Professional Documents

Culture Documents

TRA # 102 For Installation of Piping and Pipe Supports

TRA # 102 For Installation of Piping and Pipe Supports

Uploaded by

Darius DsouzaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TRA # 102 For Installation of Piping and Pipe Supports

TRA # 102 For Installation of Piping and Pipe Supports

Uploaded by

Darius DsouzaCopyright:

Available Formats

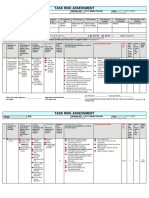

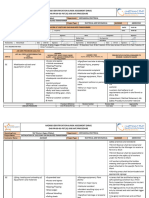

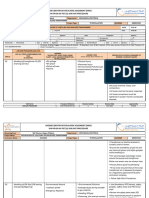

TASK RISK ASSESSMENT

Field: NEB - AL DABBIYA TRA Ref.No 102 OPS Date 25th Sept 2016

Team Members : TRA TEAM LEADER TRA MEMBER TRA MEMBER TRA MEMBER TRA MEMBER TRA MEMBER JOB PERFORMER JOB PERFORMER

(JO-EP) (ADCO-AREA HSE-ADCO HSE-TCM CONST-TCM ARCO ARCO ARCO

AUTHORITY-OPS)

Name: Issam Abu Alia Jassim Jaffar Richard Ivan K D’Souza Praveen Anzil

Calingasan Thomas

Signature

Team Members : TRA MEMBER TRA MEMBER TRA MEMBER JOB PERFORMER JOB PERFORMER JOB PERFORMER JOB PERFORMER JOB PERFORMER

ARCO ARCO-HSE ARCO HSE ARCO ARCO ARCO

Name: Harish chandra Oswald Mallillin Archier Botona Ashwin Naik Mohammed Mohammed

Abrar Yousuf

Signature

Activity: Installation of piping and pipe supports

Work Location AL DABBI’YA Surface Facilities Phase III -Offshore Cluster 2(B) Zone 0/1 Zone 2 Unclassified

Tools & equipment Welding machine, Grinding machine, Crane, Cold cutting machine, Drilling machine, Generator, Boom Truck, Flatbed trailer, Fork Lift, Pick up, Boom

Used loader, Air compressor, Survey equipment, Lifting tools and tackles, Pneumatic and electric wrench, Ratchet puller, Gas cutting set, Tripod, Torque

wrenches, Scaffolding materials and tools, Pencil grinder, Chain block, Oven, Hydrogen bake out equipment, consumables and Hand tools

References

Method Statement for Piping and Pipe support installation (ADCO No: 30.99.90.1729), Method Statement of Lifting Operations (ADCO No:

30.99.90.1831), Method Statement for Tie-in works @ Cluster -1A, 2B & 3C (ADCO No: 30.99.90.1822), Method Statement for Work at Height (ADCO

No: 30.99.90.2629), Procedure for Hydrogen Bake out of Tie-in Joints (ADCO No: 30.99.90.1832), MS for scaffolding work (ADCO Doc.

No.02.01.90.1649)

Job Performer ____________________ Issuing Authority________________________

TRA Team Leader Signature ____________________ High Risk Job Authorization____________________

(All pages) (First page only) I have checked that all controls stated in TRA are in place and conducted Tool Box Talk

TASK RISK ASSESSMENT

Field: NEB - AL DABBIYA TRA Ref.No 102 OPS Date 25th Sept 2016

# Job Step Hazard CAUSE Consequences Potential Existing Barrier / Control Recommended Action Residu ALARP Complet

Sequence of The potential to (Possible causes (The harm which Risk Describe all existing barriers Controls By al Risk Demons ion Date

working activities cause harm (Health, that will potentially could possibly occur). H/M/L / controls for each hazard Describe additional H/M/ trated

