8M, CF3, CF3M, A105, F11, F22). Manual and Electrically operated

valves are designed and manufactured in accordance with the standard of API, ANSI and BS with various testing speciality.

1

3

1 2 3 2

4 5 6

8

4 5

7 9

1. 4000mm Goggle Valve to JSW Steel Ltd., Bellary,

Karnataka

2. 42" x 300# C S Gate Valve to Reliance Petroleum Ltd.,

Jamnagar Refinery.

3. 2"-24", 150# - 600# Cast steelgate valves to BHEL,

Trichy

4. 10" x 300# Cast Steel Check Valves to TISCO,

Jamshedpur

7 8 9 5. 900 mm to 2800 mm Butterfly Dampers to SMS

Demag, Iskenderum Demir VE, Celik AS, Turkey

1 Electrically Operated Guillotine Isolator for Siemens V94.2 4 Fouress Blackhall Larner Jhonson Flow Control Valve 7. 17500 mm x 4012 mm Electro-hydraulically operated 6. 1100 mm Fouress-Raco Hot Blast, Valve (Egypt).

Gas Turbine. Project: NTPC, Faridabad. (1350mmx762mmx1350mm) supplied to Municipal Multi-Louvre Damper to Taichung Power Station, Taiwan 7. 1300 mm Hot Blast Valves to Mittal Steel, Kazakhstan.

2. Electrically Operated Diverter Damper supplied for GE Corporation of Greater Mumbai. (MCGM) through Mitsui Babcock, UK.

10 11 8. 3”-20”, 150#-600 # Cast Steel Globe Valves to JSW

Frame 9E Gas Turbine. Project: GIPCL, Baroda. 5. 3600 mm Electrically operated Knife Gate Valve with Super 8. 3100 mm Hydraulically operated Penstock Protection Valve Steel, Bellary.

3. 1400MM Electrically Operated Butterfly Valve supplied to Duplex SS blade and lining. Project: Harbor Area Treatment supplied to Wyangala Hydro Electric Power Station, Australia.

Scheme, Stone Cutter Island Hong Kong.. 9. CI Wafer Type Dual Plate Check valve in sizes 20” & 16” 10. 2200 mm Two lever valve to Alstom Projects, Delhi.

NKK, Japan 9. 1500 mm Multi-door Reflux Valve supplied to Bangalore

PN 0.6 class supplied to Dhariwal Infrastructure Ltd. 2x300 MW 11. Clean Gas Throttle Valve (Septum valve) size ND2800

6. Pneumatically Operated Multi-louver Damper internally Water Supply and Sewage Board (BWSSB)

Thermal Power Proj. Chandrapur Dist. through Punj Lloyd Ltd. supplied to RINL – Visakhapatnam Steel Plant thru Siemens

lined with Hastalloy C276 for FGD Plant. Project: JSW,

Ratnagiri. VAI Metal Technologies (P) Ltd

Mumbai Plant (BYP)

Mumbai Plant manufactures Standard and Speciality type Gate,

Globe and Check valves in Carbon steel, Alloy stel, Stainless Steel

(WCB, WC6, WC9, CF8, CF8M, CF3, CF3M, A105, F11, F22 &

others). Manual and electrically operated valves are designed and

manufactured in accordance with the standards of API, ANSI and

BS.

Also, we manufacture Ebonite lined Tamper proof Air Release

Valves (Range 40mm-250mm) for water supply and infrastructure

projects requirement and Sea Water Application . Core Capabilities

Design | Research & Development | Application Engineering | Manufacturing | Quality

Management | Field Service | Project Management | Refurbishment

At the core of Fouress lies its capability in assimilating and adapting technology. Building on early technology

partnerships with world leaders and later

carefully inter-twining easter and

western strengths, Fouress Group

has put in place a sound control,

regulation, propulsion, power

generation and lately, noise and

heat regulation in fluid paths. Flow

model testing and simulation

techniques are routinely applied for

product development, custom-made high-value

jobs such as large gas turbine diverters, Hydraulic research lab and life-cycle

2 3

1 testing facilities to validate the basic designs have contributed to brand

nomination of Fouress products for intensive capital projects. The design

center at Bangalore plant has now been accredited as recognized R&D

center by the Department of Science and Technology, Government of India.