Injury, Property release a hazard) (With no controls that are L (Yes /

damage, controls in required (with No)

environment etc) place) controls

in place

1 Material Load falling from Improperly secured Personal Injury ADCO E-PTW system Close

transportation vehicles loads Fatality in place supervision

(Land & Sea) Collision with other Improper rigging Property/Asset / Follow ADCO road Thorough visual

vehicles/hit by loading practice Equipment damage /boat safety guidelines inspection of the

vehicle Uncontrolled Proper escorting will be area and ground

Hit by extended load movements, provided for extended condition shall

from the vehicle sudden jerks loads be carried out

Hit/Stuck on existing Movement of Load secured Only approved

facilities vehicles appropriate routes to be

Mechanical failure Lack of escort ADCO inspected and followed

Poor visibility vehicle approved vehicles and Safe distances

Nature of load equipment to be need to be

Blind spots

deployed maintained from

Grounding/Berthing Unauthorized

Trained flagman existing facilities

driver/reckless

driving practice assigned for vehicle

H movement SS/JP L Yes 6 Months

Wide load

extended from ADCO approved Boat

vehicle operators

Existing live Mooring/Anchor lines

facilities inspected

Open trenches

Oil/Fuel leak

during vehicle

operations

Adverse weather

condition

Existing structure/

Facilities

GPS not followed

(on the sea)

2 Lifting Crane collapse Poor ground Personal Injury H ADCO E-PTW system Close SS/JP L Yes 6 Months

Falling of load stability Fatality in place supervision

Hit/Stuck by Overloading Property/Asset / Area will be inspected Do not leave

Job Performer ____________________ Issuing Authority________________________

TRA Team Leader Signature ____________________ High Risk Job Authorization____________________

(All pages) (First page only) I have checked that all controls stated in TRA are in place and conducted Tool Box Talk

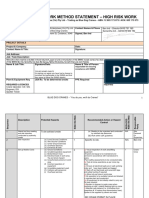

TASK RISK ASSESSMENT

Field: NEB - AL DABBIYA TRA Ref.No 102 OPS Date 25th Sept 2016

# Job Step Hazard CAUSE Consequences Potential Existing Barrier / Control Recommended Action Residu ALARP Complet

Sequence of The potential to (Possible causes (The harm which Risk Describe all existing barriers Controls By al Risk Demons ion Date

working activities cause harm (Health, that will potentially could possibly occur). H/M/L / controls for each hazard Describe additional H/M/ trated

Injury, Property release a hazard) (With no controls that are L (Yes /

damage, controls in required (with No)

environment etc) place) controls

in place

equipment’s and Damaged or Equipment damage before positioning the suspended load

vehicles inappropriate lifting crane unattended

Suspended load gears Crane outriggers are Signalling shall

Mechanical failure Unsecure load fully extended and be done only by

Unauthorized entry stable ground condition one rigger at a

Adequate access time

Area not

barricaded maintained Daily operator

Area barricaded and checklist shall be

Lack of

signage’s posted maintained

banksman/Flag

man Two taglines minimum Deploy

shall be provided to competent

Uneven slippery

guide the load flagman

surfaces and

obstacles All lifting equipment and

Break down of gears must be certified

equipment and by ADCO approved 3rd

vehicles party and colour coded

prior to commencement

Movement of other

of work

vehicle/ personnel

Crane operator and

Oil/ Fuel leak

riggers certified by

during operations

ADCO 3rd party agency

SWL must be followed

Maintain safe distance

from live/existing

facilities

3 Hot work Fire Cutting ,grinding Personal Injury H ADCO E-PTW system Always close SS/JP/ L Yes 6 Months

(Grinding, cutting, Explosion and welding Fatality in place supervision of ADCO

welding, fit up Gas leakage from Proper grounding the work firefighting

Electrocution Property/Asset /

works, Hydrogen argon cylinders /bonding done Trained and team

Fly off disc Equipment damage

bake out) Improper electrical ELCB on all electrical competent

Flying particles

connection and accessories person execute

Sparks the work

ELCB Correct rated discs and

Equipment and Gas monitoring

Damaged power machines will be used.

power tool failure

Job Performer ____________________ Issuing Authority________________________

TRA Team Leader Signature ____________________ High Risk Job Authorization____________________

(All pages) (First page only) I have checked that all controls stated in TRA are in place and conducted Tool Box Talk