Specialised software and modelling for seismic analysis of equipment for

Nuclear Power Stations, Rotary Air locks for material handling industry, Fire

safety qualification for helicopter’s Fuel Rig valves for Indian Navy are some of the

landmark achievemnts of Fouress R & D.

Manufacturing Capabilities

We manufacture our products in three major plants at different locations in India. The production activities are

4 5 6 supported by workforce of over 1000 and modern manufacturing facilities at Mumbai, Bangalore and Aurangabad.

Three more subsidiary plants are in Baroda, Chennai and Bangalore. For better control on quality and delivery, the

emphasis has always been on substantial manufacture, in-house. Eight production centers of Fouress Group in various

parts of India have been equipped with extensive manufacturing, material handling and surface treatment capabilities to

create a high-end but complementary production infrastructure.

Some High Points

• 60-ton single piece handling facility • 100000 sq. ft. under crane

• Vertical turning/boring capacity up to 6000mm • 3-dimensional profie checking for propellers and

• Shaft turning up to 15000 mm between centers turbine blades

• Hollow boring up to 7500 mm • Instruments and gauge calibration facilities relation to

8 • 250 ton press brake and shearing, 300 ton forming press national standards

7 9

• TIG/MIG/MMA and submerged arc welding up to 200 mm • CNC Gas & Plasma curring for CS & SS plates

1. 8" x 12" x 300 # WCB Gate Valves to Essar Refinery, 4. 1” - 1 1/2” x 800# Forged Steel Globe valves to Haldia 7. 8" Air Release Valves to SMC Infrastructure Pvt Ltd., Mumbai • Full penetration butt weld (Automatic & semi-automatic) • CNC Drilling

Jamnagar for Speciality Sour Service Application Petrochemicals Ltd., Kolkata 8. 2" x 600#, 4" x 150#, 6" x 150# Globe Valves to • Super finishing equipment for cylindrical and flat surface • Full back-up DG captive power

2. 6" - 16" 150# WCB Check Valves to Siemens Vai, 5. 1/2" - 2" x 800# Forged Steel Gate Valves to Blue Star Reliance Petroleum Ltd.

• FEA, Solid Modulling

Kolkata, a/c Tata Steel Ltd. Ltd., Kolkatta 9. 6” 150# WCB - Gate Vales to IOCL Panipat through

3. 6” x 600# WC6 Globe Valve to Cobepex SA., Belgium 6. 3/4" - 2" x 800# Forged Steel Check Valves to Axtel Petron Engineering Construction Ltd., Mumbai

Industries Ltd., Baroda

PRODUCT

PORTFOLIO

Product Size Range Maximum

Min. Max. Temp. Pressure

INDUSTRIAL VALVES FOR FLUID ISOLATION & REGULATION

1. Wedge Gate, Globe and Check Valves

- Forged Construction

Gate Valve 1/4" 2" - 800 # -2500 #

Globe Valve 1/4" 1.5" - 800 # - 2500 #

Check Valve 1/4" 1.5" - 800 # - 2500 #

- Cast Construction

Gate Valve 2" 64" - 150 # - 2500 #

Globe Valve 2" 20" - 150 # - 2500 #

Check Valve 2" 36" - 150 # - 2500 #

Dual Plate Check Valve 2" 48" - 150 # - 600 #

2. Dual Plate Check valve (metal seated & rubber seated) 2” 48”

3. Single/Double Eccentric Butterfly Valve 100mm 4000mm 1800C 40 kg/cm2

Bangalore Plant

Valves And Gas Tight Isolators , 4. Compact Seal Butterfly Valves 50mm 600mm 1200C 10 kg/cm2

Damper For Power, Water, 5. High Performance Butterfly Valves 4S-V5422 & 4S-V30 #300 50mm 600mm 2300C 20 kg/cm2

Wastewater, Steel, Cement, 6. Pump Discharge Buttefly Valves 450mm 3500mm Ambient 16 kg/cm2

Refineries, Petrochemicals &

Process Industries 7. Triple Eccentric multifunction valves 600mm 2000mm 1200C

8. Triple Eccentric Metal seated Butterfly Valve / Pyrogenic / 80mm 2000mm 5500C 16 kg/cm2

Fire Safe Butterfly Valves

9. Four way Flow Reversing Valves 600mm 2200mm Ambient 26 kg/cm2

10. Single door Butterfly Reflux Valve and Multi-door Reflux Valve 500mm 1800mm Ambient 10 kg/cm2

11. Air Release Valve 50mm 250mm

WATER SYSTEMS & HYDRO POWER AUXILLARIES

12. Penstock Protection/Turbine Inlet Butterfly Valve* 300mm 4000mm Ambient 45 kg/cm2

13. Rotary (Spherical) Valve 400mm 1200mm Ambient upto 100 kg/cm2

14. Discharge Regulator & Fixed Cone Dispense Valve 300mm 3000mm Ambient 10 kg/cm2

15. Lattice Blade Valve / Bi-Plane Disc Butterfly Valve* - 4000mm Ambient 45 kg/cm2

16. Plunger Valve 700mm 2000mm

SOLIDS & SLURRIES HANDLING SYSTEMS

17. FOURESS - V336D Knife Gate Valve 50mm 3600 mm upto 2300C 10 kg/cm2

18. FOURESS - V336L Knife Gate Valve 50 mm 600 mm upto 2300C 10 kg/cm2

19. FOURESS - Fully Stainless Steel/Lined Knife Gate Valve customised upto 3600mm

HIGH INTEGRITY GAS-TIGHT ISOLATORS FOR GENERAL INDUSTRIAL APPLICATION WITH FLEXIBLE METALLIC SEALING SYSTEM

20. Gullotine Isolators (tailor made to customer requirement) 500mm duct dimension onwards 6500C ±2500 mm WG

21. Glandular Spade Valve (tailor made to customer requirement) 500mm duct dimension onwards 3500C -800mm to 100mm WG

22. Goggle Spade Valve (tailor made to customer requirement) 500mm duct dimension onwards 3500C -2000mm to+100mm WG

23. Flap Isolators (tailor made to customer requirement) 500mm duct dimension onwards 6500C ±2500 mm WG

24. Twin Seal Flap Isolators (tailor made to customer requirement) 500mm duct dimension onwards 5000C ±2500 mm WG

25. Louvre Dampers (tailor made to customer requirement) 500mm duct dimension onwards 6500C ±2500 mm WG

26. Diverter Flap Valve (tailor made to customer requirement) 500mm duct dimension onwards 6500C ±2500 mm WG

GAS LINE VALVES (INDUSTRIAL VALVES) FOR METALLURGIAL INDUSTRIES AND STEEL MILLS

27. Hot Blast Valves 500mm and above upto 15500C upto 600 kpa

28. Single Disc Gate Valves 300mm 3000mm upto 9000C upto 600 kpa

29. Double Disc Gate Valves 300mm 2600mm upto 9000C upto 600 kpa

30. Slide Plate / Goggle Valvles (no limitation on size) 350mm upto 9000C upto 250 kpa

31. Double Eccentric Butterfly Valves 200mm 4200mm upto 4000C upto 600 kpa

32. Two Lever / Push Lever Valves 500mm 4000mm upto 6000C upto 600 kpa

33. Three Lever Valve 500 mm & above upto 6000C upto 600 kpa

34. Snort Valves 500 mm & above upto 3000C upto 600 kpa

35. Contacting Butterfly Valves 200mm 4200mm upto 9000C upto 600 kpa

36. Non Contacting Butterfly Valves 200mm 4200mm upto 9000C upto 600 kpa

37. Triple Eccentric Butterfly Valves 200 mm 4200mm upto 9000C upto 600 kpa

38. High Temperature Damper (BFV + Gate) 200mm 4000mm upto 16000C upto 6000kpa

39. Pressure Relief & Equalising Valves 250mm & above upto 6000C upto 2 kpa

40. Septum Valve 1200mm 3000mm upto 2000C upto 250 kpa