TASK RISK ASSESSMENT

Field: NEB - AL DABBIYA TRA Ref.No 102 OPS Date 25th Sept 2016

# Job Step Hazard CAUSE Consequences Potential Existing Barrier / Control Recommended Action Residu ALARP Complet

Sequence of The potential to (Possible causes (The harm which Risk Describe all existing barriers Controls By al Risk Demons ion Date

working activities cause harm (Health, that will potentially could possibly occur). H/M/L / controls for each hazard Describe additional H/M/ trated

Injury, Property release a hazard) (With no controls that are L (Yes /

damage, controls in required (with No)

environment etc) place) controls

in place

Fumes tools Periodical inspection to be done prior

Sharp edges Using wrong RPM and color coding on to work start

Manual handling (disc & machine) tools Flash back

during grinding Make habitat using Fire arrestor to be

metal retardant blanket for installed on both

Uninspected and welding cutting grinding sides of gas

unmaintained tools works for 100% spark cutting torch

Sound from containment Gas cylinders

existing plant and Use of mechanical aid shall be properly

machineries to avoid manual secured and

Cut metal surface handling used in trolley

Improper manual Provide proper Do not use

handling ventilation cutting torch set

techniques Trained and certified on existing pipes

stand by fire watch Cold cutting

Close and continuous machine shall be

supervision used in the

existing pipe

Before starting

job ensure tie in

points are

identified by

ADCO operation

team.

ADCO

firefighting team

stand by ( If

required)

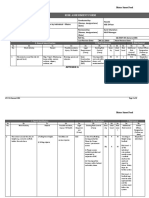

4 Scaffolding Falling from Not wearing Personal Injury H ADCO E-PTW system Close supervision Scaffolding L Yes 6 Months

Erection, height full body Fatality in place Use tool belt and Inspector/

modification and Scaffolding harness and Follow ADCO tie the tools JP/

Property/Asset /

dismantling collapse 100% tie off Equipment damage scaffolding procedure Do not over reach

Fall of tools/ Incomplete Competent and and maintain

materials guardrail approved certified proper balance

system scaffolders

Job Performer ____________________ Issuing Authority________________________

TRA Team Leader Signature ____________________ High Risk Job Authorization____________________

(All pages) (First page only) I have checked that all controls stated in TRA are in place and conducted Tool Box Talk

TASK RISK ASSESSMENT

Field: NEB - AL DABBIYA TRA Ref.No 102 OPS Date 25th Sept 2016

# Job Step Hazard CAUSE Consequences Potential Existing Barrier / Control Recommended Action Residu ALARP Complet

Sequence of The potential to (Possible causes (The harm which Risk Describe all existing barriers Controls By al Risk Demons ion Date

working activities cause harm (Health, that will potentially could possibly occur). H/M/L / controls for each hazard Describe additional H/M/ trated

Injury, Property release a hazard) (With no controls that are L (Yes /

damage, controls in required (with No)

environment etc) place) controls

in place

Tripping hazard Overloaded Proper handling of Proper material

Manual handling improper material and rest management and

bracing and breaks stacking

unstable Scaffolding inspection Proper compaction

ground by certified inspectors of ground surface

Missing toe Provide appropriate before erection

board barricades and signs Tools to be

Improper Use full body harness secured

anchorage with 100% tie off

point Perform regular periodic

Unsecured inspection and maintain

tools/Object at scaffolding register

height Standby Fast rescue boat

Material while working on site

obstacles on

the platform

and access

Improper

manual

handling

Poor balance

over reaching

Loose soil

Job Performer ____________________ Issuing Authority________________________

TRA Team Leader Signature ____________________ High Risk Job Authorization____________________

(All pages) (First page only) I have checked that all controls stated in TRA are in place and conducted Tool Box Talk

You might also like

- 005 HIRARC Hollow Core Slab InstallationDocument5 pages005 HIRARC Hollow Core Slab Installationbdiey100% (5)

- 27 Risk Assessment-Construction of Ecm Holding Tank and Silt TrapDocument5 pages27 Risk Assessment-Construction of Ecm Holding Tank and Silt TrapprabuNo ratings yet