41. Coffee Pot Valve 400mm & above upto 9000C upto 600 kpa

42. Bleeder Valves (Cap Type) 150mm & above upto 6000C upto 200 kpa

HYDRO POWER GENERATION

43. Hydro Turbines; Francis/Semi-Kaplan/Kaplan; Pelton Wheel

with governor (Hydraulic/Electronic) & Control System & Water to Wire Products Generating Capacity - upto 25 MW

AGENCY PRODUCTS

44. International Agency Division - Water System & Hydro Power

a. SFC Key Interlocks for Plant's safety, Remote Valve Operator and Flame Arrestors cum breather valves

b. Dorot-Surge Protection Control Valve, Environmental Products, RathGibson - SS tubings/coils (USA)

Chairman’s Office & Head Quarters Group Companies

Mahalaxmi Chambers, 22, Bhulabhai Desai Road, B Fouress Pvt. Ltd.

MUMBAI - 400 026 Plot No:7, KIADB Indl.Area, HOSKOTE – 562 114

Tel: +91 22 2353 4400-05 Bengaluru District, Karnataka

Fax: +91 22 2351 7544 Tel: +91 80 2797 1641

E-mail: hq@fouressindia.com Fax: +91 80 2797 1455

Website: www.fouressindia.com E-mail: info@bflhydro.com

Website: www.bflhydro.com

Plants PEE Industrial Valves Pvt. Ltd.

Fouress Engineering (India) Ltd.

Plot No: B-63(A), SIPCOT Industrial Complex

Plot No.A-324, Road No:21, Wagle Indl. Estate

GUMMIDIPOONDI - 601 201, Tamil Nadu

THANE – 400 604 Maharashtra

Tel: +91 44 2792 3050

Tel: +91 22 2582 3806 / 3602

Fax: +91 44 2792 3099

Fax: +91 22 2582 3603

E-mail: petrochemical@vsnl.com

E-mail: byp@fouressindia.com

Fouress Marketing (Intnl.) Pvt. Ltd.

Fouress Engineering (India) Ltd.

A-1/842, GIDC Indl.Estate, Makarpura

Plot 2, Phase II, Peenya Industrial Area

VADODARA - 390 010, Gujarat

BENGALURU - 560 058, Karnataka

Tel: +91 265 658 1245

Tel: +91 80 2839 5734 2839 5494

Fax: +91 265 264 6518

Fax: +91 80 2839 5176

E-mail: info@fmiplbrd.com

E-mail: info@fouressindia.com

Bombay Engineering Industries

Fouress Engineering (India) Ltd.

A-186, IV Cross, Ist Phase, Peenya Industrial Estate

C-2, MIDC Industrial Area, Paithan - 431 148

BENGALURU-560 058, Karnataka

AURANGABAD, Maharashtra

Tel: +91 80 2839 3849

Tel: +91 2431 232 074, 232190

Fax: +91 80 2839 9605

Fax: +91 2431 232 058

E-mail: beibangalore@yahoo.com

E-mail: aurangabad@fouressindia.com

The Rubber Products Ltd.

Branches & Representatives Plot C-44, Road No: 28, Wagle Industrial Estate

Mumbai feilmumbai@fouressindia.com THANE – 400 604, Maharashtra

Baroda feilbaroda@fouressindia.com Tel: +91 22 2582 2551 - 53

Delhi feildelhi@fouressindia.com Fax: +91 22 2582 0876

Hyderabad feilhyd@fouressindia.com E-mail: rpl@rubpro.com

Pune feilpune@fouressindia.com Website: www.rubpro.com

Vizag Rep. feilvizag@fouressindia.com

Chennai feilchennai@fouressindia.com

Nagpur Rep. feilnagpur@fouressindia.com

Kolkata feilkolkata@fouressindia.com

Bhubaneshwar feilbnrs@fouressindia.com

International Agency Division

iad@fouressindia.com

You might also like

- Wagle Estate DataDocument61 pagesWagle Estate DataMrudulaNo ratings yet

- Plumbing and Sanitary Systems Topic 1 Module 1 LectureDocument55 pagesPlumbing and Sanitary Systems Topic 1 Module 1 Lecturechristian001 LatagNo ratings yet