- Lifting PlanDocument31 pagesLifting PlanDarius DsouzaNo ratings yet

- Diesel RefuelingDocument3 pagesDiesel RefuelingAMIN100% (1)

- JSA - Drilling ActivitiesDocument4 pagesJSA - Drilling ActivitiesAMIN100% (1)

- Betp 1323 - Lab Sheet - Rolling and Spot WeldingDocument4 pagesBetp 1323 - Lab Sheet - Rolling and Spot Weldingsimson60% (5)

- General Purpos 13zg50e4 Gd1100Document60 pagesGeneral Purpos 13zg50e4 Gd1100azry_alqadryNo ratings yet

- De-Com - For Existing 8 12 Inch - Pipeline - TRA1Document6 pagesDe-Com - For Existing 8 12 Inch - Pipeline - TRA1Darius DsouzaNo ratings yet

- TRA For Blasting and PaintingDocument6 pagesTRA For Blasting and Paintingrizvidawar220No ratings yet

- P111-Rsme-Tra-007 - Tra For Cold Tie inDocument5 pagesP111-Rsme-Tra-007 - Tra For Cold Tie inDarius DsouzaNo ratings yet

- Back FillingDocument1 pageBack FillingRohit SinghNo ratings yet

- Travaux Genie Civil MTR JSADocument5 pagesTravaux Genie Civil MTR JSAAMINNo ratings yet

- P111-RSME-TRA-007 - TRA For Cold Tie in PDFDocument4 pagesP111-RSME-TRA-007 - TRA For Cold Tie in PDFDarius DsouzaNo ratings yet

- Man-Lift Awareness TrainingDocument54 pagesMan-Lift Awareness Trainingzareen070xNo ratings yet

- Man-Lift Awarness TrainingDocument54 pagesMan-Lift Awarness TrainingSunil YadavNo ratings yet

- JRA No 10-110 Grading, Leveling and Cleaning of ROW For Zam-4 Flow LineDocument6 pagesJRA No 10-110 Grading, Leveling and Cleaning of ROW For Zam-4 Flow LineAijaz AhmedNo ratings yet

- 310C22011 - RA - Refurbishment of Tank T-201 - For - Site Mobilization For TK 201 - SNOC Format - Rev.01 - 02Document5 pages310C22011 - RA - Refurbishment of Tank T-201 - For - Site Mobilization For TK 201 - SNOC Format - Rev.01 - 02Vinay MishraNo ratings yet

- Travaux Genie Civil MTR JSADocument5 pagesTravaux Genie Civil MTR JSAHichem FarhatNo ratings yet

- SWMS TemplateDocument5 pagesSWMS TemplateZihao ZengNo ratings yet

- JSA Mobile CranesDocument2 pagesJSA Mobile CranesAmanya DickallansNo ratings yet

- L02-02 Lifting Plan (Non Crane)Document2 pagesL02-02 Lifting Plan (Non Crane)Fabio CastroNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDPa imanNo ratings yet

- Job Safety Analysis: Rohan Builders (I) PVT LTDDocument3 pagesJob Safety Analysis: Rohan Builders (I) PVT LTDTigor GurningNo ratings yet

- Risk Assessment - Metro Street FoodDocument8 pagesRisk Assessment - Metro Street FoodNowfal HabeebNo ratings yet

- Risk Assessment 2A1Document10 pagesRisk Assessment 2A1Illias ShaikNo ratings yet

- BULLDOZER - C52JSA-044 - Using Bulldozer Ripper - 25-Feb-15Document5 pagesBULLDOZER - C52JSA-044 - Using Bulldozer Ripper - 25-Feb-15hechame TamerhouletNo ratings yet

- Backfilling, Leveling RISK ASSESSMENTDocument6 pagesBackfilling, Leveling RISK ASSESSMENTVimal ViswanathNo ratings yet

- Risk Assesment For KerbstonesDocument11 pagesRisk Assesment For KerbstonesZain butt67% (3)

- 1.9 Working at HeightDocument4 pages1.9 Working at HeightboomNo ratings yet

- JRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaDocument8 pagesJRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaAijaz AhmedNo ratings yet

- Block Work (Unit Masonary) RISK ASSESSMENTDocument8 pagesBlock Work (Unit Masonary) RISK ASSESSMENTVimal ViswanathNo ratings yet

- TRA - Scaffold Erection & ModificationDocument16 pagesTRA - Scaffold Erection & ModificationibrahimNo ratings yet

- Res HirarcDocument15 pagesRes HirarcSawLaiBoyanNo ratings yet

- OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE TF-00877 Mobilization and Preparation of Site OfficesDocument11 pagesOHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE TF-00877 Mobilization and Preparation of Site OfficesRAI AHTESHAM HaiderNo ratings yet

- Marafiq Risk Assessment 02Document5 pagesMarafiq Risk Assessment 02Arshad Mahmood50% (2)

- Task Risk Assesment Transporting MaterialDocument4 pagesTask Risk Assesment Transporting Materialabubakrelsaid90No ratings yet

- Job Safety Analysis 14 For Cable Laying and PullingDocument4 pagesJob Safety Analysis 14 For Cable Laying and PullingBishop Ojonuguwa Ameh100% (1)

- JSA For SSSP-1Document7 pagesJSA For SSSP-1thennarasuNo ratings yet

- JRA 10-005 Insttalation of New Dodo GateDocument9 pagesJRA 10-005 Insttalation of New Dodo GateAijaz AhmedNo ratings yet

- Water Testin TRADocument4 pagesWater Testin TRAabdulhanansamo65No ratings yet

- Daily Safety Inspection ChecklistDocument2 pagesDaily Safety Inspection Checklistarunjith r0% (1)

- 310C22011 - RA - Refurbishment of Tank T-201 - For - Site Mobilization For TK 201 - SNOC Format - Rev.01 - 01Document5 pages310C22011 - RA - Refurbishment of Tank T-201 - For - Site Mobilization For TK 201 - SNOC Format - Rev.01 - 01Vinay MishraNo ratings yet

- Risk Assessment Form - KingGroveDocument12 pagesRisk Assessment Form - KingGroveeric chenNo ratings yet

- Cutting ActivitiesDocument3 pagesCutting ActivitiesWalid KhelfaNo ratings yet

- Caaf 035 RGLC 1.0 Check Report MCC RevisedDocument2 pagesCaaf 035 RGLC 1.0 Check Report MCC RevisedUsman AkramNo ratings yet

- Idoc - Pub - Task Risk Assessment For RadiographyDocument5 pagesIdoc - Pub - Task Risk Assessment For RadiographySasi YNo ratings yet

- STARRT CardDocument2 pagesSTARRT Cardsanny100% (1)

- SOP For Machine Loading of Ore - 18Document7 pagesSOP For Machine Loading of Ore - 18syed aquibNo ratings yet

- JRA 10-001 Devlopment of Barrow AreaDocument5 pagesJRA 10-001 Devlopment of Barrow AreaAijaz AhmedNo ratings yet

- Preventive Maintenance For AHU & FCUDocument20 pagesPreventive Maintenance For AHU & FCUwshroslanabdullahNo ratings yet

- Working at Stabbing Board During CasingDocument2 pagesWorking at Stabbing Board During CasingkhurramNo ratings yet

- RA 02 - Earth WorkDocument38 pagesRA 02 - Earth WorkAnonymous kWfNFb100% (2)

- Transportation and Fixing of Fencing, Underground Cables, Pipes Etc For Establishing Temp FacilitiesDocument8 pagesTransportation and Fixing of Fencing, Underground Cables, Pipes Etc For Establishing Temp FacilitiesazerNo ratings yet

- Risk Assesment Excavation & BackfillingDocument5 pagesRisk Assesment Excavation & BackfillingMuhammad Jamshid100% (4)

- Diesel RefuelingDocument3 pagesDiesel RefuelingAMIN100% (1)

- RAMS-Loading, Unloading and Shifting of MaterialDocument5 pagesRAMS-Loading, Unloading and Shifting of MaterialEm Niax50% (2)