- 20brochure PDFDocument27 pages20brochure PDFparet999No ratings yet

- Tube Expander-Tools PDFDocument120 pagesTube Expander-Tools PDFmarceilinus devaluantoNo ratings yet

- OM SAI ProfileDocument10 pagesOM SAI ProfileBittuNo ratings yet

- Hdpe PipeDocument7 pagesHdpe PipeAattakaariNo ratings yet

- ProtegoDocument5 pagesProtegoNatarajan RavisankarNo ratings yet

- Hifit Industries-ProfileDocument6 pagesHifit Industries-Profileprakash 3No ratings yet

- Robot Hydraulics HsaDocument246 pagesRobot Hydraulics HsaSHANENo ratings yet

- Sewing Clutch Motor Pulley PDFDocument15 pagesSewing Clutch Motor Pulley PDFArja'un TeaNo ratings yet

- Sewing Clutch Motor Pulley PDFDocument15 pagesSewing Clutch Motor Pulley PDFArja'un TeaNo ratings yet

- Nirmala Industrial Services: Company ProfileDocument9 pagesNirmala Industrial Services: Company ProfileSaravanan DevarajanNo ratings yet

- Acasales Technologies IncDocument10 pagesAcasales Technologies IncTeoxNo ratings yet

- 2015 Shurjoint General Catalog v3Document217 pages2015 Shurjoint General Catalog v3Jesus Javier100% (1)

- Feel Ind. Engineering Co., Ltd. Fine Equipment (I) Pvt. Ltd. Feel Machine Co., Ltd. Feeleng America Inc. Feeleng Latin AmericaDocument22 pagesFeel Ind. Engineering Co., Ltd. Fine Equipment (I) Pvt. Ltd. Feel Machine Co., Ltd. Feeleng America Inc. Feeleng Latin Americapt. npm cabang kendariNo ratings yet

- 400 Series Connect2 Medical Gas Outlets: ElementsDocument4 pages400 Series Connect2 Medical Gas Outlets: ElementsfunefoNo ratings yet

- Air & Vacuum Air Valve For High Flow: PN 16 PN 25 PN 40Document4 pagesAir & Vacuum Air Valve For High Flow: PN 16 PN 25 PN 40Ramiro D Gallegos TNo ratings yet

- Robotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icDocument8 pagesRobotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icAsrul Arashi IrdianaNo ratings yet

- Thermacut HiFocus 160i/280i/360i/440iDocument4 pagesThermacut HiFocus 160i/280i/360i/440iVamesu GabiNo ratings yet

- Up Date ++ - + +++-+ Revised 01Document10 pagesUp Date ++ - + +++-+ Revised 01Priyaprasad PandaNo ratings yet

- 100AFEDocument191 pages100AFEchris pNo ratings yet

- Astral Pe/Pp Manhole & Inspection Chambers: Astral Poly Technik LimitedDocument2 pagesAstral Pe/Pp Manhole & Inspection Chambers: Astral Poly Technik LimitedKSBNo ratings yet

- MAR - GI Pipes & Fittings - 02.08.22Document107 pagesMAR - GI Pipes & Fittings - 02.08.22Ansaf AskyNo ratings yet

- Industrial TrainingDocument33 pagesIndustrial Trainingpawan0% (1)

- Ball Valves: Engineered Reliability From Design To DeliveryDocument6 pagesBall Valves: Engineered Reliability From Design To DeliveryVitória MarcenariaNo ratings yet

- Foot ValveDocument2 pagesFoot Valveshashikanth79No ratings yet

- Basic 250 EngDocument9 pagesBasic 250 EngPurushothaman JayabalanNo ratings yet

- Product Price List: Viceroy Trading & Investments, IncDocument1 pageProduct Price List: Viceroy Trading & Investments, IncViceroy2012No ratings yet