- JSA Mobile Crane Pipe Installation Tandem LiftDocument3 pagesJSA Mobile Crane Pipe Installation Tandem LiftSyed HarisNo ratings yet

- 212 Using of Portable Electrical EquipmentDocument12 pages212 Using of Portable Electrical EquipmentgrantNo ratings yet

- 007 HIRARC Construction of RC Column (Car Park)Document10 pages007 HIRARC Construction of RC Column (Car Park)bdieyNo ratings yet

- Ohs-Pr-09-03-F07 (A) Job Safe Procedure Tf-00877 ChemicalDocument5 pagesOhs-Pr-09-03-F07 (A) Job Safe Procedure Tf-00877 ChemicalRAI AHTESHAM HaiderNo ratings yet

- Job Safety Analysis - RIG-UP OF GDS, CASCADE & SAFETY EQUIPMENTDocument3 pagesJob Safety Analysis - RIG-UP OF GDS, CASCADE & SAFETY EQUIPMENTJun DandoNo ratings yet

- Concise Encyclopedia of System Safety: Definition of Terms and ConceptsFrom EverandConcise Encyclopedia of System Safety: Definition of Terms and ConceptsNo ratings yet

- 21st Century Prometheus: Managing CBRN Safety and Security Affected by Cutting-Edge TechnologiesFrom Everand21st Century Prometheus: Managing CBRN Safety and Security Affected by Cutting-Edge TechnologiesMaurizio MartelliniNo ratings yet

- 14-Telescopic Forklift Check List Hindi English - Page - 1Document1 page14-Telescopic Forklift Check List Hindi English - Page - 1Darius DsouzaNo ratings yet

- Aspire 001 IGC I Element 1-Foundations - IGC IDocument48 pagesAspire 001 IGC I Element 1-Foundations - IGC IDarius DsouzaNo ratings yet

- Heat Stress Program - J38Document24 pagesHeat Stress Program - J38Darius DsouzaNo ratings yet

- Combustible DustDocument12 pagesCombustible DustDarius DsouzaNo ratings yet

- De-Com - For Existing 8 12 Inch - Pipeline - TRA1Document6 pagesDe-Com - For Existing 8 12 Inch - Pipeline - TRA1Darius DsouzaNo ratings yet

- P111-Rsme-Tra-007 - Tra For Cold Tie inDocument5 pagesP111-Rsme-Tra-007 - Tra For Cold Tie inDarius DsouzaNo ratings yet

- Valve Station DrawingDocument1 pageValve Station DrawingDarius DsouzaNo ratings yet

- P111-RSME-TRA-007 - TRA For Cold Tie in PDFDocument4 pagesP111-RSME-TRA-007 - TRA For Cold Tie in PDFDarius DsouzaNo ratings yet

- MNGMNT CNTRCTR HSE Procedure Manual 10-4Document258 pagesMNGMNT CNTRCTR HSE Procedure Manual 10-4Darius Dsouza100% (1)

- HSE REMINDER-March 2012-Plant Turnaround SafetyDocument1 pageHSE REMINDER-March 2012-Plant Turnaround SafetyDarius DsouzaNo ratings yet

- HSE REMINDER-April 2012-Unsafe Acts & Unsafe ConditionsDocument1 pageHSE REMINDER-April 2012-Unsafe Acts & Unsafe ConditionsDarius DsouzaNo ratings yet

- HIP-Wastewater Revision 03Document14 pagesHIP-Wastewater Revision 03Darius DsouzaNo ratings yet

- Code of Practice For Safe Lifting Operations at Workplaces OnlineDocument38 pagesCode of Practice For Safe Lifting Operations at Workplaces OnlineDarius Dsouza100% (1)

- Construction Division: Polycarbonate Plant Project Saudi Kayan Petrochemical Complex CRC-KY8501Document1 pageConstruction Division: Polycarbonate Plant Project Saudi Kayan Petrochemical Complex CRC-KY8501Darius DsouzaNo ratings yet

- M38WiperVacuum 4Document6 pagesM38WiperVacuum 4jean talusNo ratings yet

- Ficha Tecnica de FC150X-CDocument5 pagesFicha Tecnica de FC150X-Casistente.peninsulaNo ratings yet

- Definition:-: Available Form and Utilizes It To Do Some Particular Type of WorkDocument41 pagesDefinition:-: Available Form and Utilizes It To Do Some Particular Type of WorkManprita BasumataryNo ratings yet

- Rotor DynamicsDocument5 pagesRotor DynamicsavciayNo ratings yet

- Nimonic Alloy 263Document12 pagesNimonic Alloy 263JJNo ratings yet

- Final Ppt-Auto LabDocument40 pagesFinal Ppt-Auto LabugtalkNo ratings yet

- What Are The Differences Between Implicit and Explicit?: Weak SpringDocument2 pagesWhat Are The Differences Between Implicit and Explicit?: Weak SpringKoral ToptopNo ratings yet

- Hydraulic Fan System 966Document4 pagesHydraulic Fan System 966Ahmed Rezk100% (2)

- 905 - Crankshaft & Thrust BearingDocument19 pages905 - Crankshaft & Thrust BearingVuHongNhatNo ratings yet

- Amtiss - Saldo - Inventory 28-01-2020Document224 pagesAmtiss - Saldo - Inventory 28-01-2020Asido PurbaNo ratings yet

- 5 2 Calorimetry PractiseDocument4 pages5 2 Calorimetry Practiseapi-210028385No ratings yet

- L05MR HJZ16 B RV E4 (Pi)Document1 pageL05MR HJZ16 B RV E4 (Pi)ark bilal jj5No ratings yet

- Actuador Abb Up D-AAP-UP - EDocument36 pagesActuador Abb Up D-AAP-UP - EHumberto SerratoNo ratings yet

- Series Gu Control Valves Globe-Single Seated, Top Guided: ConstructionDocument16 pagesSeries Gu Control Valves Globe-Single Seated, Top Guided: ConstructionMichael H. PrevooNo ratings yet

- Rigle de CuplareDocument12 pagesRigle de CuplareMarius DanNo ratings yet

- SK210 LC8Document675 pagesSK210 LC8MEHA6502100% (33)

- Technical Service Information: Ford 4F27EDocument3 pagesTechnical Service Information: Ford 4F27EAranza SuNo ratings yet

- Abnm-A5 VDSKJ222 10 15Document6 pagesAbnm-A5 VDSKJ222 10 15Emil EremiaNo ratings yet

- SSP 211 New BeetleDocument48 pagesSSP 211 New BeetleAlexandru CraiovanNo ratings yet

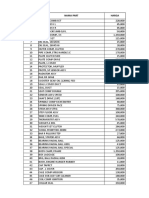

- NO Nama Part HargaDocument2 pagesNO Nama Part Hargam rizky auliaNo ratings yet

- Chinese CNE Bikes E Bike DIY User Manual PDFDocument20 pagesChinese CNE Bikes E Bike DIY User Manual PDFmotanulbirmanezNo ratings yet

- Mechanics of Materials 4 Exam CoverageDocument14 pagesMechanics of Materials 4 Exam CoverageJay Vee EstradaNo ratings yet

- Parker Flow Meter PDFDocument2 pagesParker Flow Meter PDFDaniel MarNo ratings yet

- General Catalogue: Sample Preparation MachinesDocument16 pagesGeneral Catalogue: Sample Preparation Machinesfatih_hideNo ratings yet

- Keihin PE CarburatorDocument2 pagesKeihin PE CarburatorGagibitNo ratings yet

- Shounter Volume III, Section - 4Document99 pagesShounter Volume III, Section - 4Jawad UsmaniNo ratings yet

- REXROTH - Catalog Servomotoare Sincrone MSKDocument280 pagesREXROTH - Catalog Servomotoare Sincrone MSKVlad OvidiuNo ratings yet

- Modern Metal Cutting Basic Milling Sample PagesDocument3 pagesModern Metal Cutting Basic Milling Sample PagesBoby AndreNo ratings yet