- Company Profile SimpleDocument7 pagesCompany Profile SimpleAsif MemonNo ratings yet

- VEL BS 2001aDocument20 pagesVEL BS 2001aritoh8657No ratings yet

- Sp4800 Sp8800 FlipbookDocument6 pagesSp4800 Sp8800 FlipbookTimothy Mcmillan100% (1)

- Blister Packaging-MachinesDocument8 pagesBlister Packaging-MachinesSatyam MadameNo ratings yet

- Jai Bajrang Sales, Khamgaon QTN 30 TR Cooling Tower ECT 7712 (05 OCTOBER 2020)Document14 pagesJai Bajrang Sales, Khamgaon QTN 30 TR Cooling Tower ECT 7712 (05 OCTOBER 2020)9D 24 Prem b jadhaoNo ratings yet

- Bostik India Private Limited: Equipment Master Equipment Technical DataDocument17 pagesBostik India Private Limited: Equipment Master Equipment Technical Datapradip11No ratings yet

- Watson McDaniel Product Catalog-2013Document336 pagesWatson McDaniel Product Catalog-2013sas999333100% (1)

- 3500 Series Replacement Parts For ASME/ANSI B73.1M PumpsDocument4 pages3500 Series Replacement Parts For ASME/ANSI B73.1M PumpsmetropumpsNo ratings yet

- Delta 500 EngDocument9 pagesDelta 500 EngPurushothaman JayabalanNo ratings yet

- T101 Drilling MachineDocument4 pagesT101 Drilling MachineFranklin Avendaño ArapaNo ratings yet

- T101 Drilling Machine BrochureDocument4 pagesT101 Drilling Machine BrochureRicardo OrtegaNo ratings yet

- BT1100 Teltru 16 17Document2 pagesBT1100 Teltru 16 17Prihartono Danan WingusNo ratings yet

- REEDDocument8 pagesREEDWilliam EvansNo ratings yet

- Engineered NozzlesDocument2 pagesEngineered NozzlesJavier Guillermo Nuñez ValdiviaNo ratings yet

- Delta 1000 EngDocument9 pagesDelta 1000 Engnour eldinNo ratings yet

- Manual Lubrication SystemsDocument10 pagesManual Lubrication SystemschekuswekuNo ratings yet

- Man Made Fiber IndustryDocument84 pagesMan Made Fiber Industrypkm_77No ratings yet

- Fiche Technique SableuseDocument7 pagesFiche Technique SableuseyassinNo ratings yet

- SS316 Hose FittingsDocument79 pagesSS316 Hose FittingsRasheshNo ratings yet

- Crushir - Digital Hydraulic PressDocument1 pageCrushir - Digital Hydraulic PressSUPER_HERRERANo ratings yet

- ZIGMA-02 A - AP - PDF - Atech Machinery PDFDocument27 pagesZIGMA-02 A - AP - PDF - Atech Machinery PDFsinh998No ratings yet

- Gts D Mass BrochureDocument2 pagesGts D Mass Brochureshubham7651No ratings yet

- Mobile Crusher Manual Operation SIS-AdaroDocument30 pagesMobile Crusher Manual Operation SIS-Adarohengki sahanaNo ratings yet

- (Eng) DAEMO FULL LINEUP - Catalog - 16p - 140211 (7th)Document16 pages(Eng) DAEMO FULL LINEUP - Catalog - 16p - 140211 (7th)Mahendra Tyre Works RaigarhNo ratings yet

- Water Cooled Screw Chiller R134aDocument8 pagesWater Cooled Screw Chiller R134aRehan IsmailNo ratings yet

- Black Eagle - High Pressure Oilfield Hose - API 7k HoseDocument3 pagesBlack Eagle - High Pressure Oilfield Hose - API 7k Hoseahmed.mnifNo ratings yet

- EMCO Electro - Hydraulic Drum BrakeDocument7 pagesEMCO Electro - Hydraulic Drum Brakehardik033No ratings yet

- (LR) Pressure Piping System 04062015Document32 pages(LR) Pressure Piping System 04062015ag shafiee .adzmeyNo ratings yet

- Ambica Enterprises: Bhagyashree SWR Price List Date:-15-08-2020Document5 pagesAmbica Enterprises: Bhagyashree SWR Price List Date:-15-08-2020Parth DamaNo ratings yet

- Type 680 Hydraulic Stage CollarDocument6 pagesType 680 Hydraulic Stage Collar唐辉No ratings yet

- Firelock Butterfly Valve: Series 705 With Weatherproof ActuatorDocument7 pagesFirelock Butterfly Valve: Series 705 With Weatherproof ActuatorDefy BbalNo ratings yet

- ECOSEPT P-Series CatalogueDocument2 pagesECOSEPT P-Series Catalogueaniza zazaNo ratings yet

- Fluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesFrom EverandFluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesNo ratings yet

- Goggle Valves CatalogueDocument4 pagesGoggle Valves CatalogueShankey JAlanNo ratings yet

- RT Report-2Document1 pageRT Report-2Shankey JAlanNo ratings yet

- Number of SpringsDocument1 pageNumber of SpringsShankey JAlanNo ratings yet

- Fillet Inspection SheetDocument2 pagesFillet Inspection SheetShankey JAlanNo ratings yet

- RT Report-4Document1 pageRT Report-4Shankey JAlanNo ratings yet

- RT Report-3Document1 pageRT Report-3Shankey JAlanNo ratings yet

- Rack and Pinion-Assessment ReportDocument3 pagesRack and Pinion-Assessment ReportShankey JAlanNo ratings yet

- RT Report-5Document1 pageRT Report-5Shankey JAlanNo ratings yet

- LPGTK-PVP-INT-MRQ-7001 - C - MR For CV Code-4Document61 pagesLPGTK-PVP-INT-MRQ-7001 - C - MR For CV Code-4Shankey JAlanNo ratings yet

- Control Valve DWGDocument4 pagesControl Valve DWGShankey JAlanNo ratings yet

- Balancing ValveDocument4 pagesBalancing ValveShankey JAlanNo ratings yet

- User Manual: KX-TES824 KX-TEM824Document172 pagesUser Manual: KX-TES824 KX-TEM824Shankey JAlanNo ratings yet

- 150 MM BFV DiscDocument1 page150 MM BFV DiscShankey JAlanNo ratings yet

- ASSY Model PDFDocument1 pageASSY Model PDFShankey JAlanNo ratings yet

- E-Way Bill SystemDocument1 pageE-Way Bill SystemShankey JAlanNo ratings yet

- Challan MTR Form Number-6Document1 pageChallan MTR Form Number-6Shankey JAlanNo ratings yet

- Challan MTR Form Number-6Document1 pageChallan MTR Form Number-6Shankey JAlanNo ratings yet

- QC Weekly Report 4th Week Sept.Document1 pageQC Weekly Report 4th Week Sept.Shankey JAlanNo ratings yet

- Challan 900 (08-03-2018)Document1 pageChallan 900 (08-03-2018)Shankey JAlanNo ratings yet

- MTC No 15 of Ltb2 DT 6-10-17Document1 pageMTC No 15 of Ltb2 DT 6-10-17Shankey JAlanNo ratings yet

- Chemical Compositions, Microstructure and Mechanical  Properties of Roll Core Used Ductile Iron in Centrifugal Casting Composite Rolls PDFDocument6 pagesChemical Compositions, Microstructure and Mechanical  Properties of Roll Core Used Ductile Iron in Centrifugal Casting Composite Rolls PDFShankey JAlanNo ratings yet

- Weekly Report QC Dept 2nd Week AugustDocument1 pageWeekly Report QC Dept 2nd Week AugustShankey JAlanNo ratings yet

- Chempump 500 SeriesDocument20 pagesChempump 500 Seriesozeias.rosaNo ratings yet

- PMS A10aDocument6 pagesPMS A10aVinay TrivediNo ratings yet

- Shop Decoration: Designed by Yousef BKWDocument13 pagesShop Decoration: Designed by Yousef BKWMustafa HusseinNo ratings yet

- Csi Master Catalog 2022Document156 pagesCsi Master Catalog 2022Jhon VasquezNo ratings yet

- Ems Cart Kits Cat Vane PumpsDocument2 pagesEms Cart Kits Cat Vane PumpsEdgar Rojas EspejoNo ratings yet

- Transfer Pump-2Document21 pagesTransfer Pump-2sunii19847908100% (1)

- B Series InjectorsDocument1 pageB Series InjectorsJakub DubravskyNo ratings yet

- WILO SCP RangeDocument48 pagesWILO SCP RangeSaikat PurkaitNo ratings yet

- SveDocument28 pagesSveseaqu3stNo ratings yet

- Cetrifugal Pumps PerformanceDocument36 pagesCetrifugal Pumps PerformanceBrajendra Kumar100% (1)

- 03 BR - Hydraulics Competitive CrossoverDocument24 pages03 BR - Hydraulics Competitive CrossoverAbderrahim RiadNo ratings yet

- Servo Block - Control of Functions - CATDocument2 pagesServo Block - Control of Functions - CATEdison Pfoccori BarrionuevoNo ratings yet

- PumpDocument71 pagesPumpfacebookshopNo ratings yet

- 2B) Inlet Air Shut-Off ValveDocument2 pages2B) Inlet Air Shut-Off ValveMohamed HamedNo ratings yet

- Hydraulic Pumps PDFDocument22 pagesHydraulic Pumps PDFhamza MoussaidNo ratings yet

- Sh1 Dhi p0100 M m01 Pid 5301 - Symbol and Legend 1 of 4Document1 pageSh1 Dhi p0100 M m01 Pid 5301 - Symbol and Legend 1 of 4Thanh SonNo ratings yet

- Make List SLTD-J-1401-L-6-00003-02Document4 pagesMake List SLTD-J-1401-L-6-00003-02tribhuvan ShankarNo ratings yet

- Naffco: Pre Testing & Commissioning Checklist of Fire Pumps, Fire Pumps Details & Field Test ReportDocument6 pagesNaffco: Pre Testing & Commissioning Checklist of Fire Pumps, Fire Pumps Details & Field Test ReportSultan Mahi ZubairNo ratings yet

- Quotation of PVC-U Drainage Pipe Sell3 Final2Document5 pagesQuotation of PVC-U Drainage Pipe Sell3 Final2Im ChinithNo ratings yet

- Armstrong Close-Coupled Pump (Monobloc)Document4 pagesArmstrong Close-Coupled Pump (Monobloc)rijothomasv777100% (1)

- 432d Signal Resolver Network - CheckDocument6 pages432d Signal Resolver Network - CheckDiego CatariNo ratings yet

- Dnd200-Mhx: Medium Head Dewatering PumpDocument3 pagesDnd200-Mhx: Medium Head Dewatering PumpMuhammad Jaka Surya100% (1)

- F46 520Document9 pagesF46 520zhobeysNo ratings yet

- Mitsubishi Electric PUHY-P YKB-A1 Service Parts EngDocument25 pagesMitsubishi Electric PUHY-P YKB-A1 Service Parts EngBranko VeskovicNo ratings yet

- Multi-Speed Performance Curve: 200 MCSFDocument1 pageMulti-Speed Performance Curve: 200 MCSFRubenOrtegaNo ratings yet

- Saudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeDocument7 pagesSaudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeAnonymous S9qBDVkyNo ratings yet

- R1 - 100701492-Pro-004 - Uf P&idDocument1 pageR1 - 100701492-Pro-004 - Uf P&idPrashant HuddarNo ratings yet

- Hydrotest Pressure Procedure - 2023Document15 pagesHydrotest Pressure Procedure - 2023Amit HasanNo ratings yet

- Nellimerla Champavathi River YieldtestreportDocument16 pagesNellimerla Champavathi River Yieldtestreportrama krishnaNo ratings yet